High-voltage coaxial cable joint

A coaxial cable, high-voltage technology, applied in the field of high-power pulse drive sources, can solve the problems of high current, easy ignition connection, positioning, inaccuracy, etc., and is suitable for mass production and commercialization, enhances versatility, and solves ignition problems. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

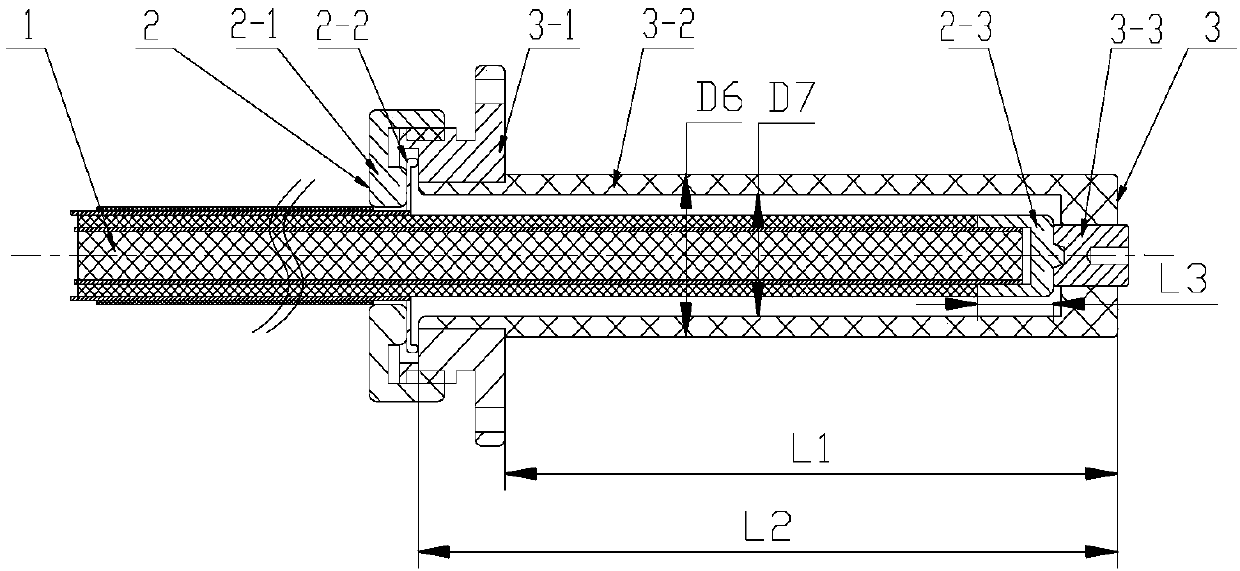

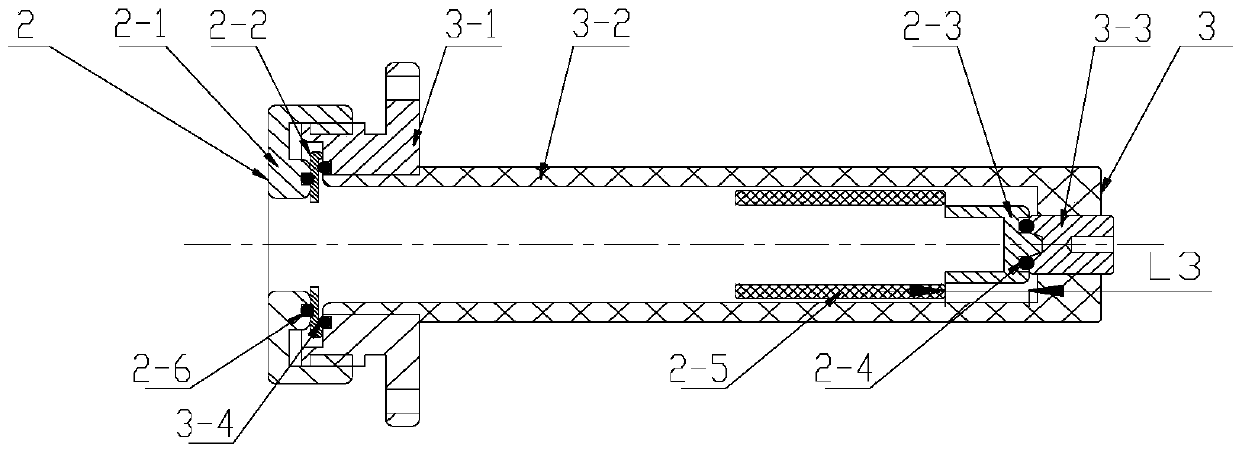

[0028] figure 1A high-voltage coaxial cable with a typical structure and its supporting connectors described in the background technology are mainly composed of a high-voltage coaxial cable 1, a cable male 2 and a cable female 3. Generally, the high-voltage coaxial cable 1 and the cable male 2 are firstly connected. Install them together, and then realize a pluggable connection with the cable female head 3 .

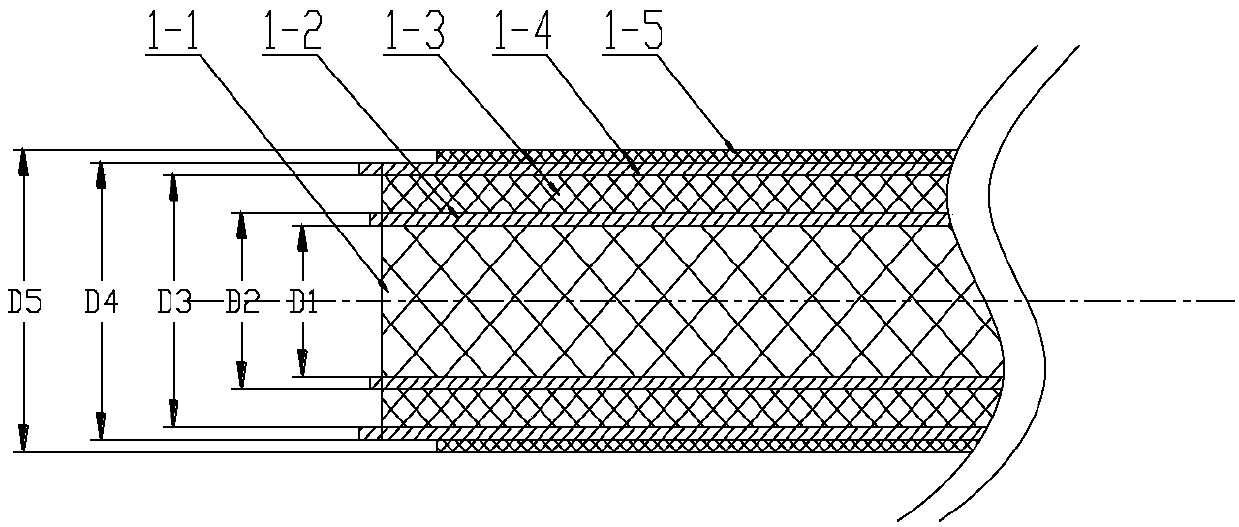

[0029] The typical structure of high voltage coaxial cable 1 is as follows figure 2 As shown, from the inside to the outside, the inner insulator 1-1, the cable inner conductor 1-2, the outer insulator 1-3, the cable outer conductor 1-4 and the insulating sheath 1-5 are coaxially nested, and the inner insulator 1- 1. The outer diameters of cable inner conductor 1-2, outer insulator 1-3, cable outer conductor 1-4 and insulating sheath 1-5 are D1, D2, D3, D4 and D5 respectively.

[0030] like figure 1 As shown, the male cable 2 is composed of a male nut 2-1, an outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com