PE (poly ethylene) corrugated compensator for high-temperature water

A corrugated compensator and high-temperature water technology, applied in the field of compensators, can solve the problems of unreasonable selection of compensating piping systems, high construction and installation accuracy, and failure to reach expected life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

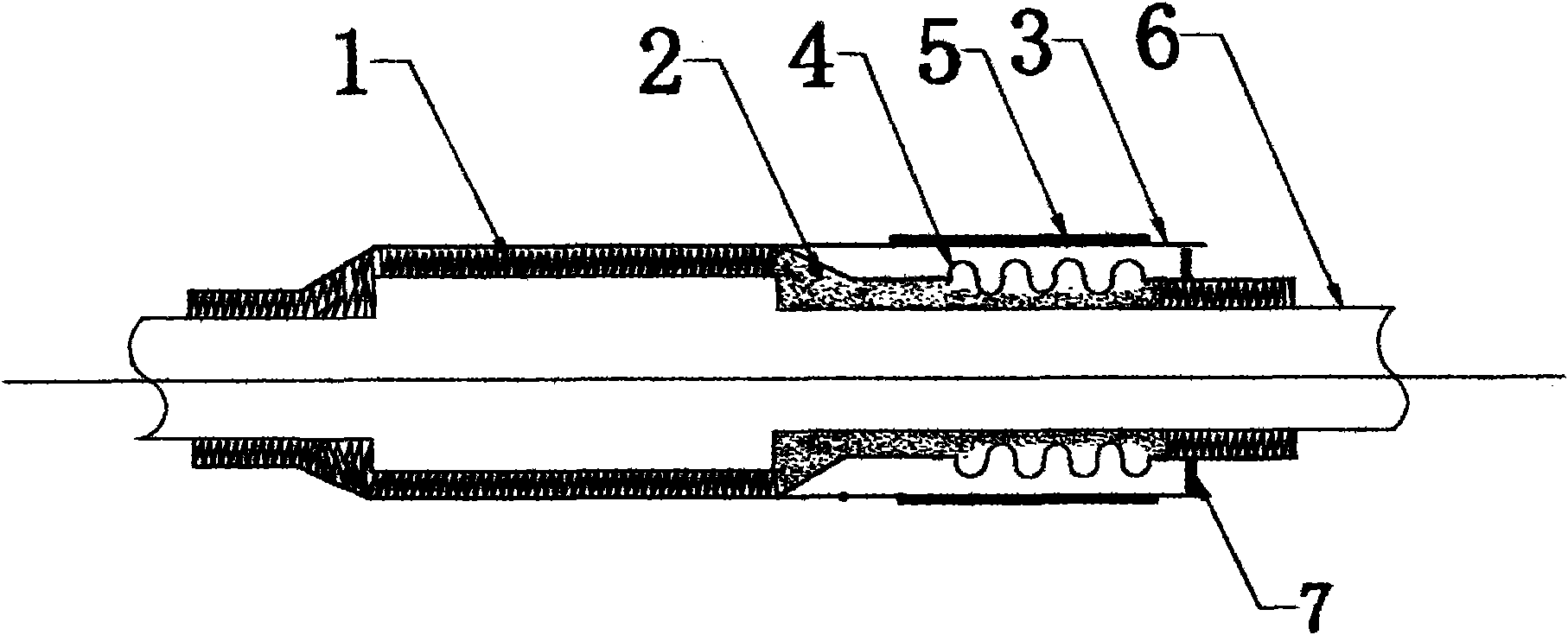

[0013] As shown in the figure, the high-temperature water PE corrugated compensator of the present invention includes a working tube compensator 6 that is covered with a hard insulation layer 1 and a soft insulation layer 2, and is tightly wrapped around the hard insulation layer 1 and the soft insulation layer. The polyethylene outer sleeve 3 outside the insulation layer 2, the hard insulation layer 1 is tightly wrapped around one end of the working tube compensator 6 and the raised part; the soft insulation layer 2 is tightly wrapped around the other end of the working compensator 6; The outer edge of the quality insulation layer 2 is provided with bellows 4.

[0014] The above bellows 4 may be PE bellows. Simultaneously, the outer edge of the above-mentioned polyethylene outer sleeve can also be provided with a protective cover 5 . The connection between the above-mentioned bellows 4 and the polyethylene outer sleeve 3 is heated and connected with resin. The material of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com