Patents

Literature

59results about How to "Avoid repeated cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

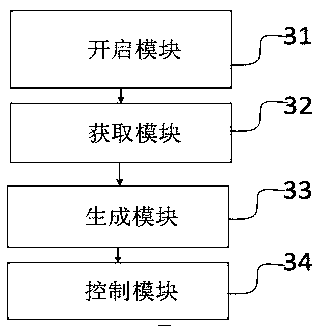

Planning method of cleaning robot cleaning route and cleaning robot

InactiveCN107328419AImprove cleanlinessShorten movement timeNavigational calculation instrumentsFloor sweeping machinesEngineeringPlanning method

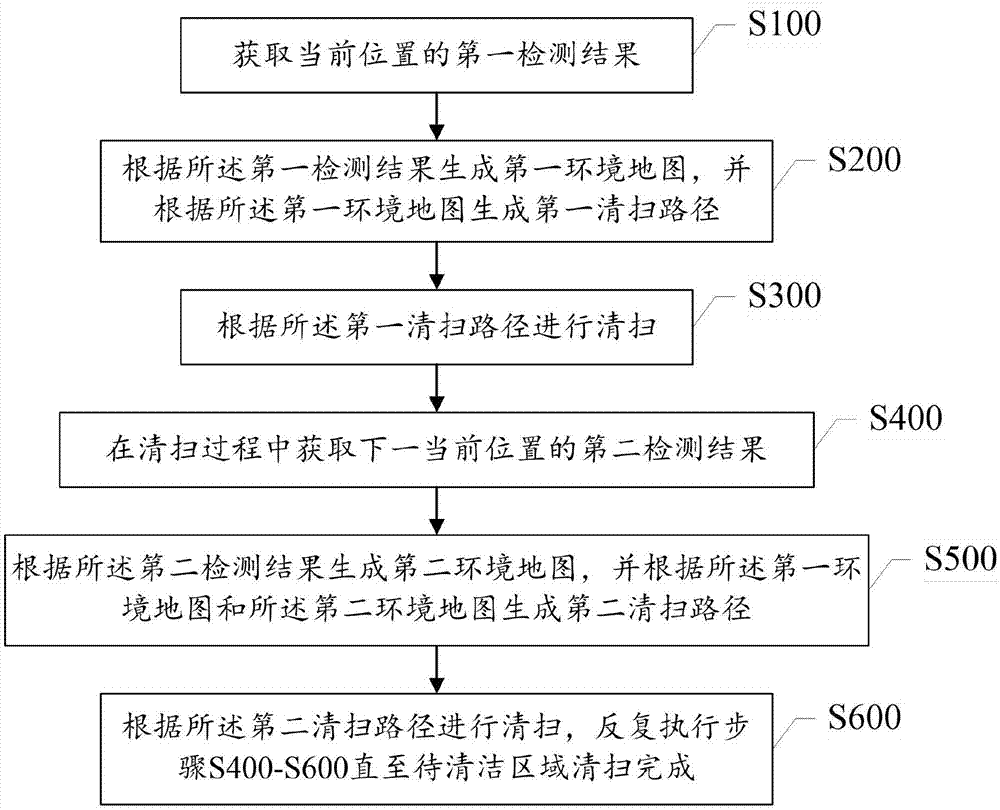

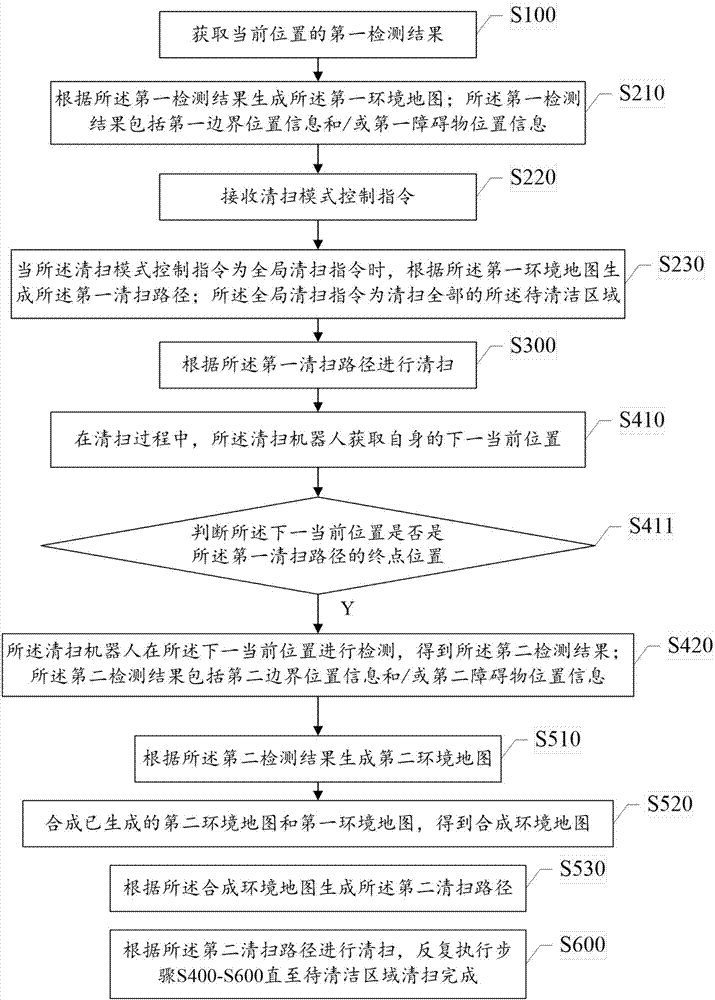

The invention provides a planning method of a cleaning robot cleaning route and a cleaning robot. The planning method comprises the steps as follows: S100, a first detection result of a current location is acquired; S200, a first environment map is generated according to the first detection result, and a first cleaning route is generated according to the first environment map; S300, the cleaning robot performs cleaning according to the first cleaning route; S400, a second detection result of a next current position is acquired in a cleaning process; S500, a second environment map is generated according to the second detection result, and a second cleaning route is generated according to the first environment map and the second environment map; S600, cleaning is performed according to the second cleaning route, and the steps S400-S600 are executed repeatedly until cleaning of a to-be-cleaned area is completed. According to the planning method and the cleaning robot, cleaning and detecting are executed simultaneously by the cleaning robot, the cleaning route is updated in real time, cleaning efficiency is improved, and resources are saved.

