Four-path high-power microwave synthesizer manufacturing method based on 3D printing and synthesizer

A high-power microwave and 3D printing technology, applied in waveguide devices, circuits, electrical components, etc., can solve the problems of physical limit of output power, improve synthesis efficiency and total output power, increase power capacity, and solve ignition problems problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

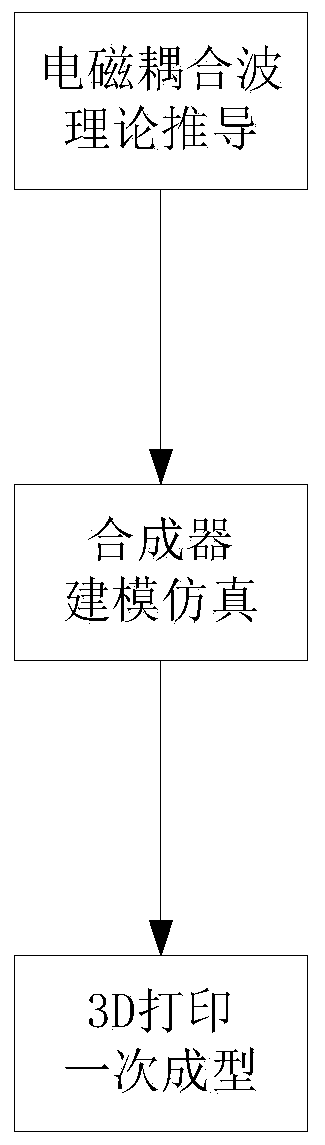

[0057] see figure 1 , an embodiment of the present invention includes the following steps:

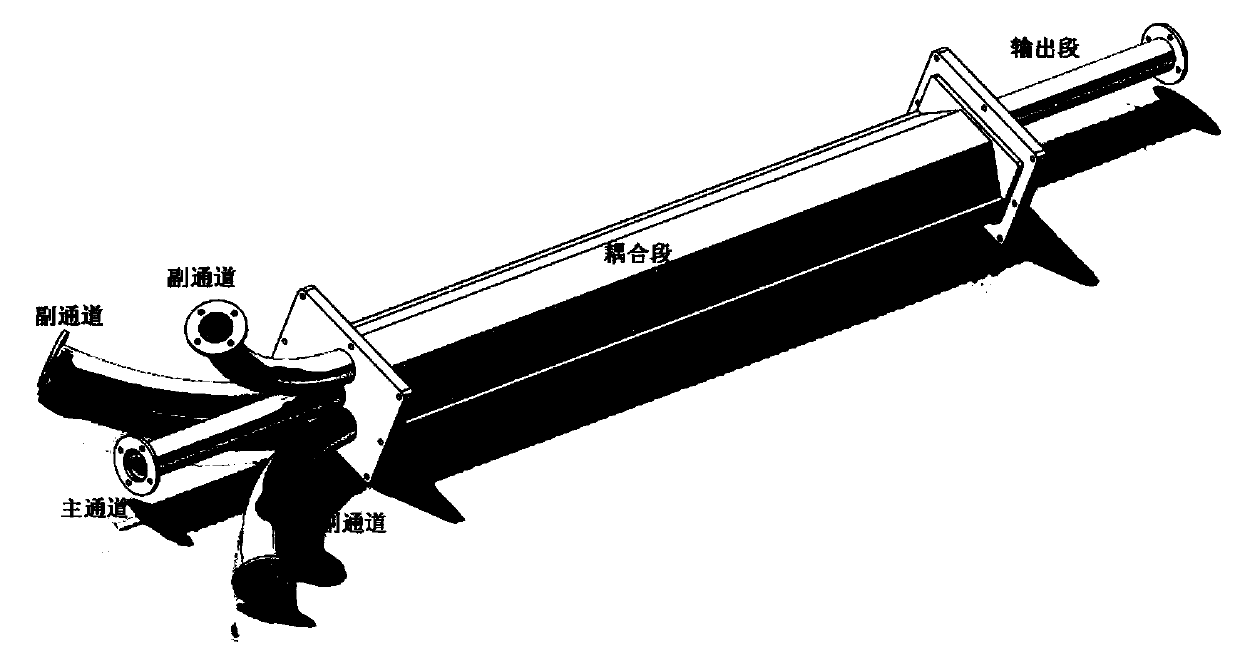

[0058] S1: According to the electromagnetic wave coupling mode equation, analyze the coupling mechanism of the four-way synthesizer, give the best mode and the best matching method; use the magnetic coupling method, analyze the influence of different input polarization modes on the coupling efficiency, and deduce the strength of the coupling degree Weak relationship with waveguide radius, microwave frequency, microwave mode and slit width, seeking four optimal polarization input methods:

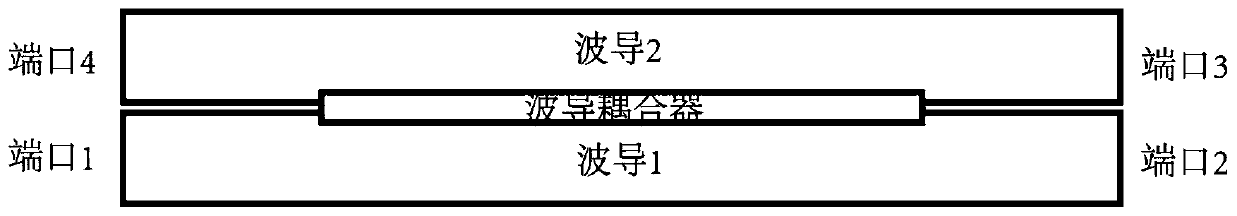

[0059] S11: see image 3 , assuming that the two-way continuous long slot coupling structure includes two back-to-back circular waveguides, namely waveguide 1 and waveguide 2, the physical dimensions of the two waveguides are the same, and there is a conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com