Patents

Literature

79results about How to "Large amount of compensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

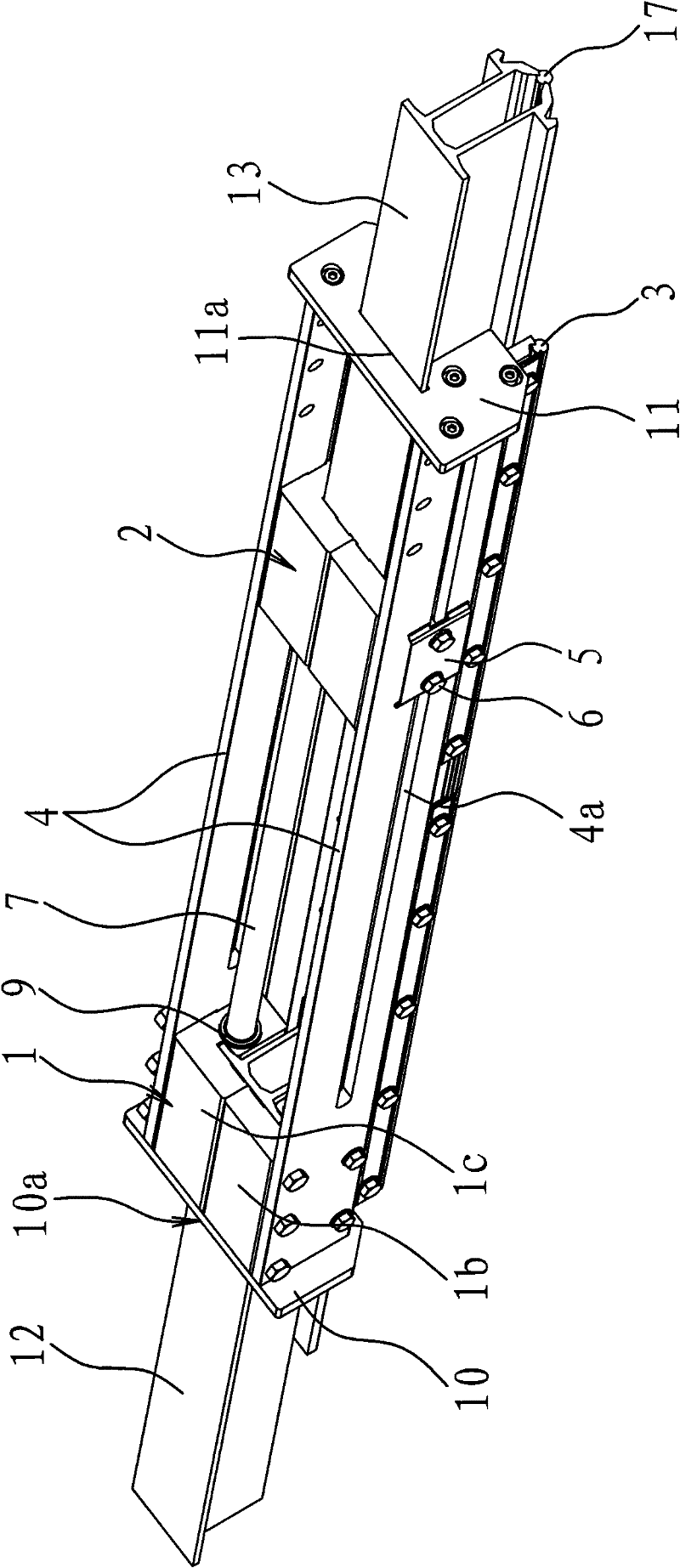

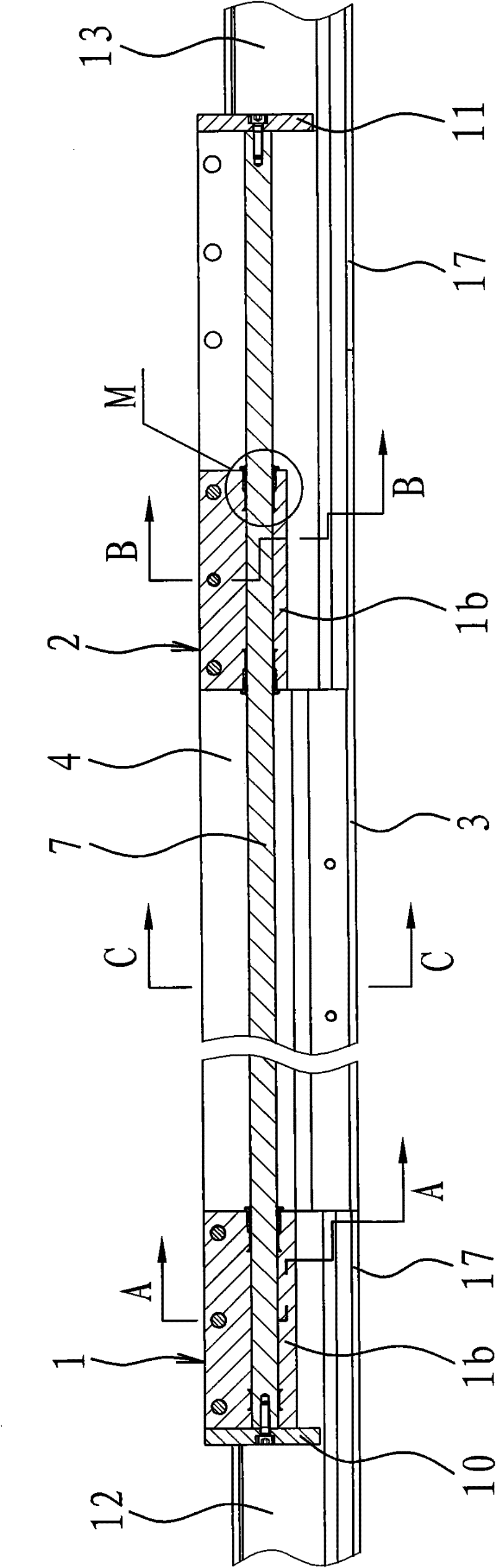

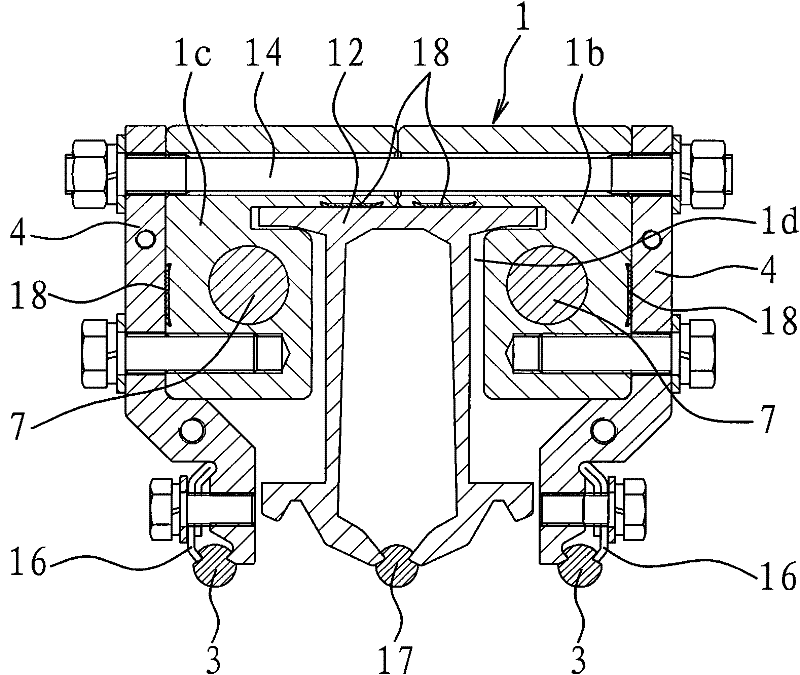

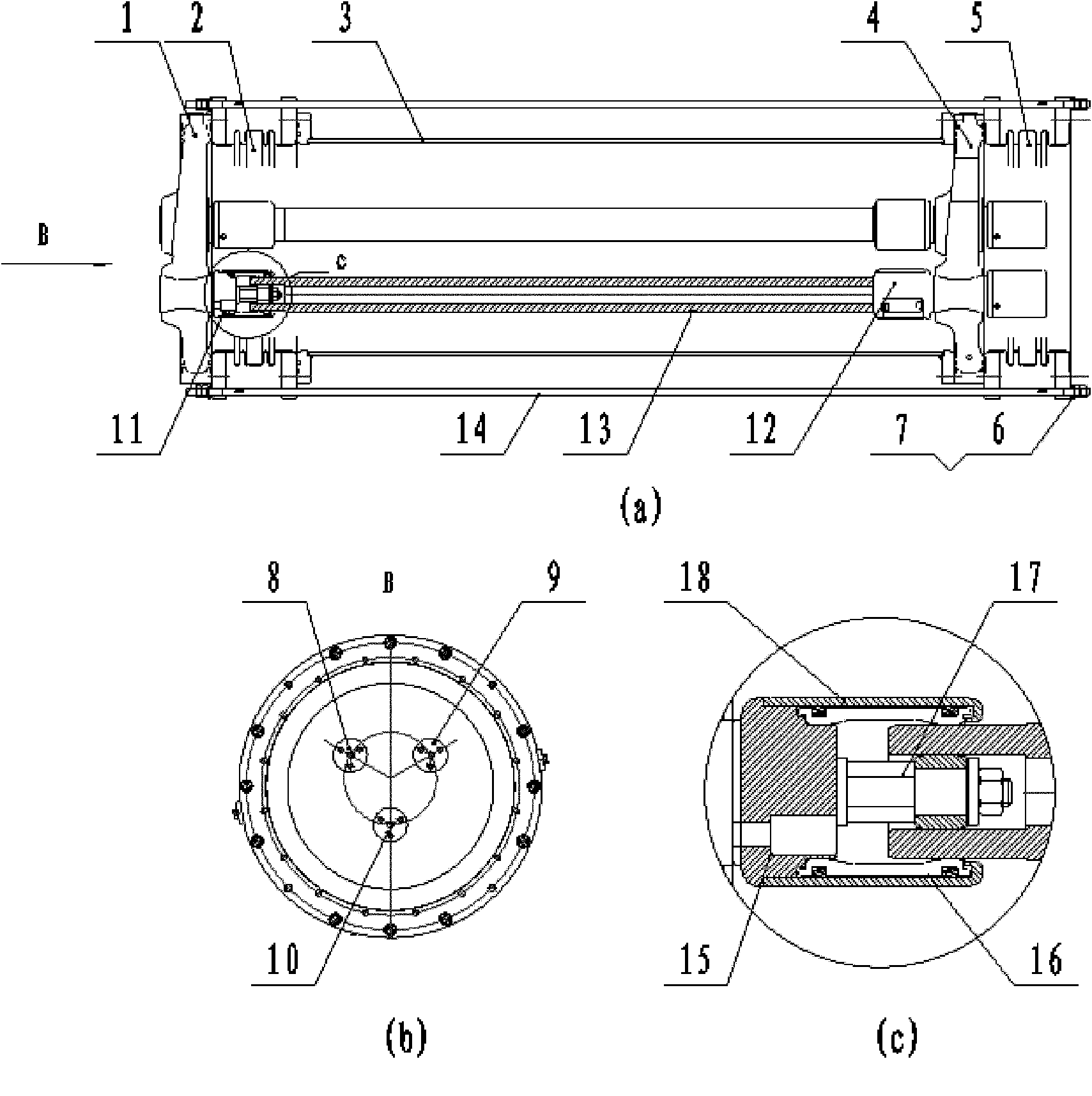

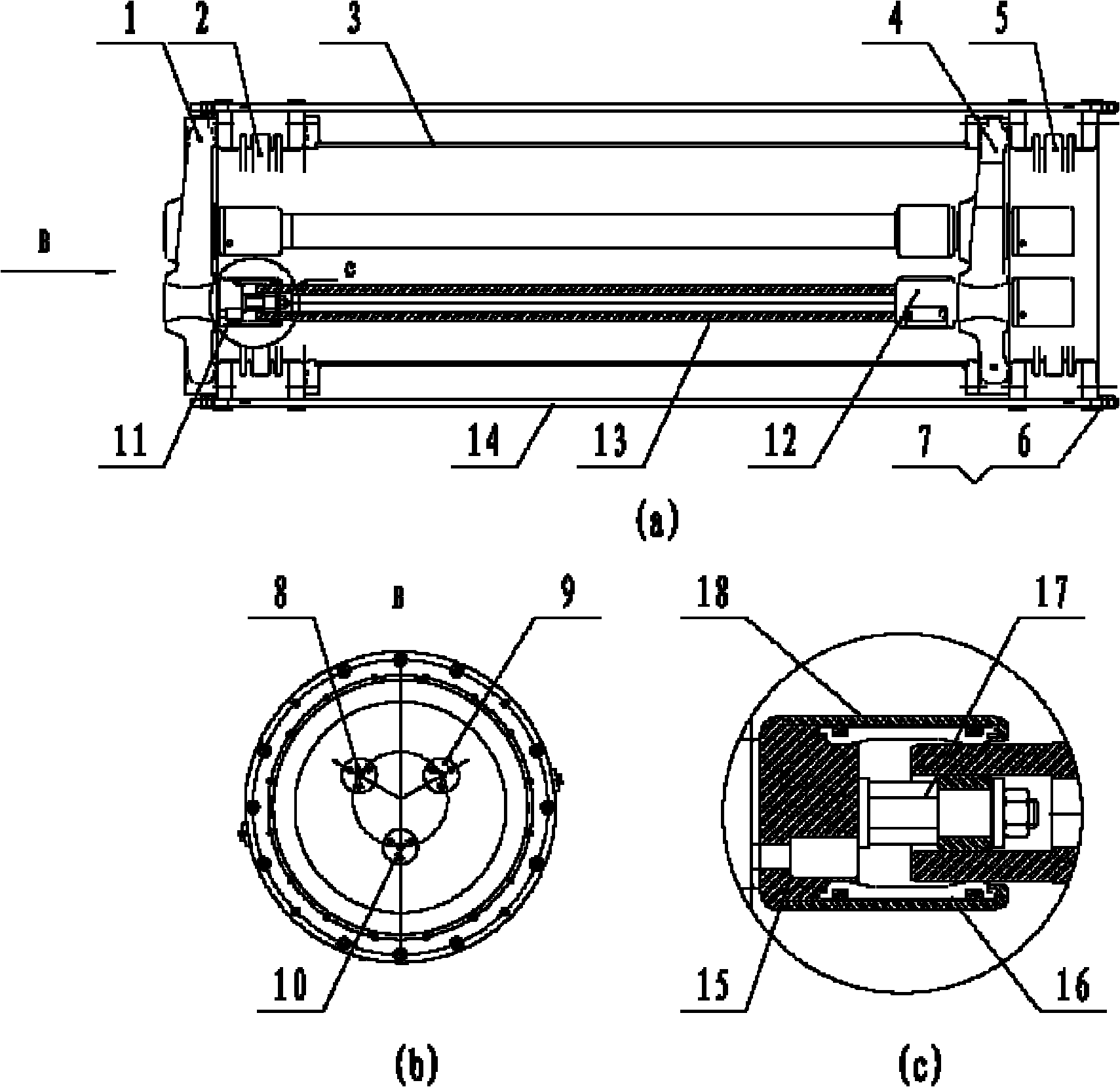

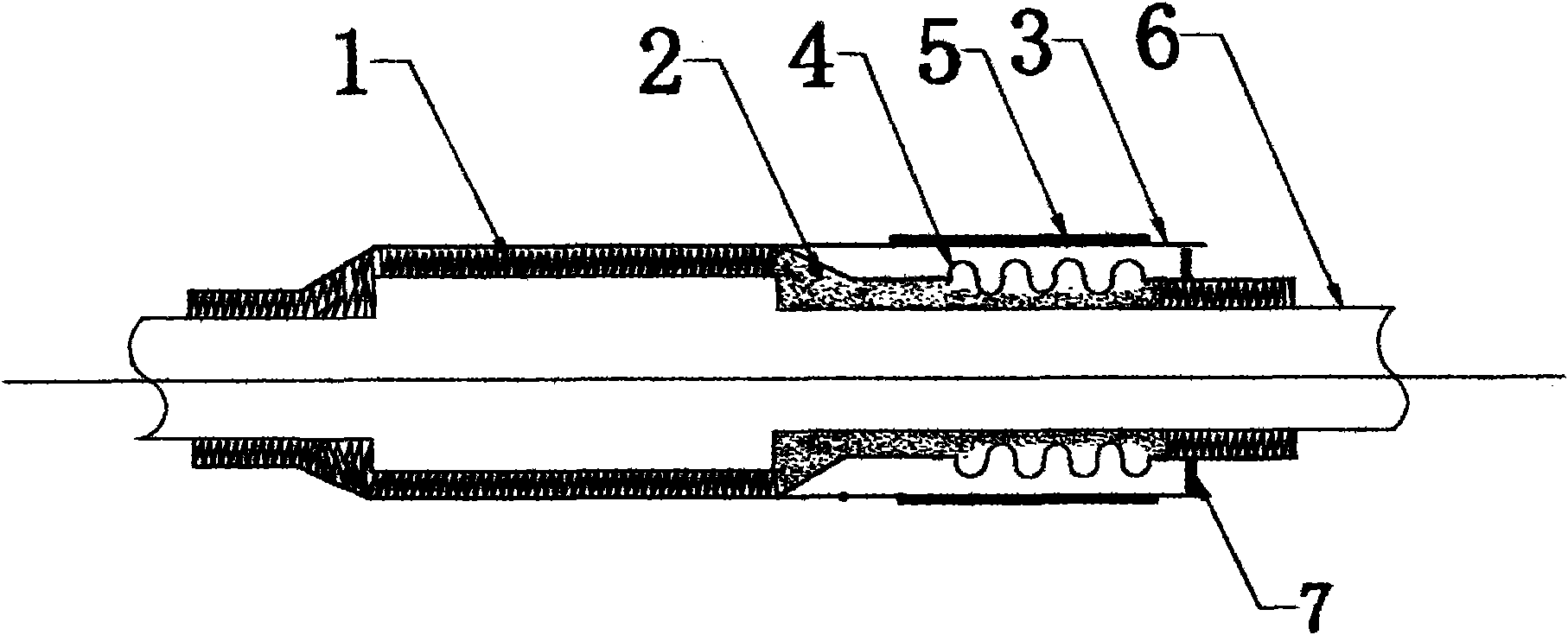

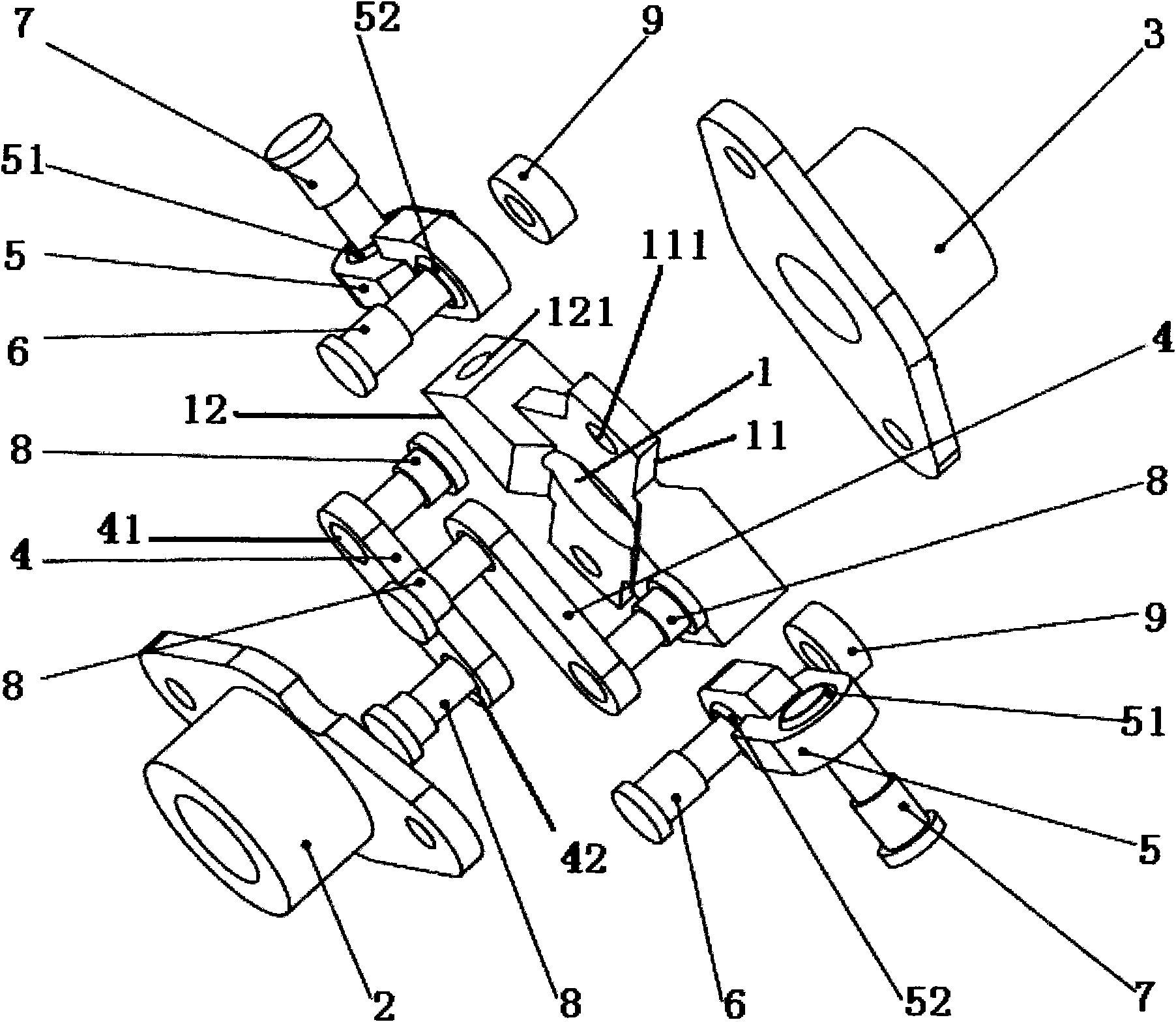

Rigid contact net expansion joint

The invention provides a rigid contact net expansion joint, which belongs to the field of rail transit equipment and solves the problems that the existing expansion joint has low compensation amount to cause high total manufacturing cost and the like. The rigid contact net expansion joint is arranged between two bus bars. The rigid contact net expansion joint is characterized by comprising a fixed joint and a movable joint which can conduct electricity; the fixed joint and the movable joint are used for fixing with the connecting end of one of the bus bars respectively; a guide piece with electric conductivity for connecting the fixed joint and the movable joint is arranged between the fixed joint and the movable joint; the fixed joint is fixed with the guide piece; the movable joint can move along with the guide piece; and a contact line 1 for transmitting current to an electric system of a train is fixedly arranged on the guide piece. The rigid contact net expansion joint is a plug-in expansion joint, and the adjacent two bus bars and the expansion joint are arranged on the same straight line, so the expansion joint is favorable for improving the utilization rate of the bus bars, equivalently improving the length of an anchorage section, and has large compensation amount.

