Preparation method of solid decontaminant for removing unsymmetrical dimethylhydrazine

A technology of unsymmetrical dimethylhydrazine and decontamination agent, which is applied in the field of preparation of solid decontamination agent, and can solve the problems of pollution, unprevented diffusion of unsymmetrical dimethylhydrazine vapor, liquid flow diffusion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples illustrate the invention.

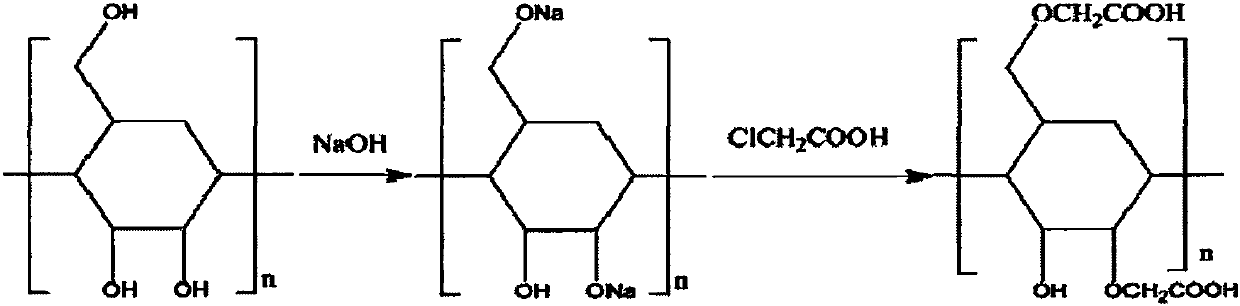

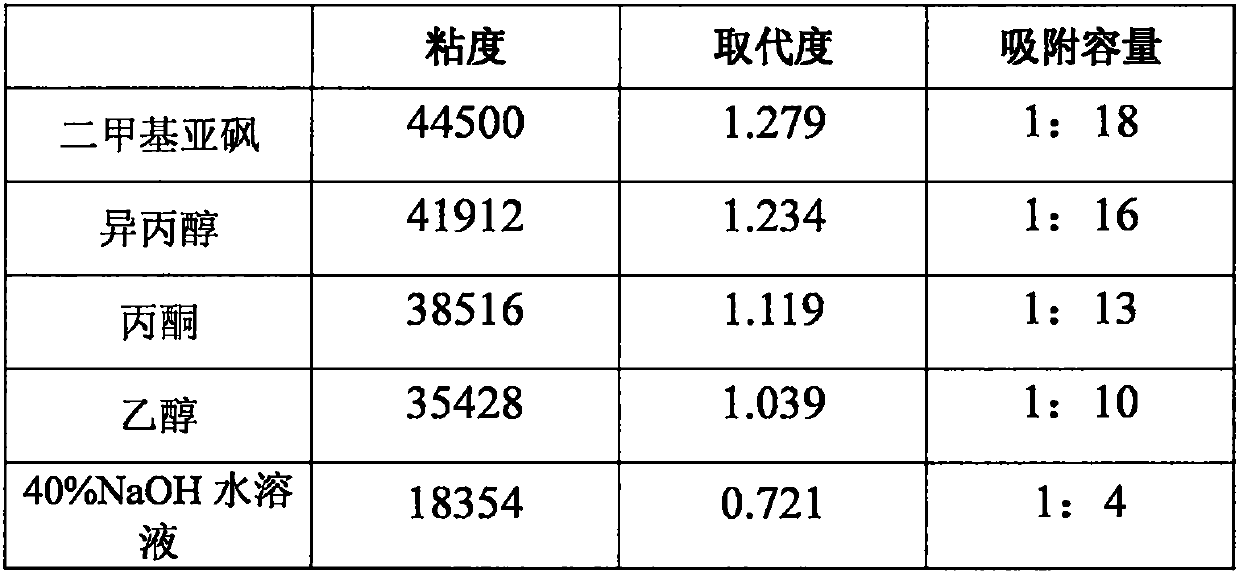

[0017] The preparation process of solid decontamination agent: 5g of cellulose, respectively with 40wt% NaOH aqueous solution, dimethyl sulfoxide, isopropanol, acetone and ethanol as swelling agent, fully swell, then carry out alkalization treatment with NaOH solution, alkalization time and The alkalization temperature is 2h and 10°C; then use chloroacetic acid solution as the acidifying agent, the acidification time and acidification temperature are 4h and 60°C, after the acidification treatment, the solid-liquid separation is performed to obtain the solid decontamination agent, each sample is numbered A , B, C, D. and E, wherein A sample is used as a comparative example.

[0018] Unsymmetrical dimethylhydrazine removal process: Take the above-mentioned body decontamination agent, sprinkle it gently on 20 times, 10 times and 5 times the mass of unsymmetrical dimethylhydrazine liquid, it is found that there is an obviou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com