Biomass gasification and combustion boiler with secondary ignition device

A technology of secondary ignition and ignition device, applied in the field of ignition system, can solve the problems of incomplete combustion of gasification gas and low furnace temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

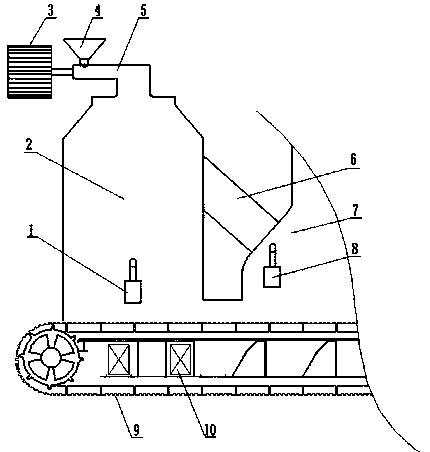

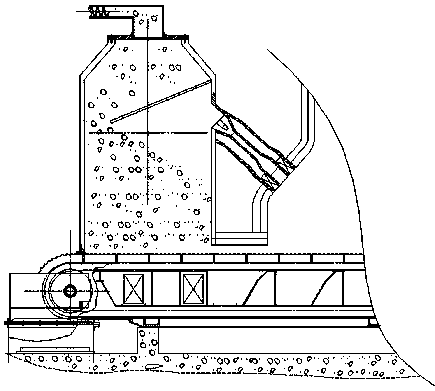

[0013] Specific implementation mode one: as figure 1 As shown, the biomass gasification combustion boiler with a secondary ignition device described in this embodiment includes a biomass gasification chamber 2, a combustion chamber 7, a primary ignition device 1, and a secondary ignition device 8; 4 enters the feeding dragon 5, the motor 3 drives the feeding dragon 4 to make the biomass fuel enter the biomass gasification chamber 2, the primary ignition device 1 starts, the biomass fuel is burned to generate gasification gas, and the gasification gas passes through the biomass gasification The connection device 6 between the chamber 2 and the combustion chamber 7 enters the combustion chamber 7, at this time, the secondary ignition device 8 is started, and when the temperature of the combustion chamber 7 reaches the requirement, the secondary ignition device 8 is turned off.

specific Embodiment approach 2

[0014] Specific implementation mode two: as figure 1 As shown, the secondary ignition device 8 described in this embodiment is located on the outer wall of the combustion chamber 7, at the outlet of the connecting device 6 between the biomass gasification chamber 2 and the combustion chamber 7; If there is not enough accumulation, the furnace temperature is low, and the temperature of the combustion chamber 7 cannot meet the requirements. The secondary ignition device 8 is activated to meet the temperature required for combustion and maintain stable combustion.

specific Embodiment approach 3

[0015] Specific implementation mode three: as figure 1 As shown, the primary ignition device 1 described in this embodiment is located at the lower end of the biomass gasification chamber 2. When the biomass fuel enters the biomass gasification chamber 2, the primary ignition device 1 is started, and the biomass fuel burns to generate gasification gas, which enters the To combustion chamber 7 combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com