Method for preparing polyurethane adhesive by modifying waste polyurethane recovery product by using montmorillonite

A polyurethane adhesive, polyurethane technology, applied in polyurea/polyurethane adhesive, adhesive, plastic recycling, etc., can solve the problem of poor compatibility between montmorillonite and polyurethane, poor dispersion of organic montmorillonite, polyurethane adhesive The performance of the adhesive is not large, and the effect of improving the mechanical strength and heat resistance, low cost and stable properties is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

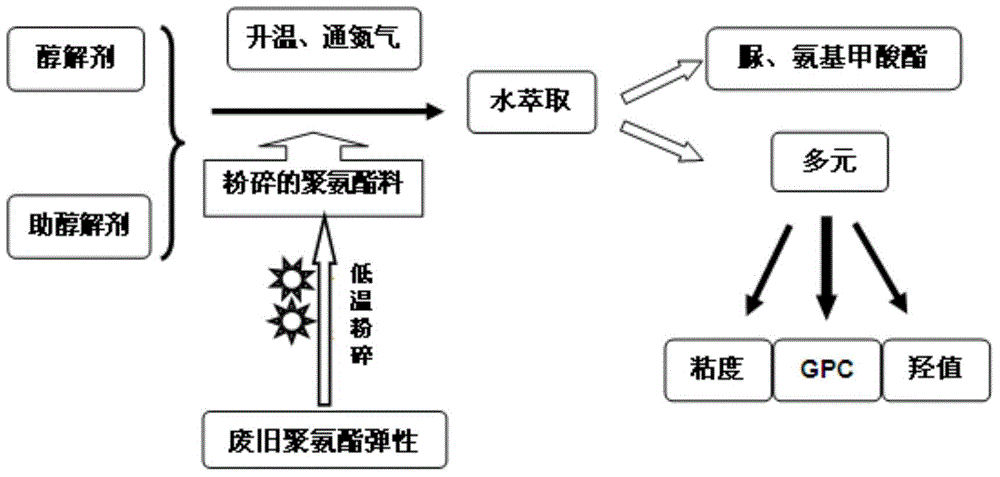

[0033] In a three-necked round-bottomed flask equipped with a stirrer, a condenser and a thermometer, 10g of waste polyurethane elastomer with a particle size of 10mm after being crushed at a low temperature of -10°C, 10g of 1,4-butanediol, and 0.5g of KOH were added while stirring. The reaction mixture was heated to 160° C. and kept at this temperature for 3 h, the polyurethane elastomer was completely dissolved, and the product was light brown. After washing with water, suction filtration, and water removal, 14 g of regenerated polyols with a molecular weight of 4600 and a hydroxyl value of 500 mgKOH / g were obtained.