Owner:浙江旺隆轨道交通设备有限公司

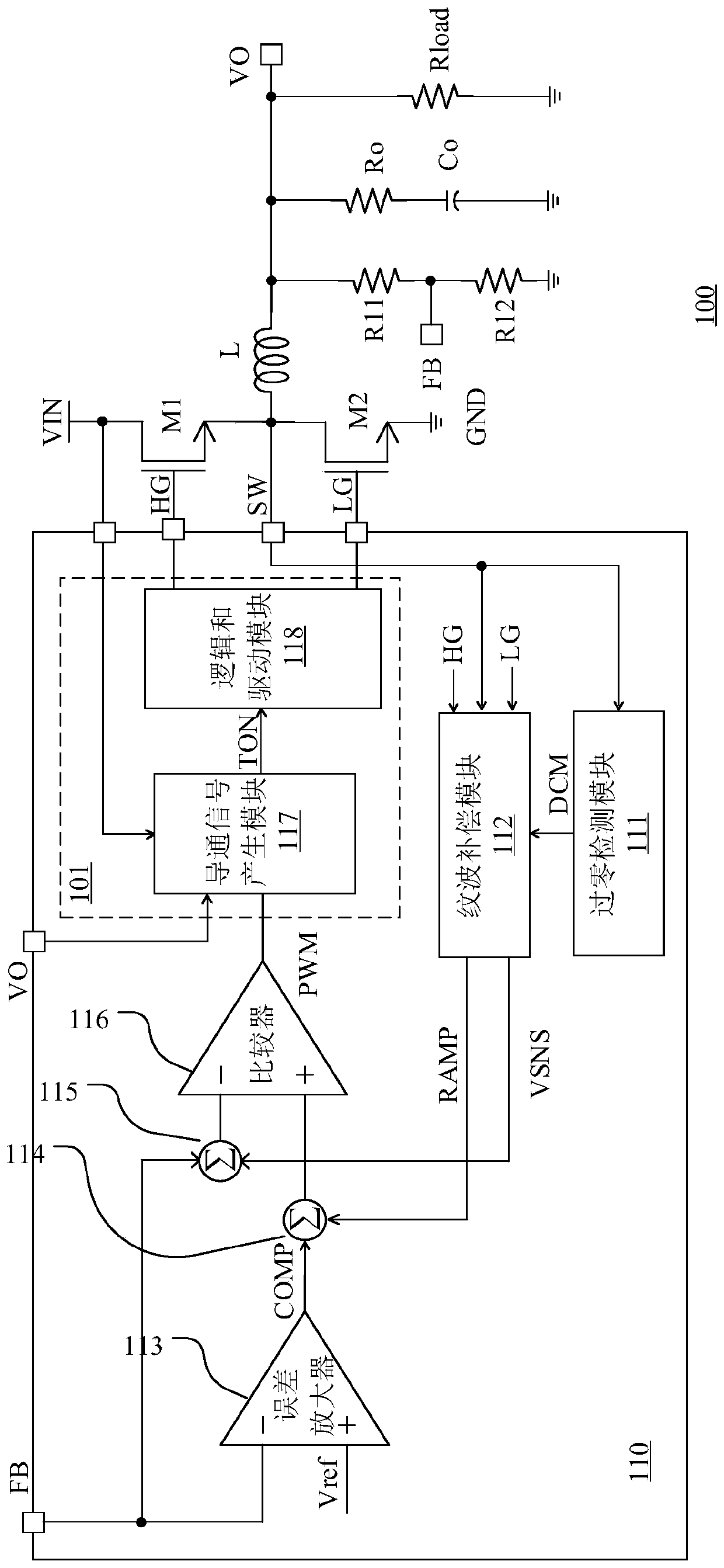

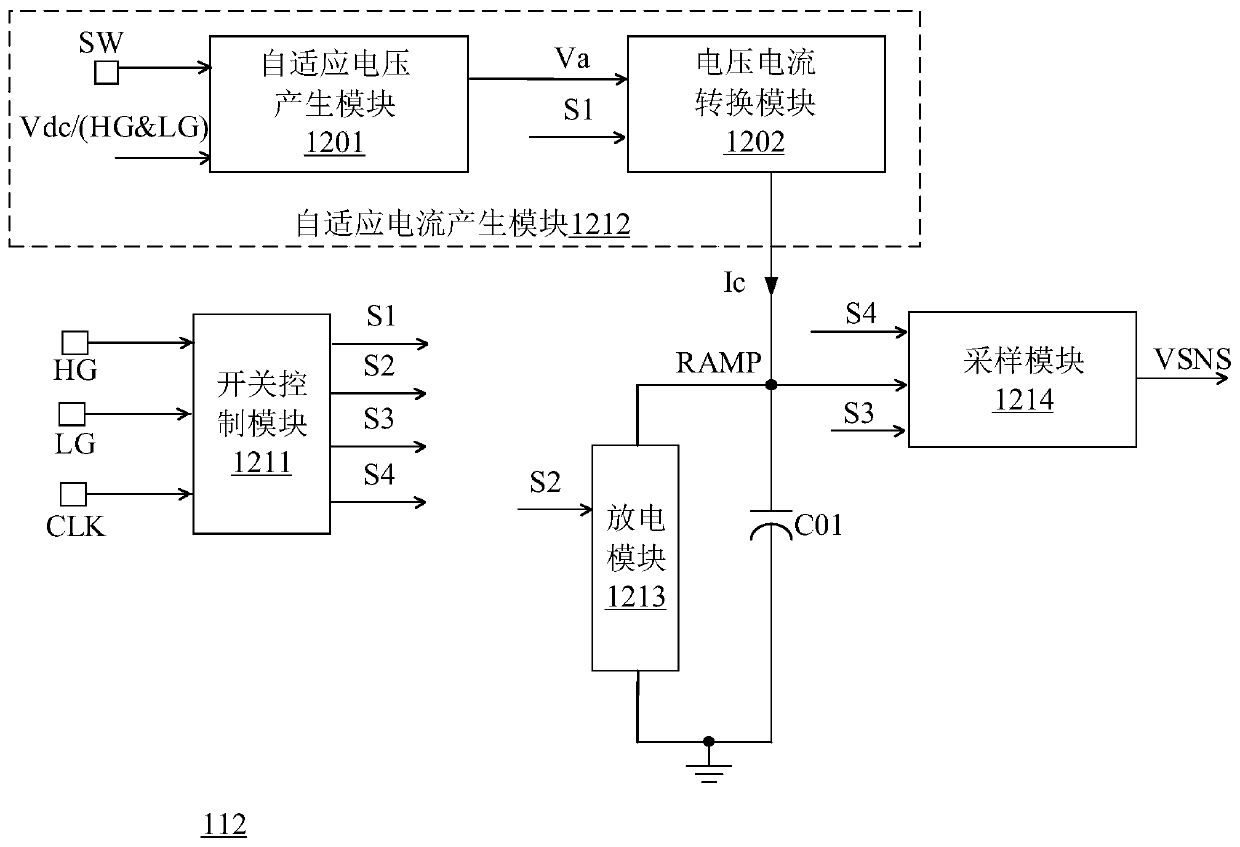

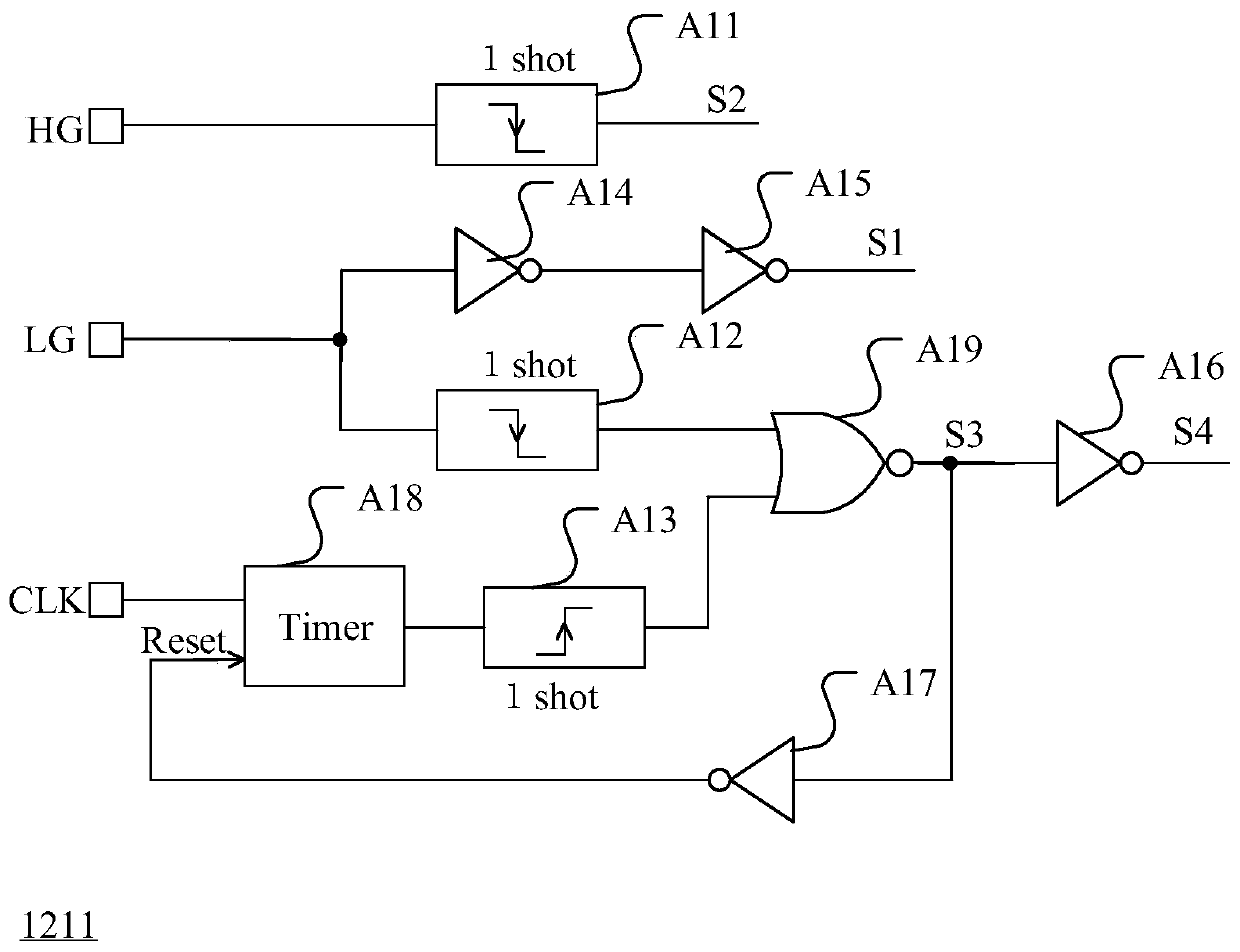

Switching converter and control circuit and method thereof

PendingCN110545039AImprove transient characteristicsImprove system stabilityDc-dc conversionElectric variable regulationEngineeringControl circuit

The invention discloses a switching converter and a control circuit and control method thereof. The control circuit comprises a ripple compensation module. According to a switching node voltage between a first switching tube and a second switching tube, a first driving signal of the first switching tube and a second driving signal of the second switching tube, the ripple compensation module generates a slope compensation signal and a direct current compensation signal, wherein the direct current compensation signal is a sampling signal of the slope compensation signal; a control circuit adoptsthe slope compensation signal to improve transient characteristics, and the direct current compensation signal is adopted to eliminate imbalance introduced by the ripple compensation module.

Owner:HANGZHOU SILAN MICROELECTRONICS

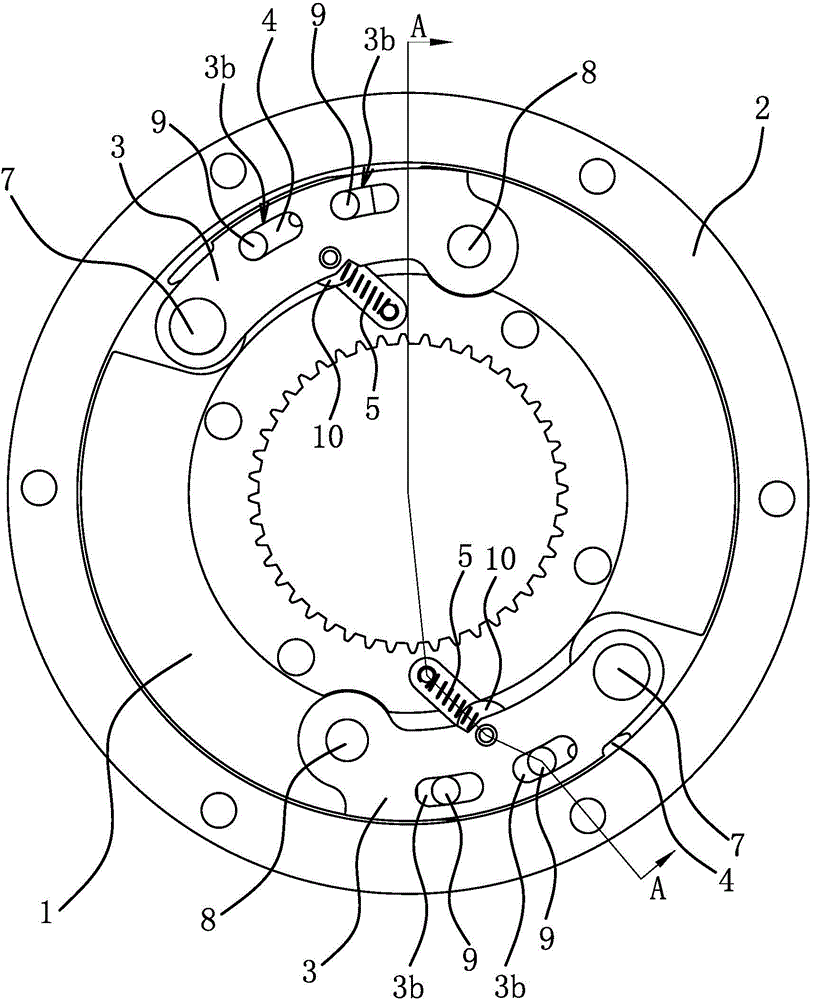

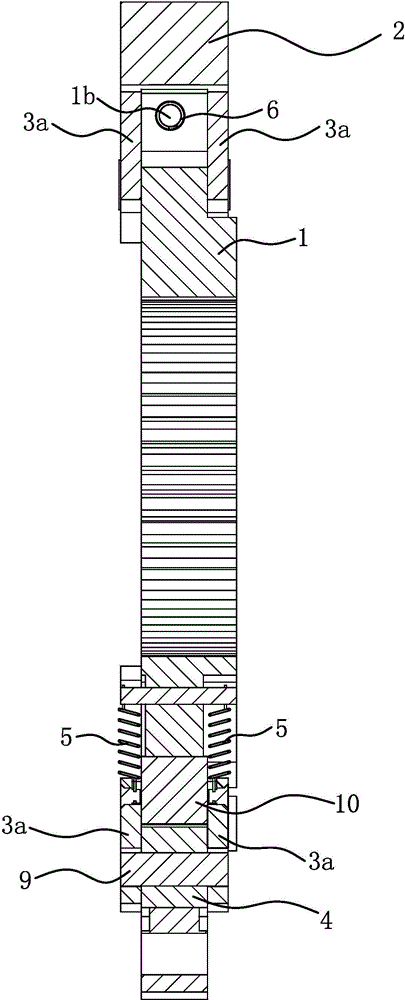

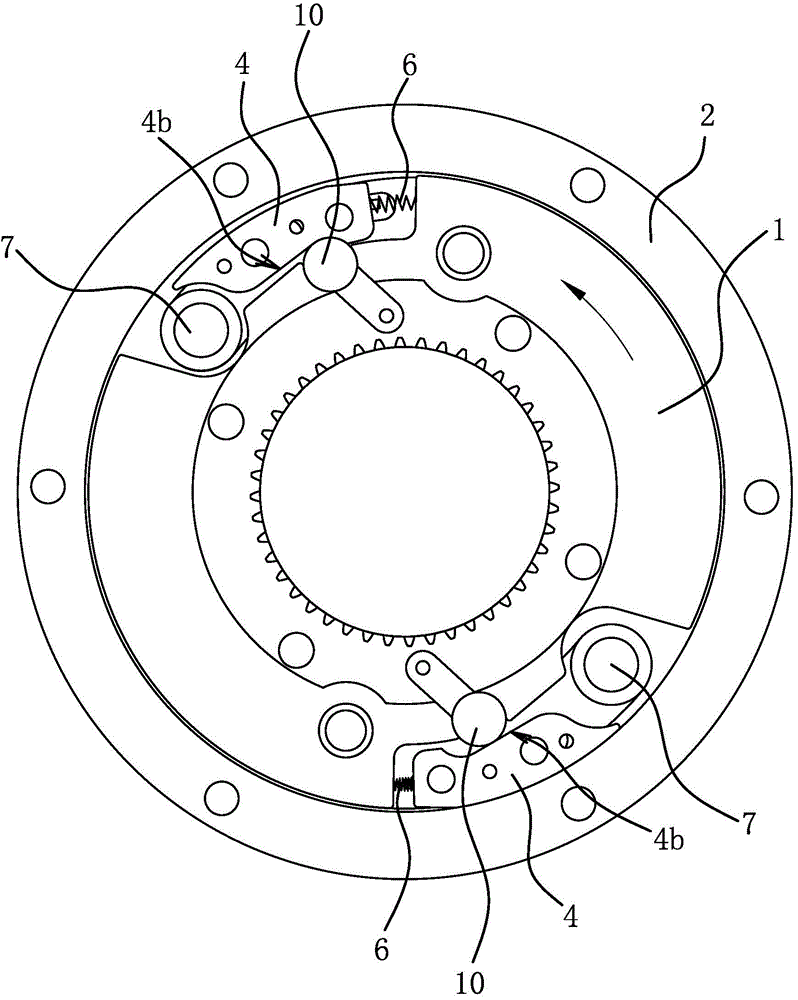

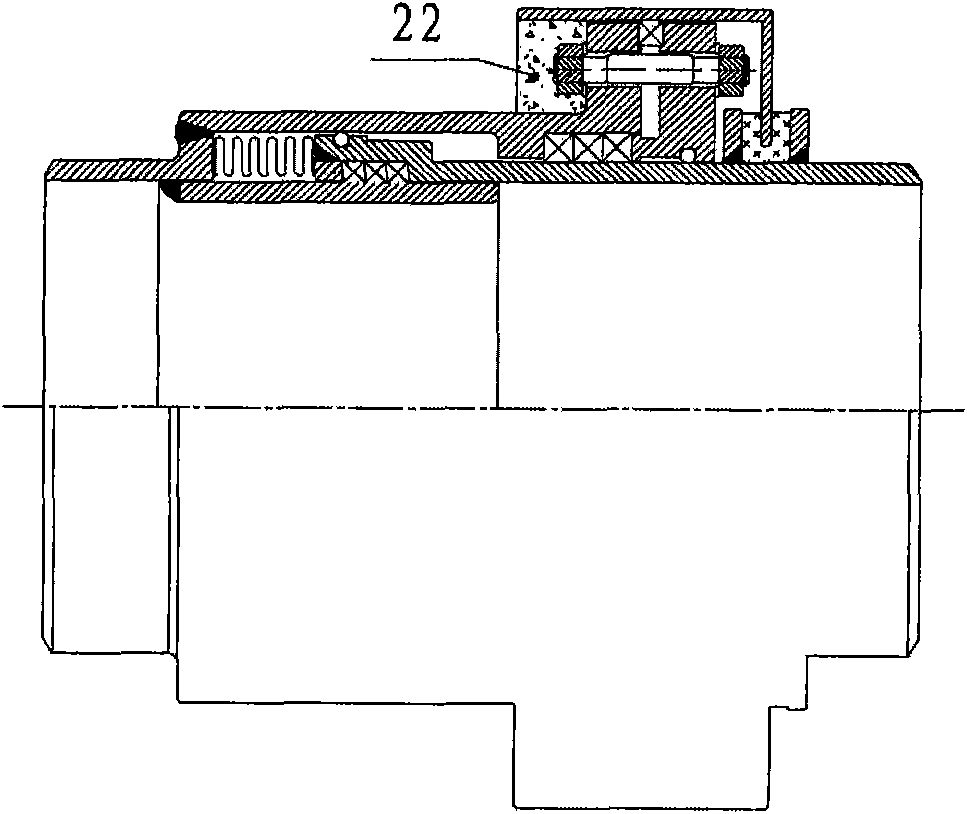

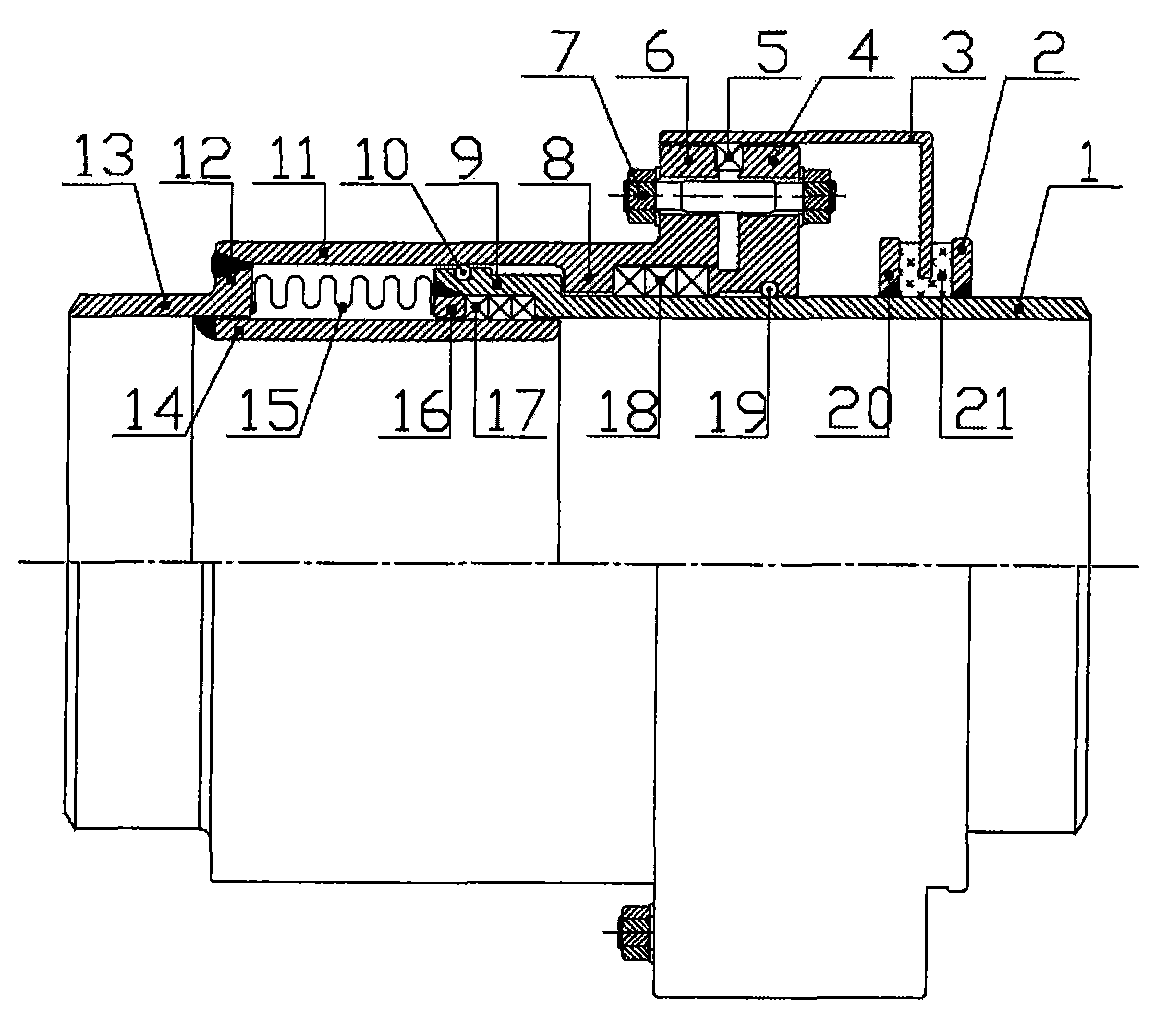

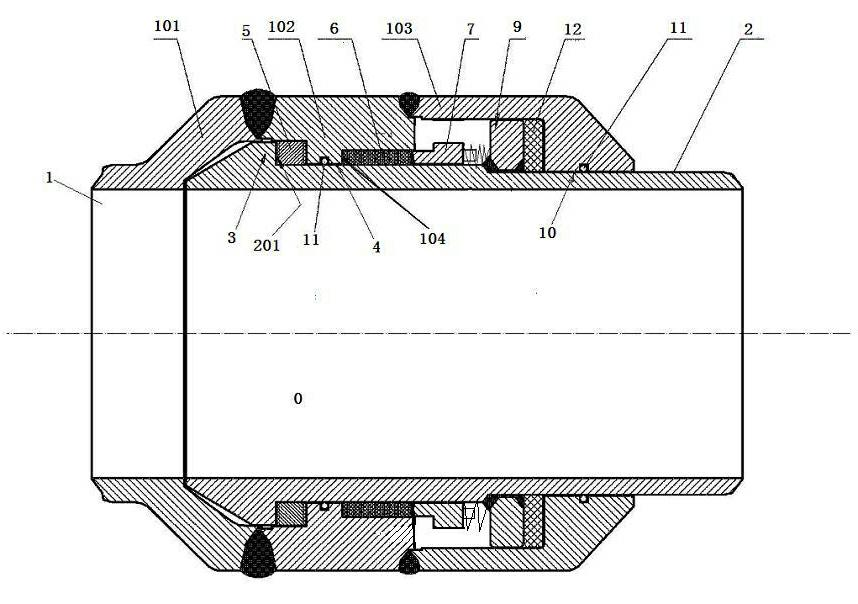

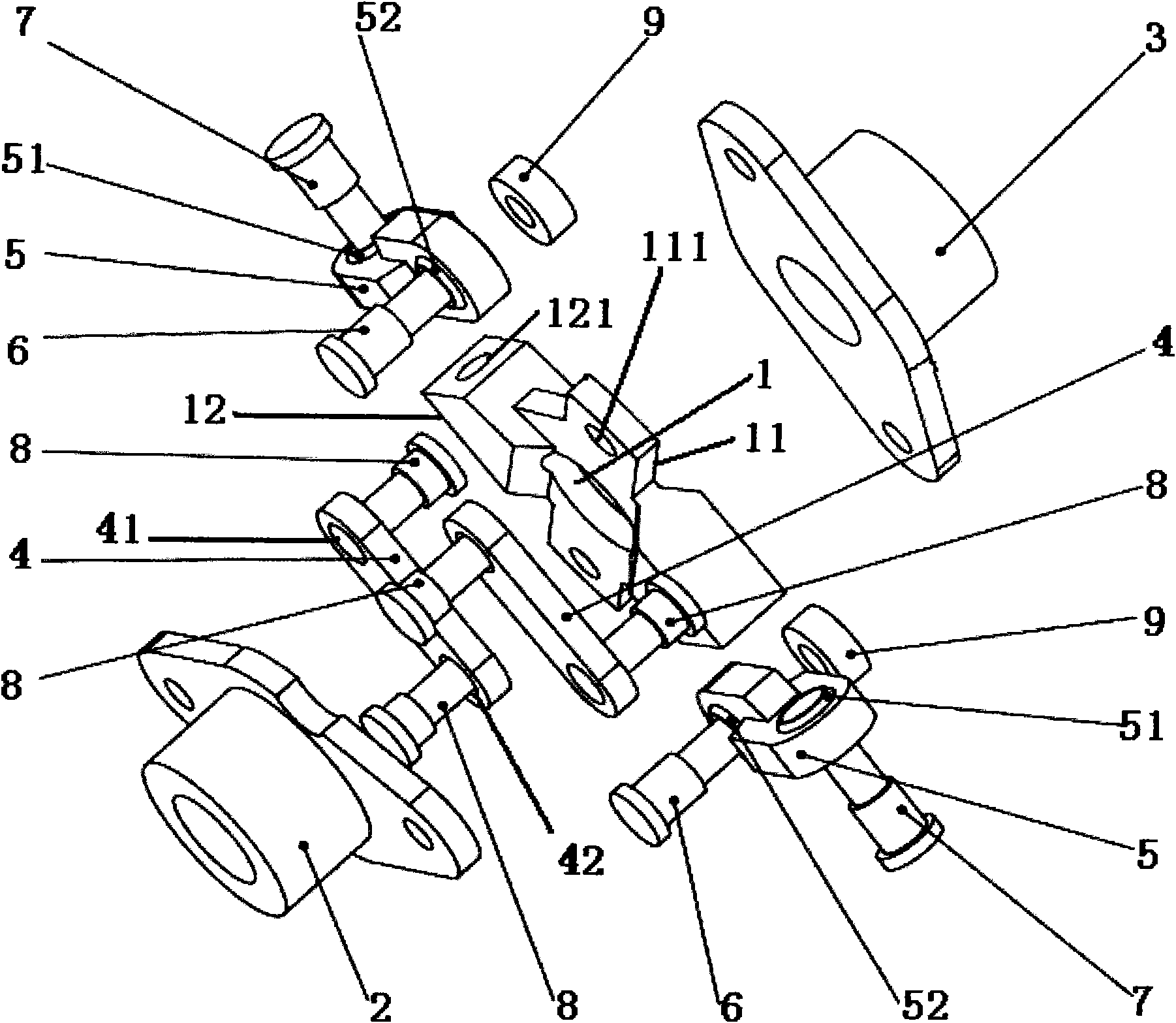

Clutch and variable speed driving hub

ActiveCN104482075AExtended service lifeImprove performanceMechanical energy handlingAutomatic clutchesEngineeringClutch

