Preparation method of graphene electrothermal film for floor heating

A technology of graphene and electric heating film, which is applied in the field of floor heating electric heating film and its preparation, can solve the problems of easy ignition and waste of floor heating electric heating film, and achieve the effect of good electrical connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

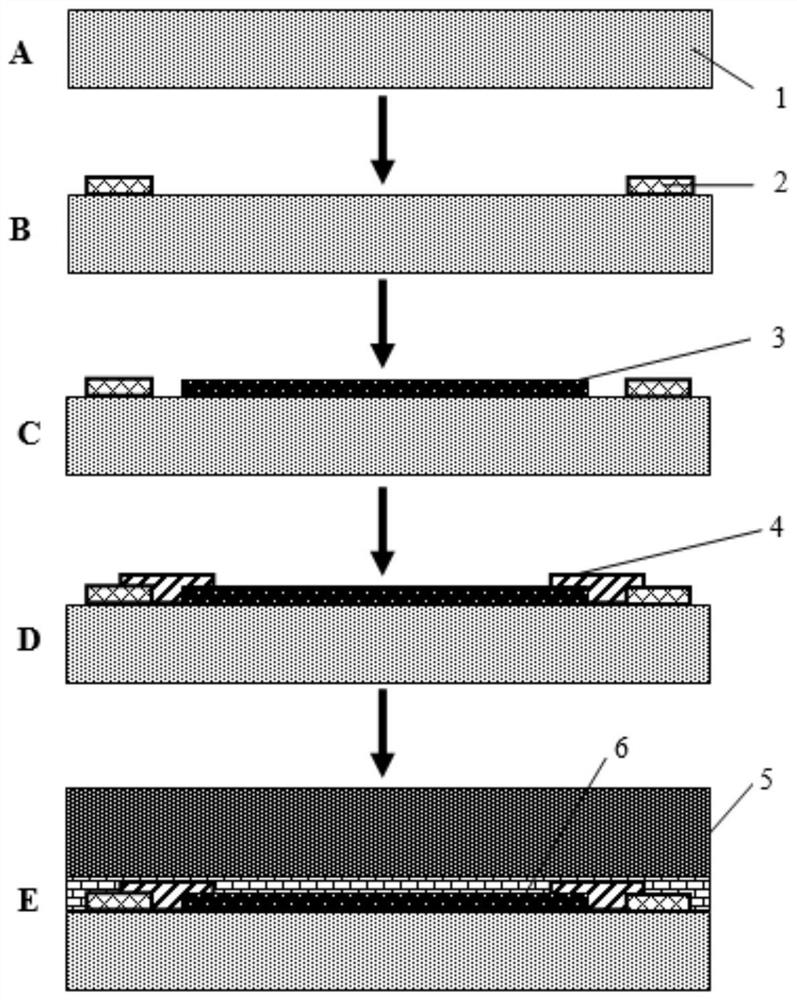

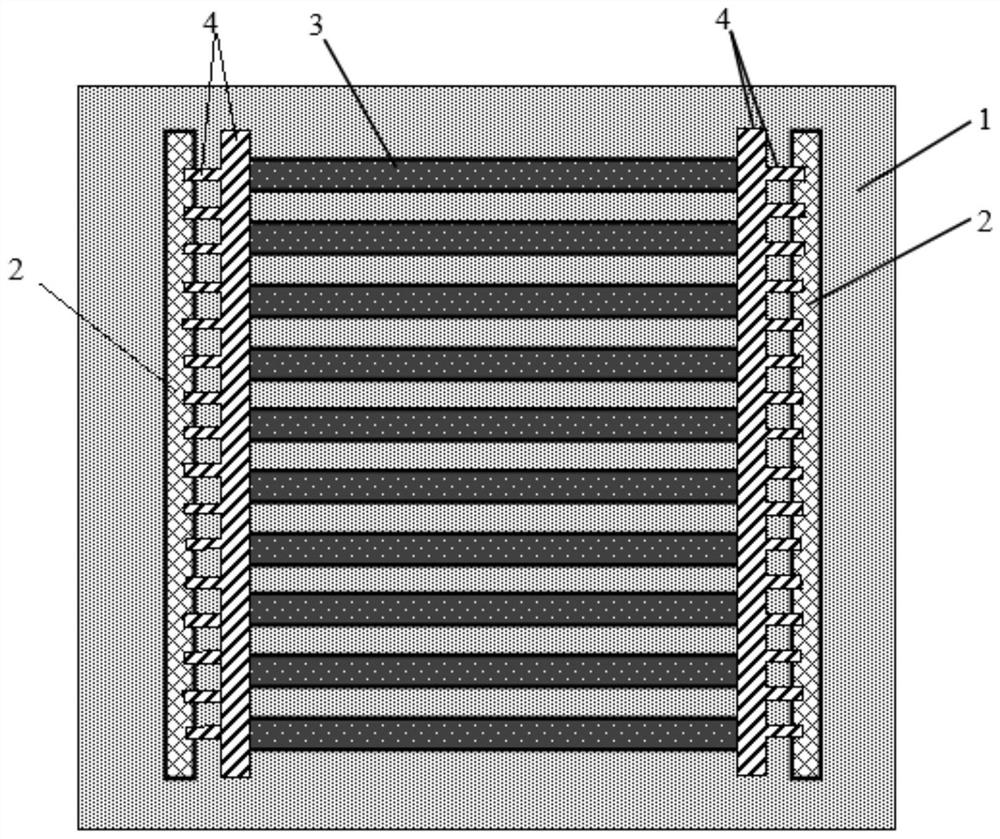

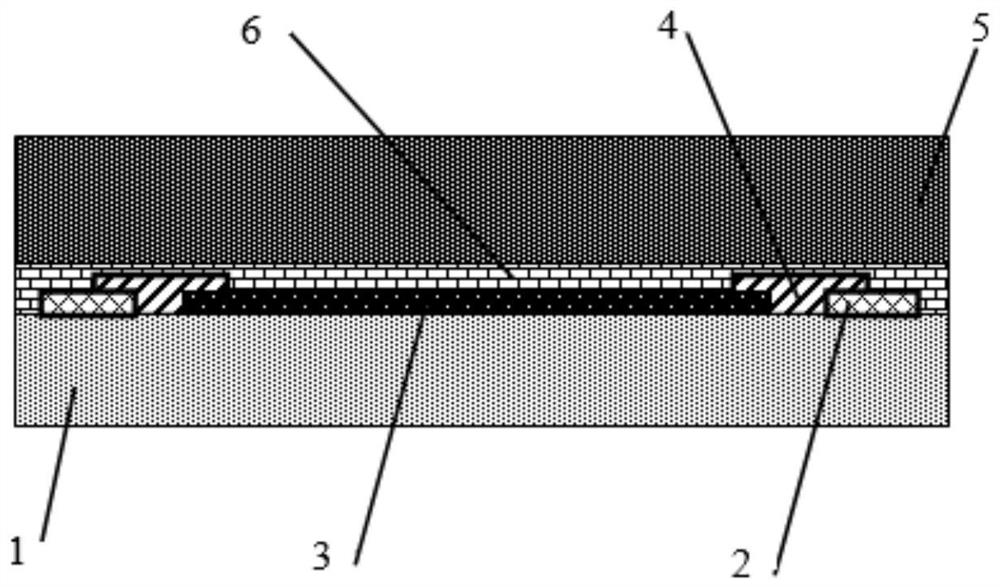

Method used

Image

Examples

Embodiment 1

[0079] 1. Coarsening treatment

[0080] Put the roll-type copper foil (strip) to be treated into the wet etching equipment, adopt the roll-to-roll micro-etching process, and use the micro-etching solution to micro-etch the copper foil, that is, immerse the copper foil (strip) in the micro-etching solution, and the copper The foil (strip) is subjected to micro-etching treatment, the copper foil (strip) passes through the micro-etching solution at a constant speed, the surface of the copper foil (strip) is corroded by the micro-etching solution, and the copper foil (strip) is under the action of a strong oxidant to form copper oxide, which is then combined with Acid reaction, resulting in etching, the total chemical equation is: H 2 o 2 +Cu+H 2 SO 4 →CuSO 4 +2H 2 O, where:

[0081] The microetching solution is a hydrogen peroxide-sulfuric acid system (that is, a mixture of hydrogen peroxide and sulfuric acid). The sum of the concentration and the concentration of sulfuric...

Embodiment 2

[0105] 1. Coarsening treatment

