Plastic pipeline expansion piece

A technology of plastic pipes and expanders, which is applied in the direction of pipe protection, pipe connection arrangement, and heat insulation protection of pipes, etc., which can solve problems such as weak anti-corrosion links, leakage, poor structure and sealing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

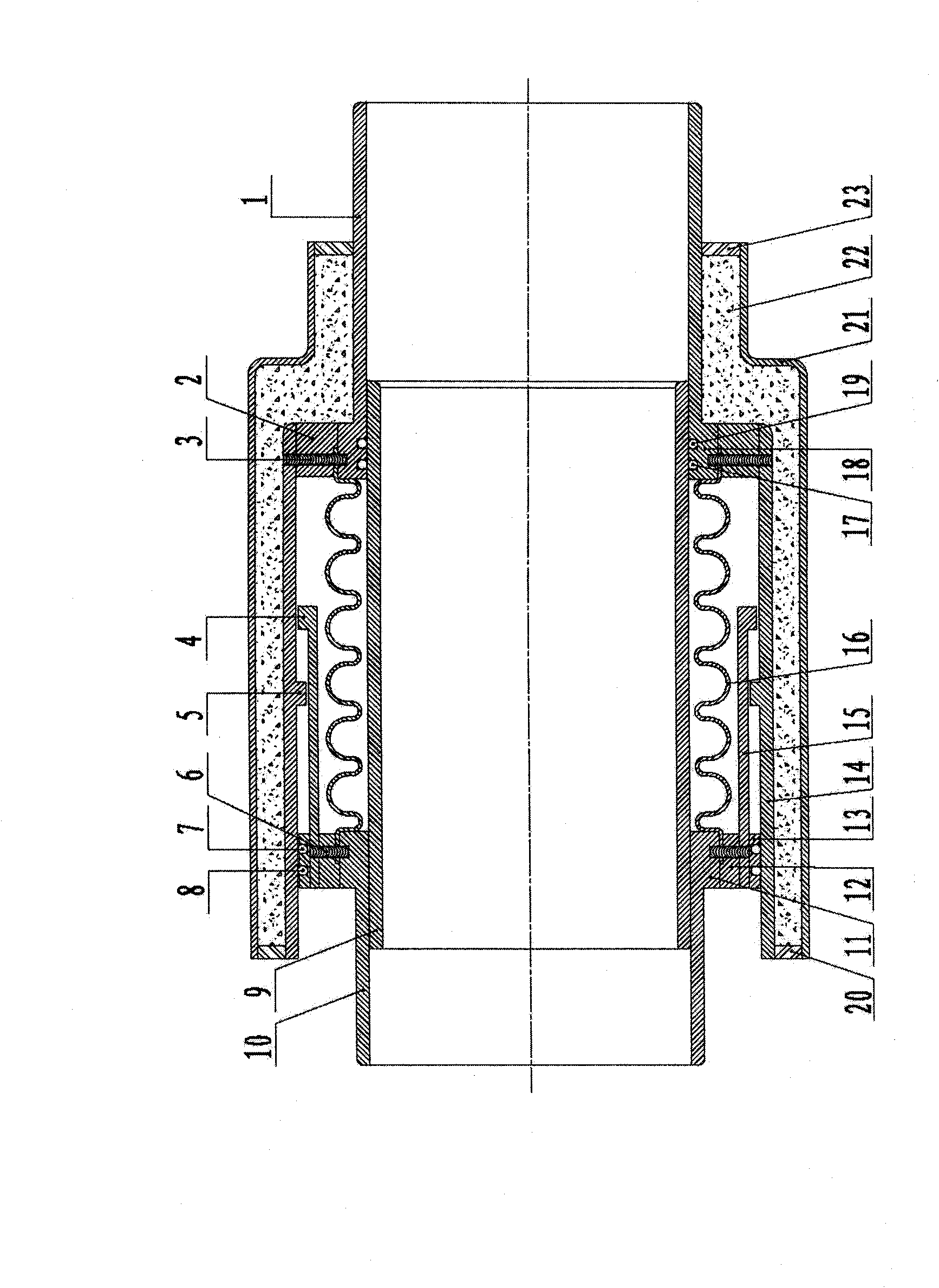

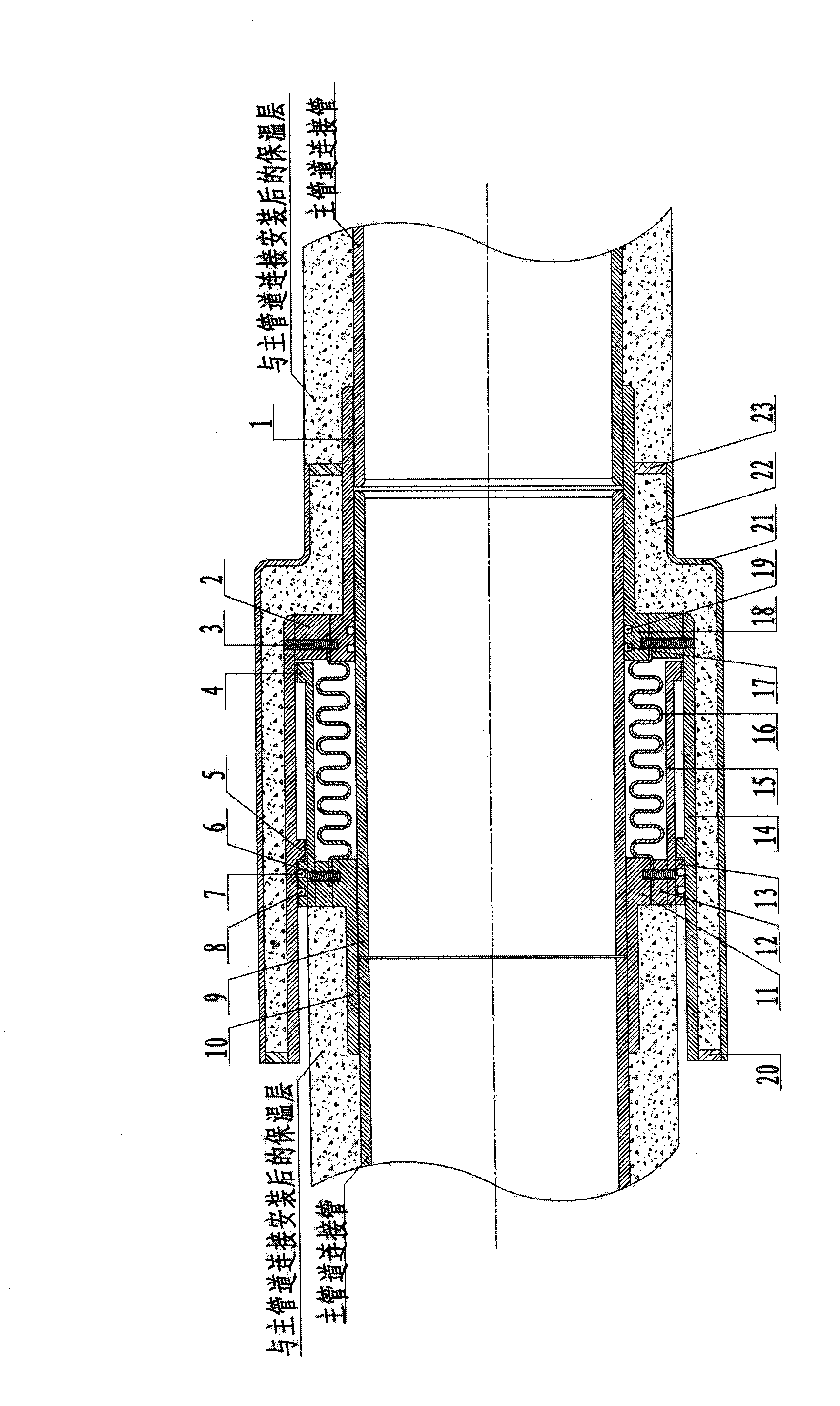

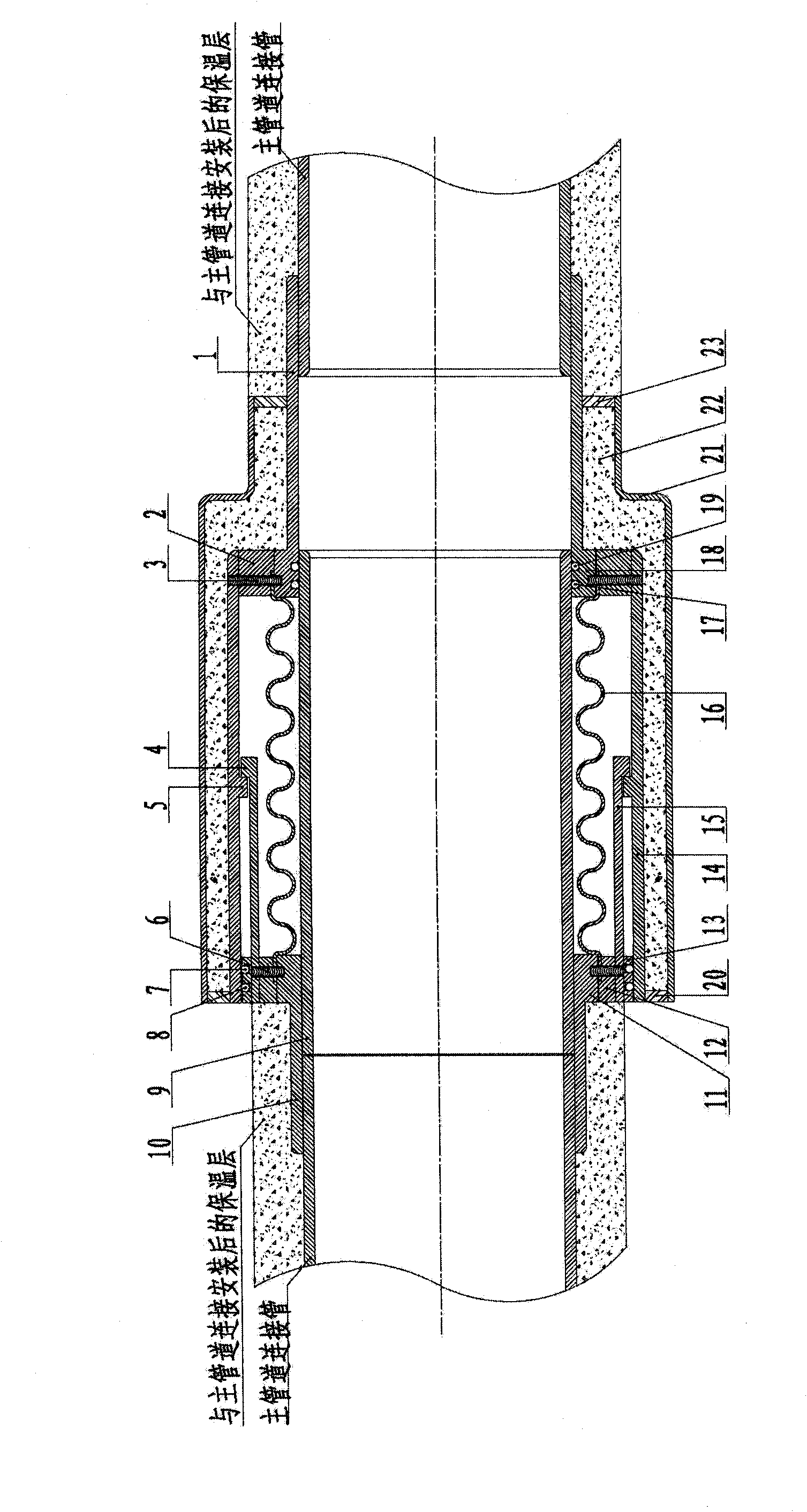

[0054] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings.

[0055] Such as figure 1 , figure 2 , image 3 As shown, a retractor for plastic pipes includes an outer connecting sleeve A1 made of plastic material, an outer plunger tube frame 2, a fixed reinforcement pin A3, a convex outer ring of the plunger inner tube 4, and an anti-pull-off limit ring 5. Fixed reinforcement pin B 6. O-ring seal B7, O-ring seal A8, core tube 9, outer connecting sleeve B10, outer connecting sleeve B convex outer ring 11, plunger inner tube structure 12, annular sealing structure 13. The plunger outer tube 14, the plunger inner tube 15, the bellows 16, the O-ring C17, the outer connecting sleeve A, the convex outer ring 18, the O-ring D19, the anti-corrosion jacket structure A20, the anti-corrosion jacket 21, the thermal insulation packing 22 and anti-corrosion jacket structure B23;

[0056] The outer ring of one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com