Flexible compensation method and flexible compensator for building drainage pipeline

A compensation method and building drainage technology, which are applied to expansion compensation devices, pipe components, pipes/pipe joints/pipe fittings for pipelines, etc., can solve the problem that the connection form cannot be matched with the interface of the cast iron drainage pipe, and the fibrous sewage hangs. Blockage, offset of riser axis and other problems, to achieve the effect of low cost, long service life and smooth inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A method for compensating for expansion and contraction of building drainage pipes in this embodiment, the steps are: installing expansion compensators at the joints of drainage pipes to ensure that when the drainage pipes are heated and deformed and elongated, the elongation can pass through the expansion The compensator is compensated.

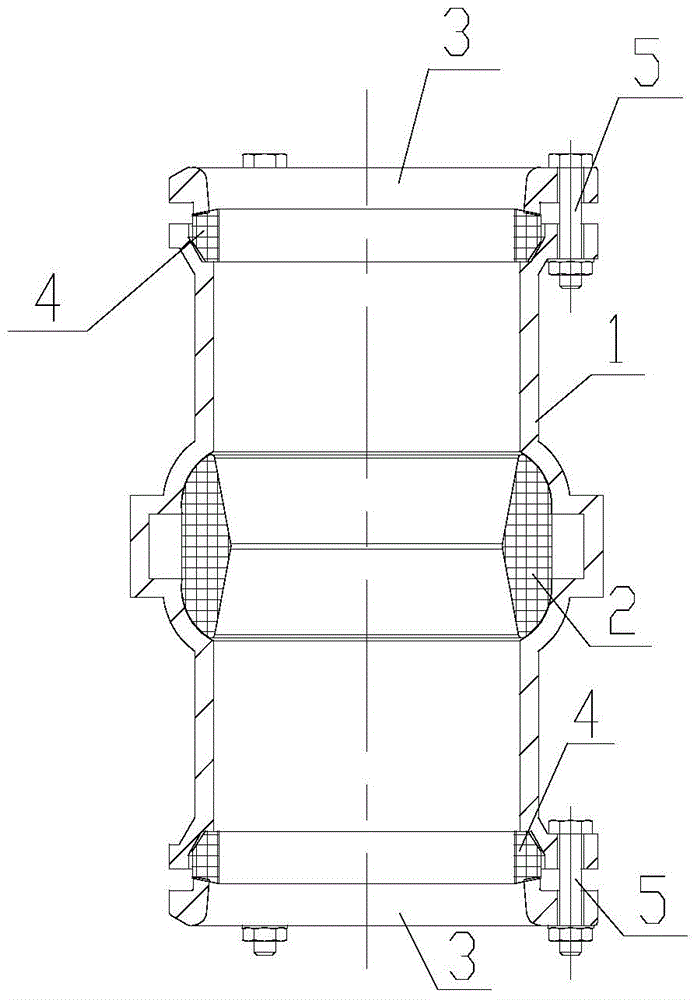

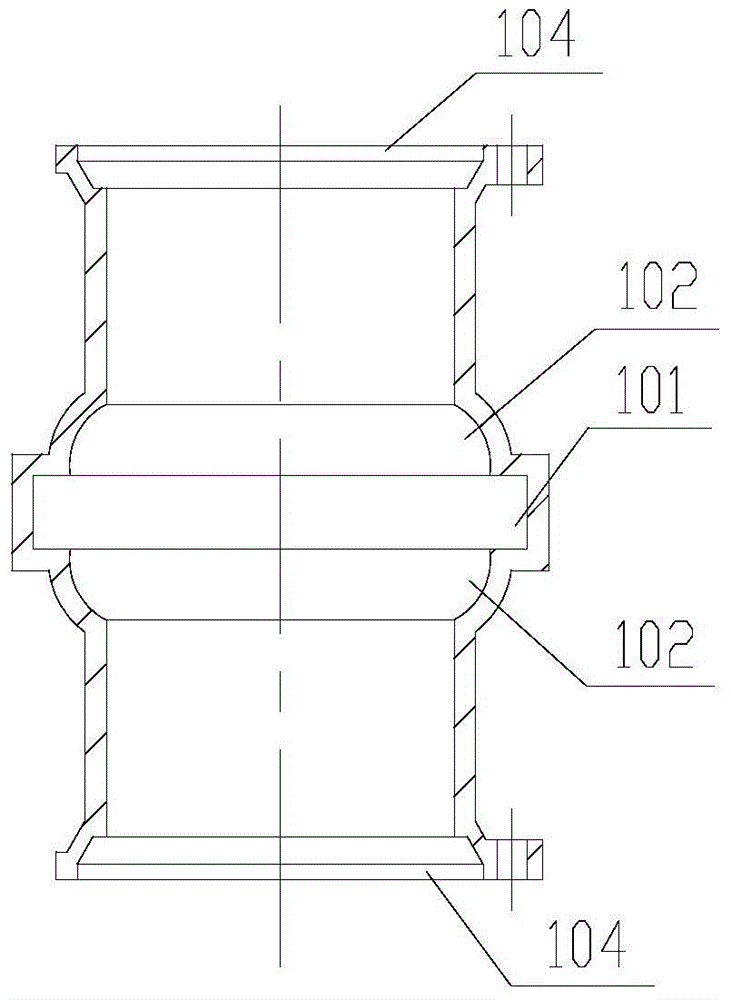

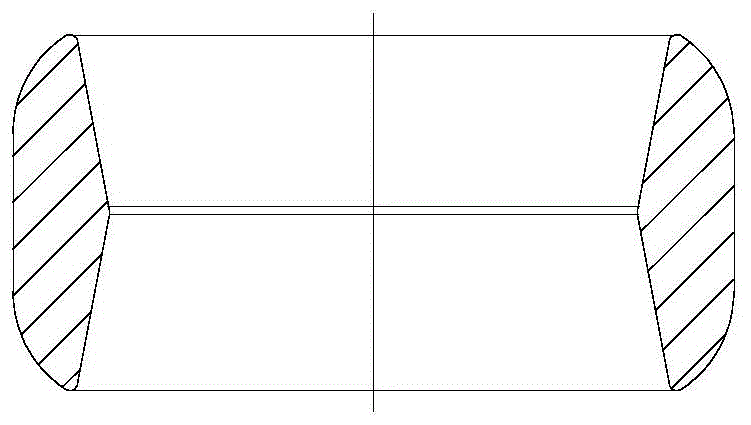

[0021] Such as Figure 1~5 As shown, the telescopic compensator in this embodiment includes a flange gland 3, a sealing rubber ring 4, fastening bolts 5, a telescopic compensator body 1 made by casting and a EPDM rubber material. The compensating rubber ring 2, the telescopic compensator body 1 is a cylinder body, the two ends of the telescopic compensator body 1 are provided with flanges 104, and the middle part of the telescopic compensator body 1 is provided with a compensating rubber ring installation groove 102 , the compensation rubber ring compensation groove 101 is provided in the middle of the compensation rubber ring instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com