Novel multi-hole ventilation circular waveguide for transmitting high power microwave and millimeter waveguide

A high-power microwave and circular waveguide technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of environmental pollution, large cost, complex structure, etc., to improve power capacity, solve ignition, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

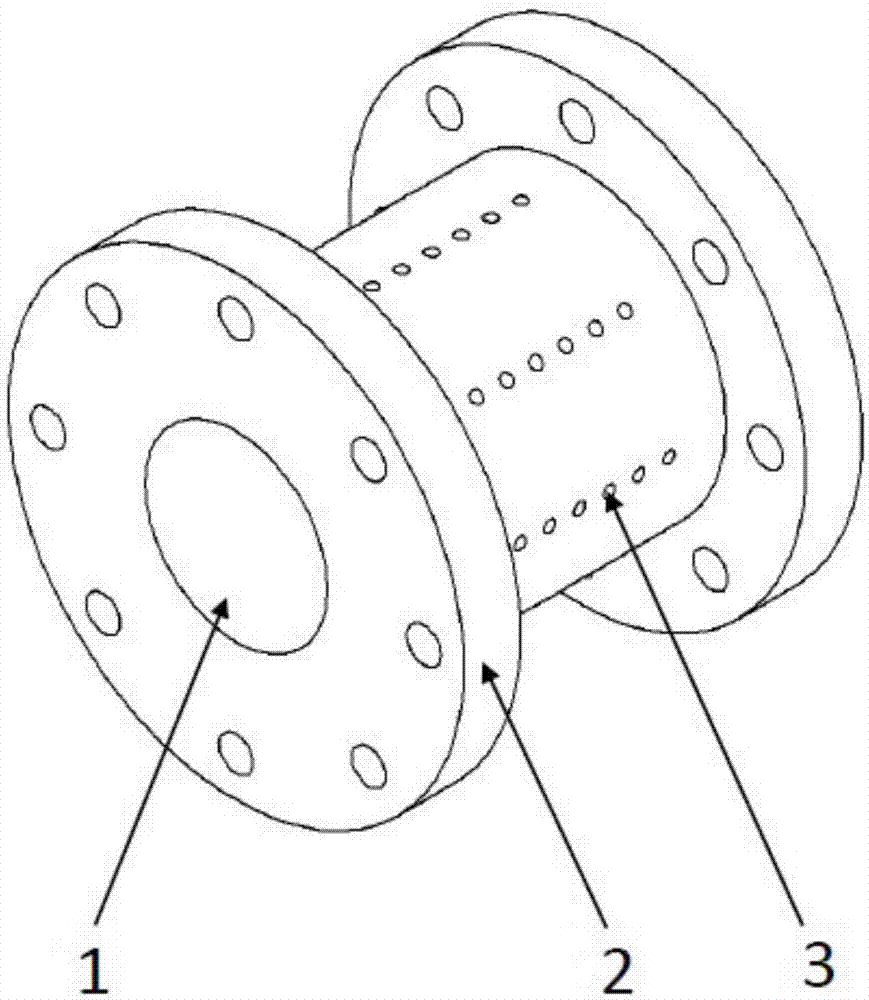

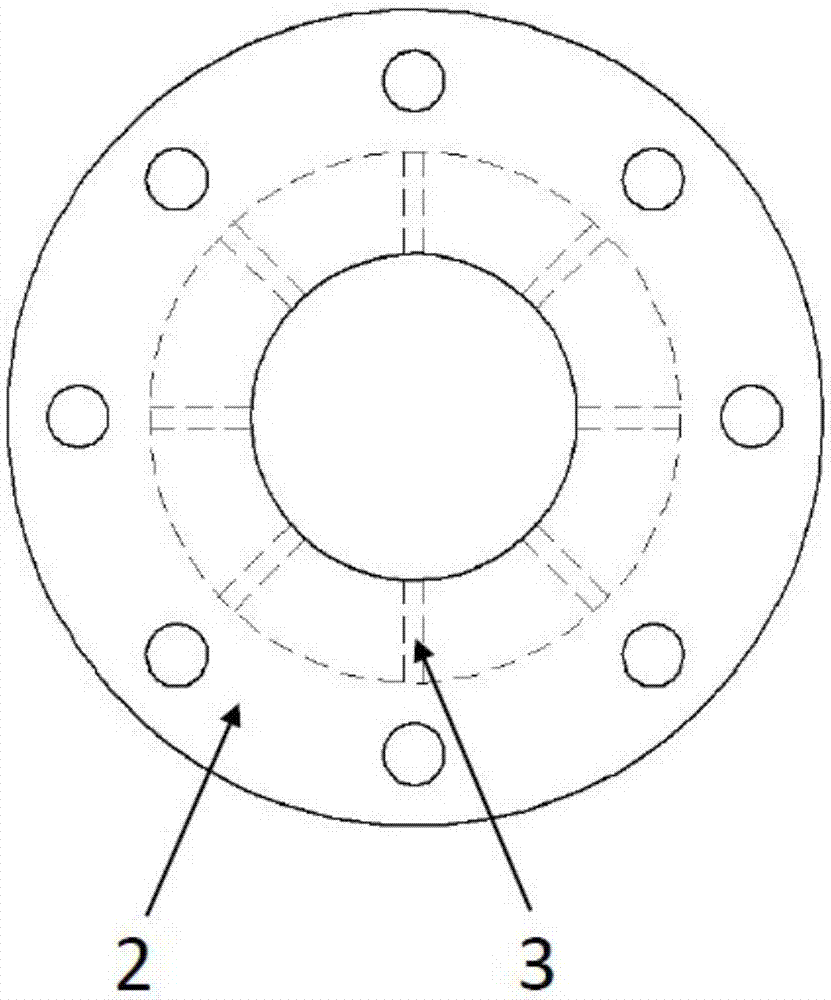

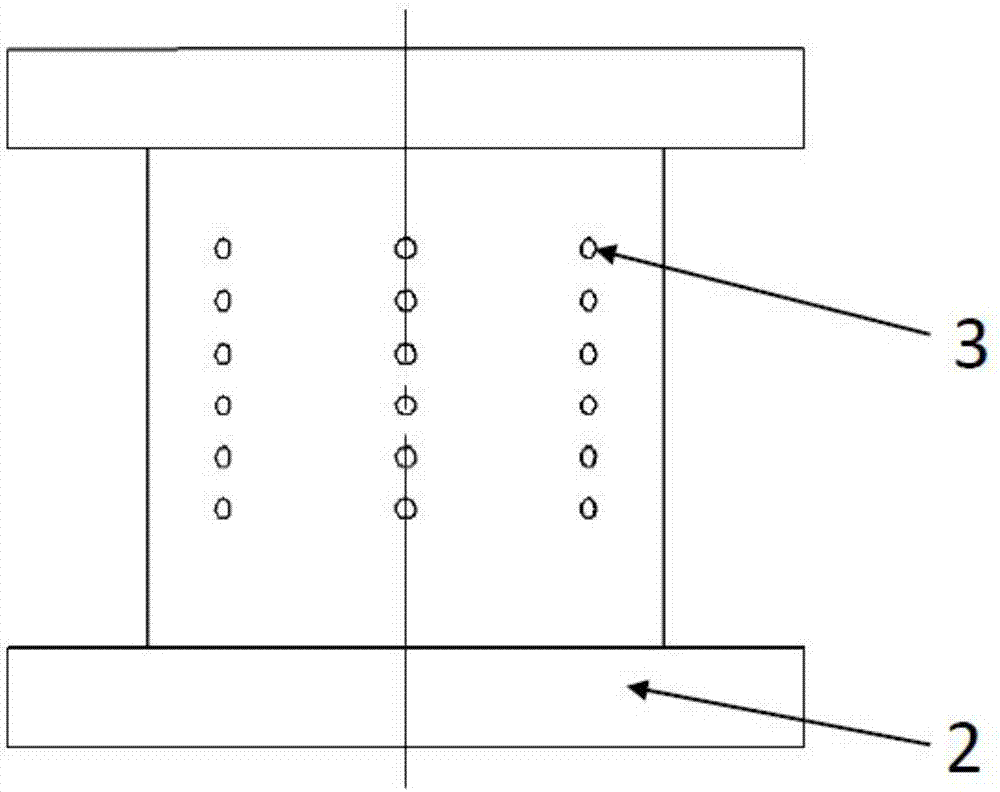

[0054] The following combines a work in the Ka band, TE 01 The design example and accompanying drawing of the novel porous ventilation circular waveguide that are used to transmit high-power microwave and millimeter wave further elaborate on the present invention:

[0055] Ka-band new porous ventilated circular waveguide technical indicators:

[0056] Working mode: TE 01 mold;

[0057] Working frequency band: Ka band (26.5GHz-40GHz);

[0058] Circular waveguide size: Inner radius of the circular waveguide: 16mm, outer radius: 26mm, height: 50mm; 8 columns of ventilation holes are arranged at equal intervals on the wall of the circular waveguide, and there are 6 ventilation holes in each column, and the radius of the ventilation holes is 1mm. The distance between two adjacent holes in a row of ventilation holes is 5.2mm.

[0059] According to the propagation characteristics of electromagnetic waves in the cylindrical waveguide, the main waveguide transmits TE 01 mode, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com