Universal orthogonal coupler

A coupling and universal technology, which is applied in the direction of couplings, elastic couplings, wind power generation, etc., can solve the problems of short distance between shaft ends, large compensation amount, and inability to compensate the runout between shafts, etc., and achieve the distance between shaft ends The effect of small size, large amount of compensation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical implementation process of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

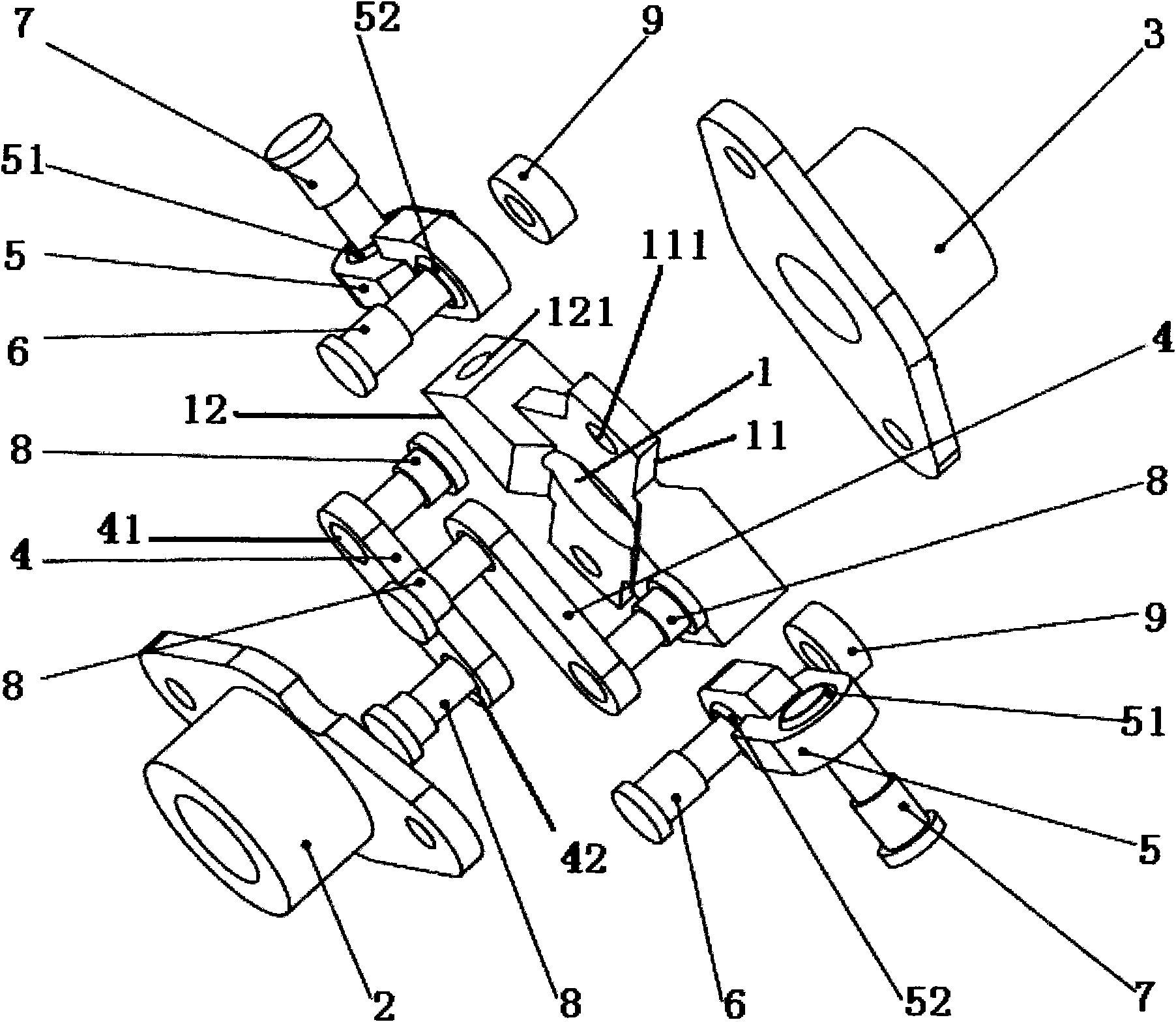

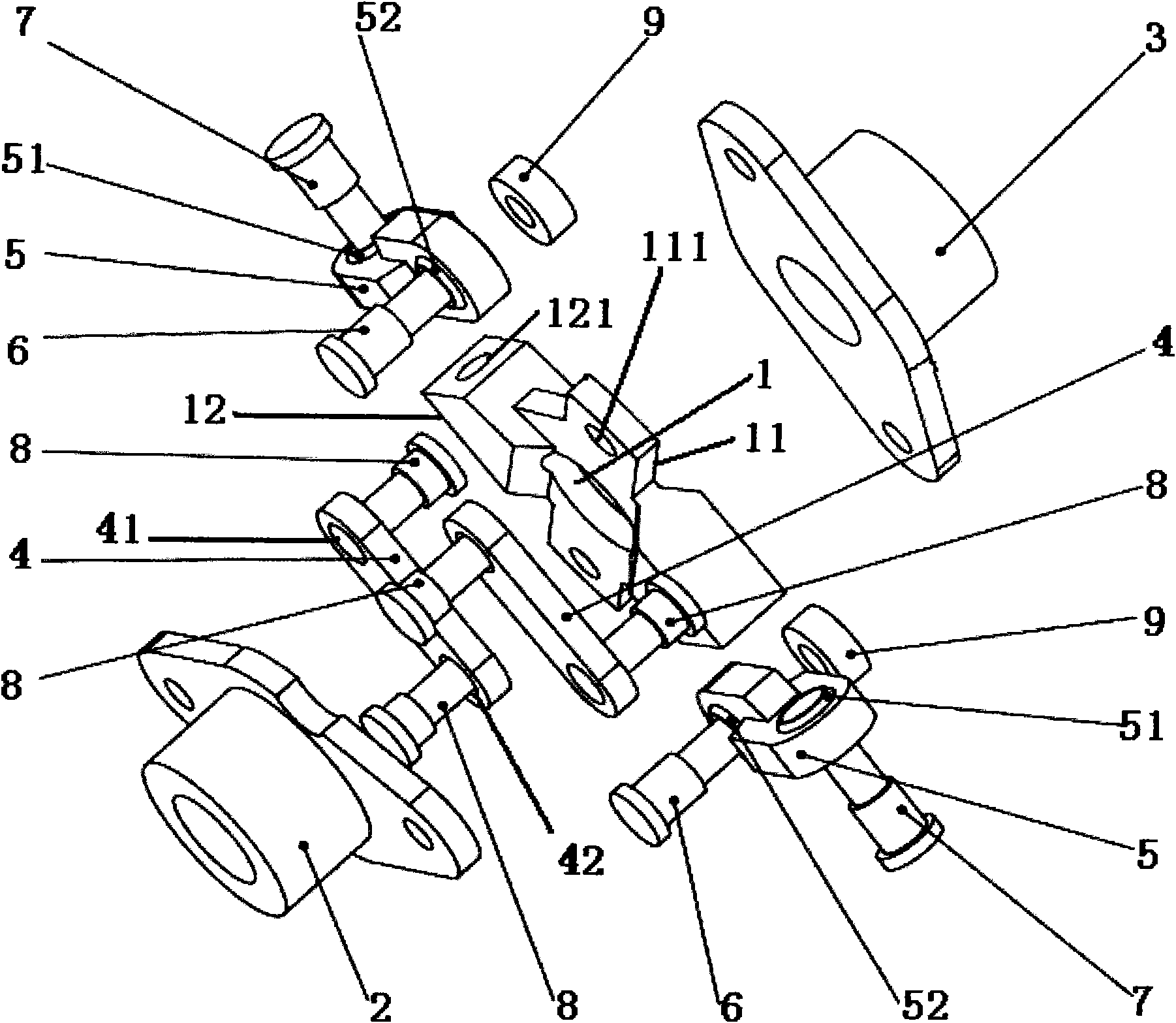

[0028] see figure 1 As shown, a universal orthogonal shaft coupling includes an intermediate bracket 1, a fixed shaft seat 2 and a universal shaft seat 3, and the fixed and universal shaft seats 2 and 3 are provided with pin shafts at both ends There is a structure with a shaft hole in the middle of the hole; the middle support 1 is a symmetrical cross structure in pairs, and the first symmetrical support 11 of the cross structure is a structure with a fixed pin shaft hole 111 on the plane. The second symmetrical support 12 is a structure in which the middle pin hole 121 is opened on the end face; the fixed shaft seat 2 is fixed on the first symmetrical support 11 through a parallel connecting arm 4; The connecting arm 5 is movably connected to the second symmetrical support 12 .

[0029] Further, a first fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com