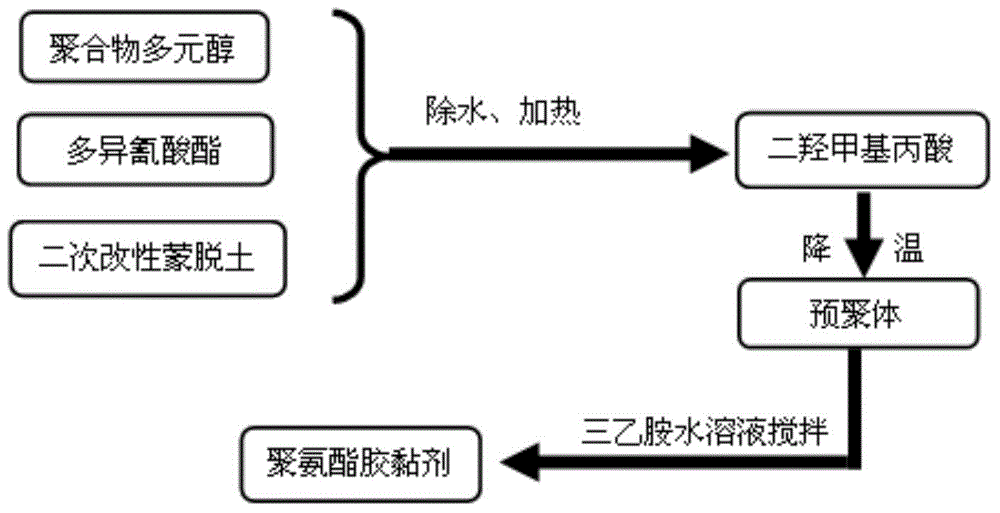

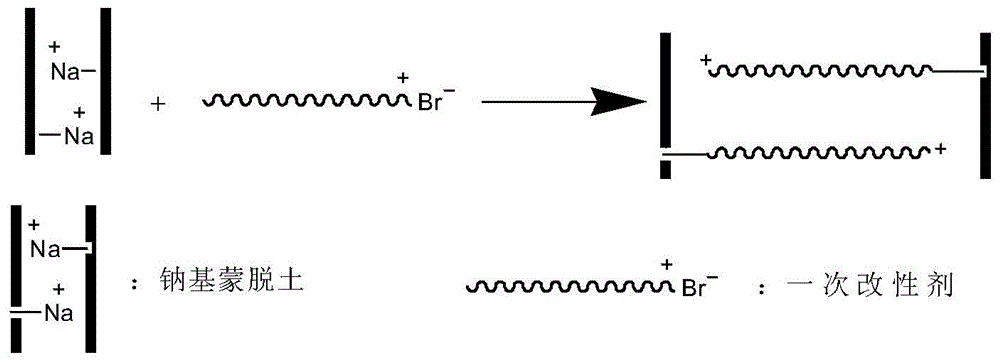

[0034] Add 5g of organic montmorillonite nanoparticles to 90g of water with mechanical stirring to form a stable suspension, add 5g of tetradecyltriphenylphosphine bromide, heat to 80°C in a water bath for 5h, wash and dry to obtain a modified montmorillonite . Dissolve 5g of primary modified montmorillonite in acetone, then raise the temperature of the syste...

Embodiment 2

[0038] Add 5g of organic montmorillonite nanoparticles into 90g of water with mechanical stirring to form a stable suspension, add 5g of cetyltriphenylphosphine bromide, heat to 80°C in a water bath for 5h, wash and dry to obtain a modified montmorillonite . Dissolve 5g of primary modified montmorillonite in acetone, then raise the temperature of the system to 80°C, add 5g of 2,4-diphenylmethane diisocyanate as a secondary modifier, react for 3h, and use the prepared montmorillonite The samples were washed three times with acetone again and then dried under vacuum at 100°C to obtain secondary modified montmorillonite.

[0039] 8 g of the polyol obtained after degradation in Example 1 was heated to 105° C. and vacuumed for 1.5 h to remove moisture, 2 g of 2,4-diphenylmethane diisocyanate was added, and 0.15 g of the above-mentioned secondary modified montmorillonite was added, and the mixture was heated to 65° C. The reaction was carried out for 3h; 1.05g of dried dimethylolpr...

Embodiment 3

[0042] Add 5g of organic montmorillonite nanoparticles to 90g of water with mechanical stirring to form a stable suspension, add 5g of tetradecyltriphenylphosphine bromide, heat to 80°C in a water bath for 5h, wash and dry to obtain a modified montmorillonite . Dissolve 5g of primary modified montmorillonite in acetone, then raise the temperature of the system to 80°C, add 5g of 2,4-toluene diisocyanate as secondary modifier, react for 3h, and use the prepared montmorillonite sample again with Washed with acetone three times and then dried in vacuum at 100°C to obtain secondary modified montmorillonite.

[0043] 4 g of the polyol obtained after the degradation of Example 1 was heated to 105°C and vacuumed for 1.5 h to remove moisture, 2 g of 2,4-diphenylmethane diisocyanate was added, 0.15 g of the above-mentioned secondary modified montmorillonite was added, and the reaction was carried out at 65°C. 3h; add 1.05g of dried dimethylolpropionic acid under constant stirring, rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com