Rotating connector

A technology of rotary joints and shells, which is applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve the problems of joints that cannot be completed, gas leakage, easy leakage, etc., to improve stability and flexibility, The effect of increasing the service life and increasing the compensation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

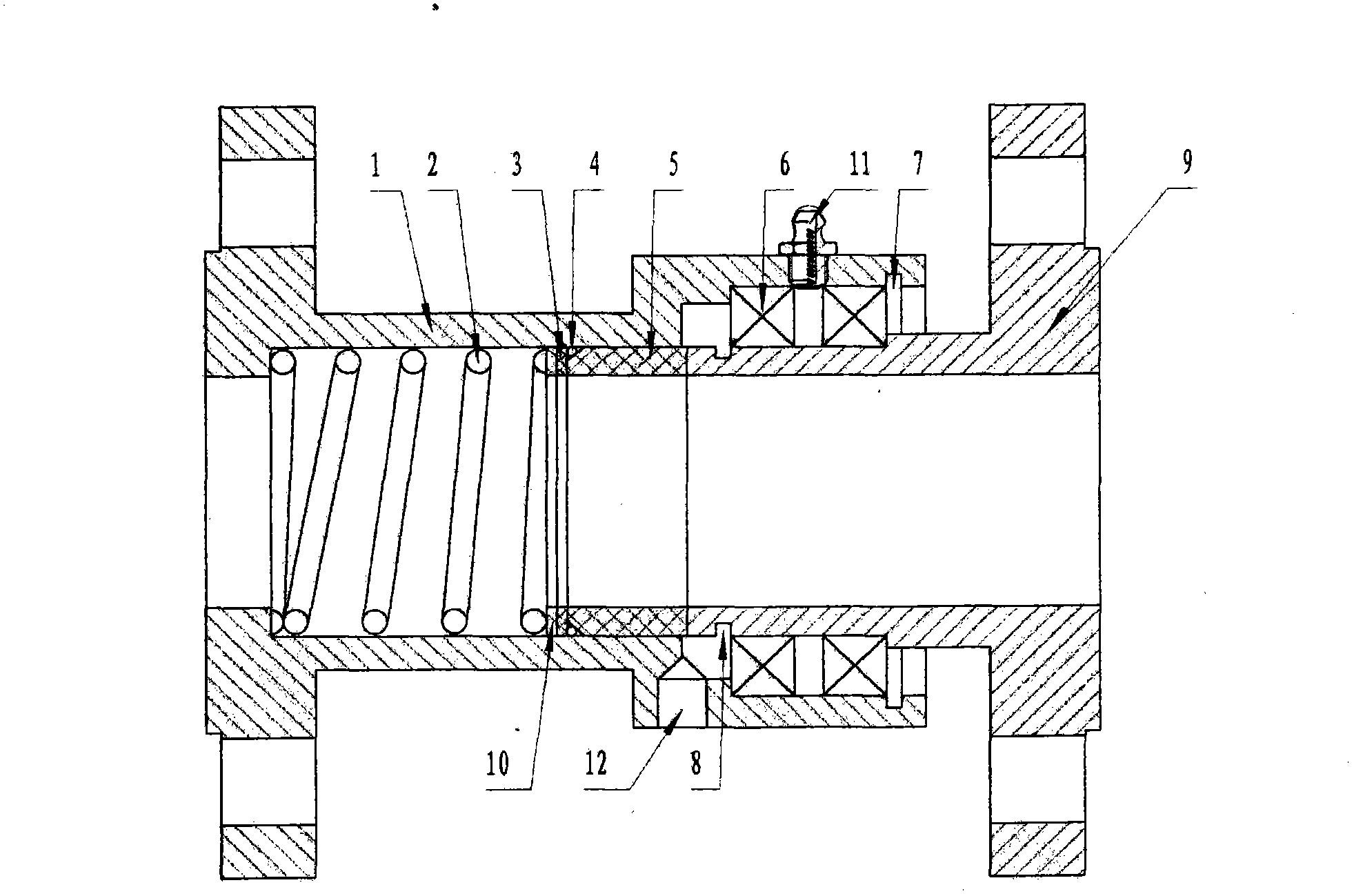

[0010] Such as figure 1 As shown, a rotary joint of the present invention includes: a housing 1, a spring 2, a rubber pad 3, an O-ring 4, a sealing ring 5, a bearing 6, a retaining ring 7 for a hole, a retaining ring 8 for a shaft, and a hollow shaft 9 1. The spring pad 10 is characterized in that: the spring 2 and the spring pad 10, the rubber pad 3, the O-ring 4, and the sealing ring 5 are arranged in the housing 1, the shaft clamp 8 is arranged in the groove of the hollow shaft 9, and the bearing 6 is arranged Between the inner hole of the housing 1 and the outer diameter of the hollow shaft 9, the grease nipple II fills the bearing 6 with lubricating oil, and the observation hole 12 is used to observe whether there is leakage. All components are connected as a whole by the retaining ring 7 for the hole.

[0011] Further, the sealing ring 5 is a graphite sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com