A kind of high chromium alloy composite wear-resistant steel plate and its production process

A high-chromium alloy, production process technology, applied in the field of wear-resistant steel plates, can solve the problems of the wear-resistant layer of the composite wear-resistant steel plate falling off, easy to form accumulation, high temperature resistance, corrosion resistance, wear resistance and other problems. Strong impact resistance, lower cost of use, smooth surface without cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

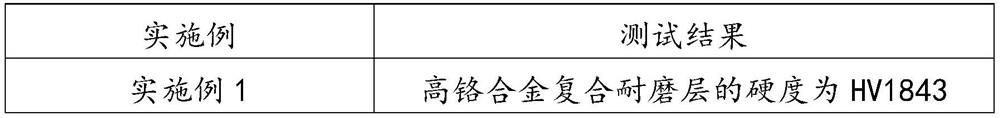

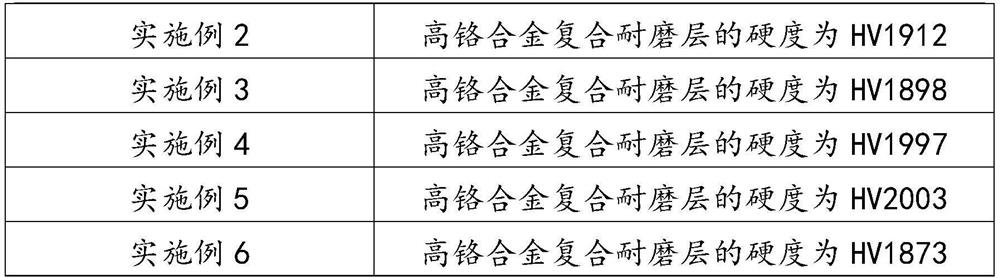

Embodiment 1

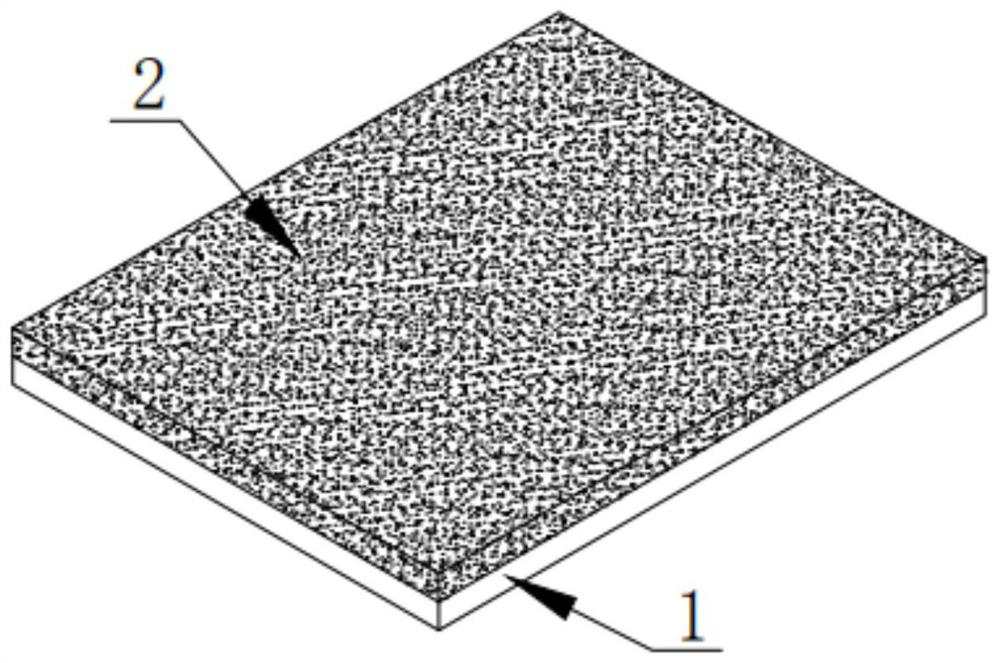

[0031] A high chromium alloy composite wear-resistant steel plate, such as figure 1 As shown, it includes a substrate 1 and a high-chromium alloy composite wear-resistant layer 2, the substrate 1 is made of steel, and the substrate 1 has an upper surface and a lower surface; the high-chromium alloy composite wear-resistant layer 2 covers the On the upper surface of the substrate 1;

[0032] Wherein, the thickness of the substrate 1 is 10 cm, and the thickness of the high chromium alloy composite wear-resistant layer 2 is 20 cm.

[0033] Wherein, the steel is Q235 ordinary carbon steel.

[0034] Wherein, the high chromium alloy composite wear-resistant layer 2 is composed of non-metal elements and metal elements.

[0035] Wherein, the non-metal element includes boron element, and the metal element includes manganese element, chromium element, tungsten element, molybdenum element, niobium element, vanadium element, aluminum element, titanium element and iron element.

[0036]...

Embodiment 2

[0043] The difference from Example 1 is that the boron element, the manganese element, the chromium element, the tungsten element, the molybdenum element, the niobium element, the vanadium element, the aluminum element, the The weight ratio of the titanium element and the iron element is 8:10:40:6:8:5:5:8:9.

Embodiment 3

[0045] The difference from Example 1 is that the boron element, the manganese element, the chromium element, the tungsten element, the molybdenum element, the niobium element, the vanadium element, the aluminum element, the The weight ratio of the titanium element and the iron element is 7:8:38:8:10:7:9:6:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com