Device and method for reducing oxygen content of coal slime drying hot air in gas oxidation furnace

A technology of oxidation furnace and oxygen content, which is applied in the direction of drying, drying machine, combustion method, etc., can solve the problems that the oxygen content of hot air drying coal slime is not economical, and the slime drying technology is difficult to popularize and apply, etc. , to achieve the effect of expanding the adaptation area and high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

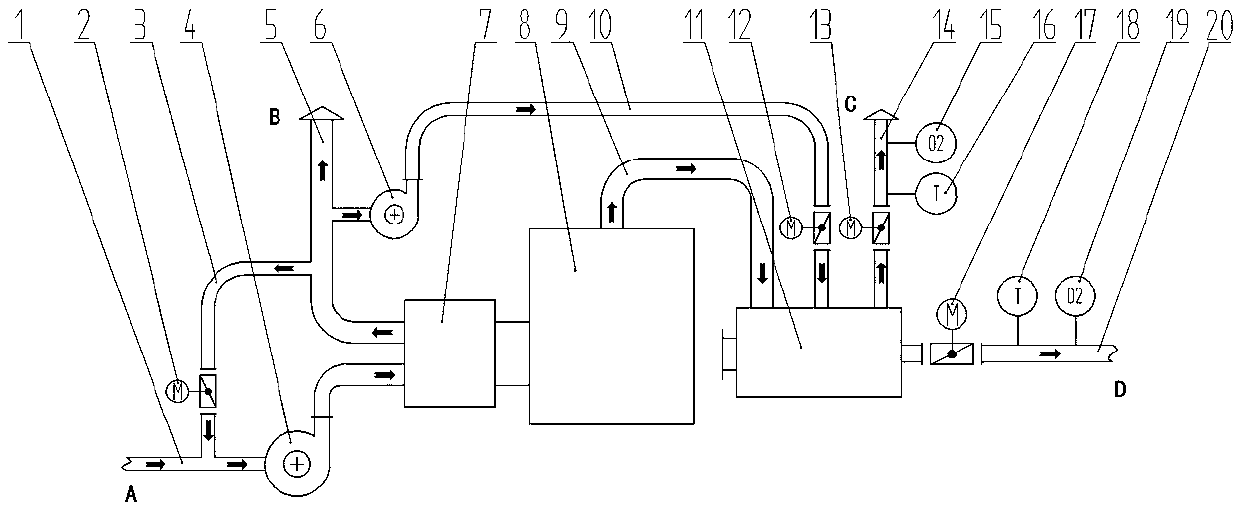

[0030] Embodiment 1, with reference to attached figure 1 , a device for reducing the oxygen content of hot air for drying coal slime in a gas oxidation furnace mentioned in the present invention, including a gas oxidation system, a drying hot air oxygen content control system, a drying hot air temperature control system, equipment start-stop and drying Hot air conveying operating system, wherein the gas pipeline 1 is connected to the inlet of the blower 4, the outlet of the blower 4 is connected to the inlet of the reversing valve 7 and the gas oxidation furnace 8 in sequence; the outlet of the reversing valve 7 is connected to the chimney of the oxidation furnace 5, and these mechanisms constitute the gas oxidation system The two ends of the return pipe 3 are connected to the gas pipe 1 and the chimney of the oxidation furnace 5, and the oxygen-containing regulating valve 2 is arranged in the middle, and these mechanisms form the oxygen content control system of the drying hot...

Embodiment 2

[0049] Embodiment 2, the device for reducing the oxygen content of the gas oxidation furnace drying coal slime hot air mentioned in the present invention, differs from Embodiment 1 in that:

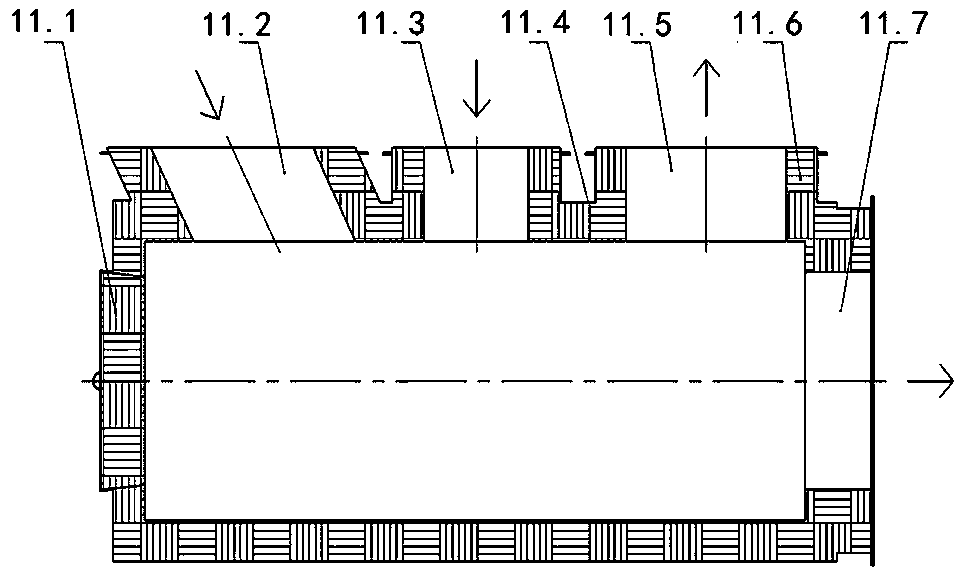

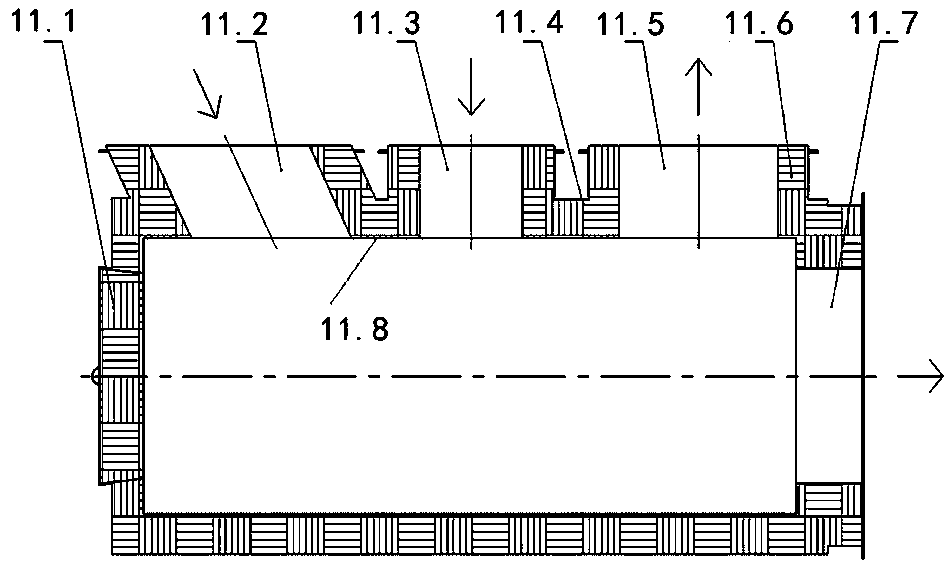

[0050] The hot air temperature control box 11 of the present invention includes a blast hole plug 11.1, a high temperature flue gas inlet 11.2, a low temperature flue gas inlet 11.3, a metal shell 11.4, a high temperature flue gas outlet 11.5, an insulation layer 11.6, a drying hot air outlet 11.7 and inner surface ceramics The coating layer 11.8, the metal shell 11.4 is a cylindrical structure, with an insulation layer 11.6 on the outside, an explosion vent hole plug 11.1 at one end, a drying hot air outlet 11.7 at the other end, and a high-temperature heat exchanger on the metal shell 11.4 in turn. Flue gas inlet 11.2, low temperature flue gas inlet 11.3 and high temperature flue gas outlet 11.5.

[0051] Among them, the high-temperature flue gas inlet 11.2 is an oblique hole inclined a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com