Cleaning mechanism of belt conveyor

A belt conveyor and cleaning mechanism technology, applied in the field of lubrication, cleaning or cleaning devices, can solve the problems of inaccessibility, loss, scraper wear, etc., and achieve the effect of increasing the amount of compensation and using it for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

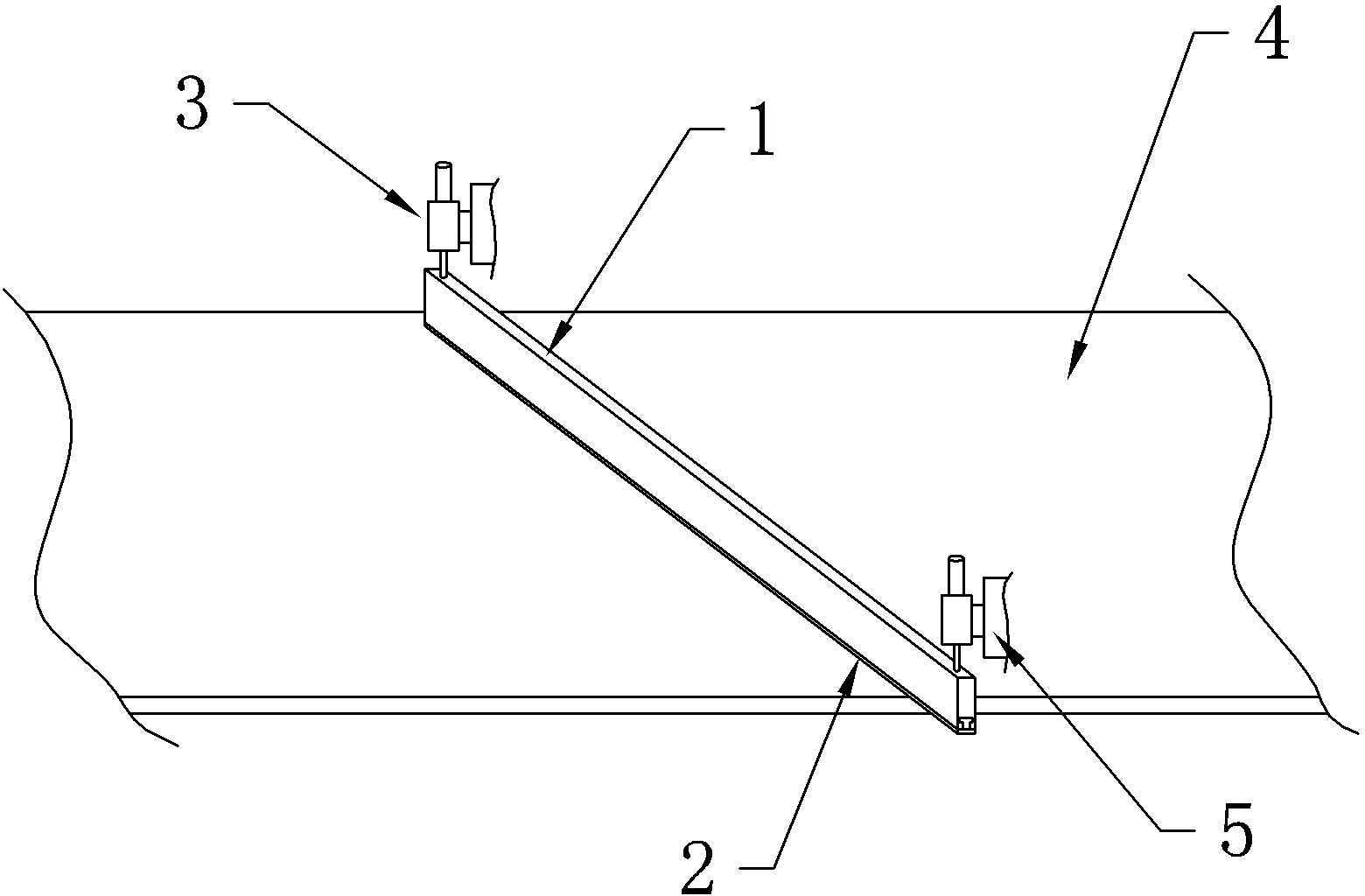

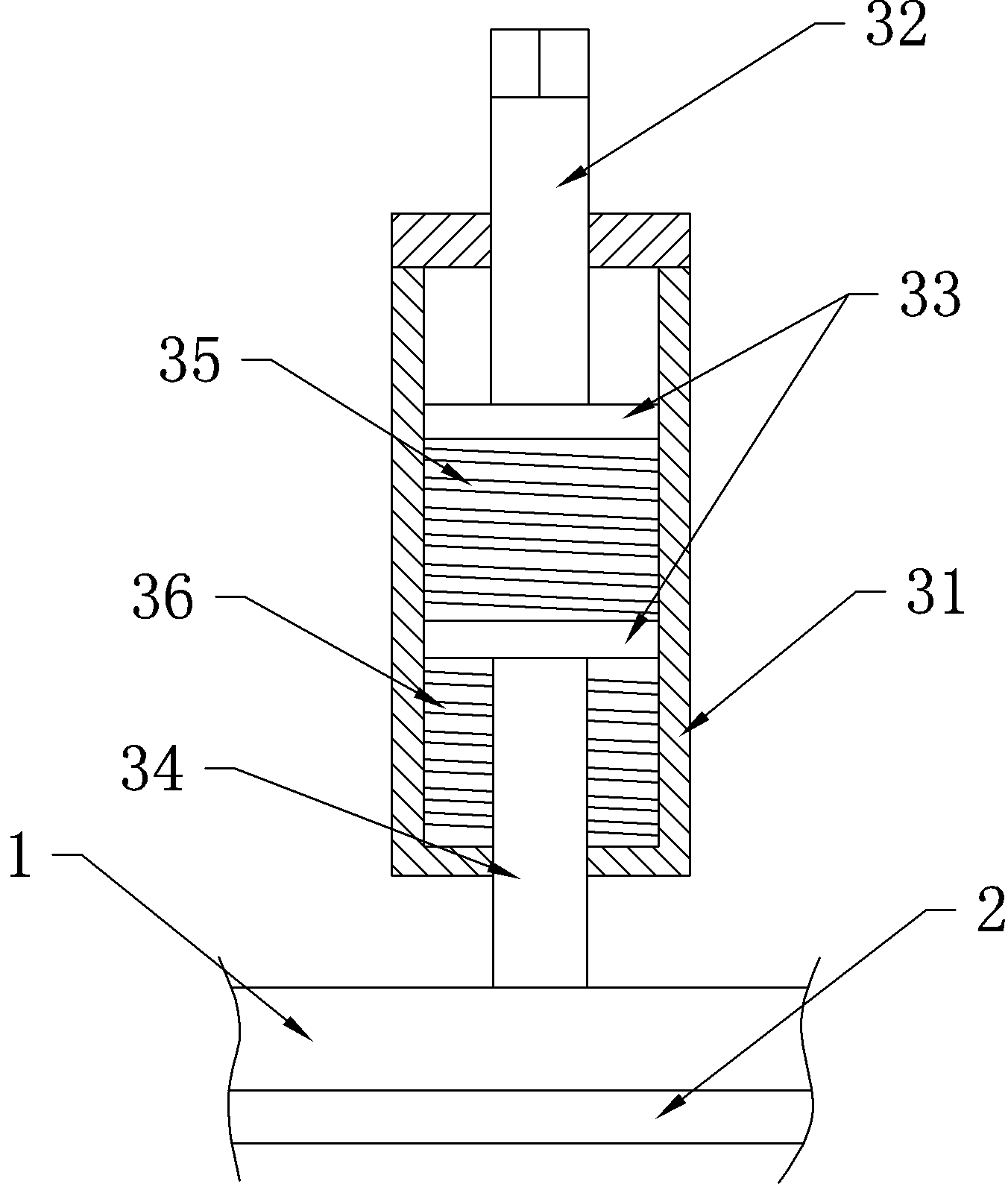

[0013] like figure 1 As shown, a belt conveyor cleaning mechanism includes a scraper 1 and a scraper 2 installed on the scraper 1, wherein an automatic compensation structure 3 is also provided, such as figure 2 , the automatic compensation structure 3 comprises a sleeve 31, a gland 33, a screw mandrel 32, a compression spring 35, a supporting spring 36 and a connecting rod 34, the elastic coefficient of the compression spring 35 is greater than that of the supporting spring 36, and the sleeve 31 is fixed on the frame 5 Above, the screw rod 32 and the connecting rod 34 extend into the sleeve 31 from both ends of the sleeve 31 respectively, and the extending ends of the screw rod 32 and the connecting rod 34 are provided with glands 33 respectively, and the compression spring 35 is located between the two glands 33 Between them, the supporting spring 36 is sheathed on the connecting rod 34, one end is supported on the gland 33, the other end is made on the inner wall of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com