The invention provides a clutch and a variable speed driving hub, belongs to the technical field of engineering components, and solves the problem that the clutch in the existing variable speed driving hub can only be subjected to gear shifting below 14 km / h. The clutch comprises an inner connecting plate, a friction ring and at least two groups of swing arms, wherein a first elastic member, which can enable the centrifugally rotated swing arms to reset, is arranged between each group of the swing arms and the inner connecting plate; friction blocks, with the number same as that of the swing arms, are arranged between the inner connecting plate and the friction ring; the friction blocks and the swing arms are arranged in a one-to-one corresponding manner; the friction blocks are connected with the swing arms through a connection structure which can enable the friction blocks to circumferentially slide relative to the inner connecting plate; a second elastic member, which can enable the circumferentially slid friction blocks to reset, is arranged between each group of the friction blocks and the corresponding swing arms or between each group of the friction blocks and the inner connecting plate; a transmission mechanism, which can enable the friction blocks and the inner connecting plate to realize transmission after the friction blocks are in contact with the friction ring, is arranged between each group of the friction blocks and the inner connecting plate. According to the variable speed driving hub with the clutch provided by the invention, the flexible adjustment can be performed in accordance with the market requirements on gear shifting speed.

Owner:ZHEJIANG DINGLI TIANYI AUTO PARTS CO LTD

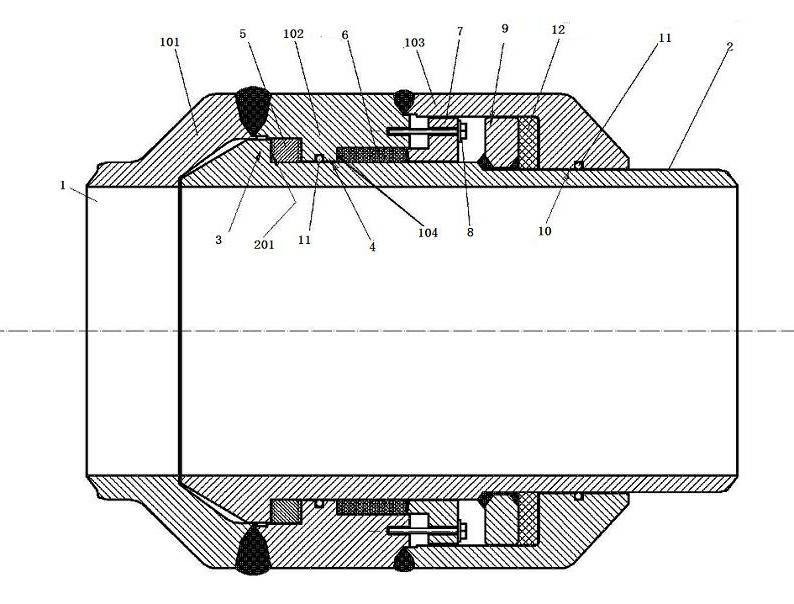

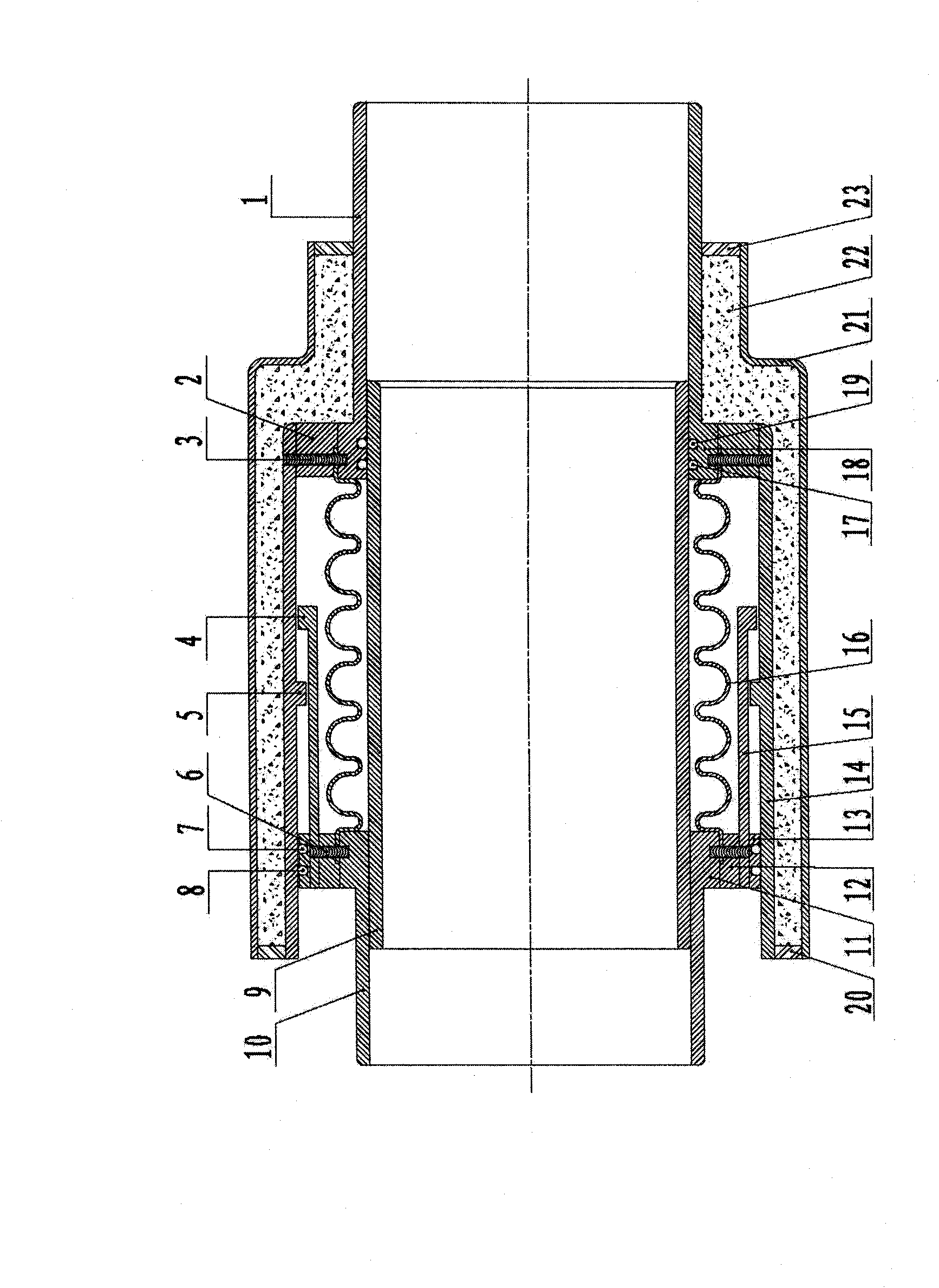

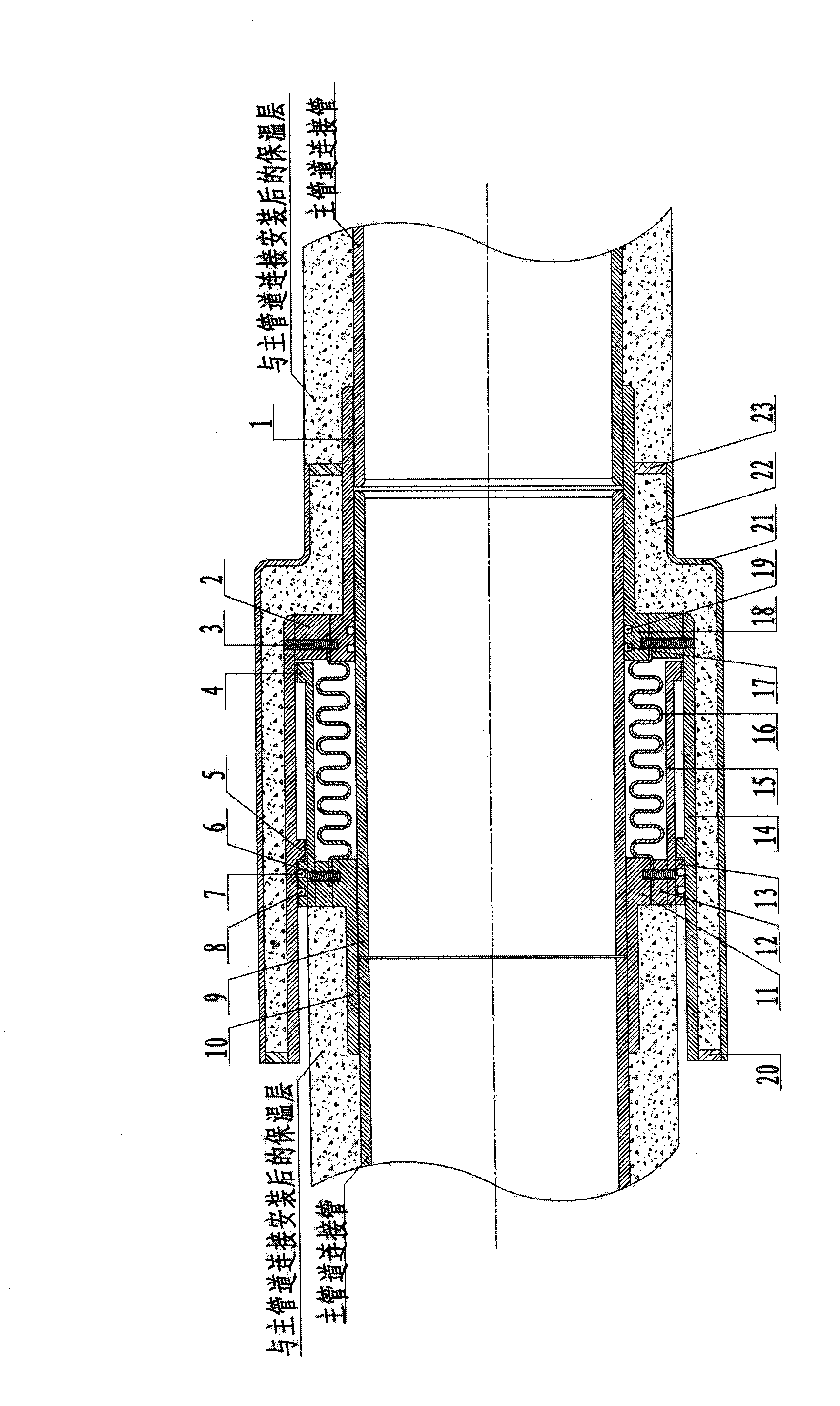

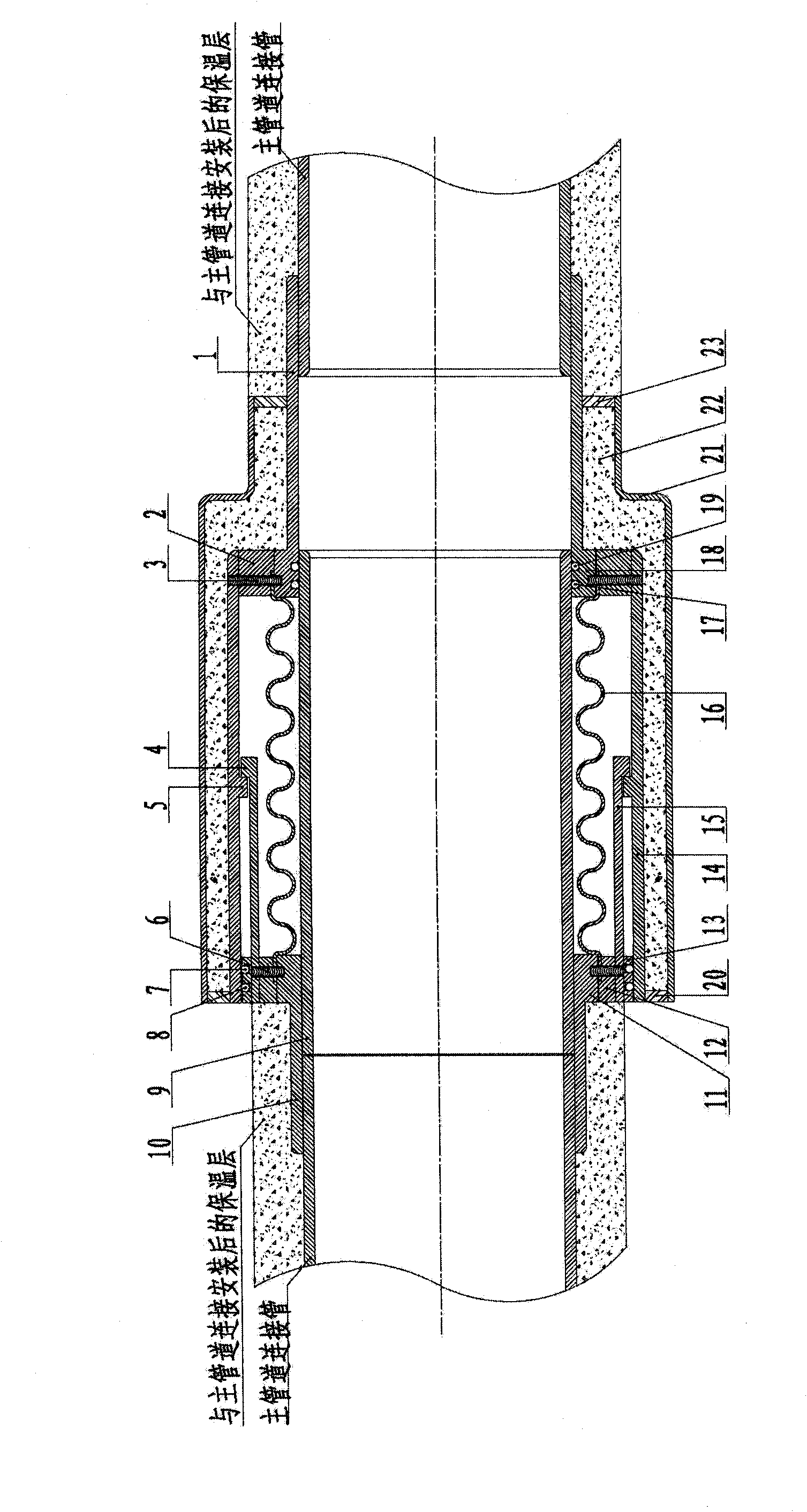

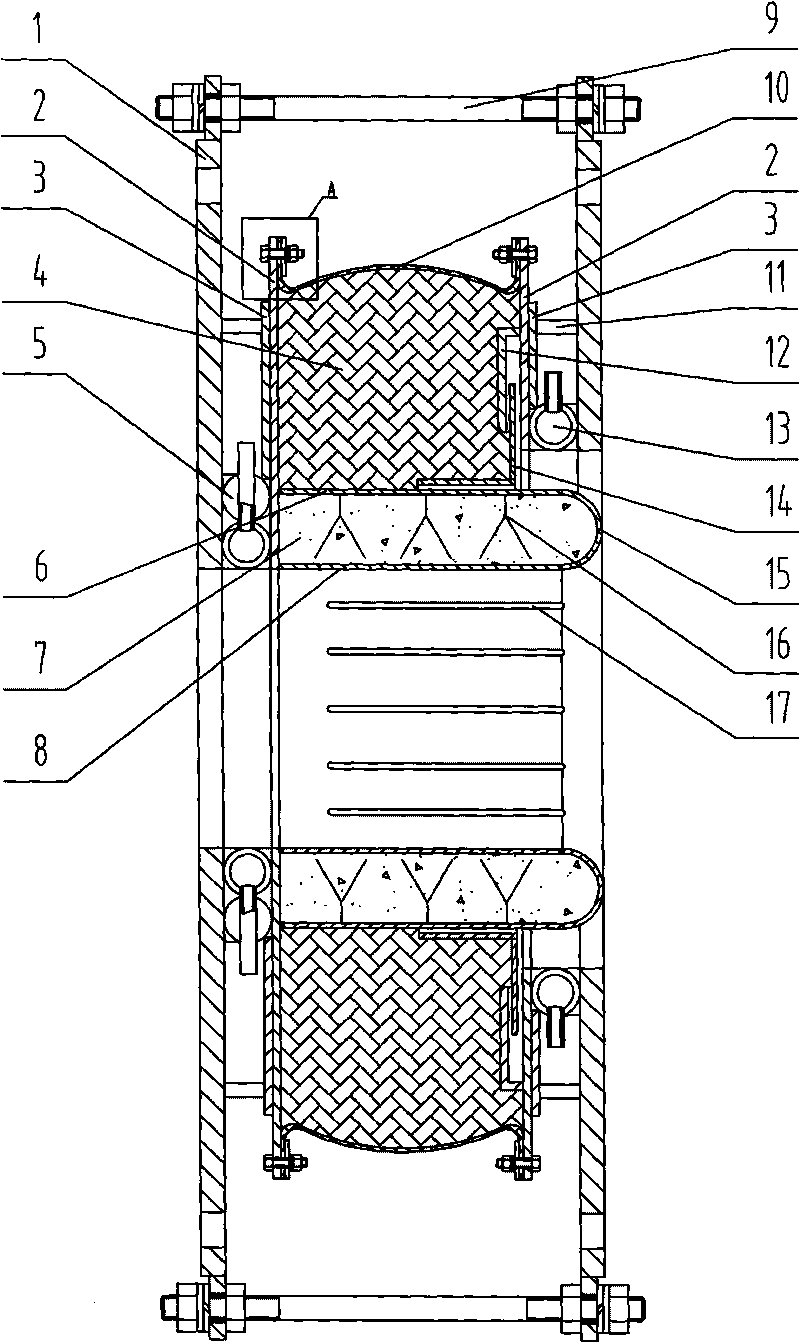

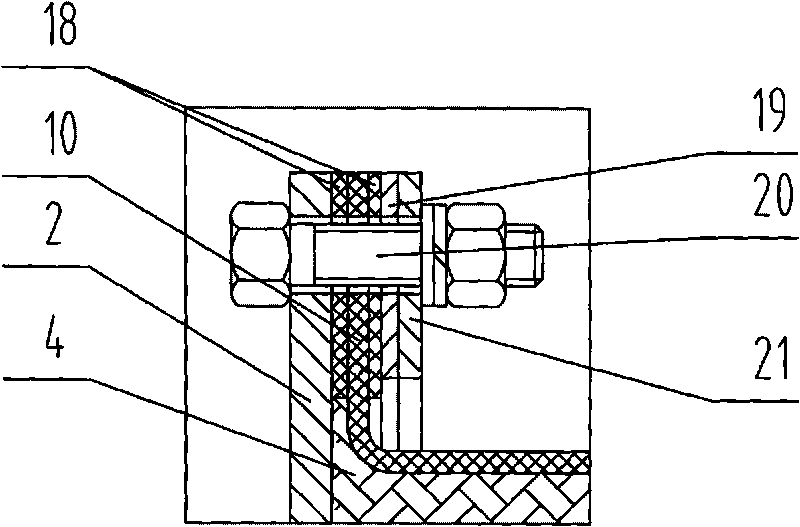

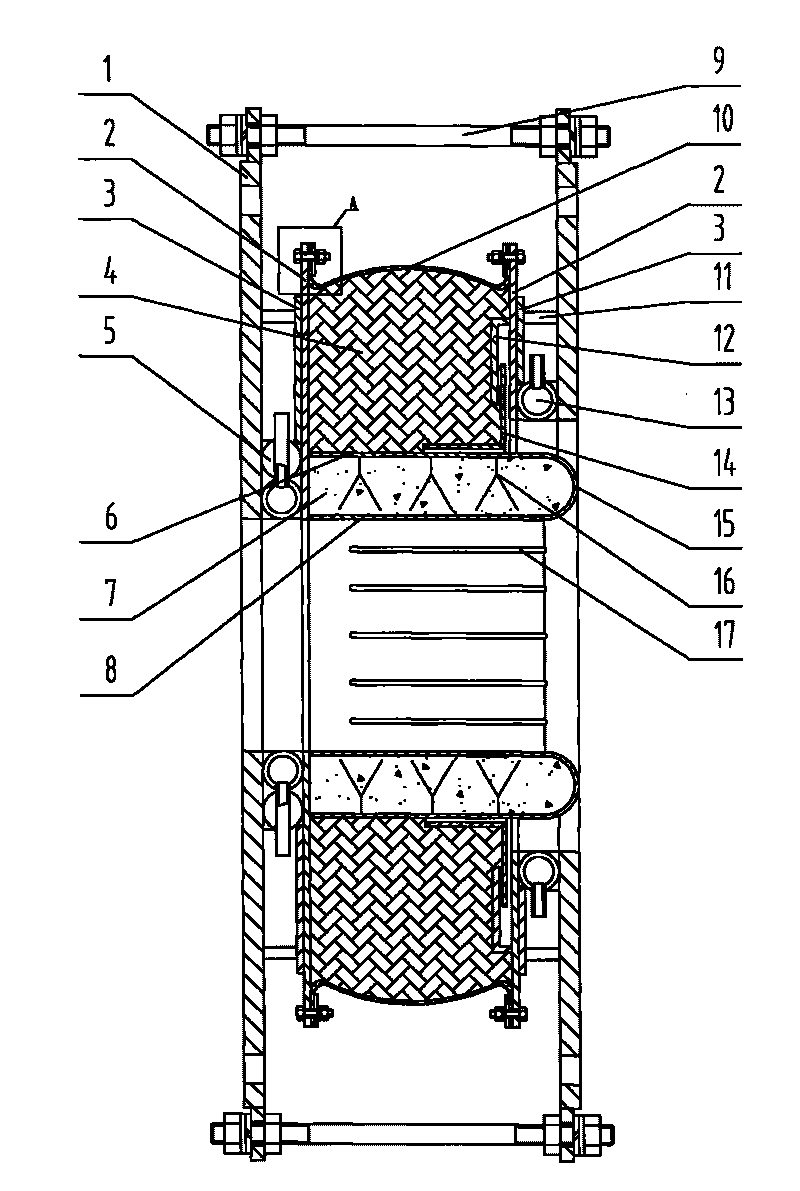

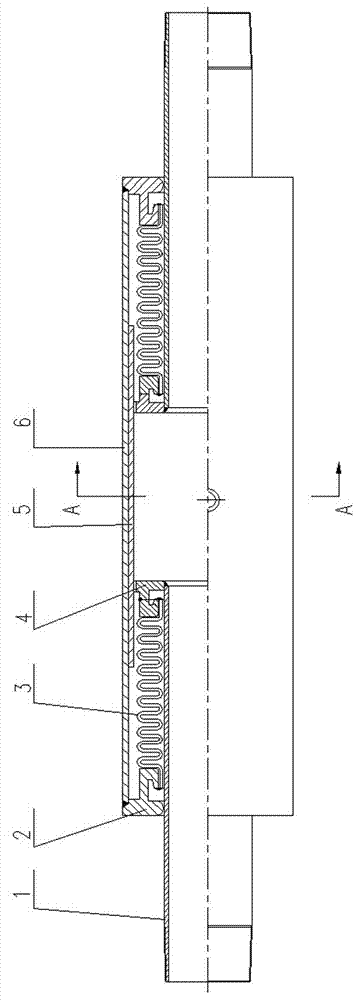

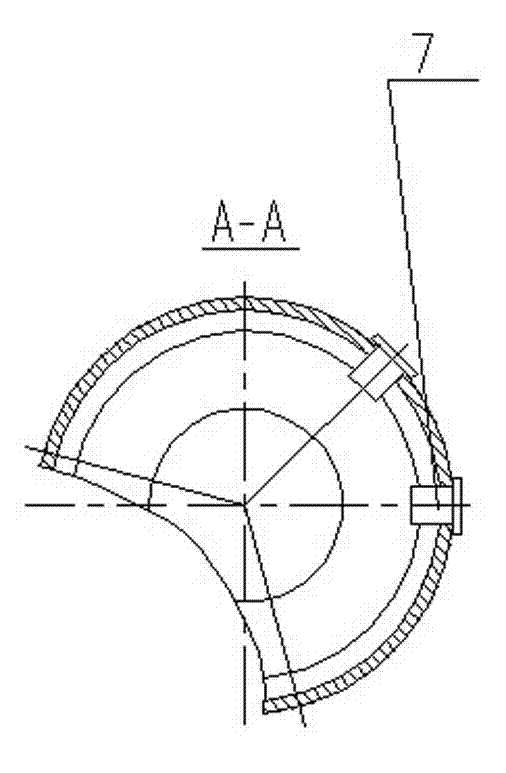

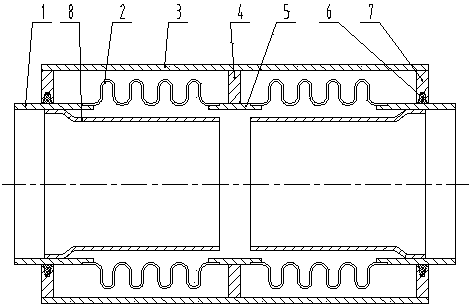

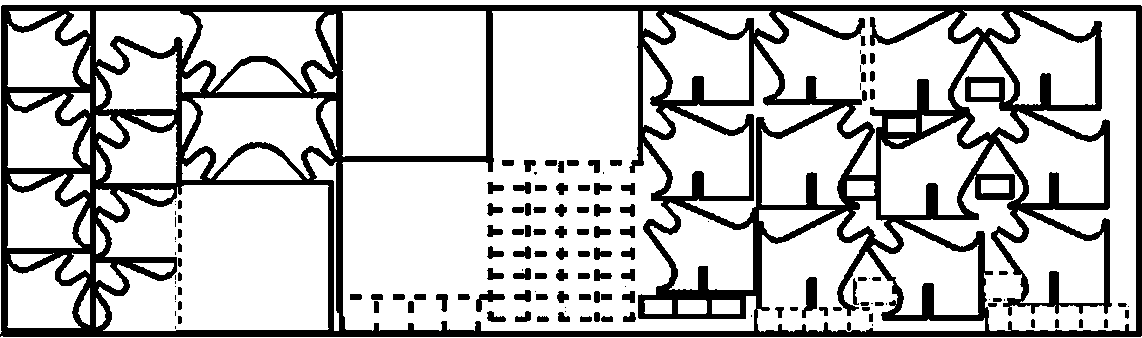

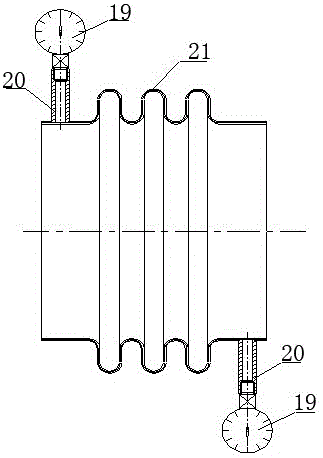

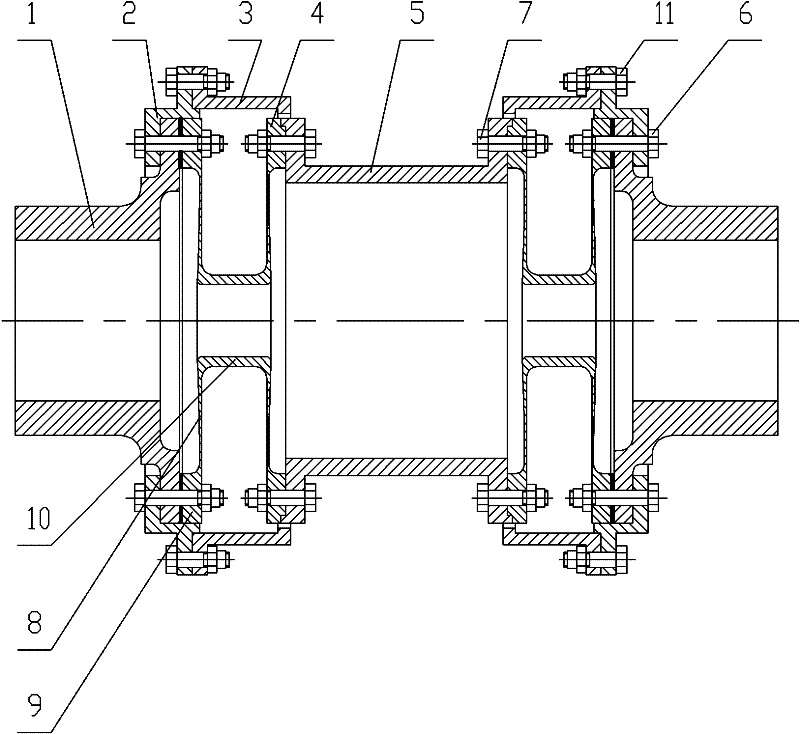

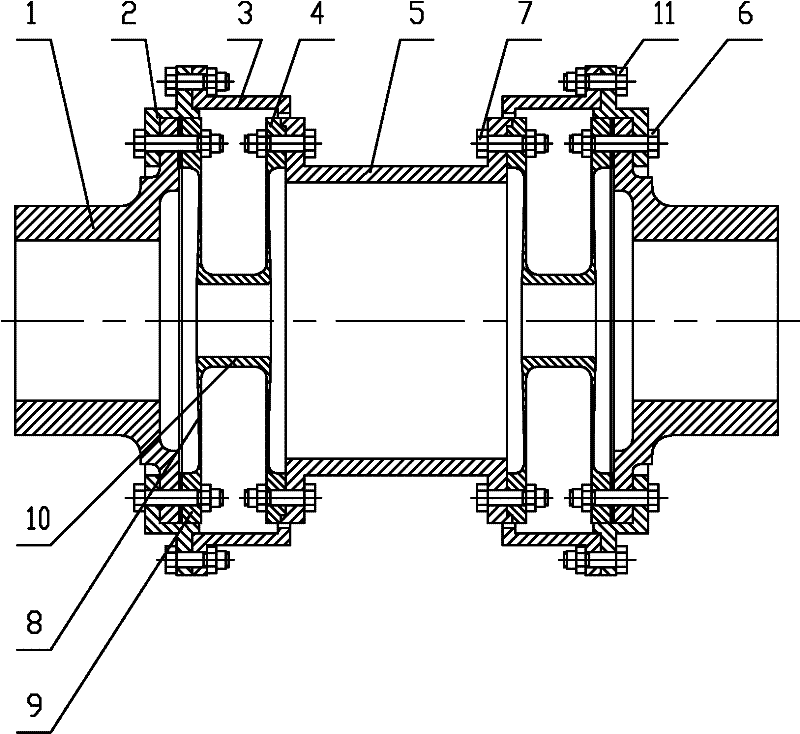

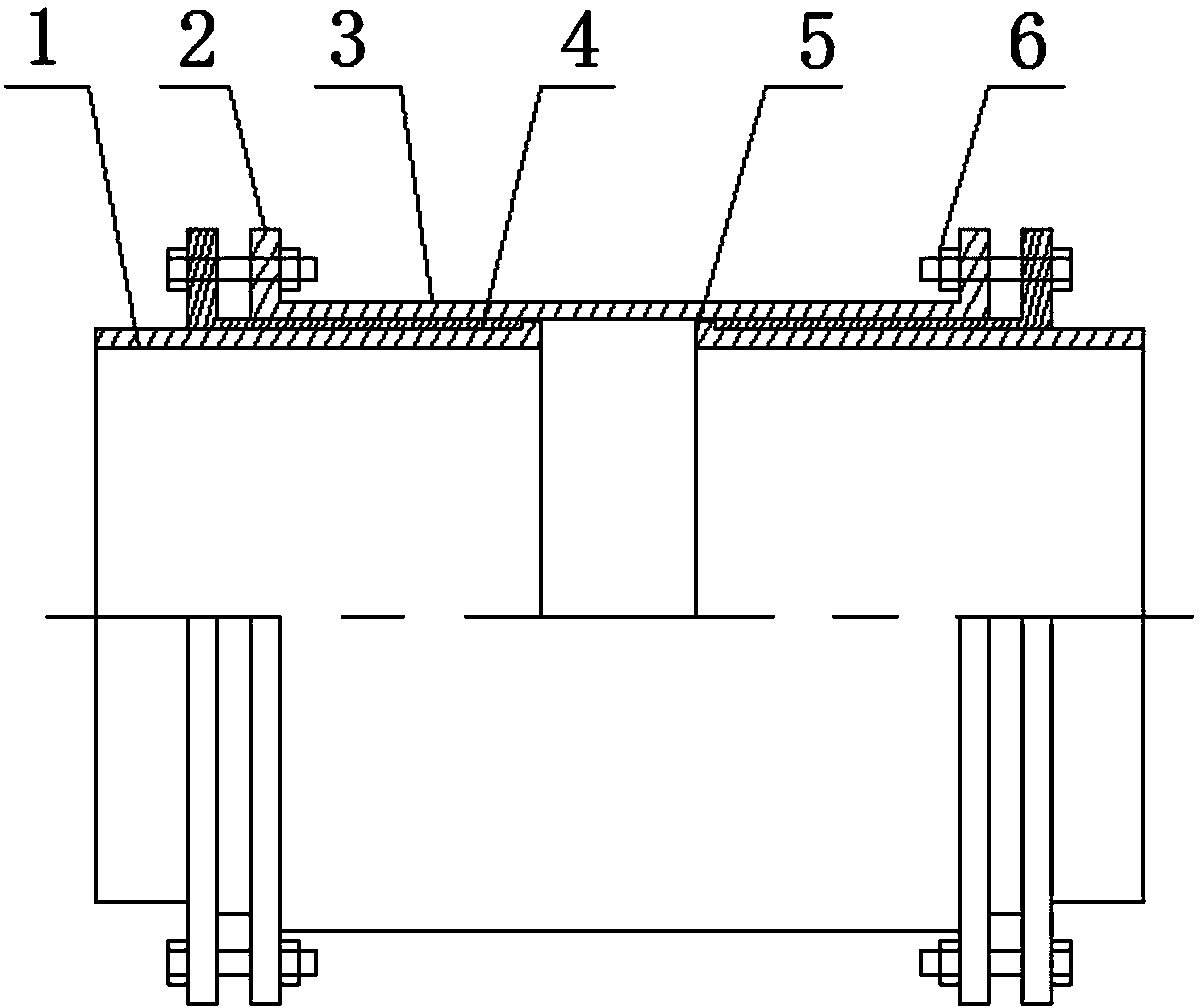

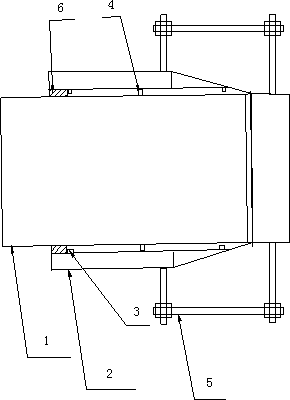

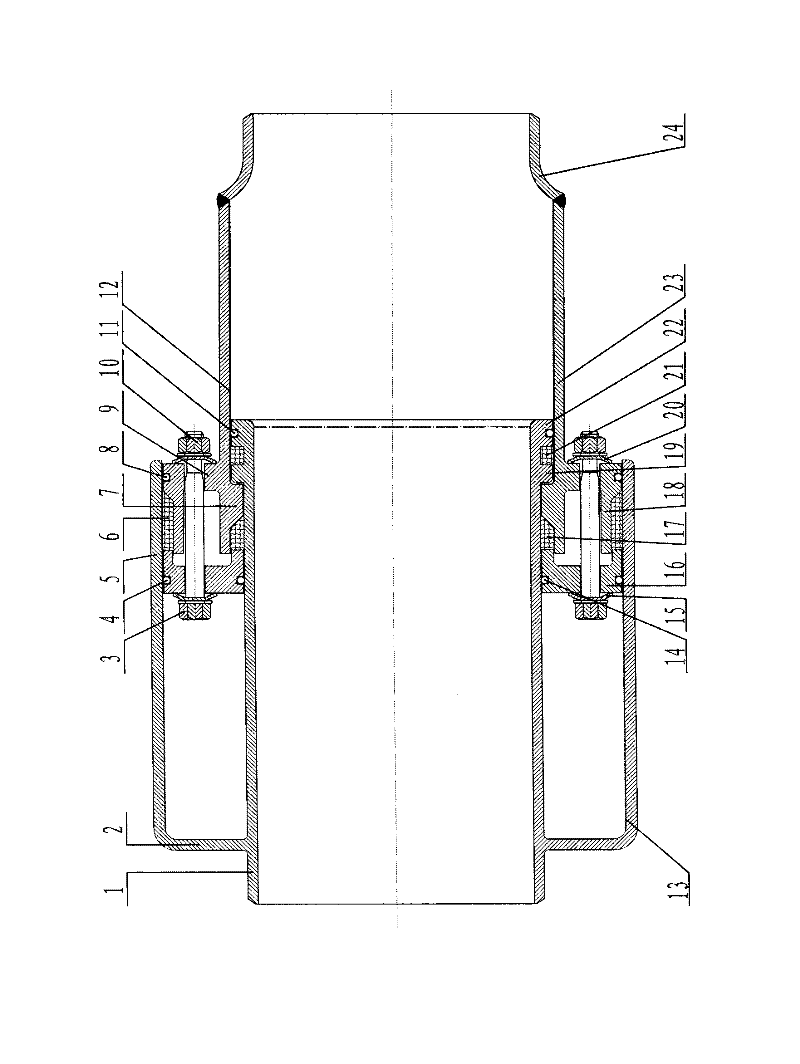

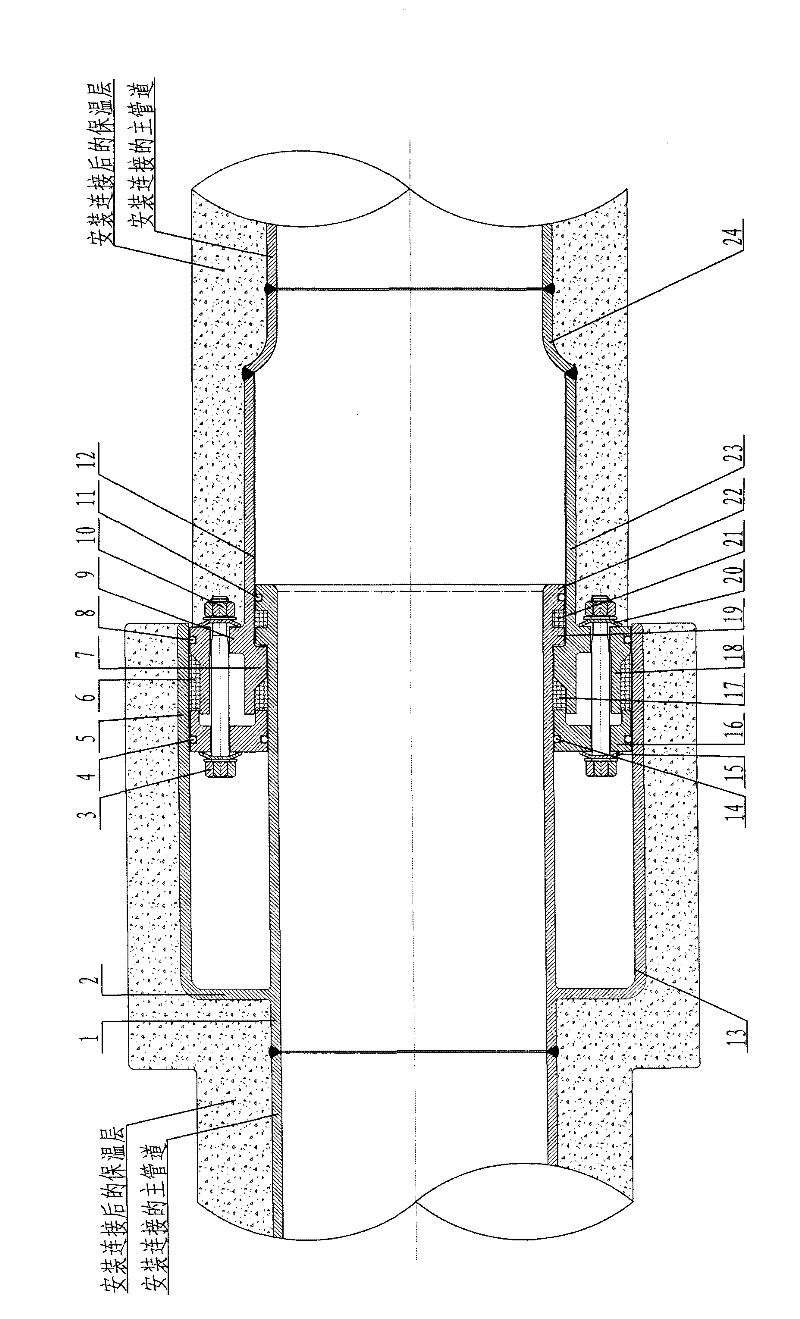

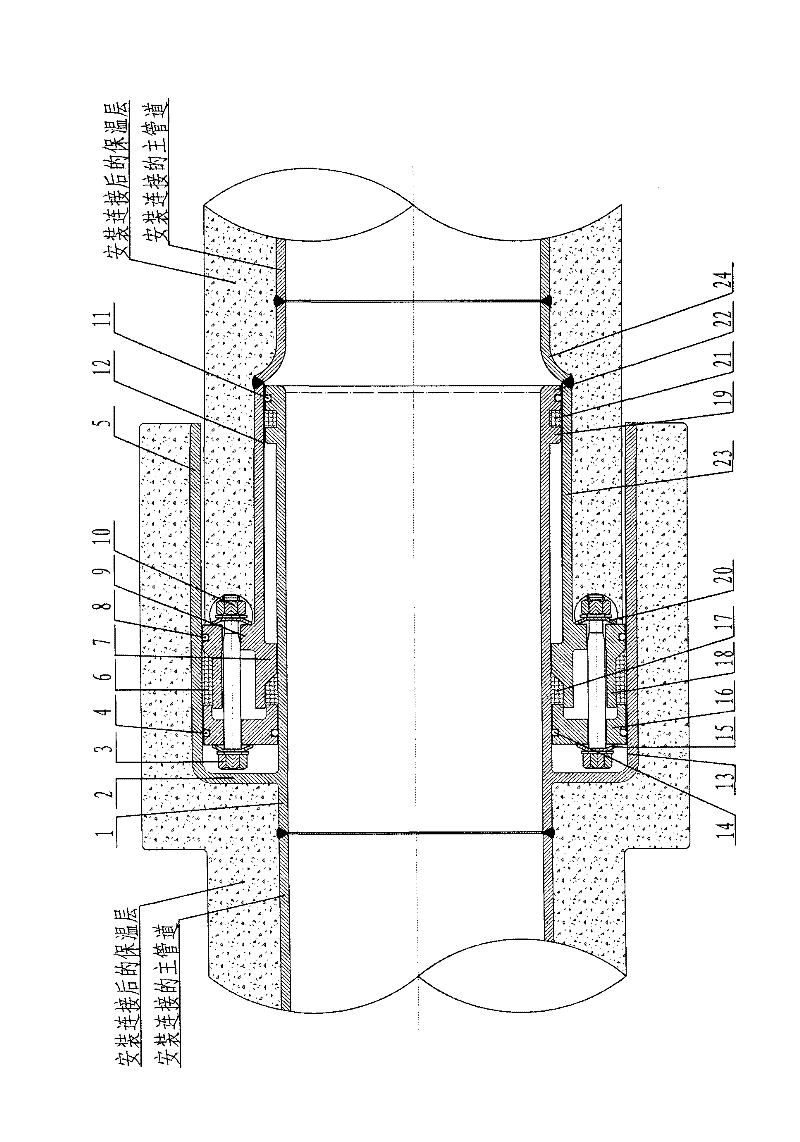

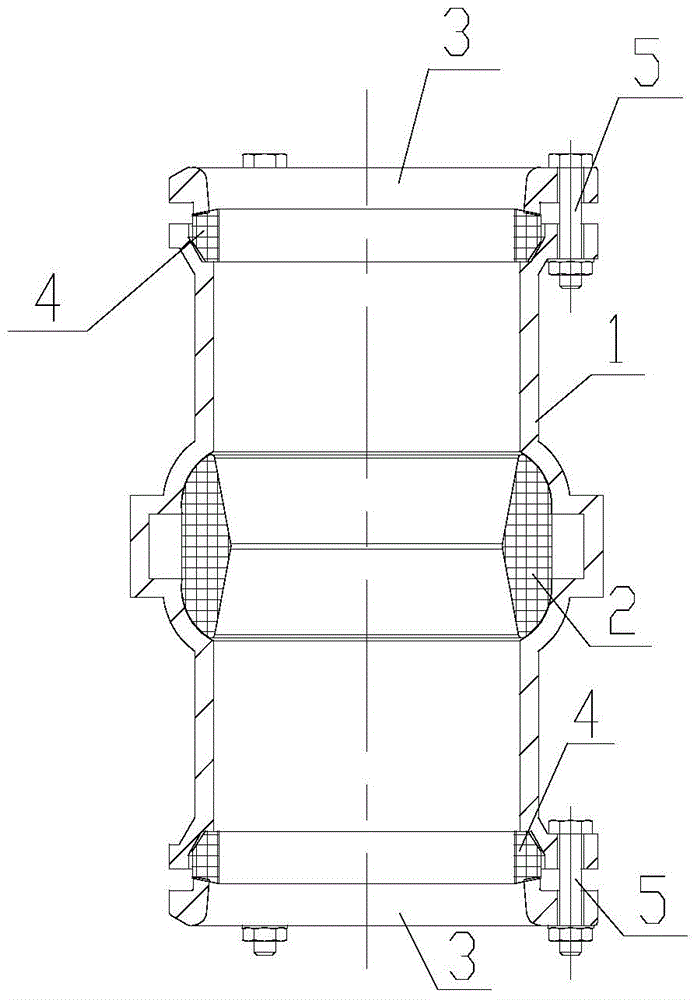

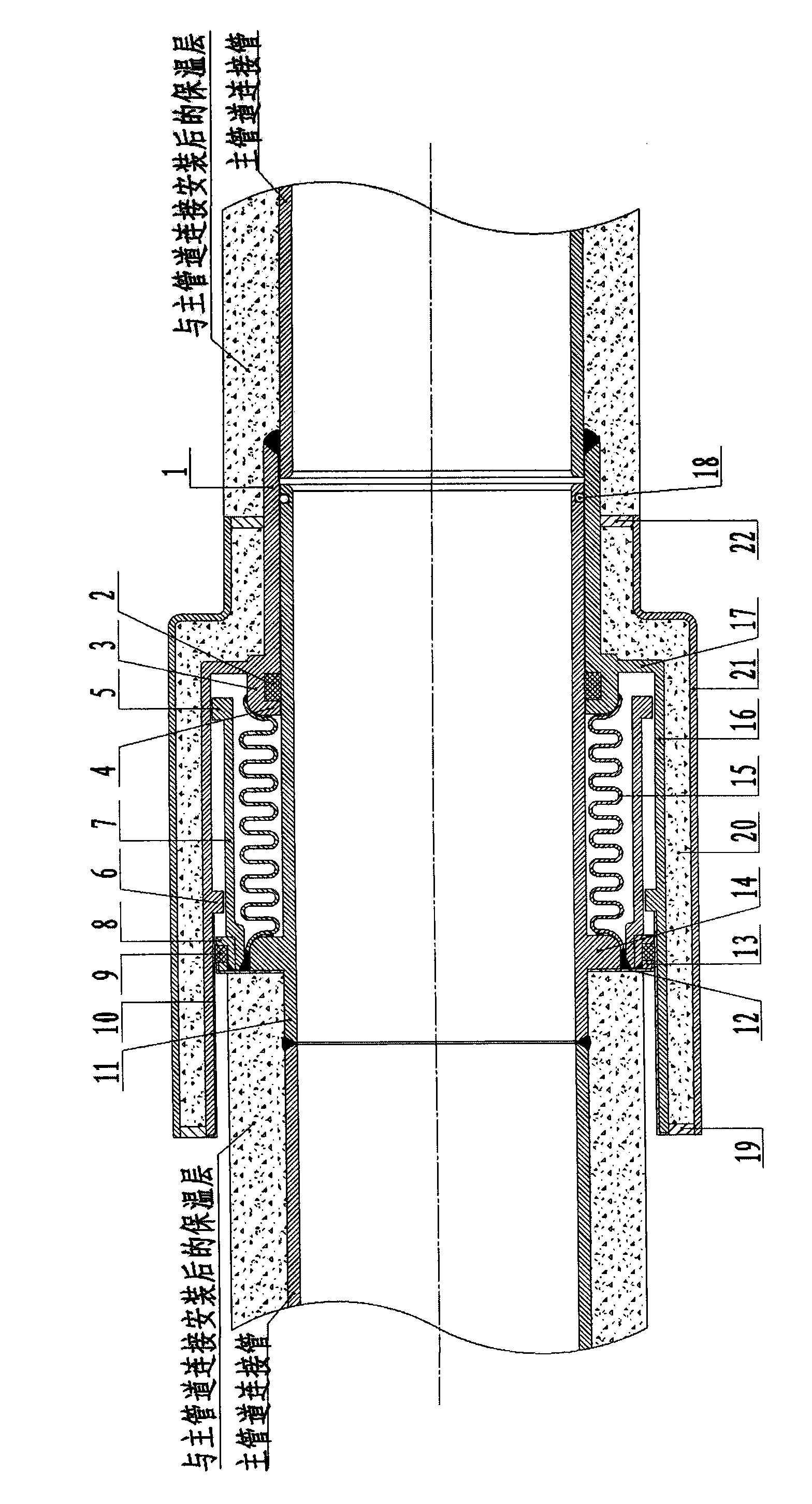

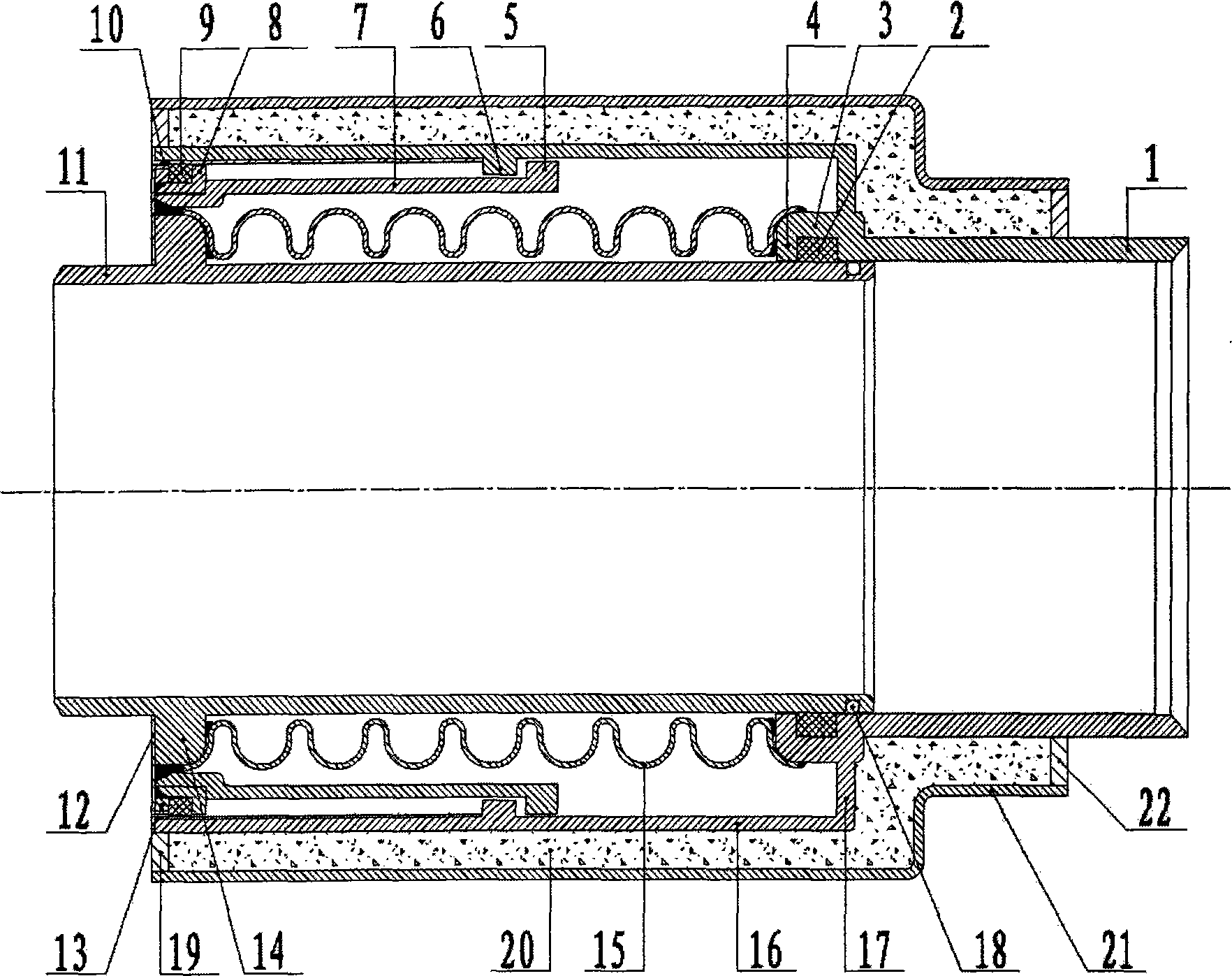

Radial compensation bus bar used for high-voltage switch

ActiveCN102136684ALarge amount of compensationLarge jump volumeBus-bar/wiring layoutsBus-bar installationThermal expansionEngineering

