A Shockless Adaptive Trigger Ignition Device Utilizing Laminar Plasma System

A laminar plasma and ignition device technology, which is applied in the ignition, plasma, combustion ignition and other directions using electric sparks, can solve the problems of high cost, low monomer power, low thermal efficiency, etc., and achieves good uniformity and fast heating speed. , the effect of uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

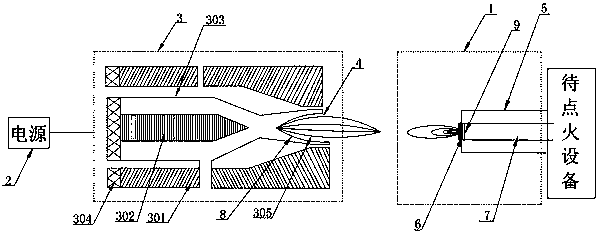

[0029] A non-impact adaptive trigger ignition device utilizing a laminar plasma system, comprising a laminar plasma system and an ignition nozzle 1, the laminar plasma system comprising a power supply 2, a laminar plasma generator 3 and a nozzle 4, the power supply 2 is connected to the layer Flow plasma generator 3, nozzle 4 is detachably connected with laminar flow plasma generator 3; Described ignition nozzle 1 is arranged on the equipment to be ignited, and ignition nozzle 1 comprises housing 5, ignition pole 6 and conduit 7, ignition pole 6 is arranged on the front end of the conduit 7, and the conduit 7 extends into the device to be ignited, and the housing 5 is arranged outside the ignition pole 6 and the conduit 7; the nozzle 4 coincides with the central axis of the ignition nozzle 1.

Embodiment 2

[0031] A non-impact adaptive trigger ignition device utilizing a laminar plasma system, comprising a laminar plasma system and an ignition nozzle 1, the laminar plasma system comprising a power supply 2, a laminar plasma generator 3 and a nozzle 4, the power supply 2 is connected to the layer Flow plasma generator 3, nozzle 4 is detachably connected with laminar flow plasma generator 3; Described ignition nozzle 1 is arranged on the equipment to be ignited, and ignition nozzle 1 comprises housing 5, ignition pole 6 and conduit 7, ignition pole 6 is arranged on the front end of the conduit 7, and the conduit 7 extends into the device to be ignited, and the housing 5 is arranged outside the ignition pole 6 and the conduit 7; the nozzle 4 coincides with the central axis of the ignition nozzle 1.

[0032] The laminar flow plasma generator 3 includes an anode structure 301, a cathode structure 302 and a multi-air film cooling device 303. The anode structure 301 is an anode structure...

Embodiment 3

[0034] A non-impact adaptive trigger ignition device utilizing a laminar plasma system, comprising a laminar plasma system and an ignition nozzle 1, the laminar plasma system comprising a power supply 2, a laminar plasma generator 3 and a nozzle 4, the power supply 2 is connected to the layer Flow plasma generator 3, nozzle 4 is detachably connected with laminar flow plasma generator 3; Described ignition nozzle 1 is arranged on the equipment to be ignited, and ignition nozzle 1 comprises housing 5, ignition pole 6 and conduit 7, ignition pole 6 is arranged on the front end of the conduit 7, and the conduit 7 extends into the device to be ignited, and the housing 5 is arranged outside the ignition pole 6 and the conduit 7; the nozzle 4 coincides with the central axis of the ignition nozzle 1.

[0035]The laminar flow plasma generator 3 includes an anode structure 301, a cathode structure 302 and a multi-air film cooling device 303. The anode structure 301 is an anode structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com