Owner:台州市吉吉知识产权运营有限公司

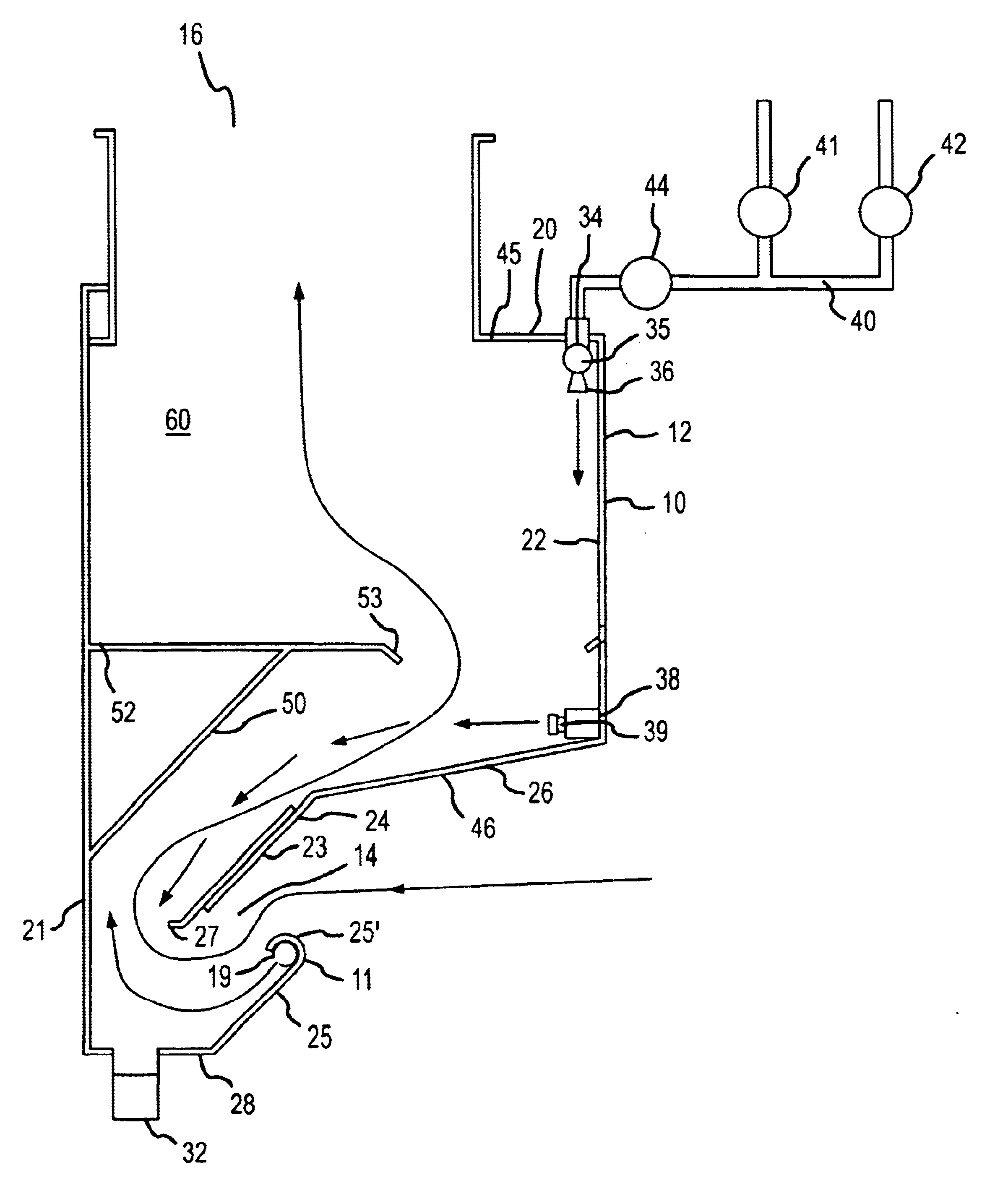

