A kind of glass cleaner composition adding cationic polymer

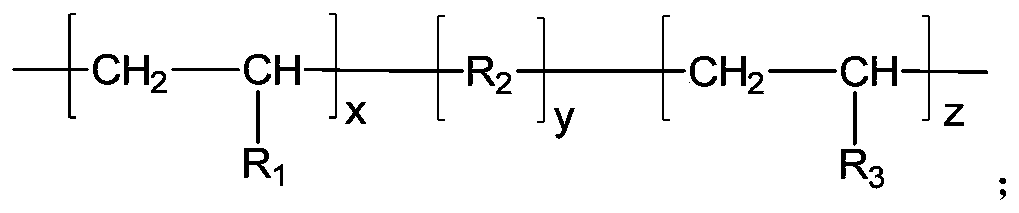

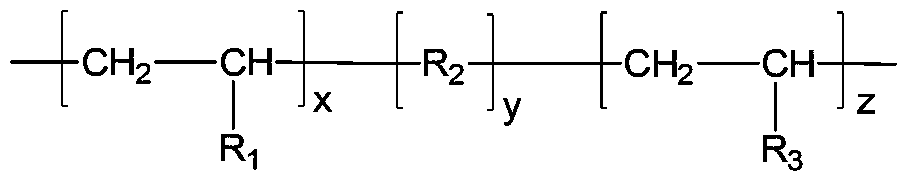

A cationic polymer, composition technology, applied in detergent compositions, nonionic surface active compounds, surface active detergent compositions, etc. Translucency and other issues, to achieve the effect of long-lasting detergent product demand, good water droplet spreading performance, time-saving and labor-saving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0121] The formula components and contents of the cationic polymer-added glass cleaner compositions 1-6 of the present invention are shown in Table 1 below. Table 1 below tested the effect on the hydrophilic modification of cationic polymer-added glass cleaner compositions 1-6 of the present invention by changing the pH value of the solution.

[0122] The influence of table 1 composition pH value on cationic polymer hydrophilic modification

[0123]

[0124] The preparation method of the glass cleaner composition 1-6 of the present invention adding cationic polymer is:

[0125] 1) Add the cationic polymer Noverite 311 (or Noverite 301) into water and stir to dissolve;

[0126] 2) Add NaOH aqueous solution to adjust the pH value of the solution, and add water to keep the weight constant.

[0127] Can be found by the test result of table 1, by soaking in the glass sheet of solution (composition 1 and composition 4) under acidic condition, after three times of rinsing, its c...

Embodiment 7-11

[0129] In glass cleaner compositions 7-11 of the present invention, the surfactant system includes one or more mixtures of anionic surfactants, zwitterionic surfactants, cationic surfactants, and nonionic surfactants. This is because the cationic polymer provided by the invention can be well compatible with various surfactants, and is also suitable under neutral and alkaline conditions.

[0130] Table 2 The formulation components and content of glass cleaner compositions 7-11 of the present invention

[0131]

Composition 7

Composition 8

Composition 9

Composition 10

Composition 11

components

content(%)

content(%)

content(%)

content(%)

content(%)

XP 80

0.3

-

-

0.3

AES270

-

0.43

-

0.43

BS-12

-

-

0.86

0.86

1227

-

-

-

0.76

Noverite 311

0.68

0.68

0.68

0.68

Ethylene glycol

0.5

0.5

0.5

0.5

0.5

...

Embodiment 12-15

[0143] Table 5 Formula components and contents of glass cleaner compositions 12-15 of the present invention

[0144]

[0145]

[0146] The preparation method of the glass cleaner composition 12-15 of the present invention adding cationic polymer is:

[0147] 1) Add cationic polymer Noverite 311 (or Noverite 301) and ammonia water (or NaOH solution) into water respectively, and stir to dissolve;

[0148] 2) Add short carbon chain fatty alcohol and surfactant respectively, stir and mix;

[0149] 3) Add detergent additives, adjust the pH value of the solution, and add water to keep the weight constant.

[0150] The data in Table 5 fully prove that the glass cleaner composition containing the cationic polymer can make the surface of the glass sheet have better hydrophilicity, and the hydrophilicity has better washing resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com