Coaxial two-way external pressure type anti-twisting expansion joint

A technology of external pressure and expansion joints, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of bellows fatigue damage and other problems, so as to improve service life, facilitate installation, The effect of a large amount of compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following, the present invention will be further explained based on the drawings and the embodiments.

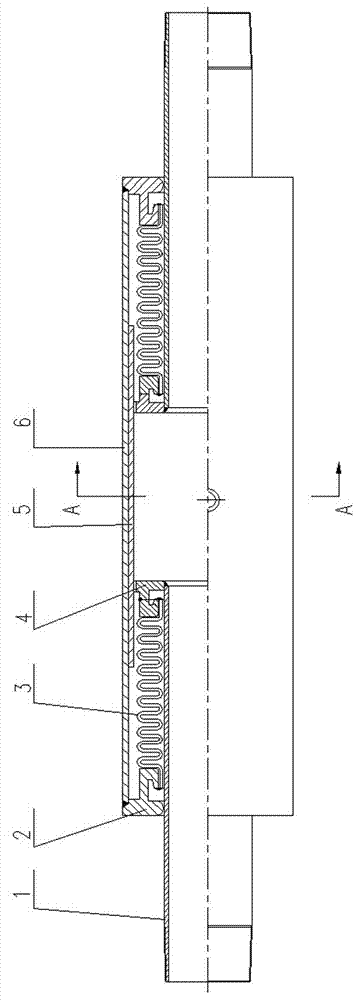

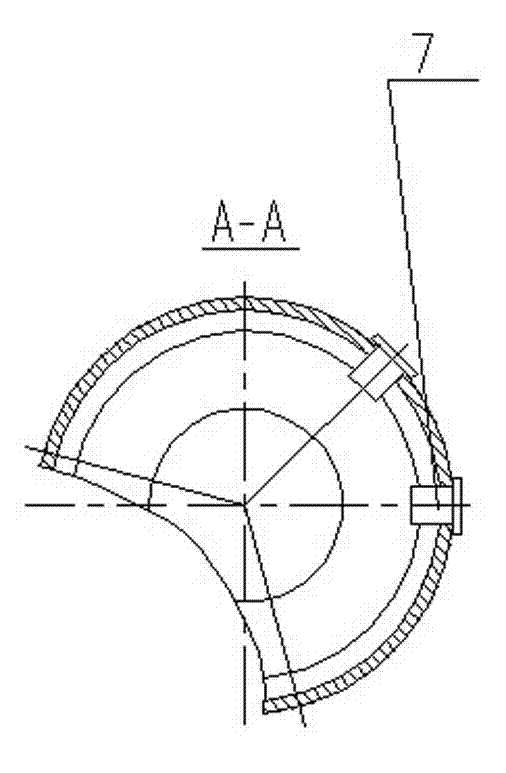

[0017] figure 1 The shown coaxial two-way external pressure torsion-resistant expansion joint is composed of an inner tube 1, an outer joint 2, a bellows 3, an inner joint 4, a key bar 5, an outer tube 6 and a pin 7. The outer tube 6 is a round straight tube, which is a housing member in the present invention, and the inner tube wall of the middle section of the outer tube 6 is fixedly connected with the axially installed key strip 5. The inner tube 1 extends into the inner cavity of the outer tube 6 from both ends. On the outer wall of the inner tube 1 of the overlapping section, the inner tube 1 is sleeved from the inside to the outside, and the inner joint 4, the bellows 3 and the outer joint 2 are connected in sequence. 1 The inner end hole and the inner joint 4 are sealed and connected to form an independent axial compensation component. This embodiment is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com