Complex industrial process data modeling method based on dynamic convolutional neural network

A convolutional neural network and industrial process technology, applied in the field of data-driven soft sensor modeling, can solve the problems of inconsistent data time series correlation, gradient dispersion, and inability to effectively analyze the dynamic characteristics of the process, so as to eliminate adverse effects and reduce The effect of parameter scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

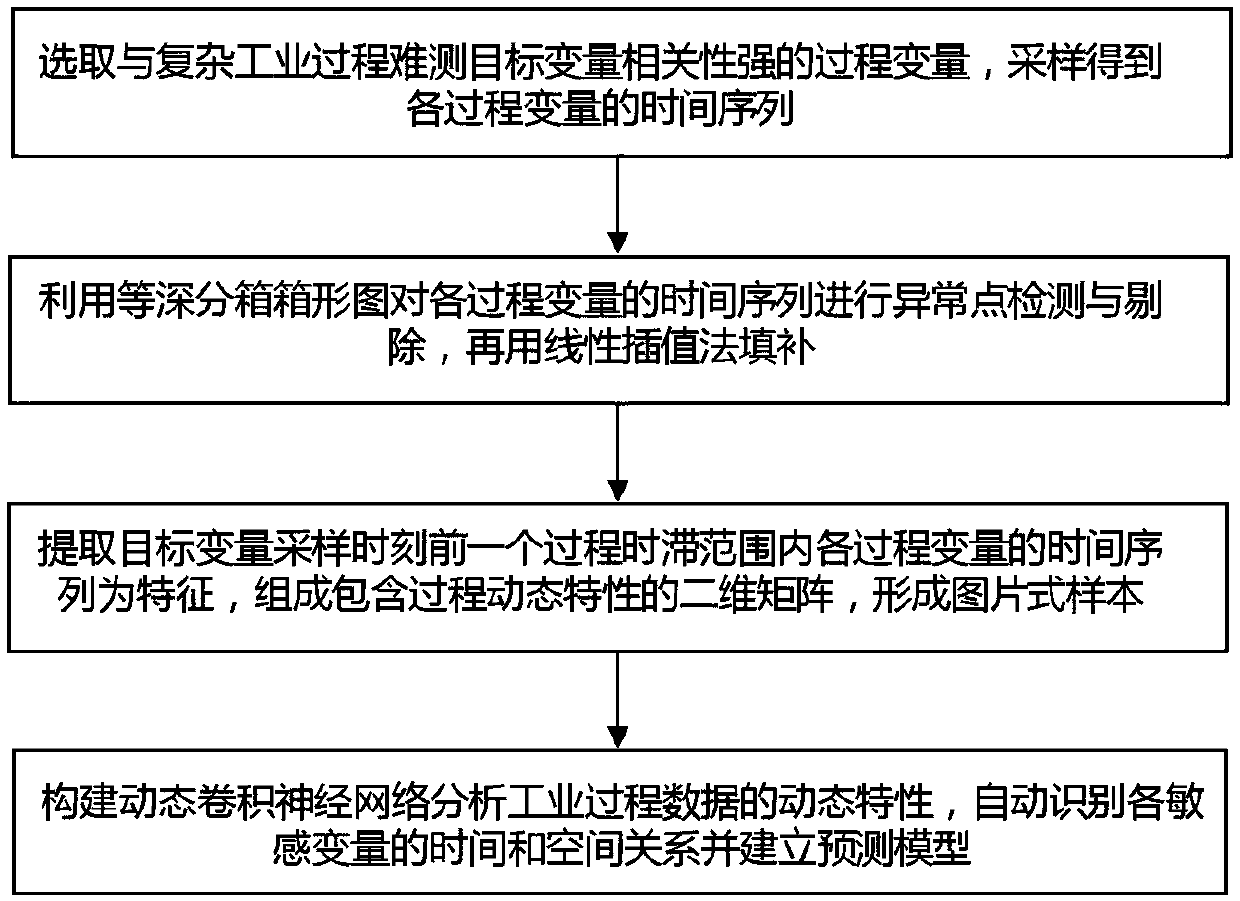

[0024] like figure 1 As shown, this embodiment provides a complex industrial process data modeling method of a dynamic convolutional neural network, comprising the following steps:

[0025] a. Select process variables that are strongly correlated with difficult target variables in complex industrial processes, and obtain the time series of each process variable by sampling;