The invention discloses a radial compensation bus bar used for a high-voltage switch in the technical field of high-voltage electrical appliances. The radial compensation bus bar used for the high-voltage switch comprises three groups of conductive components with the same structure, connecting pieces, and two basin-type insulators, two corrugated pipes and a shell connected with the connecting pieces, wherein a first basin-type insulator and a first corrugated pipe as well as a second basin-type insulator and a second corrugated pipe are respectively arranged at the two ends of the shell fixedly; the two ends of a first conductive component, a second conductive component and a third conductive component are respectively and fixedly connected with the first basin-type insulator and the second basin-type insulator positioned at the two ends of the shell; and the conductive components are arranged in the shell in a sealing way. The radial compensation bus bar used for the high-voltage switch meets the compensation for the axial and radial deformation in gas-insulated metal-enclosed switchgear (GIS), the adjustment of an installation error and the compensation for the deformation of expansion caused by heat and contraction caused by cold of the bus bar per se, has a large compensation amount for radial deformation, and can keep high performance of the electrical appliances.

Owner:SHANGHAI SIEYUAN HIGH VOLTAGE SWITCHGEAR

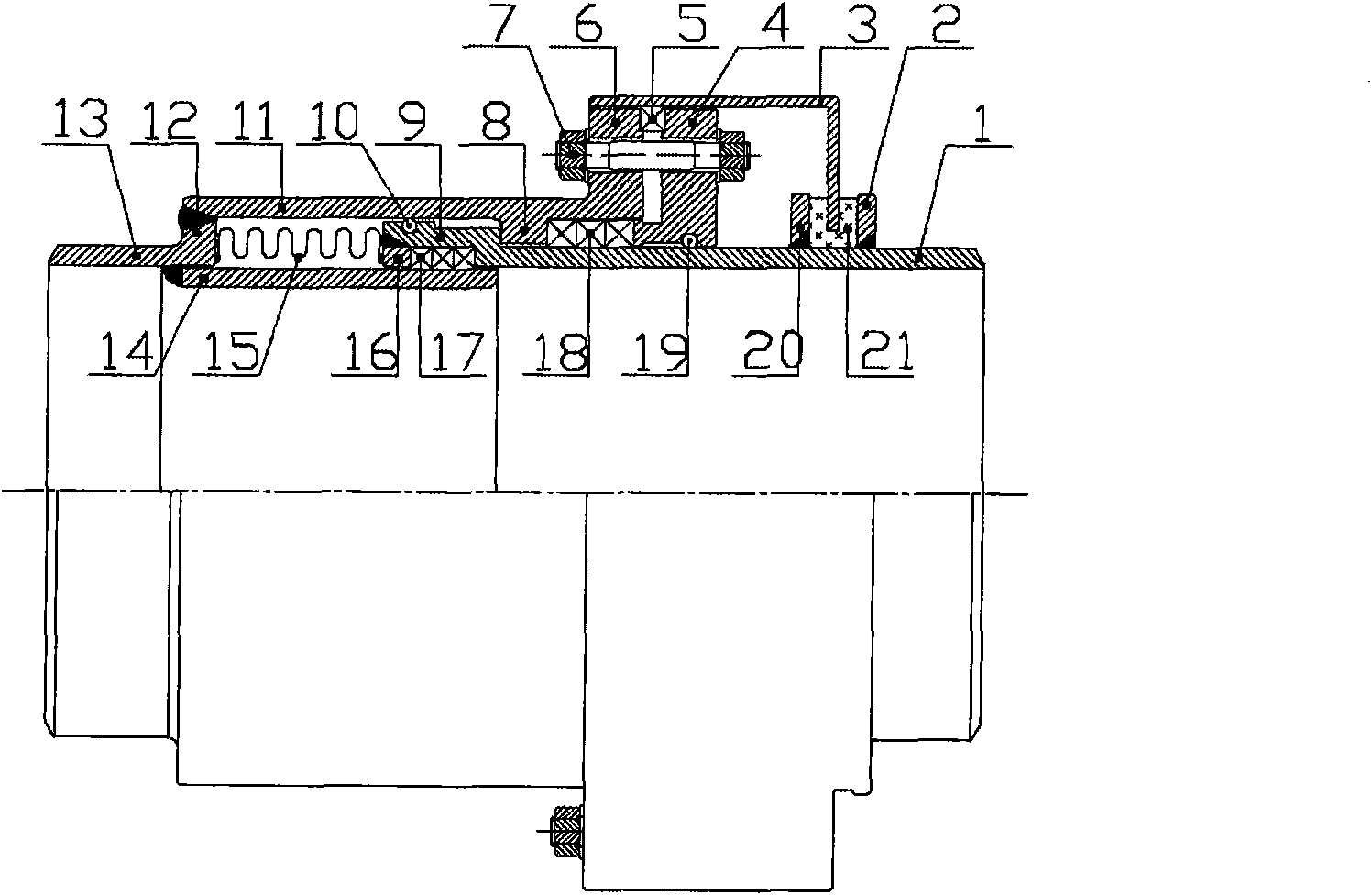

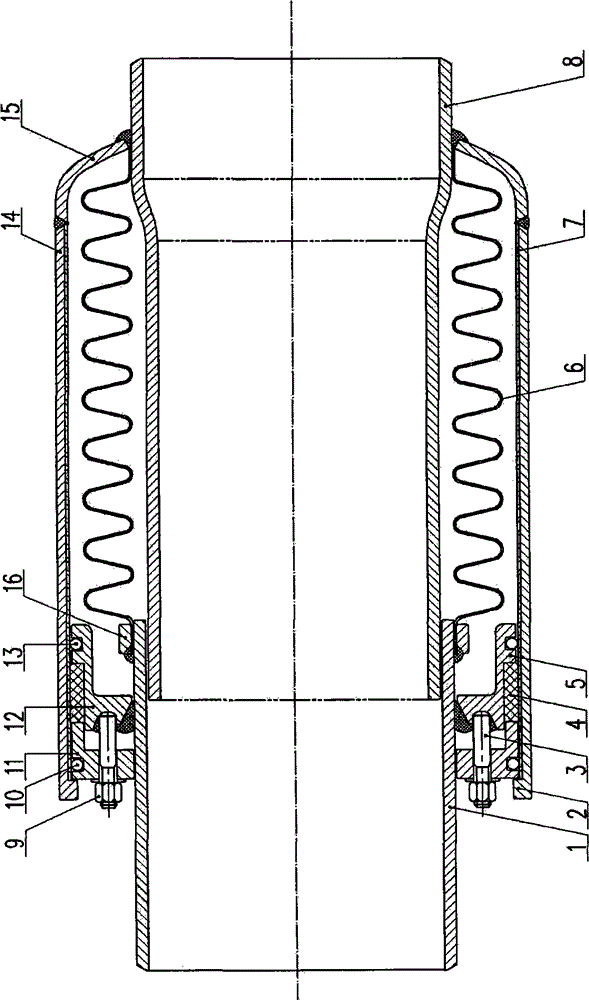

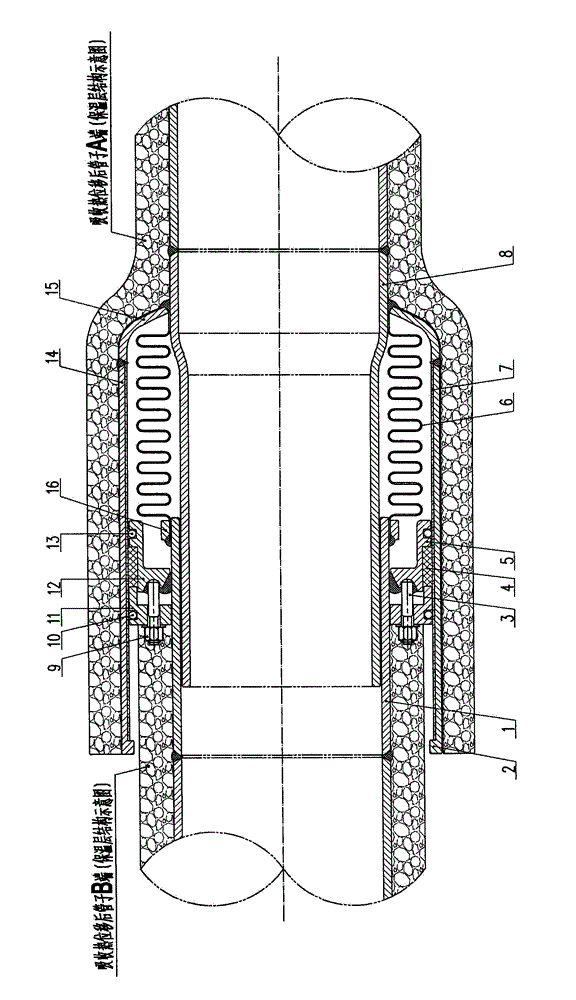

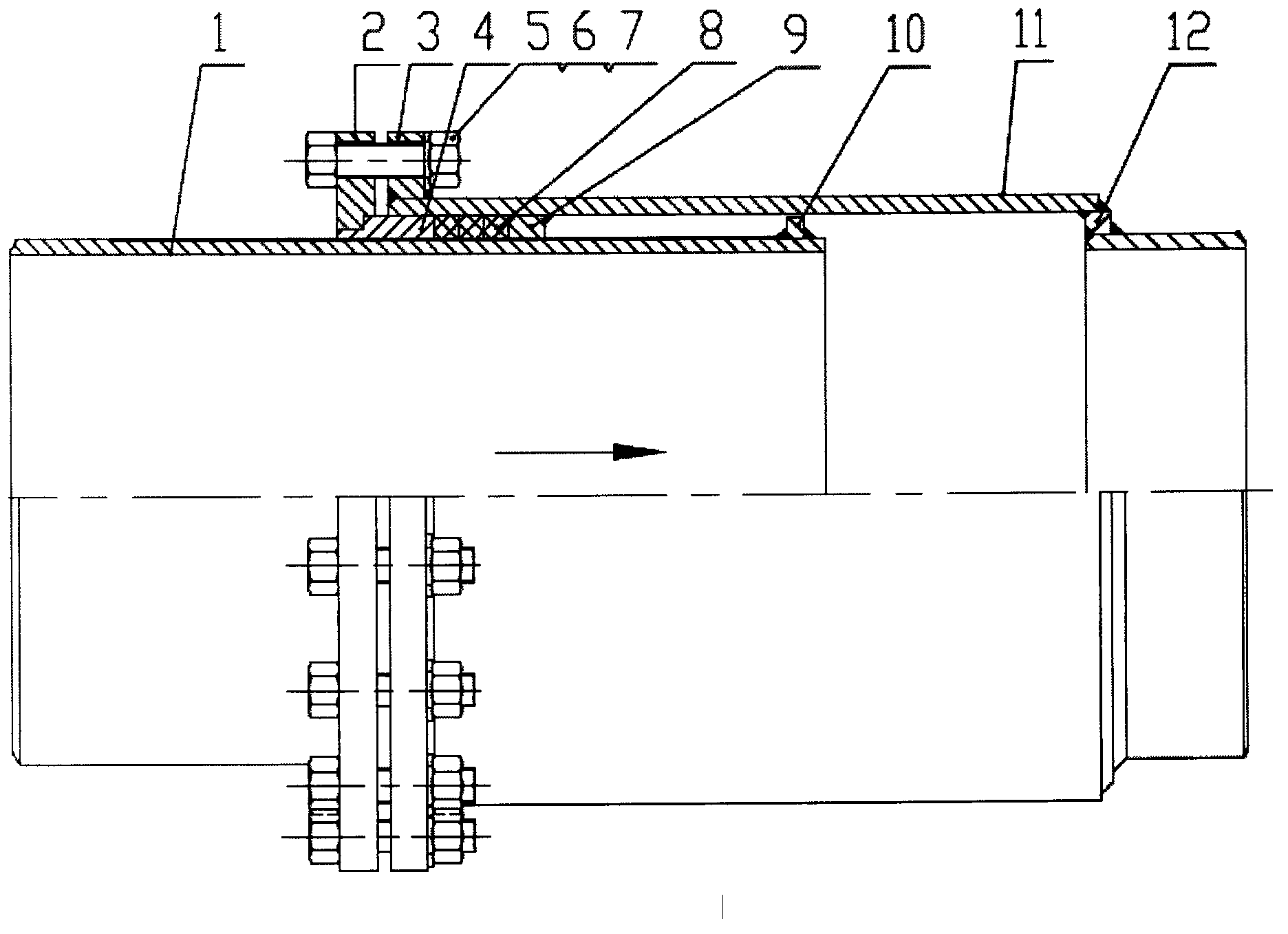

Compound compensator for high pressure pipeline

InactiveCN101832443AStress reliefLow running costPipeline expansion-compensationAxial displacementEngineering

The invention discloses a compound compensator for a high pressure pipeline, belonging to the technical field of the compensating equipment of the heat distribution pipeline. The compound compensator comprises an inner pipe, an anticorrosive pipe, a gland cover flange, a wear sleeve flange, a wear sleeve, a reduction adapter, a guide pipe, a corrugated pipe, a pressure head and the like, wherein the wear sleeve is ringed on one end of the inner pipe, the outer ring of the outer end of one side of the wear sleeve is provided with the wear sleeve flange, the end on other side of the wear sleeve is welded and fixed with a reduction adapter supporting platform integrated with the reduction adapter; the reduction adapter and the inner pipe are separately sleeved on the two ends of the guide pipe, one end of the guide pipe is fixedly connected with the reduction adapter, the corrugated pipe is arranged between the guide pipe and the wear sleeve, and the two ends are butted with the pressure head and the reduction adapter and are connected and fixed through welding. By adopting the structure, when the inner pipe is extruded and pushed by the axial heat expansive force, the axial displacement can be absorbed through the flexible deformation of the corrugated pipe; the coaxial, synchronous and integral movement of the anticorrosive pipe and the like along with the inner pipe can be performed along the axial direction, thus the compound compensator can be used as the buried pipeline or the overhead pipeline; in addition, the compound compensator has multifunctional characteristics of being used as the gas or liquid pipeline and also as the slurry pipeline.

Owner:陈墅庚

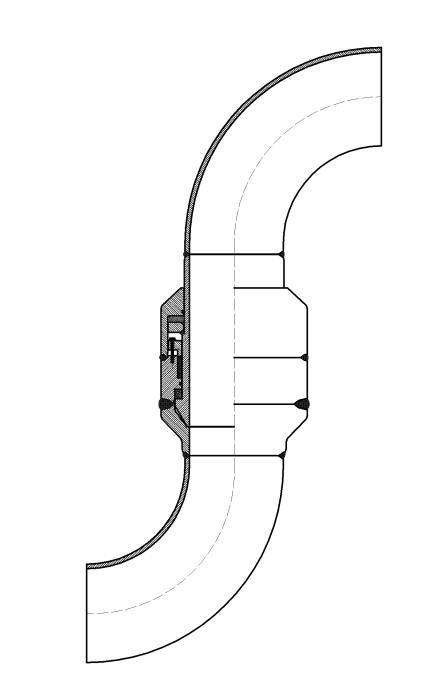

