Steel pipe cleaning device

A technology for cleaning devices and steel pipes, which is applied to workpiece cleaning devices, cleaning hollow objects, cleaning methods, and utensils. It can solve the problems of lack of cleaning, complex overall structure, and damage to workers' limbs, and achieve strong cleaning power and guarantee cleaning. The effect of quality, simplification of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

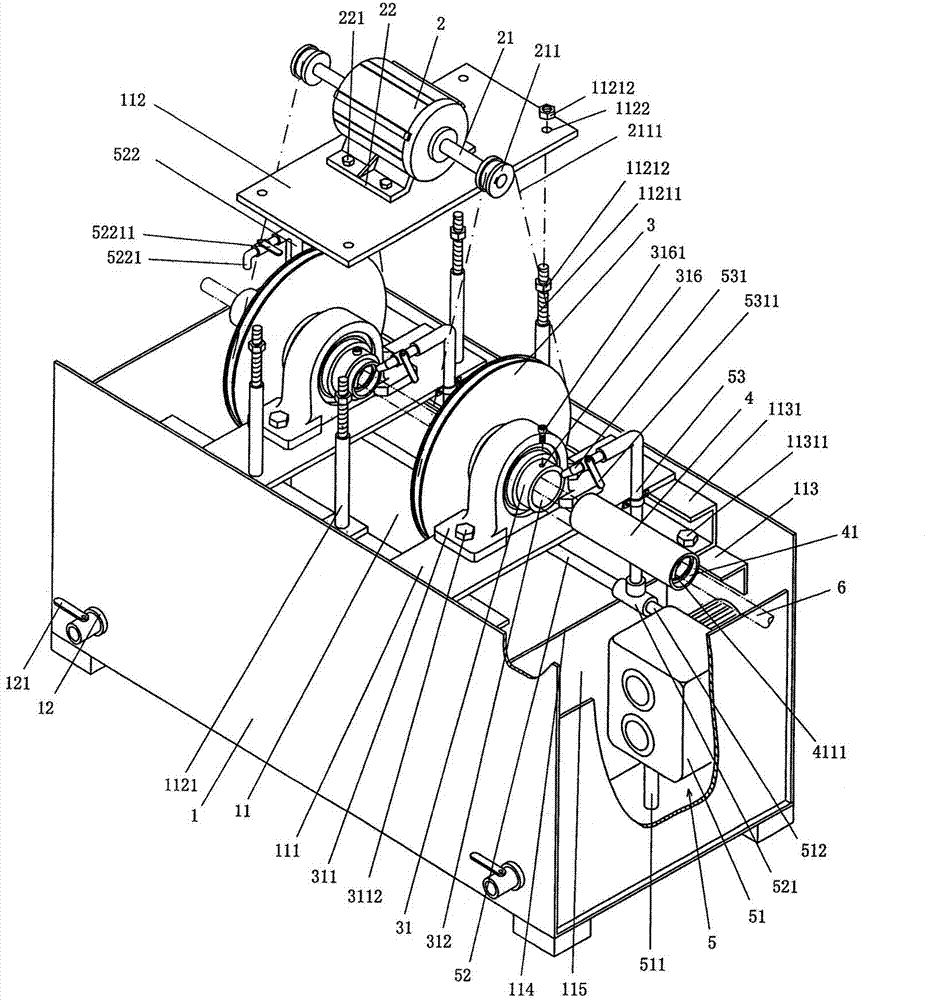

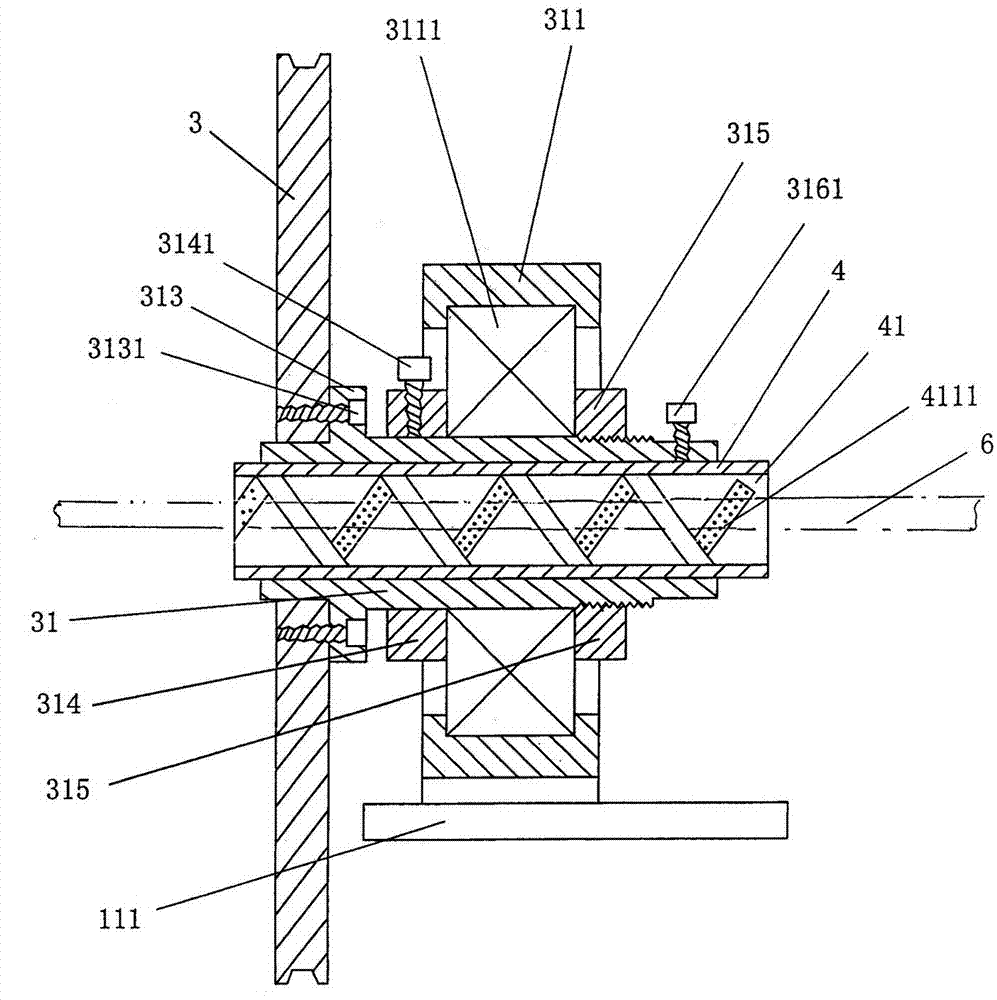

[0025] See figure 1 , a cleaning liquid tank body 1 with a rectangular parallelepiped structure is provided, the upper part of the cleaning liquid tank cavity 11 of the cleaning liquid tank body 1 is open, that is, not closed, and is set in the cleaning liquid tank cavity 11 There is a tank cavity partition plate 114, and the right end of the cleaning liquid tank tank cavity 11 is formed by the tank cavity separating plate, that is, a cleaning liquid circulation chamber 115 is formed, which is located at the left end of