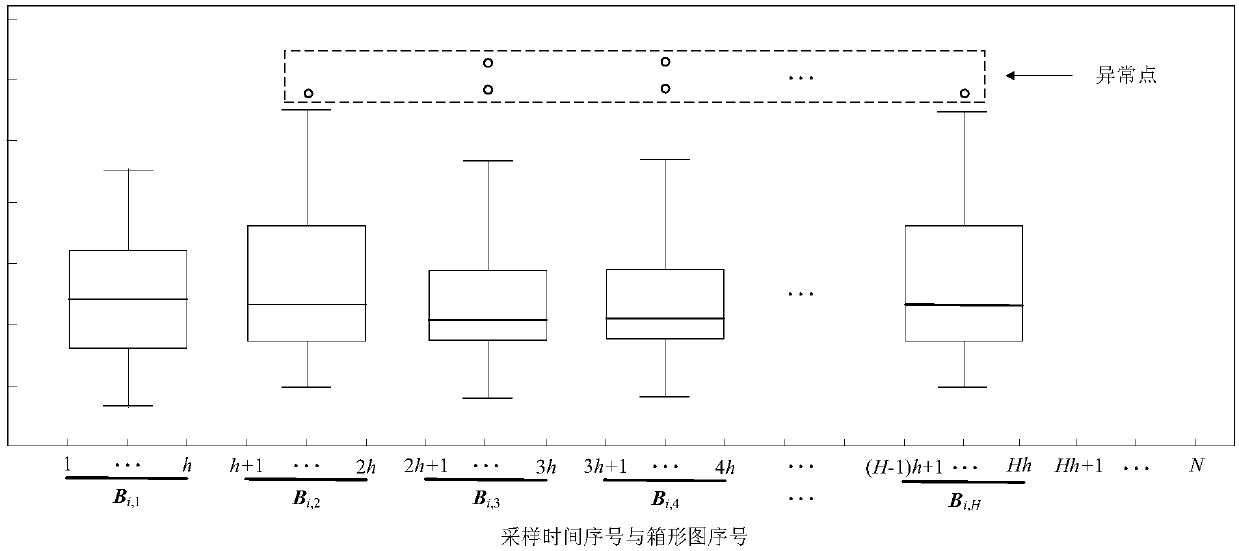

[0026] b. Use the iso-depth binned box diagram to detect abnormal points in the time series of each process variable, and remove the detected abnormal points, and then use linear interpolation to fill in the removed abnormal point positions;

[0027] c. Extract the time series of each process variable within the range of process time lag before the sampling time of the target variable as a feature, form a two-dimensional matrix containing the dynamic characteristics of the process, and form a picture sample;

[0028] d. Construct a dynamic convolutional neural network (DCNN) to analyze the dynamic charac...

Embodiment 2

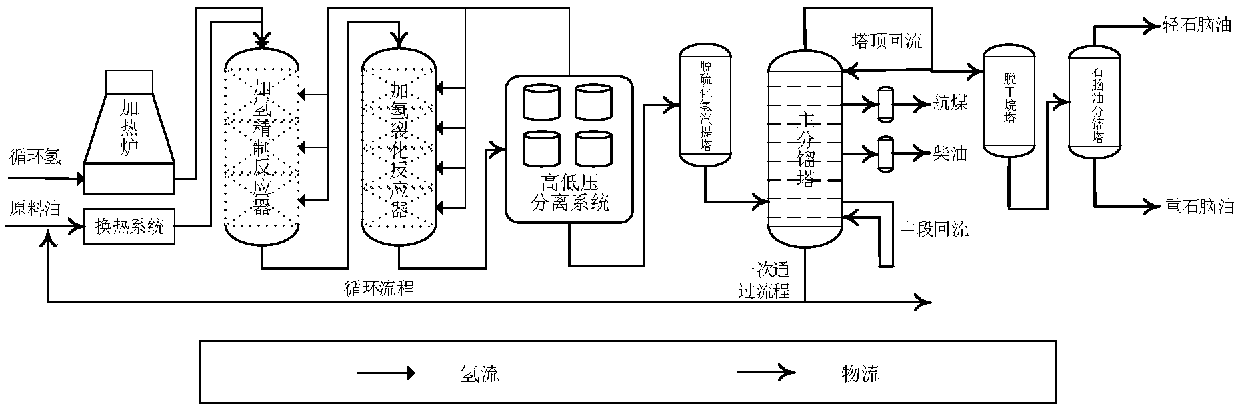

[0095] like figure 2 , 3 , 4, 5, 6, 7 and 8, on the basis of the above embodiments, this embodiment further provides a method for predicting the quality of diesel products in a hydrocracking process, using a dynamic convolutional neural network as described above A complex industrial process data modeling approach for the prediction of diesel product quality in hydrocracking processes.

[0096] Specifically, the hydrocracking process diesel product quality prediction method includes the following steps:

[0097] a, according to the hydrocracking process (such as figure 2 (shown) operating procedures and post operation methods, through mechanism analysis, a total of 38 process variables that are highly correlated with the quality of diesel products in the hydrocracking process are selected, as shown in Table 1;

[0098] In this embodiment, the sampling time interval T=5min is determined according to the modeling requirements, and 126,720 samples are taken from the extracte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com