Novel composite type compensator for pipeline

A composite and compensator technology, which is applied to the structure of thermal pipeline compensation device and the field of thermal pipeline compensation device, can solve the problems of weak anti-corrosion link, large gap, leakage and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

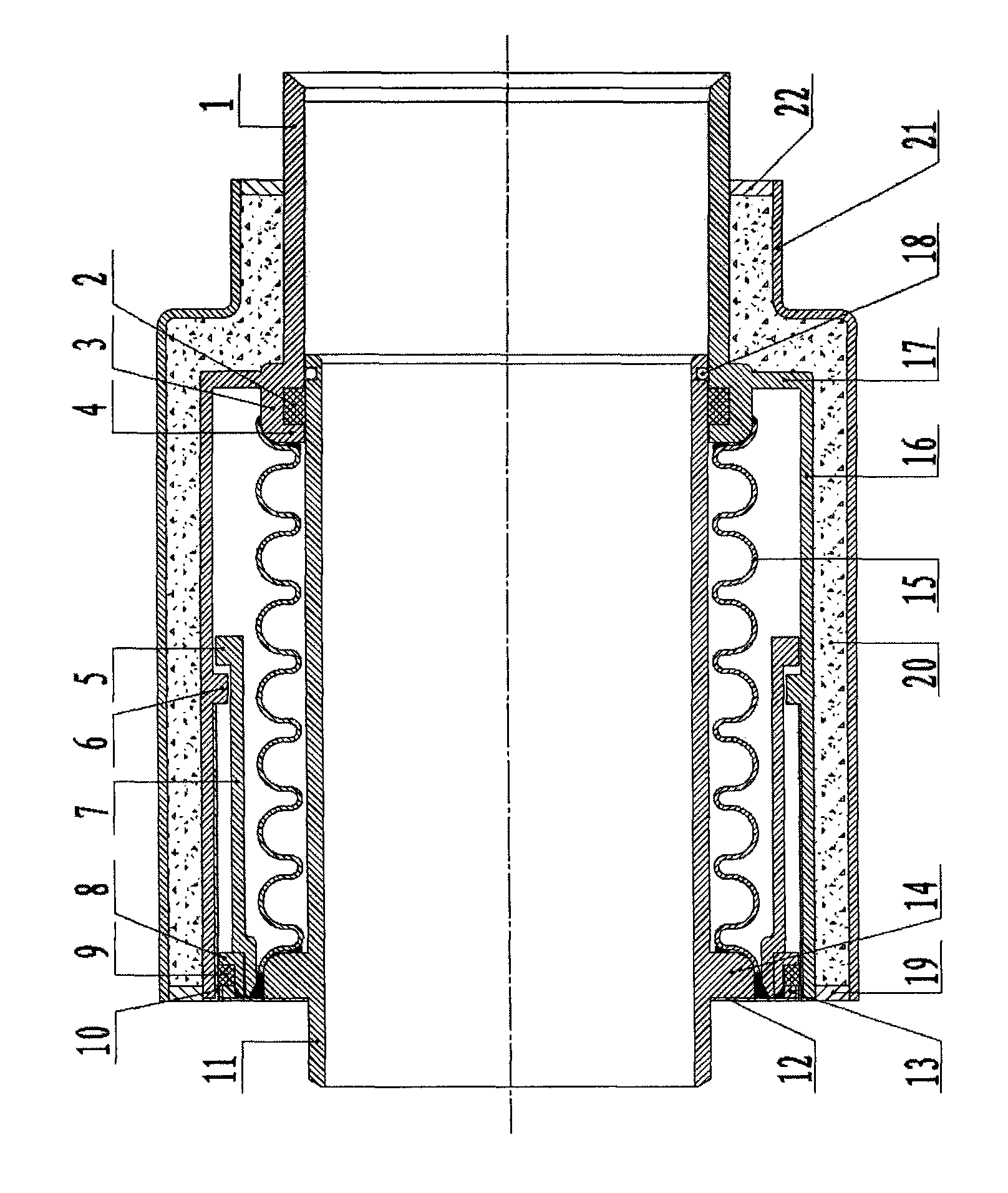

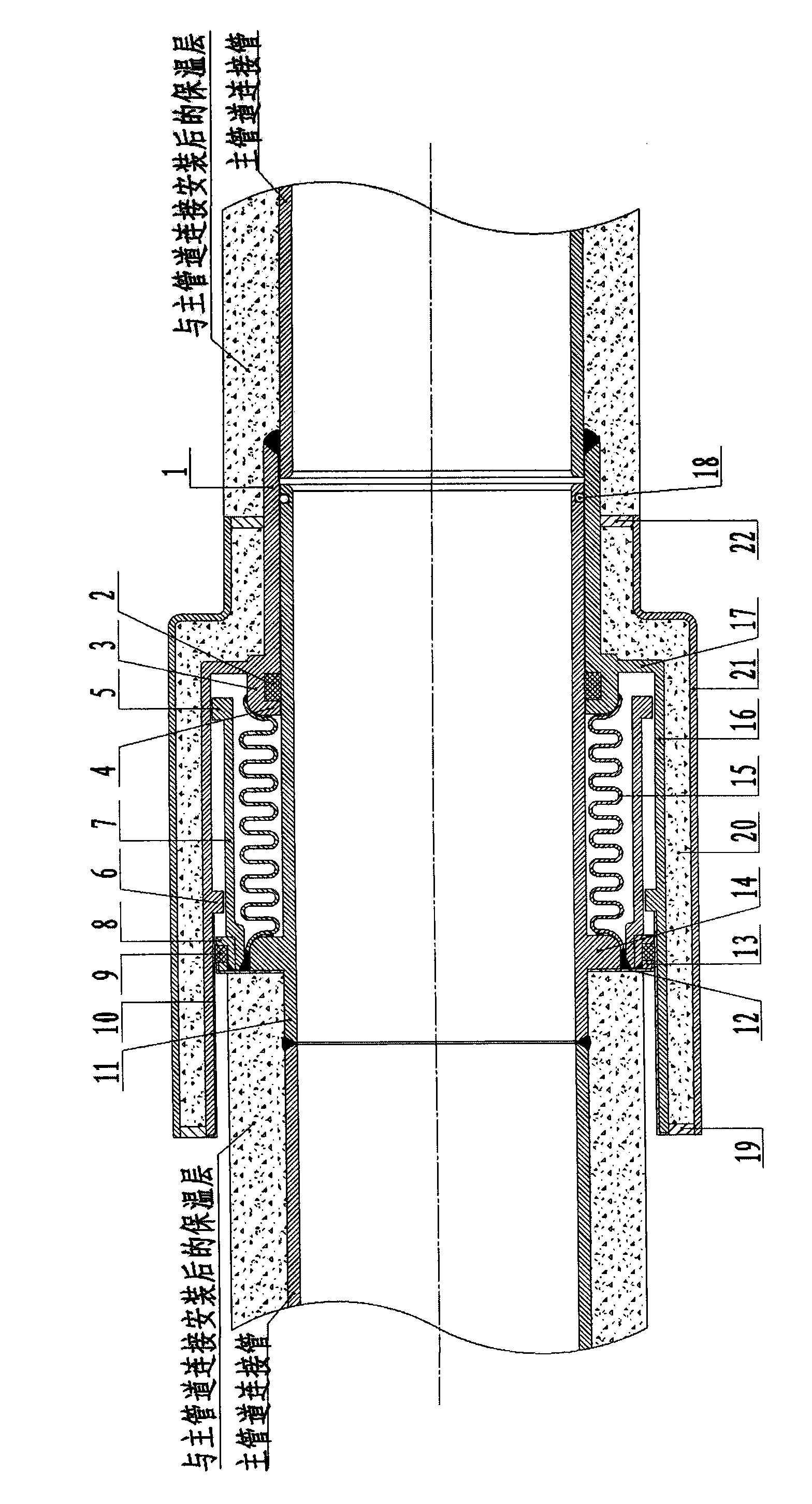

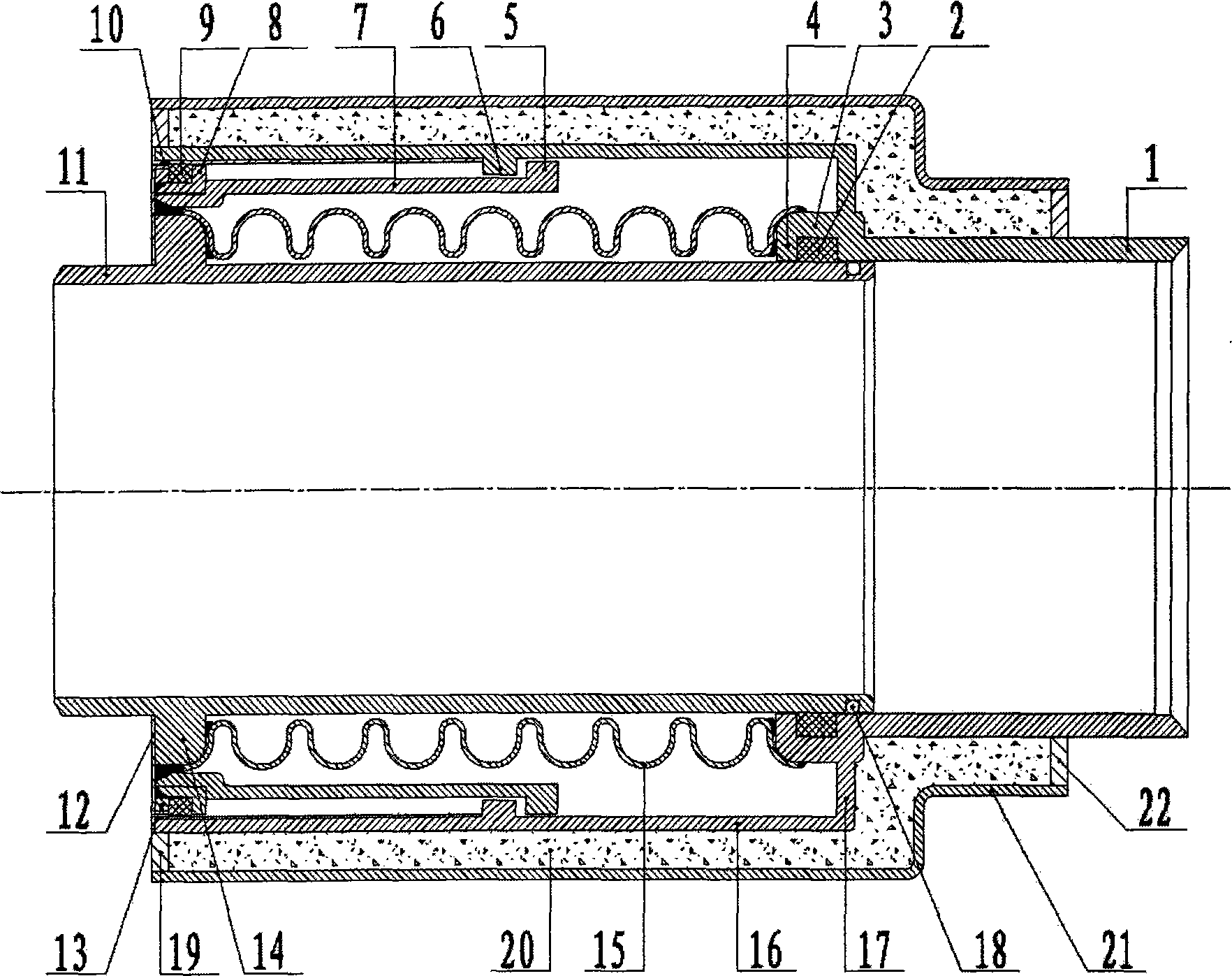

[0052] Below with the accompanying drawings figure 1 (Schematic diagram of the structure before absorption heat displacement) and figure 2 (Schematic diagram of the structure after absorbing thermal displacement) The technical solution of the present invention is described in detail as follows.

[0053] like figure 1 A schematic diagram of the structure before absorbing heat displacement, a new composite compensator for pipelines, including outer connecting sleeve 1, seal A2, outer connecting sleeve convex outer ring 3, seal A head 4, plunger inner tube Convex outer ring 5, anti-pull-off limit ring 6, plunger inner tube 7, annular sealing structure 8, seal B9, anti-corrosion layer A10, core tube 11, anti-corrosion layer B12, seal B head 13, core tube convex Outer ring 14, bellows 15, plunger outer pipe 16, plunger outer pipe structure 17, steel ball 18, anti-corrosion jacket structure A19, heat insulating filler 20 anti-corrosion jacket 21 and anti-corrosion jacket structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com