Thermal expansion amount control method of numerical control flame cutting steel plate part sizes

A technology of flame cutting and thermal expansion, which is applied in the direction of gas flame welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of restricting the dimensional accuracy and production efficiency of CNC flame cutting, not allowing multiple trial cutting, and large size deviation of parts , to achieve the effect of eliminating adverse effects, stable and reliable dimensional accuracy, and small dimensional deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

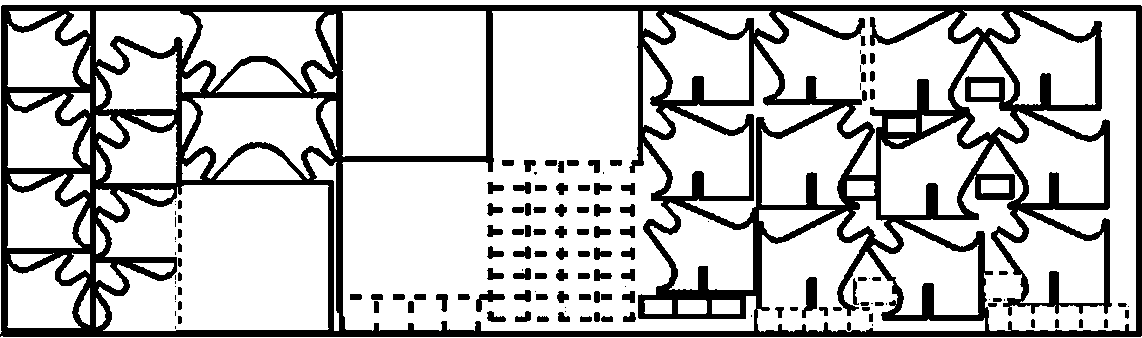

[0034] The steel plates of 4 sets of 85 tons ladles are cut by conventional CNC flame cutting, such as figure 1 For the discharge of the steel plate parts shown, when the thermal expansion △t is not added to the slot compensation K, due to the small size of the parts, the large number, and the intensive discharge, a large amount of heat is input into the steel plate during cutting, and the dotted line in the figure is due to thermal expansion. Dimensional deviations occur after the parts cool down. The specific parameters are as follows:

[0035] The weight of the blanking part is: 139.31 tons, the pass rate of the blanking is: 95%, the average price of the plate: 5000 yuan / ton, the labor wage: 332 yuan / day / person, the daily consumption: 120 yuan / ton, the scrap steel price: 2500 yuan / Ton.

[0036] The resulting damage is calculated as follows:

[0037] The size does not match the weight: 139.31 tons × 5% = 6.96 tons,

[0038] Labor wages: 332×6.96×2=2312 yuan,

[0039] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com