Clutch and variable speed driving hub

A clutch and hub technology, applied in the fields of variable-speed drive hubs, motors, clutches, and transmission components, can solve the problems of clutch failure, harsh noise, etc., and achieve the effects of long service life, large compensation, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

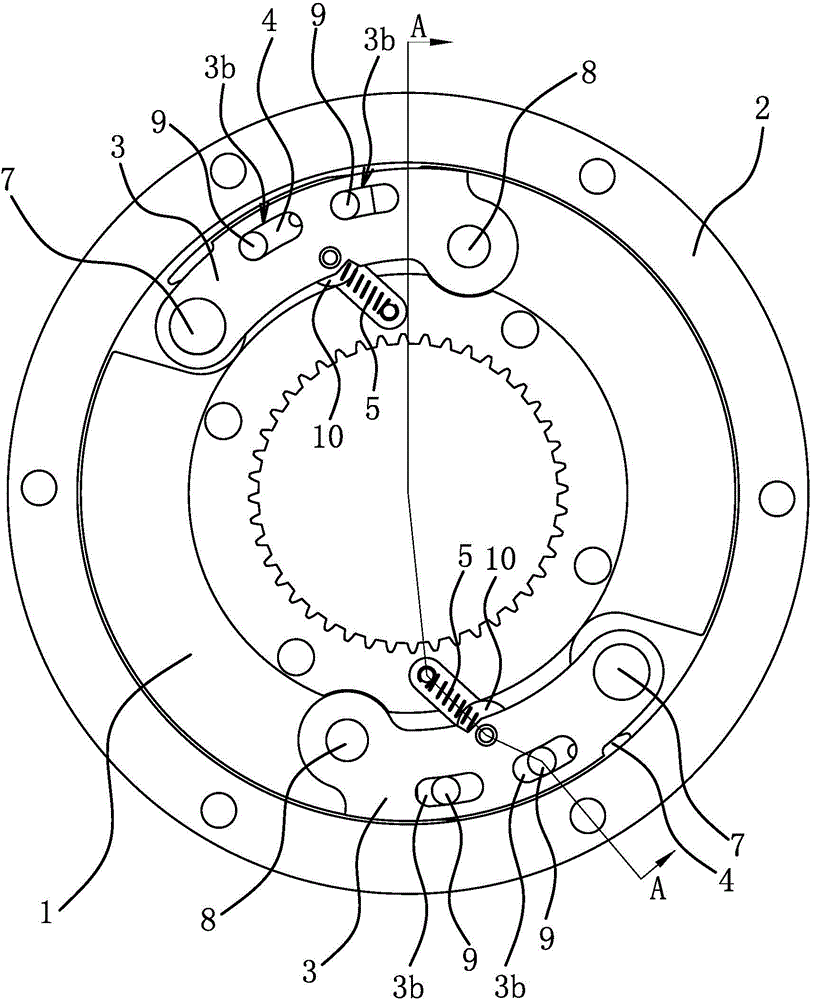

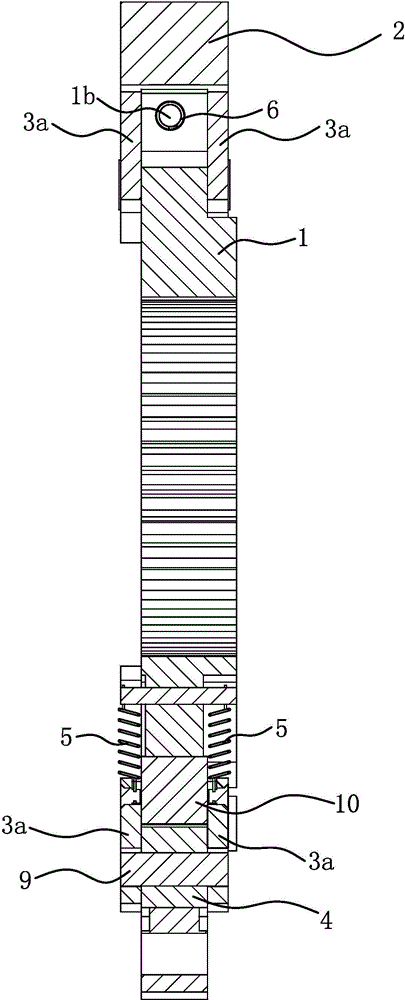

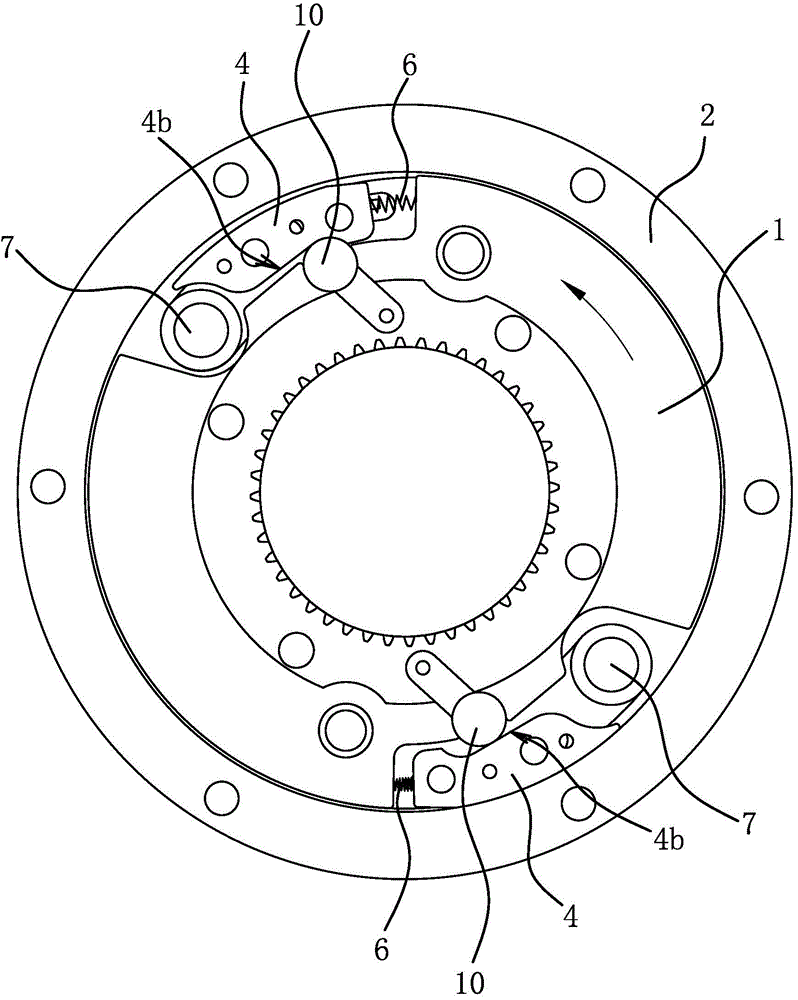

[0039] Such as Figure 1 to Figure 4 As shown, the clutch includes an inner connecting plate 1 , a friction ring 2 , a swing arm 3 , a friction block 4 , a first elastic member 5 and a second elastic member 6 .

[0040]The inner connecting plate 1 is circular, and the friction ring 2 is sleeved outside the inner connecting plate 1 , and the inner connecting plate 1 and the friction ring 2 are arranged coaxially. The number of swing arms 3 is at least two groups, and the swing arms 3 are evenly distributed along the circumference of the inner connecting plate 1; the number of swing arms 3 given in the drawings of this specification is two groups; . The other end of the swing arm 3 is fixedly connected with a first counterweight 7 . Specifically, each set of swing arms 3 includes two strip-shaped swing plates 3a, and the two swing plates 3a are respectively located on both sides of the inner connecting plate 1; a hinge shaft 8 is fixed on the inner connecting plate 1, and the ...

Embodiment 2

[0055] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described redundantly. Only the differences will be described. The difference is that the other end of the swing arm 3 is not fixed with the first counterweight 7, the friction block 4 is connected to the other end of the swing arm 3 .

Embodiment 3

[0057] The structure and principle of this embodiment are basically the same as those of Embodiment 1, and the basic similarities will not be described in detail. Only the differences are described. The difference is that the first elastic member 5 is a torsion spring, and the torsion spring has a cylindrical shape. The winding part and two rod-shaped force parts, the cylindrical winding part is sleeved on the hinge shaft 8, one rod-shaped force part is connected with the inner connecting plate 1, and the other rod-shaped force part is connected with the swing arm 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com