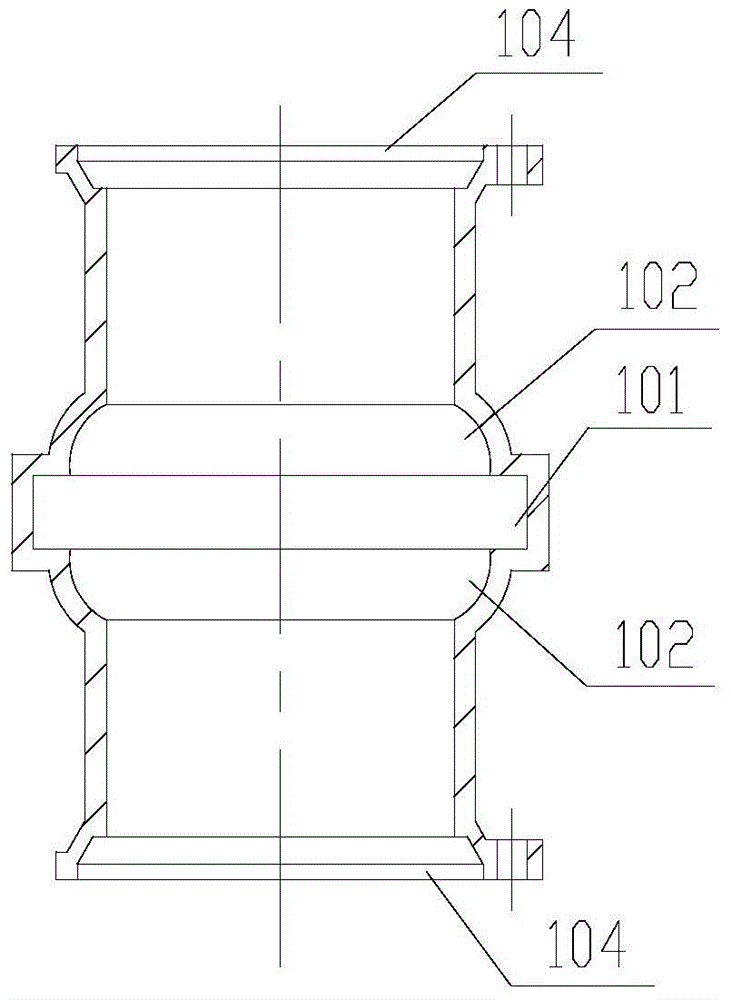

Safety anti-explosion self-sealing rotary compensator

ActiveCN102359690AHigh safety factorPrevent disengagementPipeline expansion-compensationEngineeringMechanical engineering

The invention relates to a safety anti-explosion self-sealing rotary compensator. The compensator comprises a reducing outer pipe (1) and an inner pipe (2), wherein one end of the inner pipe (2) is positioned in the reducing outer pipe (1); at least one end face sealing cavity provided with a sealing piece (5) is formed between the inner pipe (2) and the reducing outer pipe (1); and the sealing cavity consists of the end face of an annular outer boss (3) on the inner pipe (2), the end face of an annular outer boss (4) on the reducing outer pipe (1), which is adjacent to the annular outer boss(3), the external surface of the inner pipe (1) and the internal surface of the reducing outer pipe (1). The compensator is characterized in that: at least one anti-explosion structure is arranged between the inner pipe (2) and the reducing outer pipe (1) and is formed by matching an annular outer convex shoulder (9) on the external surface of the inner pipe (1) with an annular inner convex shoulder (10) on the internal surface of the reducing outer pipe (1). The safety of the rotary compensator is radically improved, and the application range of the rotary compensator is further expanded.

Owner:JIANGSU HONGXIN REVOLVING COMPENSATOR TECH

Plastic pipeline expansion piece

InactiveCN102720912AReduce stressOperating costThermal insulationPipeline expansion-compensationPlastic pipeworkThermal expansion

The invention discloses a plastic pipeline expansion piece belonging to the technical field of pipeline compensation devices. The plastic pipeline expansion piece includes a core pipe, an outer connecting sleeve B, a convex outer ring of the outer connecting sleeve B, a plunger piston inner pipe framework, a plunger piston inner pipe, and a ring seal framework, which are all connected into an integrative structure, wherein the plunger piston inner pipe is provided with a convex outer ring of the plunger piston inner pipe, and the ring seal framework is provided with an O-type seal ring A and an O-type seal ring B. When one end of the core pipe is subjected to pushing of axial thermal expansion force, the outer connecting sleeve B, the core pipe, the plunger piston inner pipe provided with the convex outer ring of the plunger piston inner pipe and connected on the plunger piston inner pipe framework, and the ring seal framework provided with the O-type seal ring A and the O-type seal ring B can move wholly, coaxially and synchronously in the axial direction through the convex outer ring of the outer connecting sleeve B which is propped against a corrugated pipe capable of deformation by self-flexibility. Through adopting the structure, the plastic pipeline expansion piece has multifunctional characteristics of reducing pipeline stress, enhancing sealing performance, improving loading capacity, having corrosion protection efficacy, and realizing large compensation dosage and broad application range.

