Corner tangential boiler with thermal power flexibility adjusting function and adjusting method of corner tangential boiler

A technology of four-corner cutting and adjustment method, which is applied in the direction of adjusting fuel supply, combustion method, and combustion using lump fuel and liquid fuel, and can solve problems such as sacrificing boiler efficiency, furnace fire extinguishing and blasting, and easy flameout, etc., to achieve improvement Peak shaving flexibility, fast load response, and the effect of increasing furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

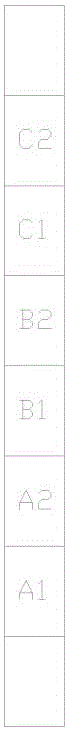

[0058] Embodiment one, combine figure 1 It can be seen that the four-corner tangential circle boiler of this embodiment includes a total of 6 burners, of which A1 and A2 are the lower burners, B1 and B2 are the middle burners, and C1 and C2 are the upper burners. Any one or two layers of the lower burner is a peak-shaving burner; any one or two layers of the lower burner is a peak-shaving burner, and the peak-shaving burner is an internal combustion burner, which can ignite pulverized coal inside the burner. And stable combustion, other burners are ordinary burners, ordinary burners are internal combustion burners or external combustion burners. The four-corner tangential boiler referred to in the present invention can be a boiler with the above structure directly produced by the manufacturer, or an ordinary boiler composed of ordinary burners, which is reformed by burners, that is, according to the structure of the present invention Transform some common burners into peaking...

Embodiment 2

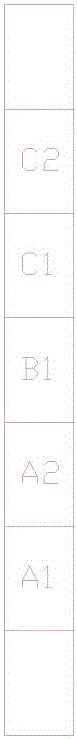

[0095] Embodiment two, such as figure 2 The boiler structure of the shown embodiment 2 is basically the same as that of the embodiment 1, the difference is that the four-corner tangential circle boiler of this embodiment includes a total of 5 layers of burners, of which layers A1 and A2 are the lower burners, and layer B1 is the middle burner , C1, C2 layer is the upper burner, any one or two layers of the upper burner is a peak-shaving burner; any one or two layers of the lower burner is a peak-shaving burner,

[0096] In this embodiment, there are many ways to arrange the burners, including at least the following:

[0097] The first type, C2 and A1 are peak-shaving burners, and A2, B1 and C1 are ordinary burners;

[0098] The second type, C2 and A2 are peak-shaving burners, and A1, B1 and C1 are ordinary burners;

[0099] The third type, C1 and A1 are peak-shaving burners, and A2, B1 and C2 are ordinary burners;

[0100] The fourth type, C1 and A2 are peak-shaving burner...

Embodiment 3

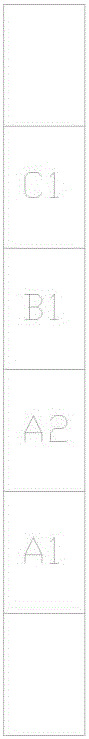

[0106] Embodiment three, such as image 3 The boiler structure of the third embodiment shown is basically the same as that of the first embodiment, the difference is that the four-corner tangential circle boiler of this embodiment includes a total of 4 layers of burners, of which layers A1 and A2 are the lower burners, and layer B1 is the middle burner , the C1 layer is the upper burner, and the upper burner is a peaking burner; any one or two layers of the lower burner is a peaking burner,

[0107] In this embodiment, there are many ways to arrange the burners, including at least the following:

[0108] The first type, C1 and A1 are peak-shaving burners, and A2 and B1 are ordinary burners;

[0109] The second type, C1 and A2 are peak-shaving burners, and A1 and B1 are ordinary burners;

[0110] The third type, C1, A1, and A2 are peak-shaving burners, and B1 is an ordinary burner;

[0111] The boiler control method of the third embodiment is basically the same as that of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com