Nonmetal compensator

A non-metallic compensator, non-metallic technology, applied in expansion compensation devices for pipelines, pipes/pipe joints/fittings, adjustable connections, etc., to achieve good practicability, prolong service life, and improve resistance to alternating temperatures effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

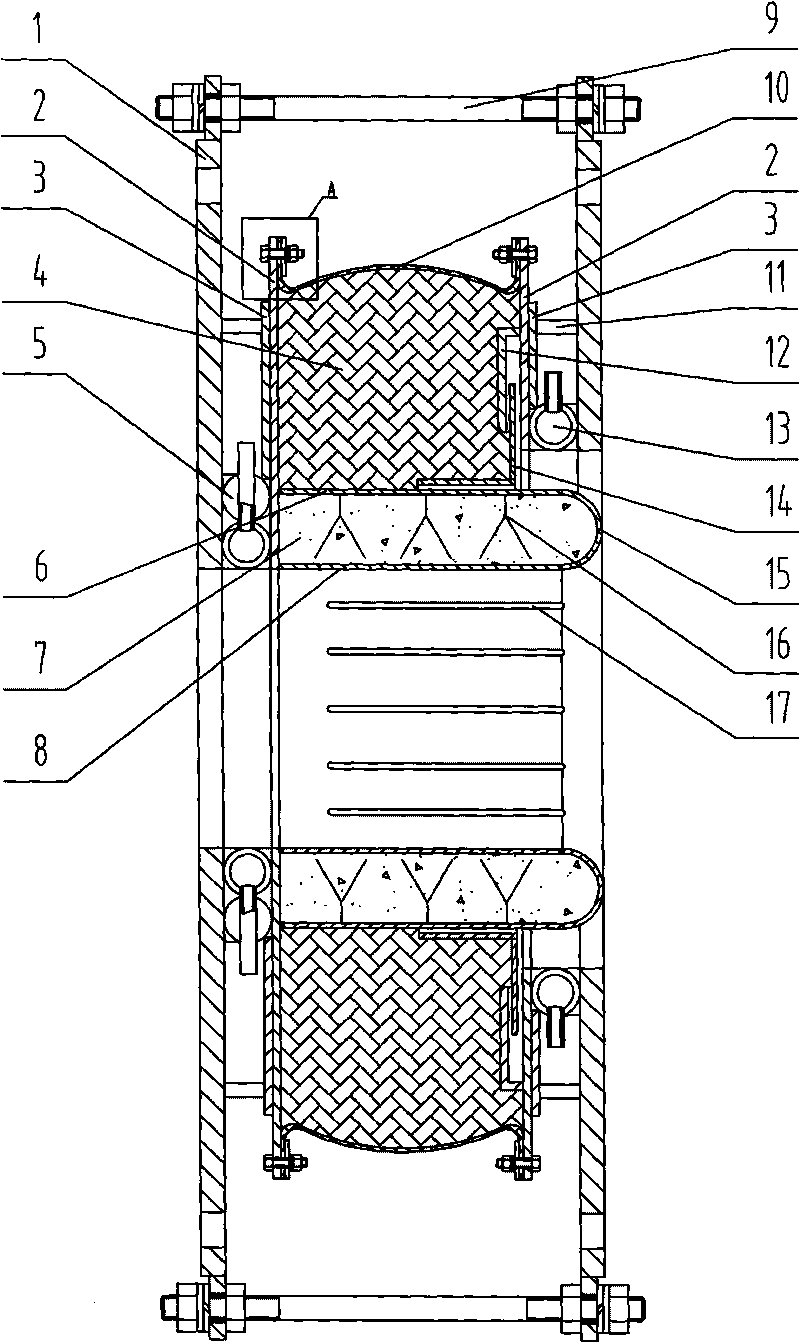

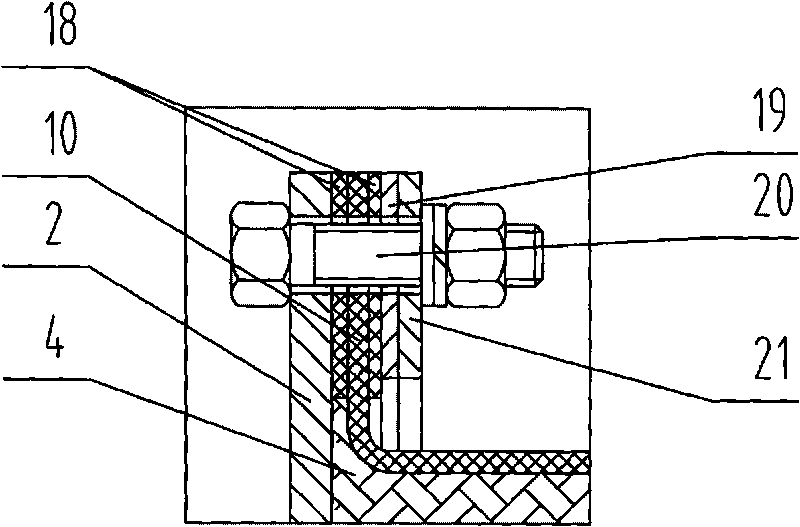

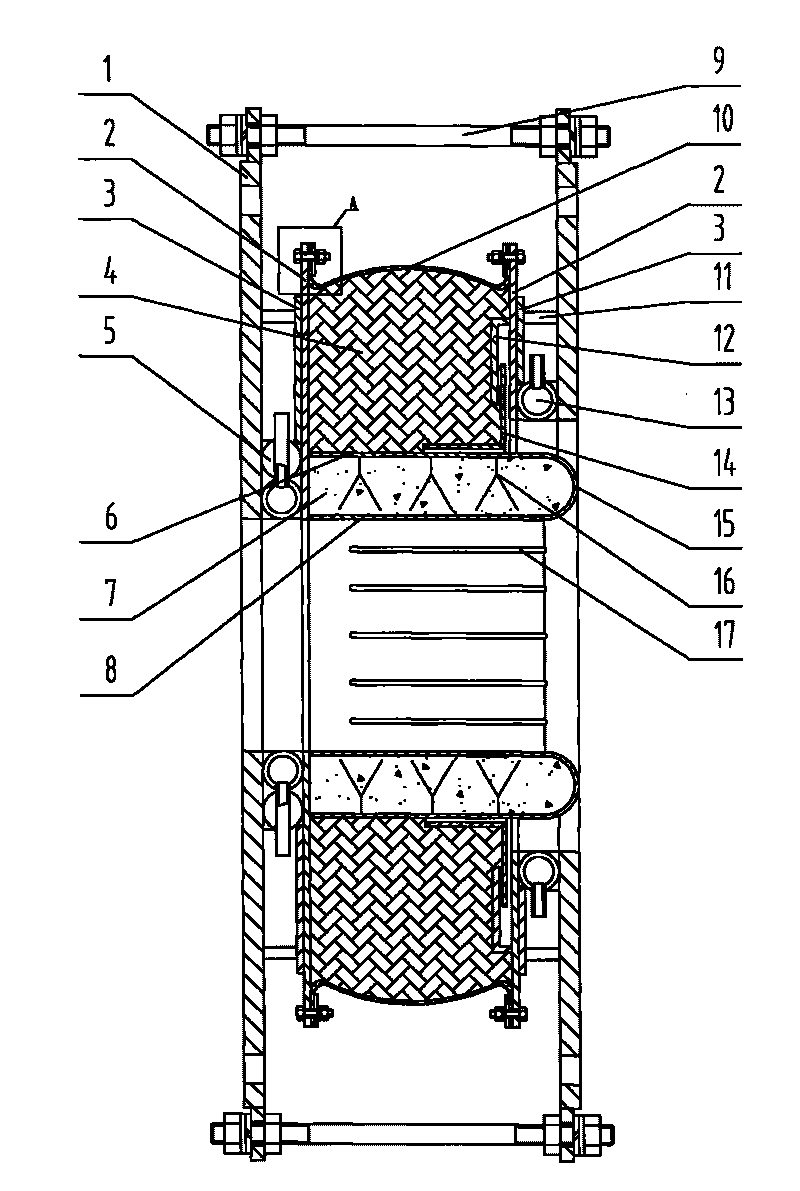

[0031] A non-metallic compensator, including a flange 1, a ring plate 2, an inner sleeve I 6, an inner sleeve II 8, an inner sleeve cover plate 15 and a non-metallic composite layer 10, the non-metallic composite layer 10 is fixed by bolts 20 On the ring plate 2, the inner sleeve I6 and the inner sleeve II8 are welded on the ring plate 2, and the two ends of the inner sleeve cover plate 15 are respectively welded on the inner sleeve I6 and the inner sleeve II8.

[0032] Casting material 7 capable of withstanding a high temperature of 1200°C is poured between the inner sleeve I 6 , the inner sleeve II 8 and the cover plate 15 to form the heat insulation layer of the compensator.

[0033] The space formed by the non-metallic composite layer 10, the ring plates 2 at both ends and the inner sleeve 16 is filled with a high-temperature-resistant heat-insulating material 4, forming the thermal insulation layer of the compensator.

[0034] The thermal insulation material 4 is a high-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com