Owner:陈墅庚

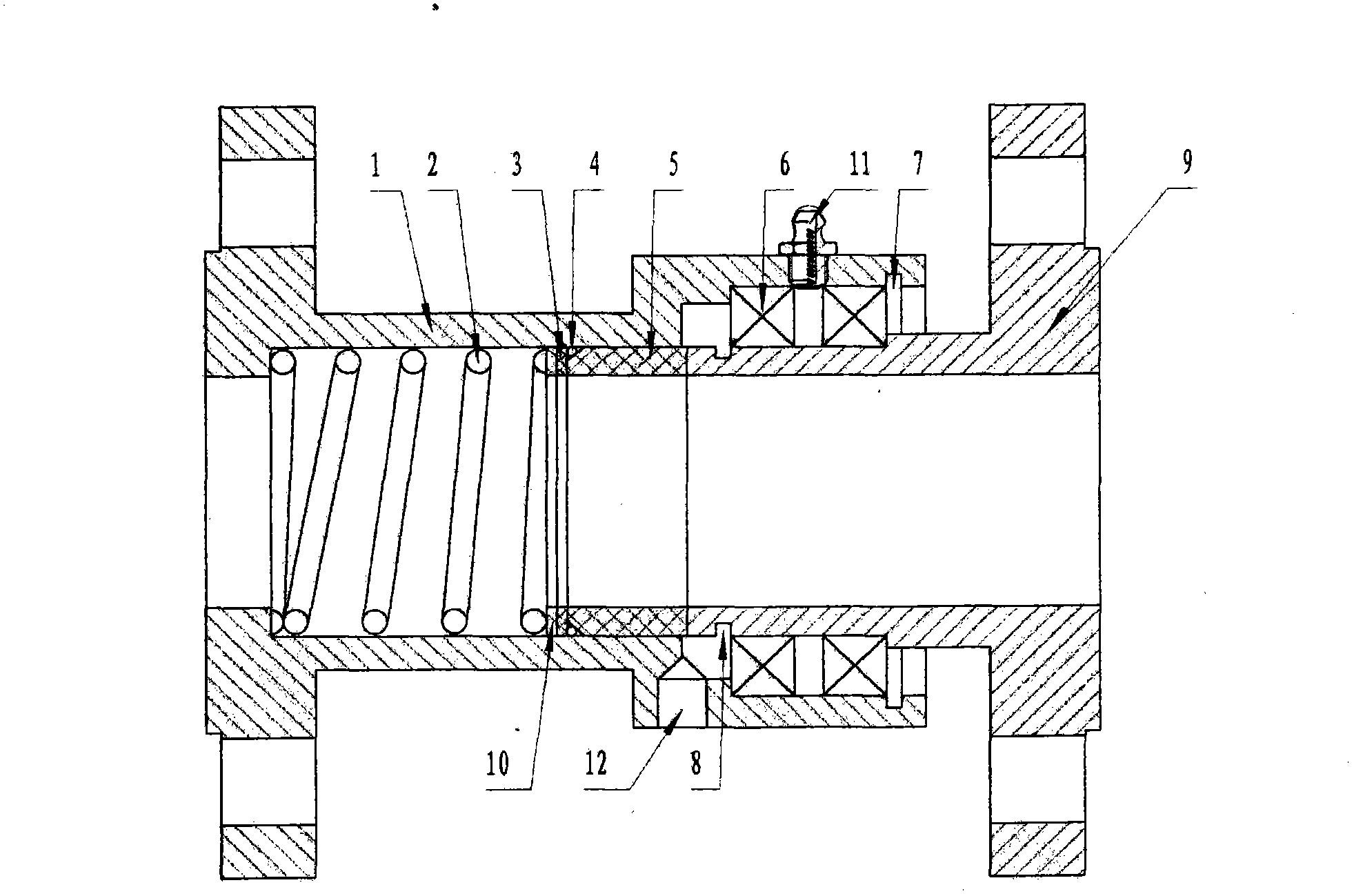

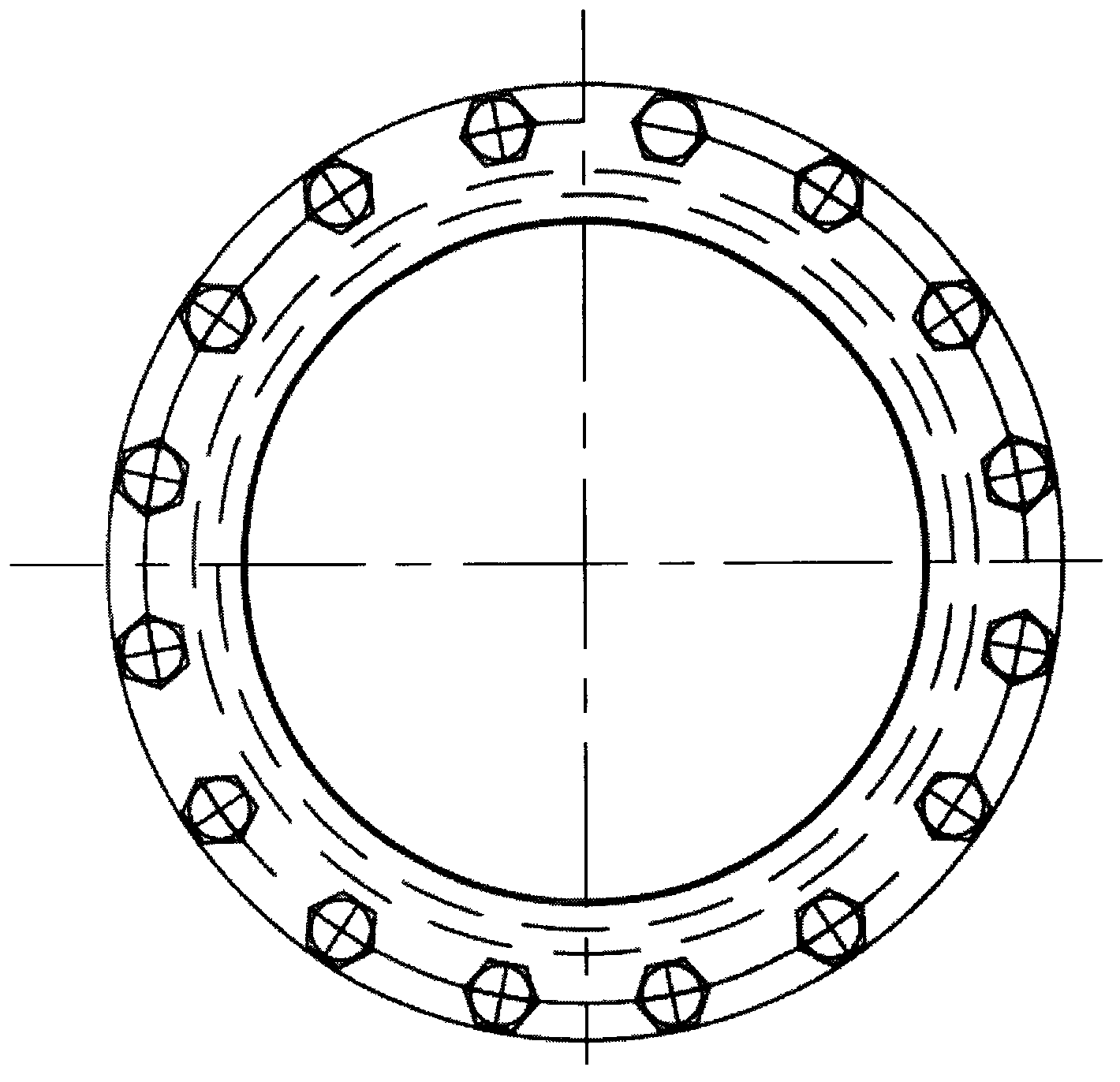

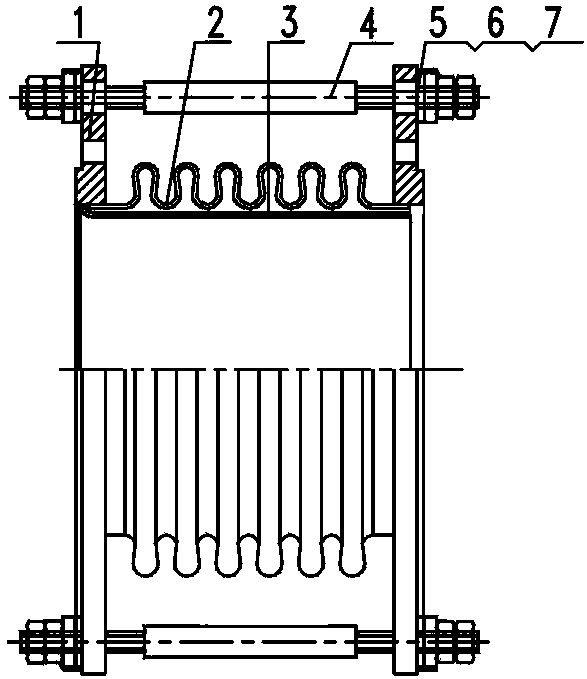

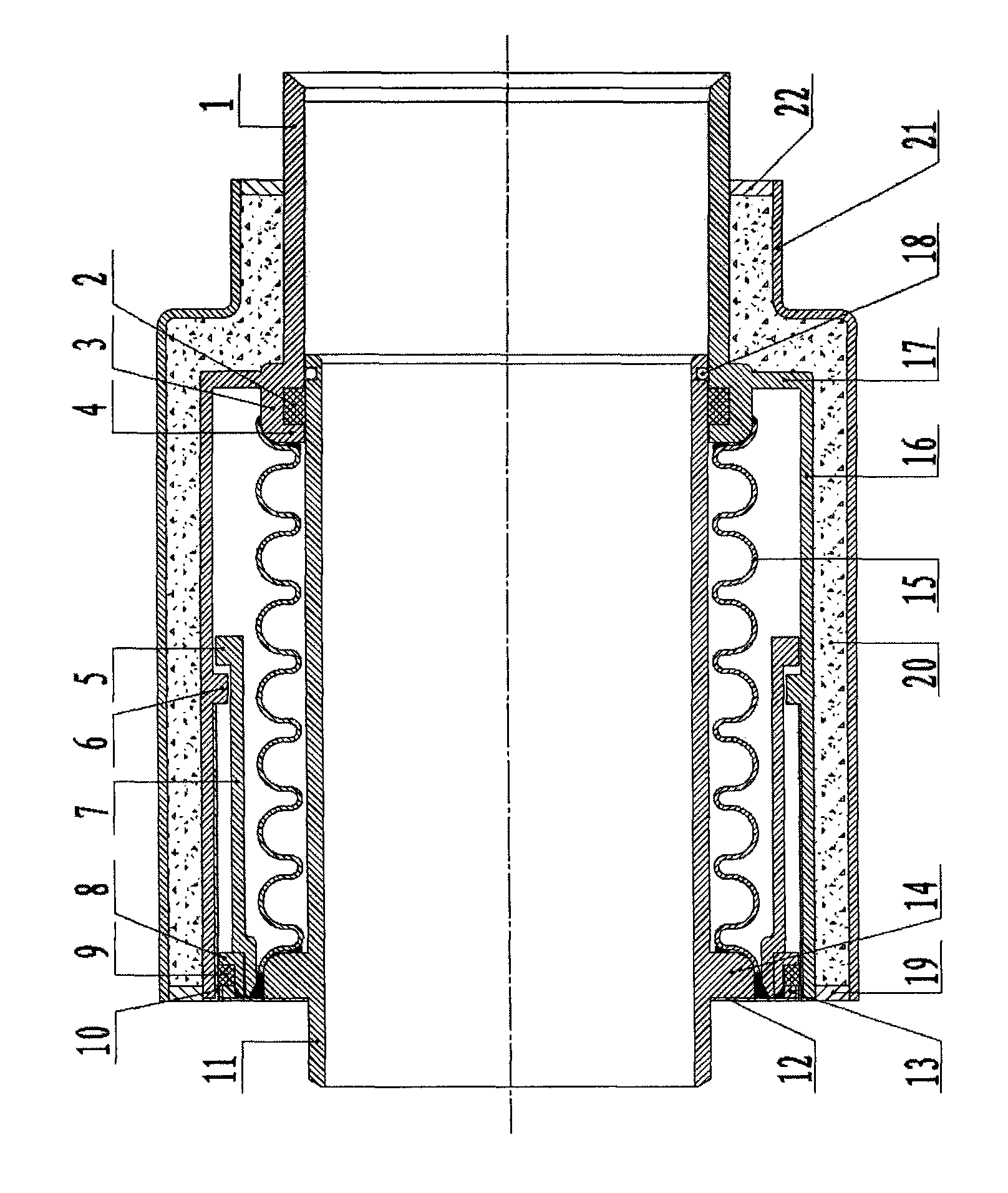

Nonmetal compensator

ActiveCN101694260AImprove sealingLarge amount of compensationPipeline expansion-compensationAdjustable jointsAxial displacementEngineering

The invention relates to a nonmetal compensator of a pipeline, in particular to a nonmetal compensator of high sealing and high temperature resistance. The nonmetal compensator comprises a flange, annular plates, an inner sleeve I, an inner sleeve II, an inner sleeve cover plate and nonmetal compound layers, wherein the nonmetal compound layers are fixed on the annular plates by bolts; the inner sleeve I and the inner sleeve II are welded on the annular plates; both ends of each inner sleeve cover plate are respectively welded on the inner sleeve I and the inner sleeve II; casting materials are cast among the inner sleeve I, the inner sleeve II and the inner sleeve cover plates to form a heat insulating layer of the compensator; and heat insulating materials with high temperature resistance are filled in a space formed by the nonmetal compound layers, the annular plates on both ends and the inner sleeve I as a temperature keeping layer of the compensator. The nonmetal compensator can adapt to severe alternating high temperature of 100 DEG C to 1200 DEG C, has a water cooling pipe coil, has larger compensation quantity on the axial displacement and the radial displacement of the pipeline and also has high sealing performance and good practicality in a primary smoke gas pipeline system of a converter.

Owner:无锡市东方环境工程设计研究所有限公司

Coaxial two-way external pressure type anti-twisting expansion joint

InactiveCN103939703ASimple structureHighly integratedPipeline expansion-compensationAxial displacementExpansion joint

The invention discloses a coaxial two-way external pressure type anti-twisting expansion joint. The coaxial two-way external pressure type anti-twisting expansion joint is composed of inner tubes, outer joints, corrugated tubes, inner joints, a key, an outer tube and pins jointly. The inner wall of the middle section of the outer tube is fixedly connected with the key which is arranged in the axial direction. The inner tubes extend into an inner cavity of the outer tube from the two ends of the outer tube respectively. The inner joints, the corrugated tubes and the outer joints are arranged on the overlapping sections between the inner tubes and the outer tube in a sleeved mode to form axial compensation assemblies which are independent of one another, wherein the inner joints, the corrugated tubes and the outer joints are sequentially connected in a sealed mode. The outer wall of each inner joint is provided with an axial open slot matched with the key. The inner joints and the key move relatively to form an axial compensation assembly displacement track structure. Orifices in the two ends of the outer tube are in sealing connection with the matched outer joints respectively to form two symmetrically-arranged axial compensation assembly integrated structures. The coaxial two-way external pressure type anti-twisting expansion joint is simple in structure, high in integration level and capable of conducting independent one-way compensation and synchronous two-way compensation. Built-in coaxial displacement tracks are coaxial, do not influence axial compensation and have an anti-twisting function, so it can be guaranteed that the corrugated tubes only conduct axial displacement movement and the service life of the expansion joint can be prolonged.

Owner:JIANGSU SHUGUANG PRESSURE VESSEL

Novel composite pipe compensator

ActiveCN103982737AReduce stressLow running costPipeline expansion-compensationCorrosion preventionEngineeringThermal expansion

The invention discloses a novel composite pipe compensator and belongs to the technical field of heat distribution pipe compensation devices. The novel composite pipe compensator is characterized in that an outer sleeve seal head is arranged on an outer ring of a pipe A, a pipe B is coaxially and annularly sheathed on the outer ring at one end of the pipe A, a corrugated pipe is annularly sheathed on the surface of the outer ring of the pipe A, and the two ends of the corrugated pipe are respectively, tightly and fixedly connected with the pipe A and the pipe B; an outer sleeve is arranged on the outer side of a sealing seat to form a structure that the outer sleeve seal head which is integrally arranged on the outer ring of the pipe A and one end, including the corrugated pipe, of the outer pipe sleeve are of an integrated structure and can coaxially, synchronously and integrally move under the squeezing and pushing effect of axial thermal expansion force. By adopting the structure, the novel composite pipe compensator has the advantages that the pipe stress is reduced, the sealing performance is enhanced, the pressure bearing capacity is improved, large compensation can be realized and the application scope is wide.

Owner:陈墅庚

Rotating connector

InactiveCN103775768ALarge amount of compensationExtended service lifeAdjustable jointsLubricantNozzle

The invention discloses a rotating connector. The rotating connector comprises a shell (1) and is characterized in that a spring (2), a spring cushion (10), a rubber cushion (3), an O-shaped ring (4) and a seal ring (5) are arranged in the shell (1), a shaft clamp (8) is arranged in a groove of a hollow shaft (9), a bearing (6) is arranged between an inner hole of the shell (1) and the external diameter part of the hollow shaft (9), lubricant oil is injected into the bearing (6) through an oil nozzle II, and an observation hole (12) is used for a worker to observe whether leakage exists or not. A hole check ring (7) is used for performing limiting to connect all components into a whole. The rotating connector has the advantages of being simple in structure, stable in supporting and large in bearing pressure, the resisted pressure is 2.0 MPa, the revolving speed is 0-500 r / min, the rotating connector is suitable for the operation of a pipeline, and media are cooling water, saturated steam, conduction oil, air and the like.

Owner:刘明

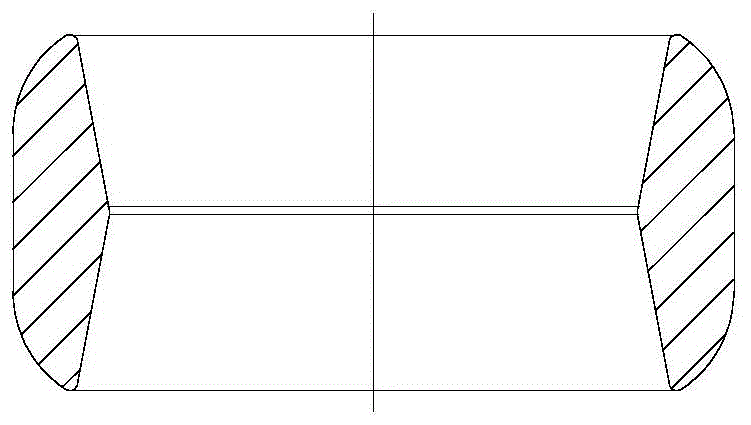

Sleeve type compensator

InactiveCN103807555ALarge amount of compensationEasy maintenancePipeline expansion-compensationAdjustable jointsArray data structureEngineering

The invention provides a sleeve type compensator, and relates to the technical field of compensating devices of thermal fluid pipelines. A body pipe is coaxially connected to the outer wall of the rear half segment of a telescopic pipe of the compensator in a sleeved mode, a gland is tightly connected between the front end of the body pipe and the outer wall of the telescopic pipe in a sleeved mode, a plurality of sealing parts are tightly arranged on the rear side of the gland, a first check ring is tightly arranged on the rear sides of the sealing parts, a first supported flange is tightly connected to the outer wall of the front end of the gland in a sleeved mode, a second supported flange is tightly connected to the outer wall of the front end of the body pipe in a sleeved mode, the first supported flange and the second supported flange are fixedly connected through a plurality of sets of bolts, nuts and flat gaskets, a second check ring is welded to the outer wall of the rear end of the telescopic pipe, and a bushing ring is welded to the inner wall of the rear end of the body pipe. The sleeve type compensator has the advantages of being large in compensation amount, convenient to maintain, high in safety performance, long in service life, wide in using range, low in constructing cost of projects, wide in market prospect and extremely high in research and design value.

Owner:江苏星光波纹管有限公司

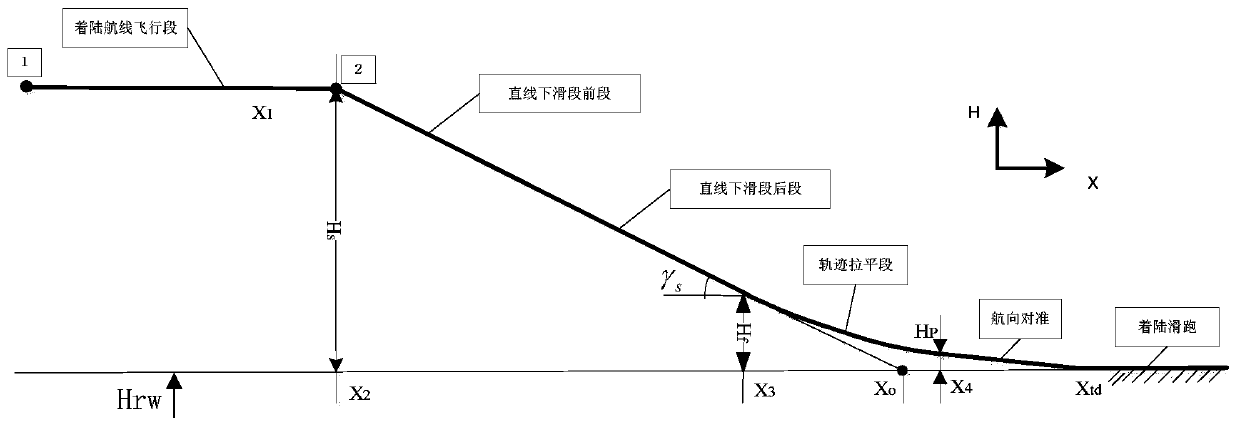

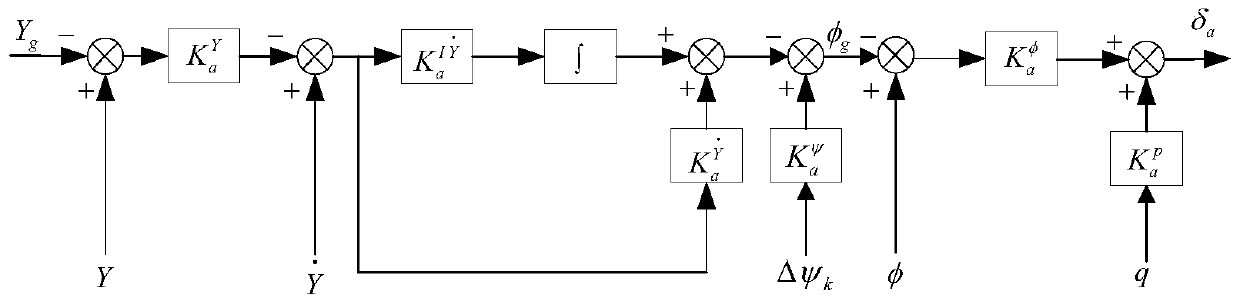

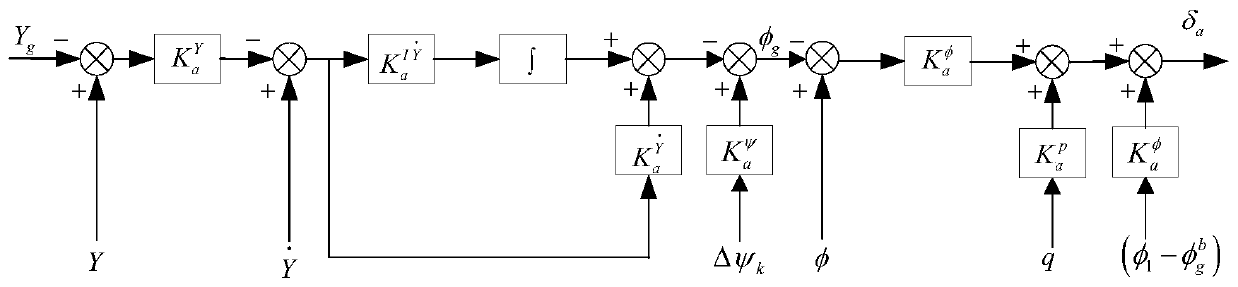

Transverse control method of single-side missile hanging landing

ActiveCN110096070AAvoid moppingLarge amount of compensationAttitude controlPosition/course control in three dimensionsLateral asymmetryAviation

