Safety anti-explosion self-sealing rotary compensator

A rotary compensator and self-sealing technology, which is applied in expansion compensation devices for pipelines, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of lack of secondary explosion-proof measures, low safety factor and unable to apply pipelines, etc. Achieve the effect of simple structure, low cost and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

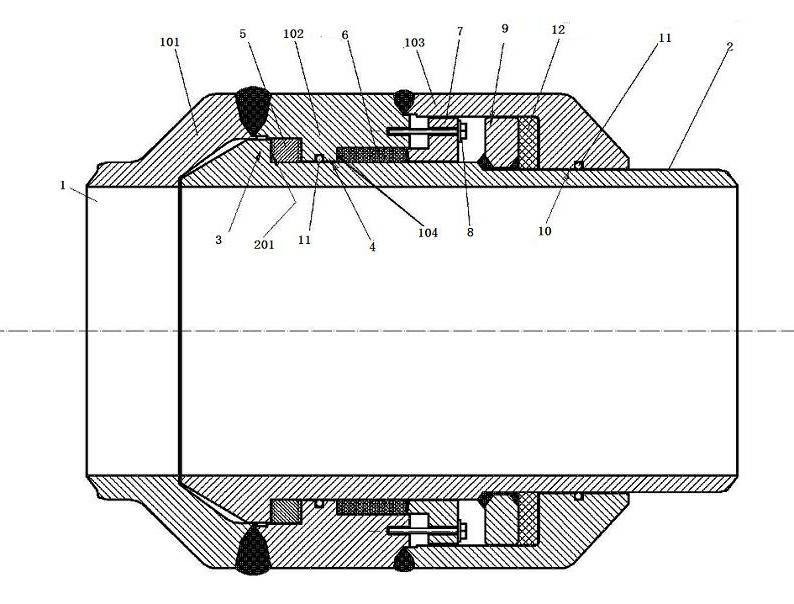

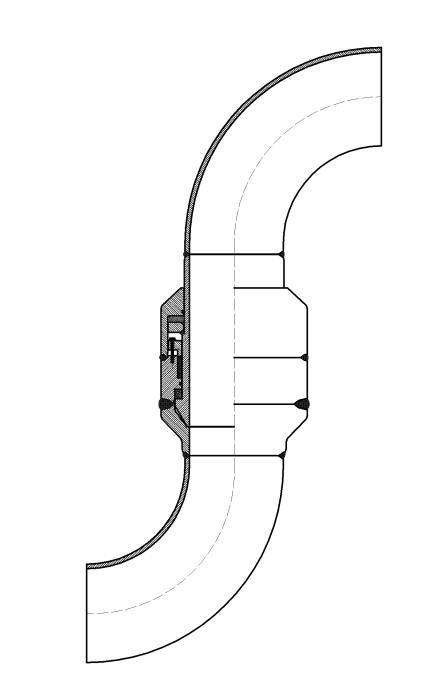

[0027] like figure 1 , 2 shown.

[0028] A safe explosion-proof high-pressure resistant self-sealing rotary compensator, which includes a different-diameter outer tube 1 and an inner tube 2. One end of the different-diameter outer tube 1 is connected to the delivery pipeline, and the other end is sleeved on the inner tube 2. The inner tube 1 One end is inserted into the outer pipe of different diameter 1, and the other end is connected with another section of delivery pipeline, such as figure 2 shown. One end of the inner tube 2 is positioned in the outer tube 2 with a different diameter, and at least one end face sealing cavity with a seal 5 is formed between the inner tube 2 and the outer tube 1 with a different diameter. The end face of the annular outer boss 3, the end face of the annular inner boss 4 on the inner tube 1 of different diameter adjacent to the annular outer boss 3, the outer surface of the inner tube 1 and the inner surface of the outer tube 1 of the dif...

Embodiment 2

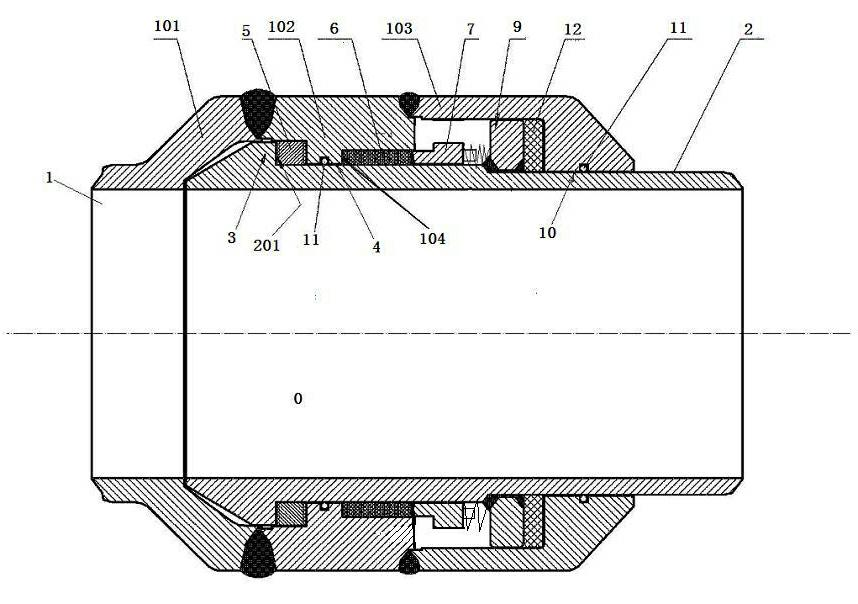

[0033] like image 3 shown.

[0034] The difference between this embodiment and Embodiment 1 is that the flange for positioning the annular sealing ring 6 is positioned by an elastic positioning device composed of a spring and a guide rod. The spring is set on the guide rod, and the guide rod is installed on the end face of the flange. superior. like image 3 shown.

Embodiment 3

[0036] like Figure 4 shown.

[0037]A safe explosion-proof self-sealing rotary compensator, which is suitable for compensating pipelines with low pressure, it includes a different-diameter outer tube 1 and an inner tube 2, and one end of the inner tube 2 is positioned in the different-diameter outer tube 2. Between the inner tube 2 and the outer tube 1 with a different diameter is formed at least one annular sealing cavity equipped with a ring sealing ring 6, and at least one explosion-proof structure is provided between the inner tube 2 and the outer tube 1 with a different diameter. The explosion-proof structure is composed of an annular outer shoulder 9 on the outer surface of the inner tube 1 and an annular inner shoulder 10 on the inner surface of the outer tube 1 with different diameters. The explosion-proof structure of this embodiment must be located between the ring surface sealing ring 6 and the end of the special-shaped outer tube 1 with the insertion hole. the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com