High-tension ceramics lead wire lever being resistant to high power radio frequency pulse peak power

A technology of radio frequency pulse and peak power, which is applied in the field of radio frequency slab CO2 lasers, can solve the problems of not being effective and not completely eradicating the sparking on the surface of the lead rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

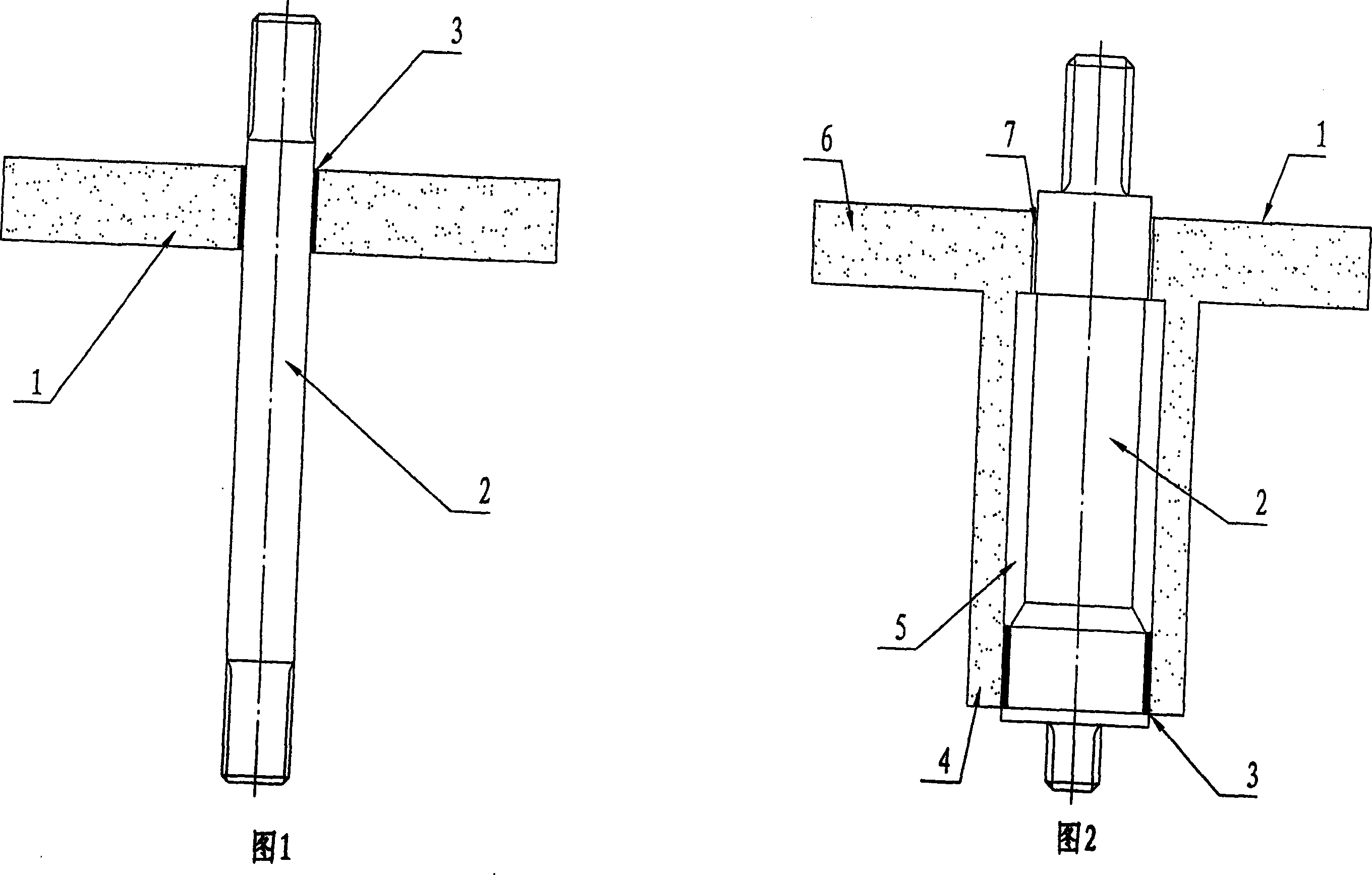

[0017] As shown in FIG. 2 , the present invention relates to a high-voltage ceramic lead rod capable of withstanding high-power radio frequency pulse peak power, which consists of a ceramic part 1 and a lead rod 2 .

[0018] The ceramic part 1 is in a "T" shape, and is composed of a ceramic disc 6 with a central hole 7 and a ceramic cylinder 4 extending downward from the lower end of the ceramic disc 6 to form an integral structure.

[0019] The lead rod 2 is a silver-plated copper rod.

[0020] The lead rod 2 passes through the inner hole 5 and the central hole 7 of the ceramic part 1 , and the two ends of the lead rod 2 extend out of the ceramic part 1 .

[0021] The inner hole 5 at the lower end of the ceramic cylinder is metallized to form a layer of metal layer 3, and the ceramic cylinder 4 is silver-copper welded with the lower part of the lead rod 2 through the metal layer 3, and the center hole 7 of the ceramic disc 6 The hole wall is no longer metallized. There is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com