The invention relates to a transverse control method of single-side missile hanging landing, and belongs to the field of aviation flight. The method comprises the following steps that 1) an integral quantity is taken from a (phi<g>) calculation formula (delta) before a course aligning phase is turned to, and turned into a calculation formula in the course aligning phase, and the amplitude ofthe (phi<g>) is not triggered; 2) a mean value of the present roller angle of a UAV in multiple continuous beats during cut-in is taken as the feedback roll angle, and a mean value of multiple continuous beats during cut-in is taken as the integral quantity; and 3) a single-side missile hanging control strategy is widened from only the course aligning phase to linear downslide, trajectory flareout and course aligning phases, and the limit of the relative height of 150m during cut-in is set for the trajectory flareout phase. The roll angle is not limited to a given limit value, a transverse asymmetric aileron tromming tab compensation quantity is added to avoid the UAV from influence of the given roll angle limit value, and the original given roll angle limit value can play original roles.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

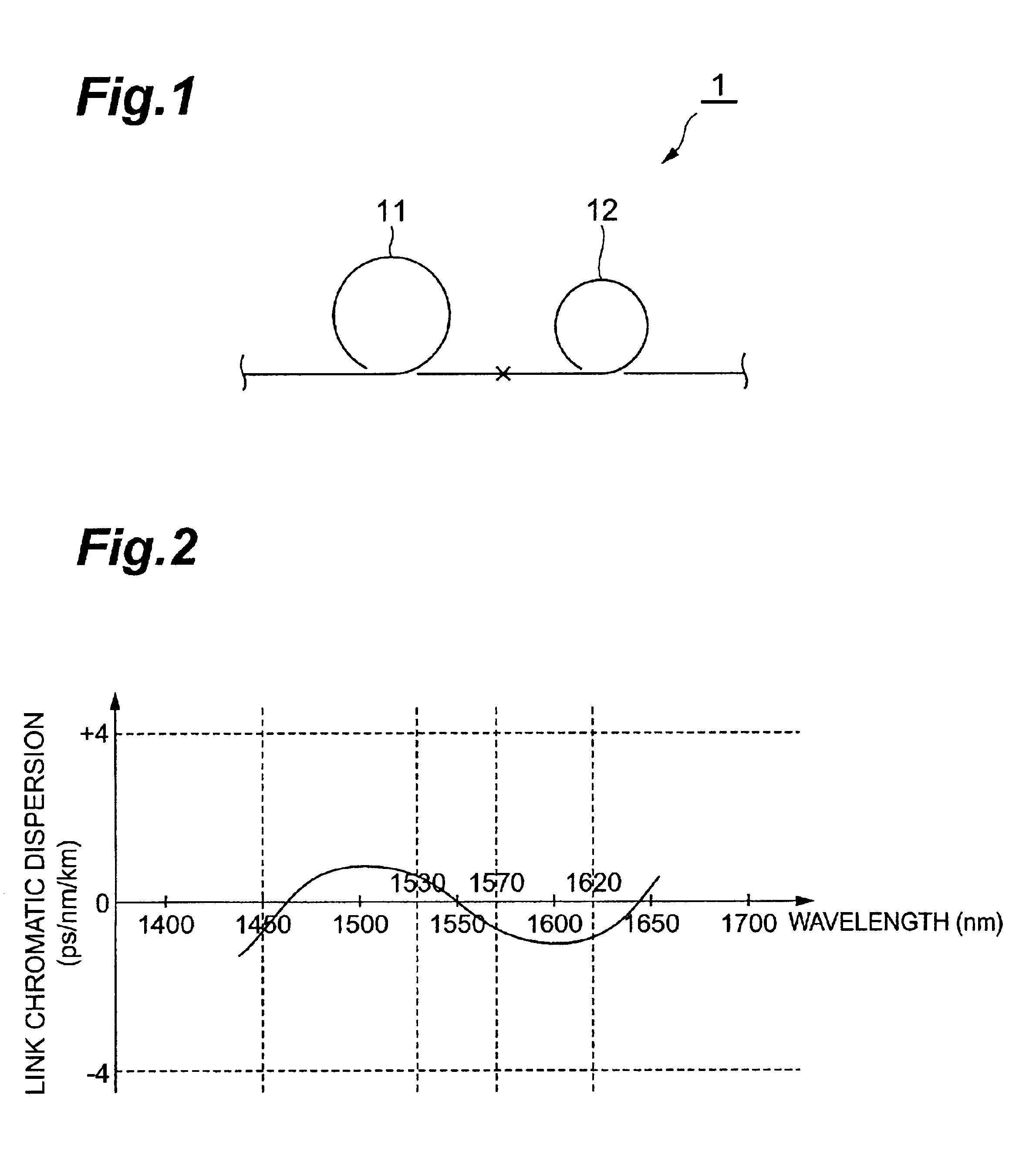

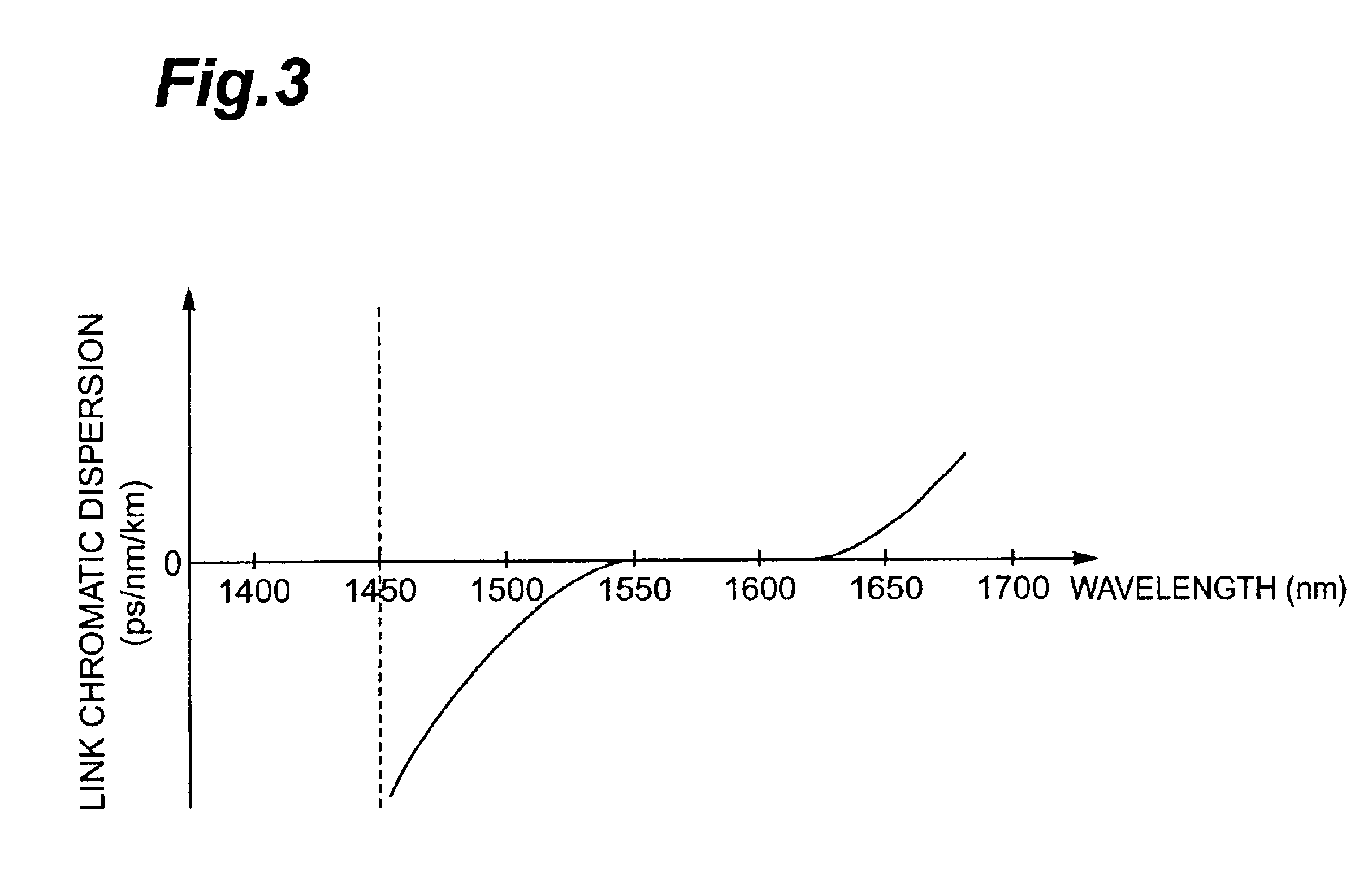

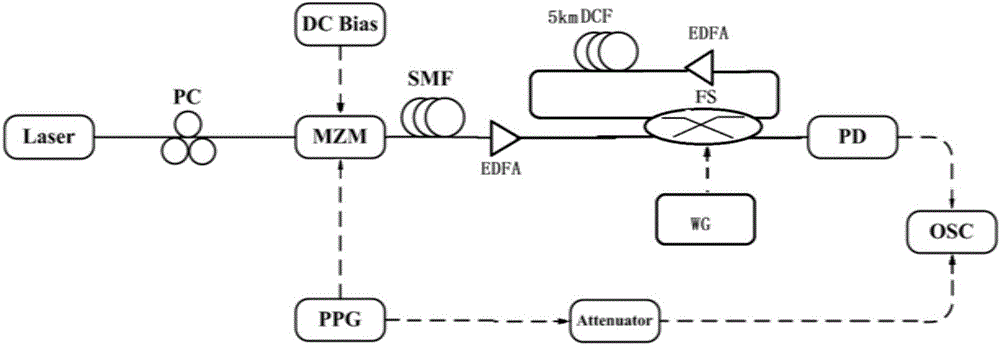

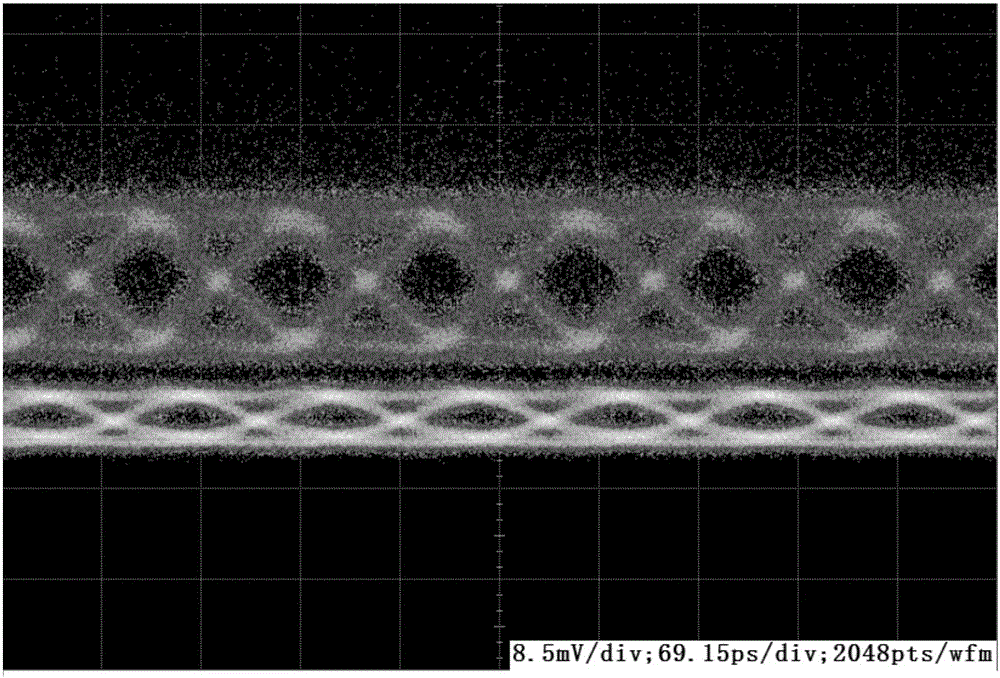

Optical transmission line, and optical fiber and dispersion compensating module employed in the same

InactiveUS6862391B2Long distanceLarge capacityOptical fibre with multilayer core/claddingWavelength-division multiplex systemsLength waveDispersion compensation

The present invention relates to an optical transmission line and the like having a chromatic dispersion with a small absolute value as a whole within a signal wavelength band including S, C, and L bands. This optical transmission line comprises a single-mode optical fiber and a dispersion-compensating optical fiber which are connected to each other; and has, as characteristics of the whole optical transmission line at a wavelength of 1550 nm, a chromatic dispersion with an absolute value of 4 ps / nm / km or less, and a dispersion slope of −0.015 ps / nm2 / km or more but less than 0 ps / nm2 / km. Its chromatic dispersion has a maximum value within a wavelength range of 1450 to 1530 nm, and a minimum value within a wavelength range of 1570 to 1620 nm.

Owner:SUMITOMO ELECTRIC IND LTD

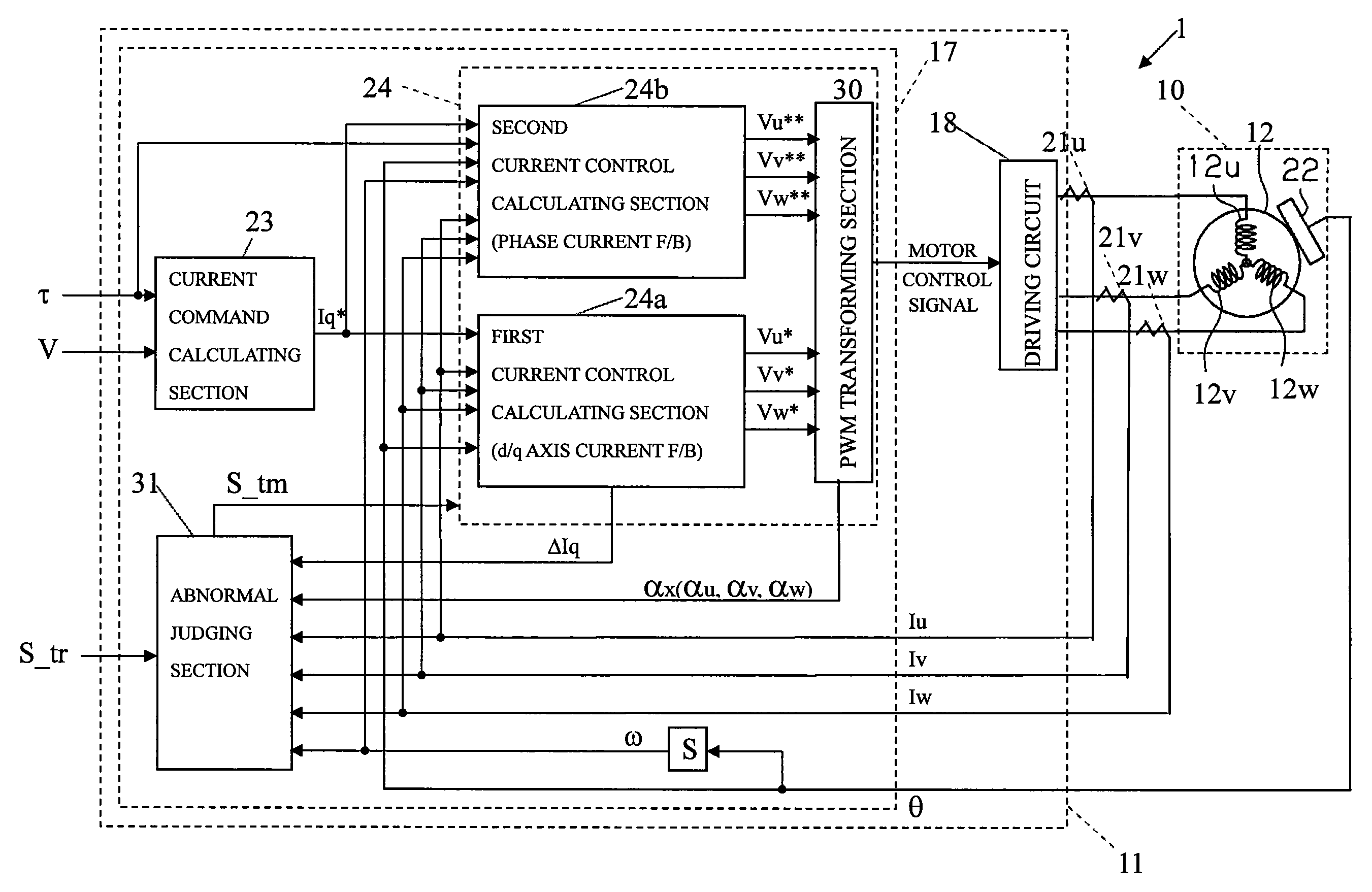

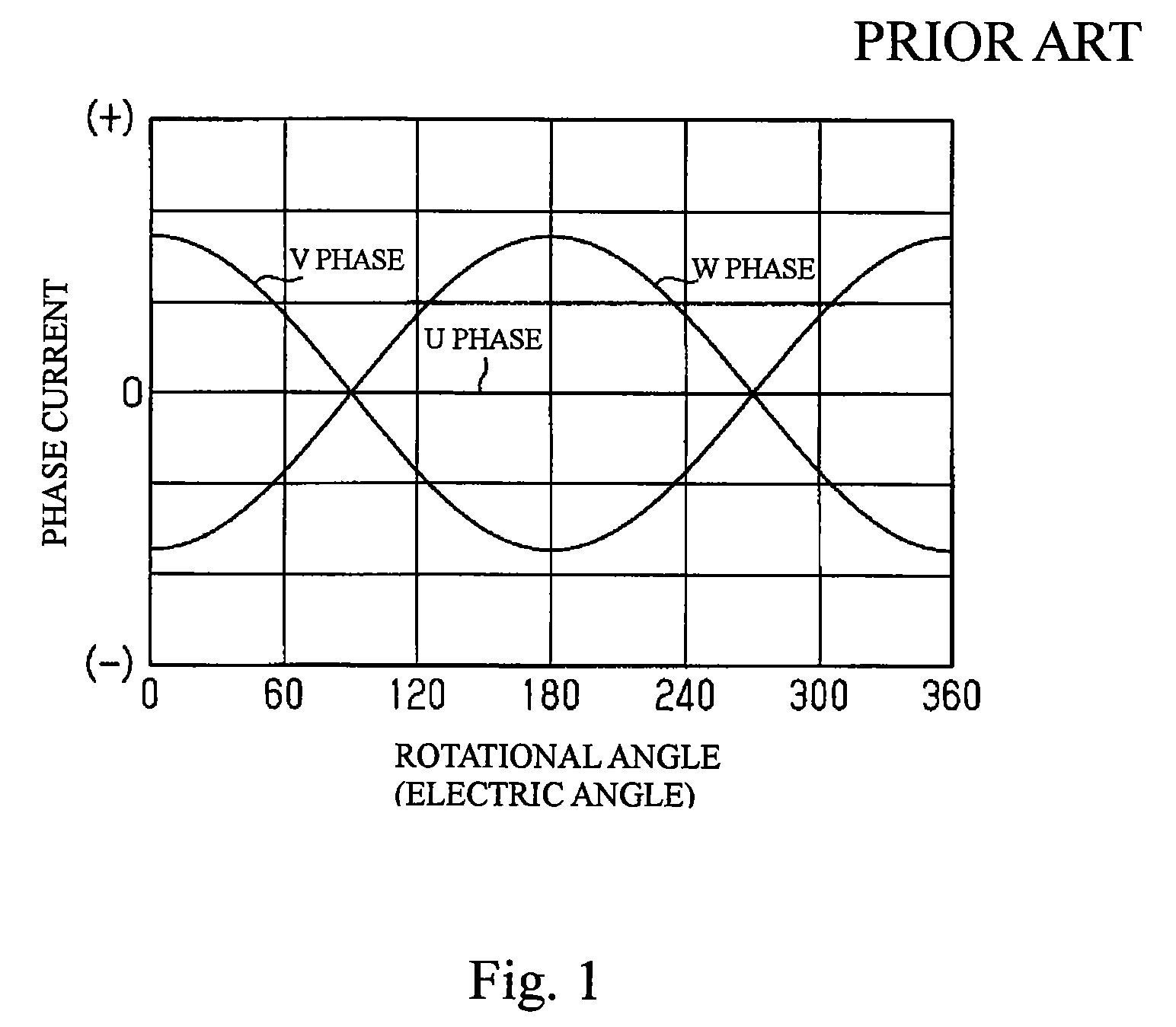

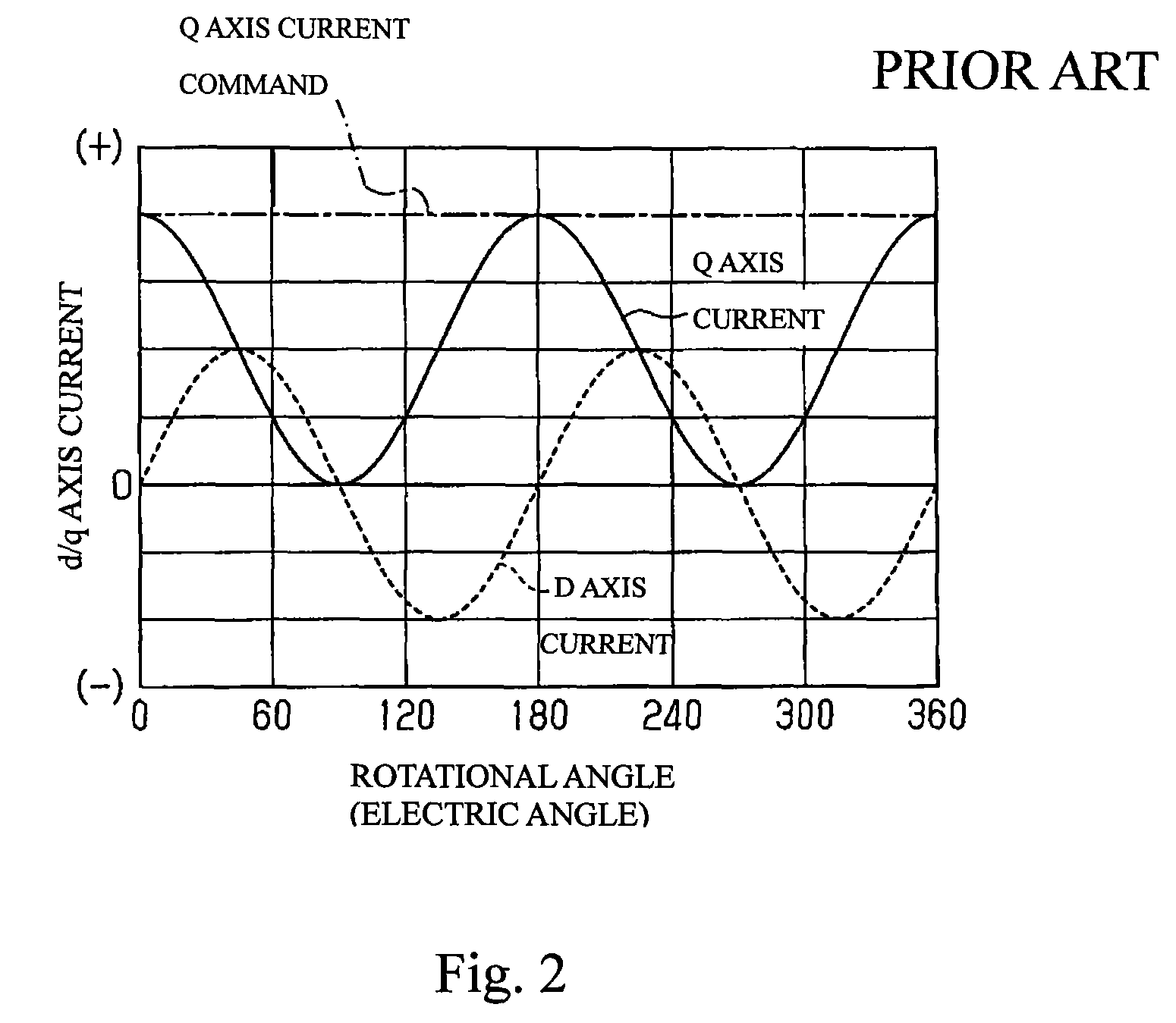

Motor controller and electric power steering apparatus

InactiveUS7990094B2Improve output performanceSmooth rotationTorque ripple controlSynchronous motors startersElectric power steeringPhase currents

Owner:JTEKT CORP

PE (poly ethylene) corrugated compensator for high-temperature water

InactiveCN102734587AImprove performanceImprove insulation effectPipeline expansion-compensationThermal insulationIonThermal insulation

The invention discloses a compensator used in a concentrated-heating hot water network, and concretely relates to a PE (poly ethylene) corrugated compensator for high-temperature water. The compensator comprises an operating tube compensator and an outer polyethylene sleeve, wherein the operating tube compensator is externally sleeved with a hard thermal insulation layer and a soft thermal insulation layer, the outer polyethylene sleeve is tightly wrapped on the outsides of the hard thermal insulation layer and the soft thermal insulation layer, and the hard thermal insulation layer is tightly wrapped on one end of the operating tube compensator and raised parts; the soft thermal insulation layer is tightly wrapped on the other end of the operating tube compensator; and the outer edge of the soft thermal insulation layer is provided with a corrugated pipe. The compensator disclosed by the invention is extremely compact in structure; the compensator is strong in bearing capacity, has the characteristics of acid, alkali and chloride ion corrosion resistance, and prevents the rupturing of an outer pipe in the process that an operating tube is drawn, thereby prolonging the service life of the compensator and saving energy; meanwhile, because of the setting of a protective cover, the heat preservation effect can be further increased; due to the selection of materials, the compensator is more practical; and because of the simple structure and process, the installation process is easier, thereby solving the problem of inconvenience in installation.

