Mica high temperature resistant electrothermal film and preparation method thereof

A high temperature resistant, electric heating film technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of high power density, short circuit of electric heating wire, oxidation, etc., and achieve the effect of solving high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

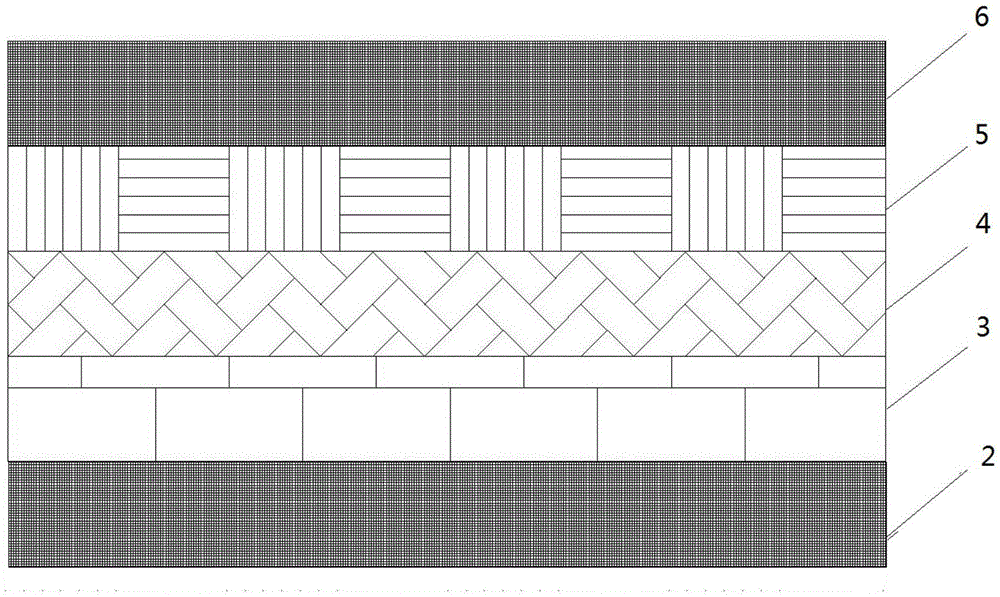

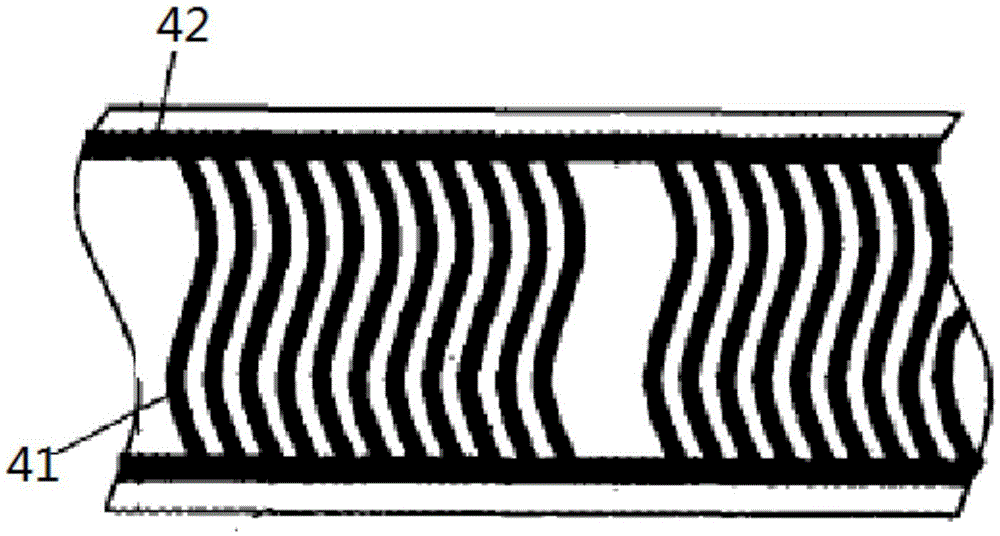

[0027] refer to figure 1 , a kind of mica high temperature resistant electric heating film provided by the present invention, including: metal electrodes (not shown) and the first mica layer 2, the first heat conducting film 3, the metal heating layer 4, the second Thermally conductive film 5, second mica layer 6; the first thermally conductive film 3 is evenly coated on the upper surface of the first mica layer 2; the metal heating layer 4 is arranged on the upper surface of the first thermally conductive film 3; The metal heating layer 4 is evenly distributed with a number of conductive alloy strips 41; the metal electrodes (not shown) are electrically connected to the metal heating layer 4; the second heat conducting film 5 is evenly coated on the upper surface of the metal heating layer 4 ; The second mica layer 6 is arranged on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com