Regenerating system using waste gas itself as heating carrier

A regeneration system, waste gas technology, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of high energy consumption, oxygen combustion, explosion, etc., to achieve good safety, low cost, low cost of post-processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

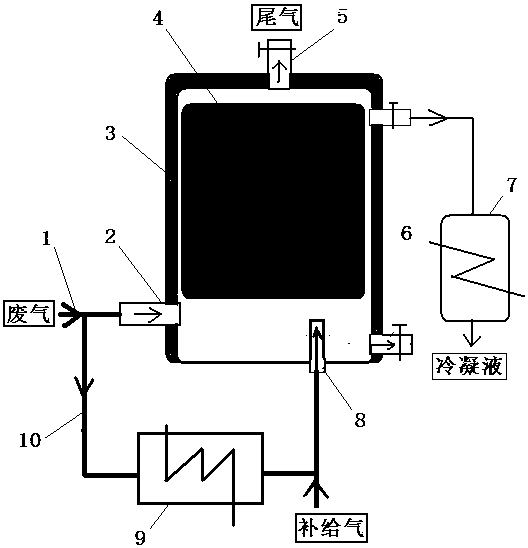

[0012] Such as figure 1 The shown regeneration system using exhaust gas itself as a heating carrier has an adsorption-desorption tank containing adsorption fillers, and the adsorption-desorption tank has an exhaust gas inlet, a desorption gas inlet, a purified gas outlet, and a regeneration gas outlet; the desorption gas inlet What enters is the exhaust gas itself, and a heating device is installed on the pipeline between the exhaust gas source and the desorption gas inlet to heat the exhaust gas, and use the higher temperature exhaust gas to bake and desorb the adsorption filler.

[0013] The valve of the purified gas outlet can be closed at the initial stage of adsorption, opened at the later stage of adsorption, and closed during the whole desorption process; the valve of the regeneration gas outlet is closed during the whole adsorption process and opened during desorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com