Owner:QINGDAO JINBANG ANTI CORROSION INSULATION PIPELINE

Internal compression type rubber self-sealing flange connection pipeline universal joint

An internal compression type rubber self-sealing flange connection pipeline universal joint comprises an outer sleeve and an inner sleeve. One end of the inner sleeve is sleeved with one end of the outer sleeve, and a sealing device is arranged on the sleeving portion. The universal joint is characterized in that the sleeved end of the inner sleeve is provided with a sphere pipe part; the two ends of the outer spherical surface of the sphere pipe part are matched with a spherical surface on the inner wall of the outer sleeve and a spherical surface arranged on the inner wall of a pressing flange respectively; the pressing flange is connected with the outer sleeve through a bolt to fix the sphere pipe part; the sphere pipe part can freely rotate by a certain angle to achieve universal compensation; the pressing flange, the inner wall of the outer sleeve and the middle of the outer spherical surface of the sphere pipe part form a closed cavity; a sealing ring is arranged in the cavity; an annular inner pressing cavity with the axial section being in a swallow-tail shape or a T shape is formed in the inner ring face of the sealing ring; the outer surface of the sealing ring makes contact with the pressing flange, the inner wall of the outer sleeve and the outer surface of the sphere pipe part; a certain number of inner pressing through holes are formed in the pipe wall, opposite to the opening of the annular inner pressing cavity, of the sphere pipe part, so that the annular inner pressing cavity is communicated with the inner cavity of the inner sleeve.

Owner:刘从荡

Two-way thrust-free directly-buried compensator

InactiveCN104019317ALarge amount of compensationImprove installation efficiencyPipeline expansion-compensationStructural engineeringSymmetric structure

The invention discloses a two-way thrust-free directly-buried compensator which comprises an end connection tube, two corrugated tubes and a middle connection tube. The middle connection tube is sequentially connected with the corrugated tubes and the end connection tube to two ends to form a double-corrugated-tube compensation structure; the outer side of the double-corrugated-tube compensation structure is provided with a protective sleeve; the two ends of the protective sleeve are fixedly connected with end plates, and the end plates are in clearance fit with the outer wall of the end connection tube; the protective sleeve and the middle connection tube are fixedly connected through a fixing ring. The compensator is characterized in that the walls of inner holes of the end plates are provided with radial annular grooves, and sealing rings are arranged in the radial annular grooves and are attached to the outer wall of the end connection tube to form radial sealing structures. The compensator is of a horizontal symmetry structure, can be installed in two directions, and is large in compensation amount. Meanwhile, fixing supports do not need to be installed at the two ends of the compensator during installation, so that installation efficiency is effectively improved, and installation cost is saved. Meanwhile, the radial sealing structures are formed at the two ends, so that impurities, dust and the like can be effectively prevented from entering waves of the corrugated tubes, and use reliability is remarkably improved.

Owner:江苏晨光波纹管有限公司

Novel shock absorption expansion joint

InactiveCN109442127AImprove flexibilityLarge amount of compensationPipeline expansion-compensationNon-rotating vibration suppressionWave structureEngineering

The invention discloses a novel shock absorption expansion joint. The novel shock absorption expansion joint comprises an internal shell, a corrugated pipe and two groups of lug flanges, wherein the corrugated pipe is arranged outside the internal shell, and the two groups of lug flanges are correspondingly arranged at the two ends of the corrugated pipe. The waveform of the corrugated pipe is inan omega shape; a shock absorption rod is arranged between the two groups of lug flanges; the shock absorption rod penetrates through connecting holes of the two groups of lug flanges and is connectedand fixed to the connecting holes through fastening connecting pieces; the fastening connecting pieces comprise spring washers, rubber washers and fastening bolts; the spring washers are pressed on the lug flanges, and the rubber washers are pressed on the spring washers; and the fastening bolts are pressed on the rubber washers. The corrugated pipe of the novel shock absorption expansion joint adopts a thin-wall multilayer condensation wave structure, and has good flexibility and a large compensation amount. The connecting flanges at both ends and lugs are of an integral structure, the lugsand a pull rod can bear the thrust generated by the deformation of the corrugated pipe, and the strength requirement of a product is met.

Owner:江苏耀宇新型管业有限公司

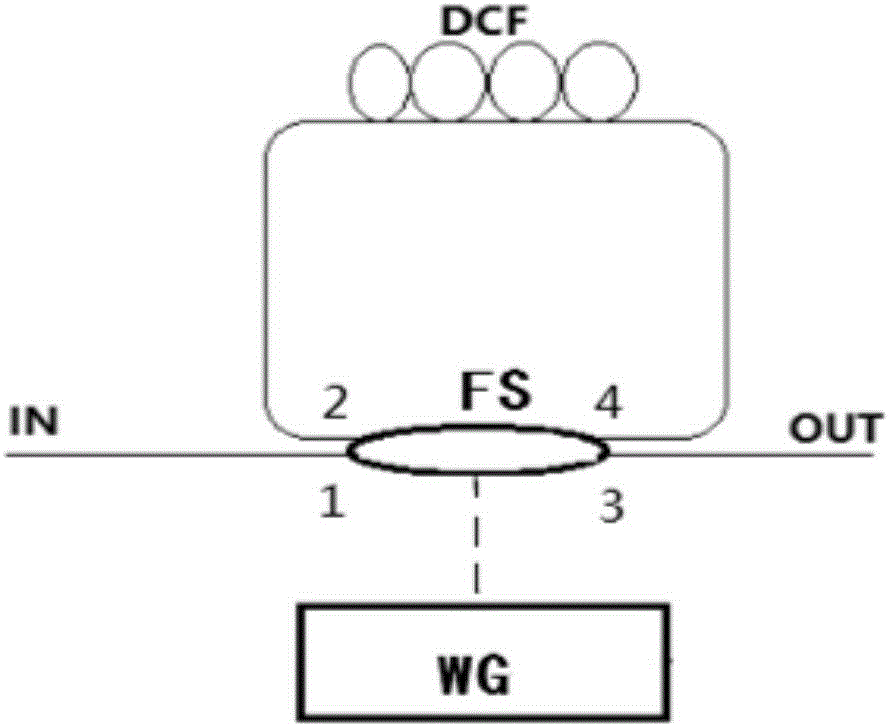

Loop-tunable dispersion compensation method and device

ActiveCN106100744AReduce usageLarge amount of compensationElectromagnetic transmissionControl signalDispersion compensation

The invention relates to a loop-tunable dispersion compensation method and device. An optical signal is input into a loop through the input end of the loop composed of a DCF, and circulates in the loop; and the optical signal after dispersion compensation for several times is output through the output end of the loop. According to the loop-tunable dispersion compensation method and device disclosed by the invention, the DCF loop is equivalent to a DCF long link; the use amount of the DCF is reduced; the relatively high compensation amount is generated; simultaneously, tunableness of the dispersion compensation amount can be realized by changing the control signal of an optical switch; and the loop-tunable dispersion compensation method and device can realize seamless compatibility with the existing optical fibre network.

Owner:上海光织科技有限公司

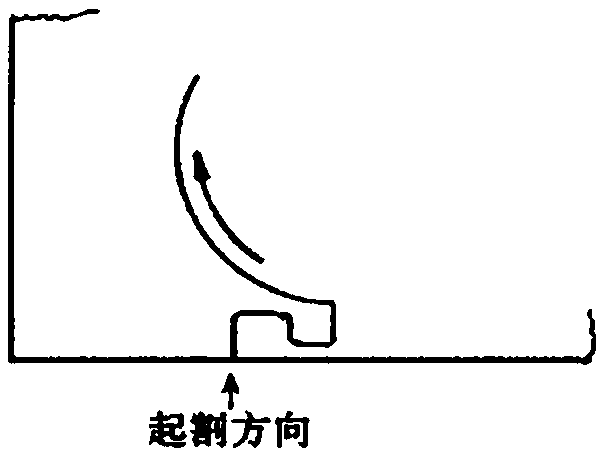

Thermal expansion amount control method of numerical control flame cutting steel plate part sizes

InactiveCN109465517AEliminate bad effectsHigh dimensional accuracyGas flame welding apparatusSteel platesLongest Diameter

The invention discloses a thermal expansion amount control method of numerical control flame cutting steel plate part sizes. The method includes the steps that the long and short diameter ratio is calculated according to the sizes of pre-cut formed parts; the average temperature T1 of steel plates corresponding to the parts during cutting is estimated according to the thicknesses of the steel plates and the sizes and the shapes of the parts, and the cutting temperature difference delta T=T1-room temperature is calculated; and thermal expansion compensation amounts are calculated, wherein the unilateral thermal expansion compensation amount delta t is added to the kerf compensation K of the parts with the long and short diameter ratio of 1.0-1.3, the unilateral thermal expansion compensation amount delta t1 is added to the short-diameter direction kerf compensation K1 of the parts with the long and short diameter ratio not smaller than 1.2-1.3, and the unilateral thermal expansion compensation amount delta t2 is added to the long-diameter direction kerf compensation K2 of the parts with the long and short diameter ratio not smaller than 1.2-1.3. The corresponding thermal expansion compensation amounts are added to kerfs according to part temperature rise and the long and short diameter ratio, and therefore bad influences of thermal expansion of numerical control flame cutting onthe part sizes are eliminated.

Owner:YUNNAN HEAVY EQUIP MFG GRP

Universal orthogonal coupler

InactiveCN101979890ALarge amount of compensationIntermittent smallYielding couplingWind energy generationEngineeringCoupling

Owner:苏州高新区禾云设备设计事务所

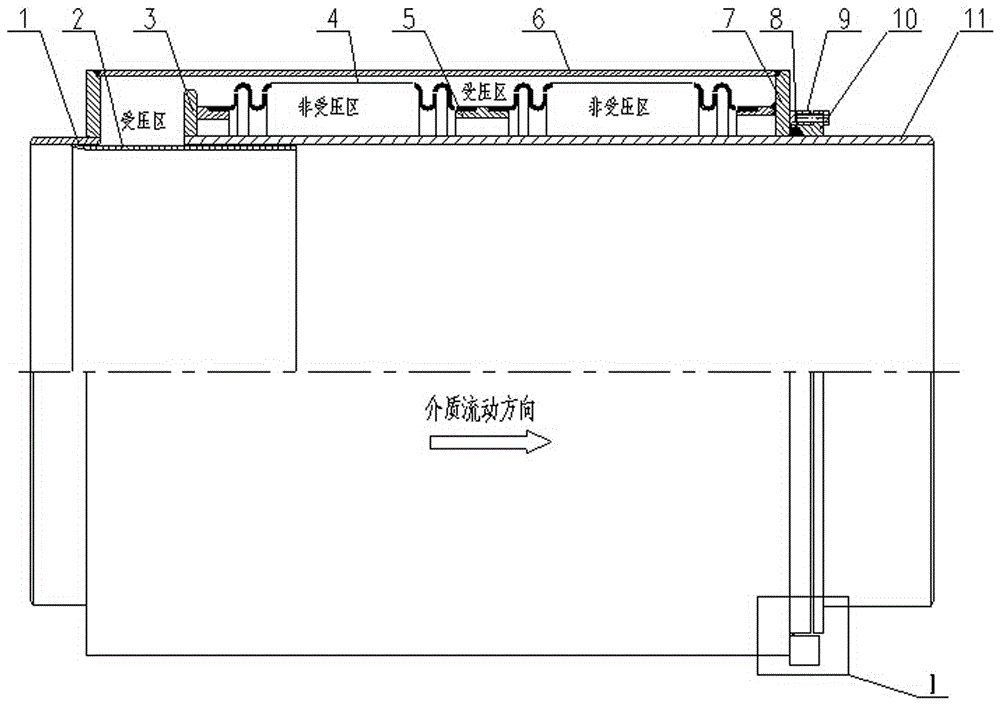

Quantitative detection device for external pressure expansion joint leakage

ActiveCN106287237ALarge amount of compensationHigh detection sensitivityPipeline expansion-compensationPipeline systemsEngineeringExpansion joint

Disclosed is a quantitative detection device for external pressure expansion joint leakage. Through quantitative detection on the leakage mount of media, in combination with structural characteristics of an external pressure expansion joint, the leakage amount of a non-pressed cavity can be detected in real time, and real-time early warning is provided for overhauling or replacing of the expansion joint.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

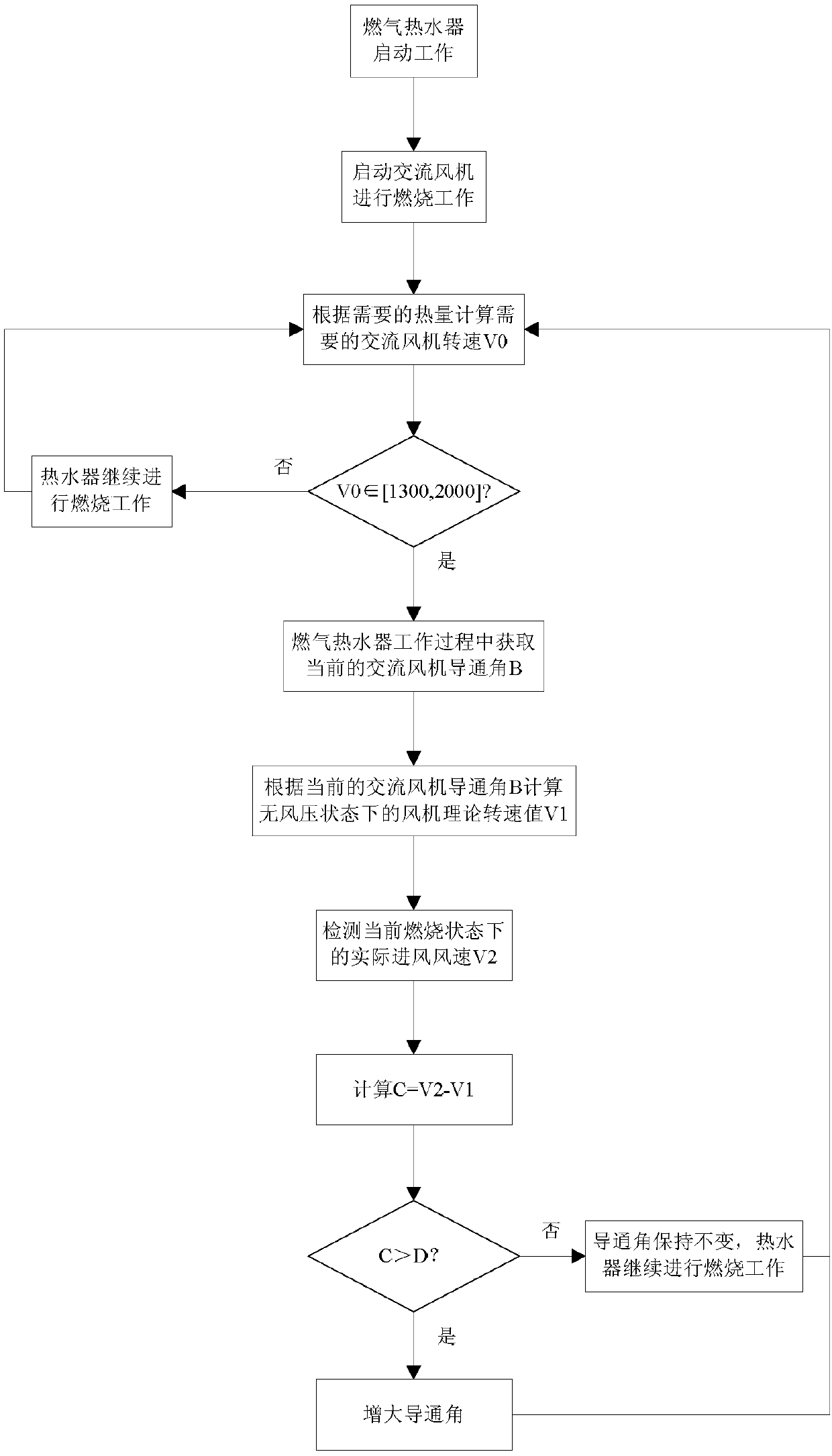

Gas water heater fan wind pressure resistance control method based on alternating current fan

InactiveCN111089425AIncrease powerIncrease speedFluid heatersAir supply regulationThermodynamicsAir velocity

The invention relates to a gas water heater fan wind pressure resistance control method based on an alternating current fan. The method comprises the following steps that a fan theoretical rotating speed value V1 in a wind pressure-free state corresponding to a current alternating-current fan conduction angle is compared and calculated with a detected actual air inlet speed V2, and C is equal to V2-V1; and if C exceeds a set threshold value D, it is judged that the external wind pressure is too large, and the conduction angle of the alternating-current fan is controlled to be increased. According to the gas water heater fan wind pressure resistance control method based on the alternating current fan, the situation that the external wind pressure is increased can be effectively detected, under the situation that the external wind pressure is too large, the alternating current fan power is increased through increasing the alternating current fan conduction angle, the rotating speed of the alternating current fan is increased, and then the influence of the external wind pressure on water heater combustion is resisted, so that the situation that flames are extinguished is effectively avoided, normal combustion of the gas water heater is guaranteed, and the adaptability of the gas water heater is enhanced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

High-elasticity film disk shaft coupling structure

ActiveCN102312931AEasy to assemble and disassembleConducive to maintenanceYielding couplingPhysicsEngineering

The invention relates to a high-elasticity film disk shaft coupling structure which comprises a spacing shaft, double film disks symmetrically arranged at two ends of the spacing shaft and mounting disks. The high-elasticity film disk shaft coupling structure is characterized in that the molded surfaces of the double film disks are curve molded surfaces; the molded surfaces of the double film disks are integrally connected into a U-shaped structure shape; both sides of the double film disks are provided with films, the tops of the films are provided with film disk flanges, and the bottoms of the films at both sides are connected into a whole by film disk bodies; the double film disks are connected with the mounting disks through the film disk flanges at one side and are connected with transmission torque through first bolt assemblies; the film disk flanges at the other sides of the double film disks and the spacing shaft are positioned through convex-concave seam allowances and are connected with the transmission torque through second bolt assemblies; and a first protection plate and a second protection plate cover the exteriors of the double film disks. The high-elasticity film disk shaft coupling structure provided by the invention is of a double-film-disk high-elasticity structure, so that more compensation dosage can be achieved; and the high-elasticity film disk shaft coupling structure provided by the invention is convenient to assemble and disassemble and beneficial to overhaul and maintenance.

Owner:无锡创明传动工程有限公司

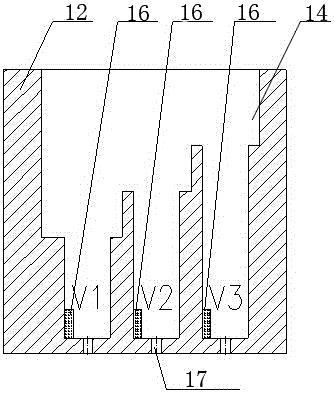

Multiple two-direction sleeve expansion joint

InactiveCN103822037ASmall flow frictional resistanceExtended service lifeAdjustable jointsSaline waterOuter Cannula

The invention discloses a multiple two-direction sleeve expansion joint. According to the technical scheme, the multiple two-direction sleeve expansion joint comprises a moving pipe, a compressing flange, an outer casing pipe, sealing filling, an anti-dropping ring and a compressing bolt, wherein the moving pipe is externally connected with the outer casing pipe, the sealing filling serves as the interlayer between the moving pipe and the outer casing pipe, the compressing flange is arranged at the end of the outer casing pipe and provided with the compressing bolt, and the anti-dropping ring is arranged at the end, located in the outer casing pipe, of the moving pipe. The multiple two-direction sleeve expansion joint has the advantages that flowing friction resistance, caused by the multiple two-direction sleeve expansion joint, of fluid is small, and the multiple two-direction sleeve expansion joint is compact in structure, long in service life and low in construction cost; sliding surfaces are good in anti-corrosion performance under a saline water environment or a saline solution environment or other environments because of having being subjected to special treatment; when the sealing effect is weakened, the flange can be tightened again or the bolt is unloosened, one or two layers of sealing rings are arranged, and the multiple two-direction sleeve expansion joint can continue being used; the two-direction characteristic means sliding sleeves at the two ends of the expansion joint can freely slide no matter from which end media flow, and accordingly two-direction compensation is achieved, and the amount of compensation is increased.

Owner:JIANGSU XINSHENG BELLOW

Intelligent double-flow-direction compensator

InactiveCN105508794AGuaranteed not to leakGuaranteed axial slidingPipeline expansion-compensationAdjustable jointsAgeingCompensation effect

The invention discloses an intelligent double-flow-direction compensator, and relates to the technical field of pipeline compensators. The compensator comprises an inner sleeve, an outer sleeve, limiting rings, a check ring, a protecting component and a seal ring. The inner sleeve is connected with a pipeline. The outer sleeve is arranged on the periphery of the inner sleeve. The inner sleeve can freely slide in the outer sleeve when the pipeline is stretched out and drawn back. The two ends of the inner wall of the outer sleeve are provided with the limiting rings respectively. The check ring is arranged on the inner sleeve. The protecting component is arranged on the outer sleeve. The seal ring is arranged between the outer port of the outer sleeve and the inner sleeve. The seal ring is a novel flexible graphite ring made of seal material. The compensator has the advantages that the sealing requirements of any pipeline can be met; the novel synthesis material for sealing is adopted between the outer sleeve and the inner sleeve and can resist high temperature, corrosion and ageing, axial sliding can be ensured, it can be ensured that a medium in a pipe does not leak, a double-flow-direction compensation structure is adopted, a double-direction compensation effect is achieved, and the compensation amount is increased.

Owner:江苏威创能源设备有限公司

Plunger type multifunctional pipeline compensator

ActiveCN102518901AReduce stressLow running costThermal insulationPipeline expansion-compensationThermal expansionSteel ball

The invention discloses a plunger type multifunctional pipeline compensator, which belongs to the technical field of heat distribution pipeline compensation devices. A fixed sealing press cover flange and a reducing connection pipe are adopted. An outer sleeve assembly with an outer sleeve inner bearing platform, a plunger inner pipe framework and a plunger inner pipe is integrally sleeved at one end of a core pipe assembly with a plunger outer pipe framework, a plunger outer pipe, a core pipe convex outer ring and a sealing part A. A steel ball and a sealing part are used for straightening. When one end is extruded and pushed by axial thermal expansion force, the core pipe assembly and the outer sleeve assembly can synchronously, integrally and relatively move in coaxial mode. By means of the structure, stress of pipelines is reduced, sealing performance is enhanced, bearing capacity is improved, the effect of corrosion resistance is provided, and the purpose of large compensation amount and wide application scope can be achieved.

Owner:陈墅庚

Flexible compensation method and flexible compensator for building drainage pipeline

ActiveCN104595611AImprove interchangeabilityEasy to repair and replacePipeline expansion-compensationFiberEngineering

The invention relates to a flexible compensation method and a flexible compensator for a building drainage pipeline, and mainly aims to solve the technical problems of poor corrosion resistance, short service life, easiness in axis deflection of a vertical pipe, easiness in blockage of the pipeline by fiber pollutants, poor drainage performance and incapability of matching a connection way with a cast iron drainage pipe interface in the conventional pipeline compensator. The flexible compensator is arranged on a joint between drainage pipelines in order to ensure that the elongation amount can be compensated through the flexible compensation when the drainage pipelines are deformed in an extending way in a heating way. The flexible compensation method and the flexible compensator have the advantages of high corrosion resistance, long service life, prevention of axis deflection of the vertical pipe, prevention of blockage of the pipeline by the fiber pollutants, high drainage performance, and matching between the connection form and the cast iron drainage interface.

Owner:SUNS CASTING CO LTD

Novel composite type compensator for pipeline

InactiveCN102654228AReduce stressLow running costThermal insulationPipeline expansion-compensationMechanical engineeringAnti-corrosion

The invention discloses a novel composite type compensator for a pipeline, belonging to the technical field of a compensation device for a thermal pipeline. According to the novel composite type compensator for the pipeline provided by the invention, a convex outer ring for a core pipe is arranged on the core pipe; an outer connection casing pipe is coaxially and annularly sleeved on an outer ring at one end of the core pipe; a corrugated pipe is annularly sleeved on the surface of the outer ring of the core pipe, and the both ends of the corrugated pipe are respectively fastened and fixedly connected with the convex outer ring for the core pipe and a sealing head of a sealing piece A; a plunger inner pipe is sleeved at the outer side of the corrugated pipe; a plunger outer pipe is sleeved at the outer side of the plunger inner pipe, so as to form a structure that the core pipe consisting of the plunger inner pipe integrally connected with the outer ring, an annular sealing framework, a sealing piece B and the corrugated pipe can entirely coaxially and synchronously move along an axial direction when being pushed and squeezed through an axial heat expansion force. With the adoption of the structure, the novel composite type compensator has the advantages of reducing a pipeline stress, enhancing a sealing property, improving bearing capability, having anti-corrosion effect, and realizing large compensation amount.

Owner:陈墅庚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com