Laser cleaning device and cleaning method

A laser cleaning and to-be-cleaned technology, applied in cleaning methods and appliances, chemical instruments and methods, workpiece surface treatment equipment, etc. High-level problems, to achieve fast and efficient cleaning, improve cleaning efficiency, and ensure the effect of cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The object of the present invention is to provide a laser cleaning device and a cleaning method to realize efficient cleaning of objects to be cleaned on a production line.

[0041] In order to make the above objects, features and advantages of the present invention more comprehensible, the technical invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

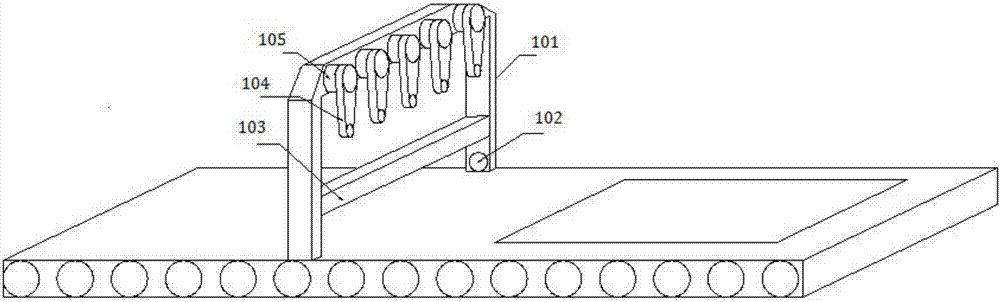

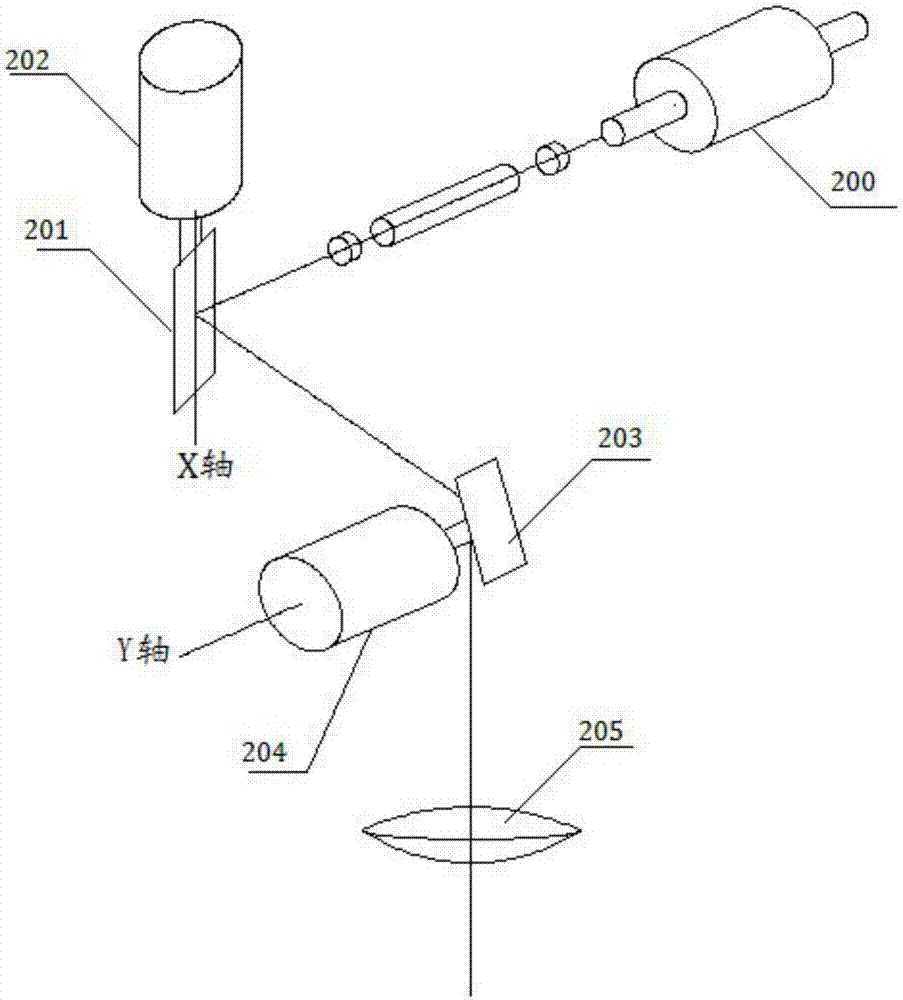

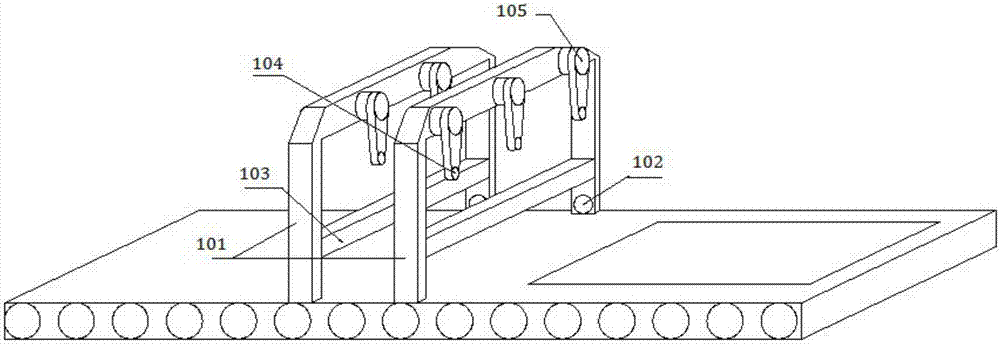

[0042] Such as figure 1 As shown, the present invention provides a laser cleaning device, including a bracket 101, a position sensor 102, a controller, a scale collection device 103, a plurality of laser cleaning heads 104, a plurality of swing motors 105 and a plurality of image sensors;

[0043] The bracket 101 is used to install the laser cleaning device on the production line of objects to be cleaned;

[0044] The swing motor 105 is fixedly connected on the support 101; the output shaft of the swing motor 105 is connected with the swing center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com