the cleaning liquid tank tank cavity 11. A pair of bearing seat fixing plates 111 and a motor support plate 112 are fixed on the upper part. The pair of bearing seat fixing plates 111 are parallel to each other, and one motor support plate 112 corresponds to the upper part between the pair of bearing seat fixing plates 111 in an empty state. .

[0026]Preferably, a sewage discharge interface 12 is provided on the tank wall of one side in the length direction o...

Embodiment 2

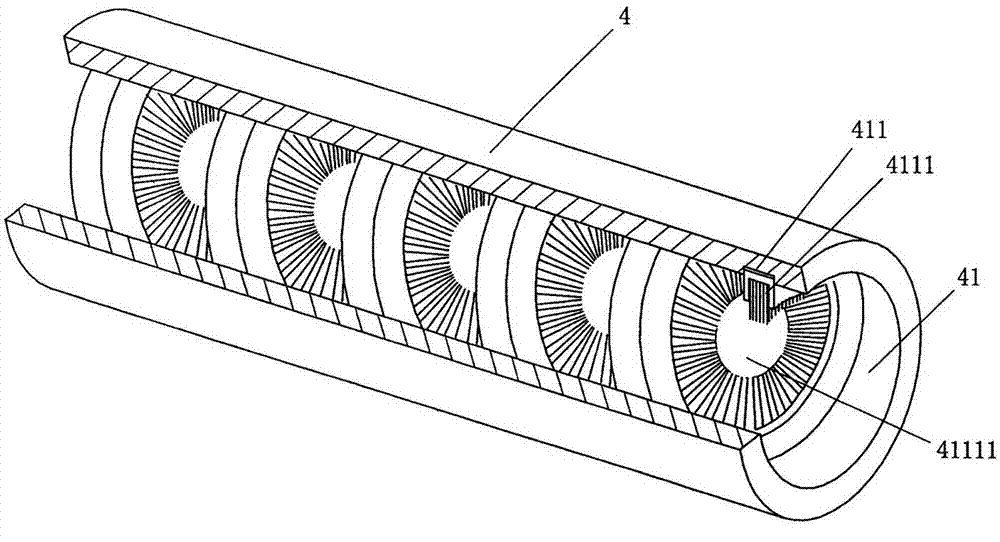

[0040] See Figure 4 , on the inner wall of the brush lumen 41 of the brush tube 4, a straight brush positioning groove 411 is opened in an interval state, and the hair brush 4111 is a straight brush, which is inserted into the straight brush positioning groove Inside 411. Preferably, the cross-sectional shape of the straight brush positioning groove 411 is designed as a dovetail shape, and the steel pipe 6 is cleaned by a group of radially distributed brushes 4111 . All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com