[0106] In addition to the microetching solution, the hydrogen peroxide-sulfuric acid system is used, in which the total concentration of hydrogen peroxide and sulfuric acid is 105g / L, the concentration ratio of hydrogen peroxide and sulfuric acid is: 1:2.5, the concentration of hydrogen peroxide is 30g / L, the concentration of sulfuric acid is 75g / L, and the reaction temperature is 25°C, the moving speed of the copper foil is 3m / min, the etching time is 100s, and the surface roughness Ra of the roughened copper foil is 2.5±0.5μm, the rest is the same as that of the embodiment 1.

[0107] 2. Implantation of copper electrodes

[0108] Except that the first adhesive is epoxy resin adhesive, the baking temperature is 100°C (usually 50-200°C, preferably 50-140°C); bake for 5 minutes (usually 1-20min); 2 symmetrically placed The roughened copper foil (strip) is 1.5cm away from the edge of the PET film of the first insulating substrate; the distance b...

Embodiment 3

[0117] 1. Coarsening treatment

[0118] In addition to the microetching solution, the hydrogen peroxide-sulfuric acid system is selected, in which the total concentration of hydrogen peroxide and sulfuric acid is 135g / L, the concentration ratio of hydrogen peroxide and sulfuric acid is: 1:3.5, the concentration of hydrogen peroxide is 30g / L, the concentration of sulfuric acid is 105g / L, and the reaction temperature is 30 °C, the moving speed of the copper foil (strip) is 2.5m / min, the etching time is 100s, and the roughness Ra of the surface of the roughened copper foil is 3.5±0.5μm, the rest are the same as in Example 1.

[0119] 2. Implantation of copper electrodes

[0120] Except that the first adhesive is an acrylic resin adhesive; the baking temperature in the oven is 80°C (usually 50-200°C, preferably 50-140°C); bake for 10min (usually 1-20min); symmetrical The distance between the two roughened copper foils (bars) placed is 0.5cm from the edge of the PET film of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Separation distance | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com