Enhanced heat transfer unit of self-drive periodically brushing boundary layer fracture in heat exchange tube

A technology to enhance heat transfer and boundary layer, applied in the direction of heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of poor heat transfer effect and inability to improve heat transfer performance in essence, and achieve enhanced strengthening effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment, but present embodiment is not intended to limit the present invention, and every adopt similar structure of the present invention and similar change thereof, all should be included in the protection scope of the present invention.

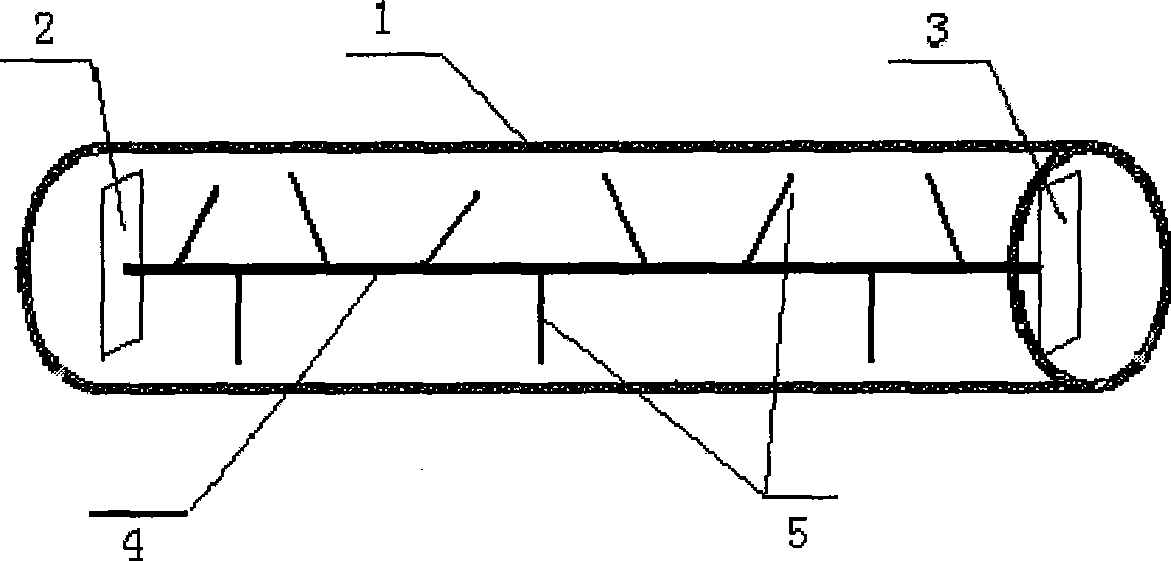

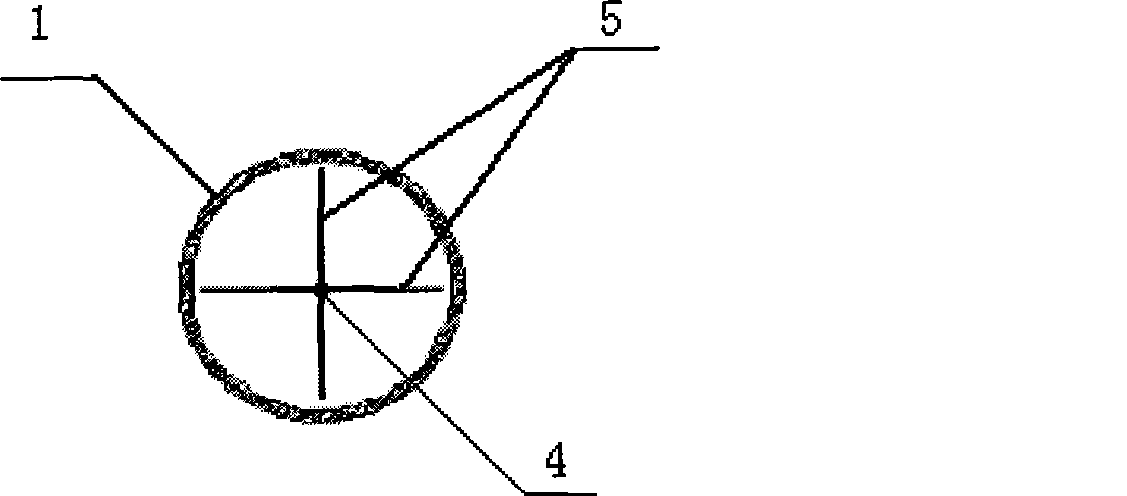

[0020] The self-driven periodic brush boundary layer rupture in the heat exchange tube enhances the heat transfer device, such as figure 1 shown. An impeller is arranged at both ends of the smooth heat exchange tube 1 (or straight pipe section), and the outer end surfaces of the two impellers are respectively fixed with the flange, that is, the front impeller and the fixed flange 2 and the rear impeller and the fixed flange are combined. 3. The inner end surfaces of the two impellers are located at the central axis of the smooth heat exchange tube 1 (or straight tube section), and are connected with stainless steel metal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com