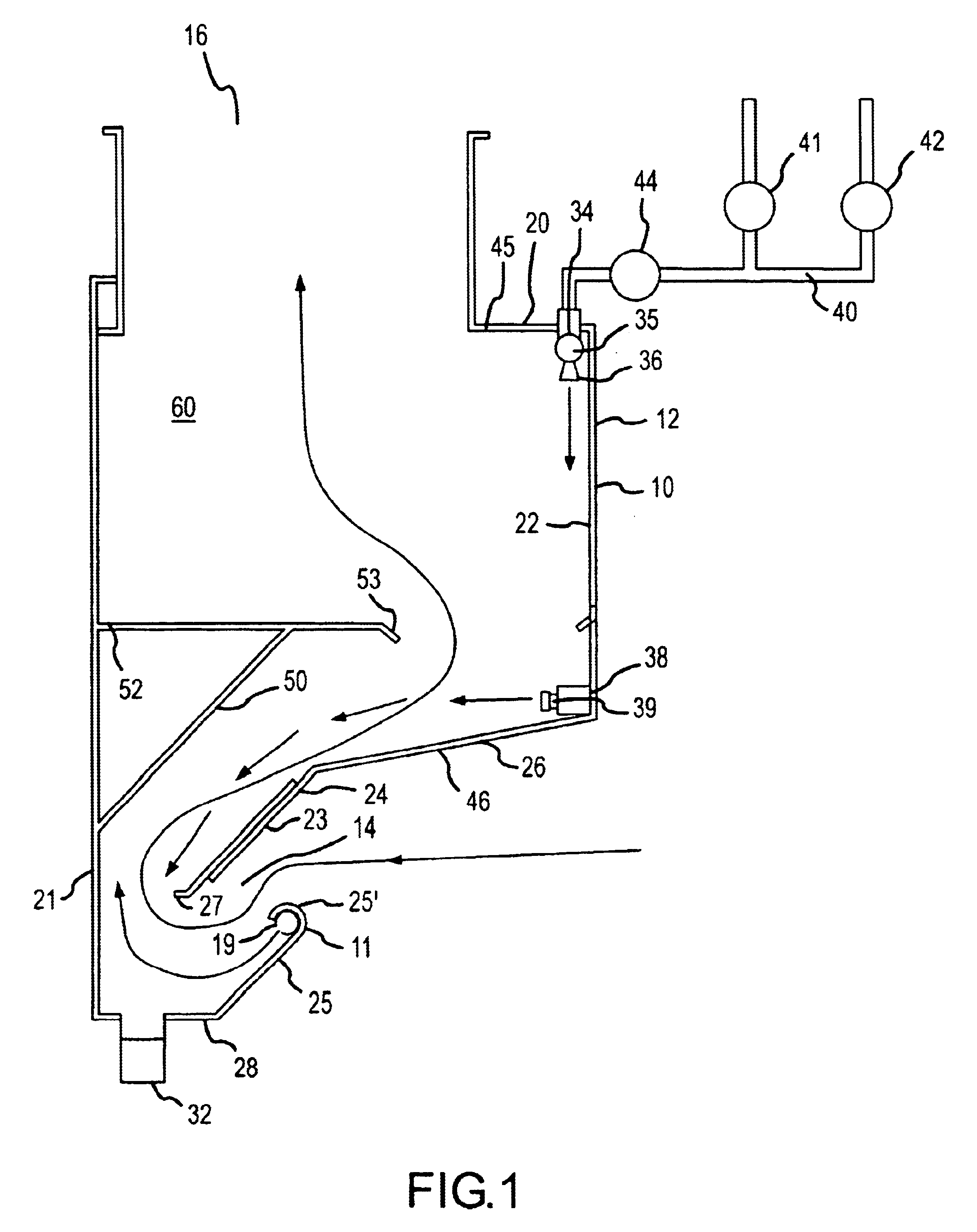

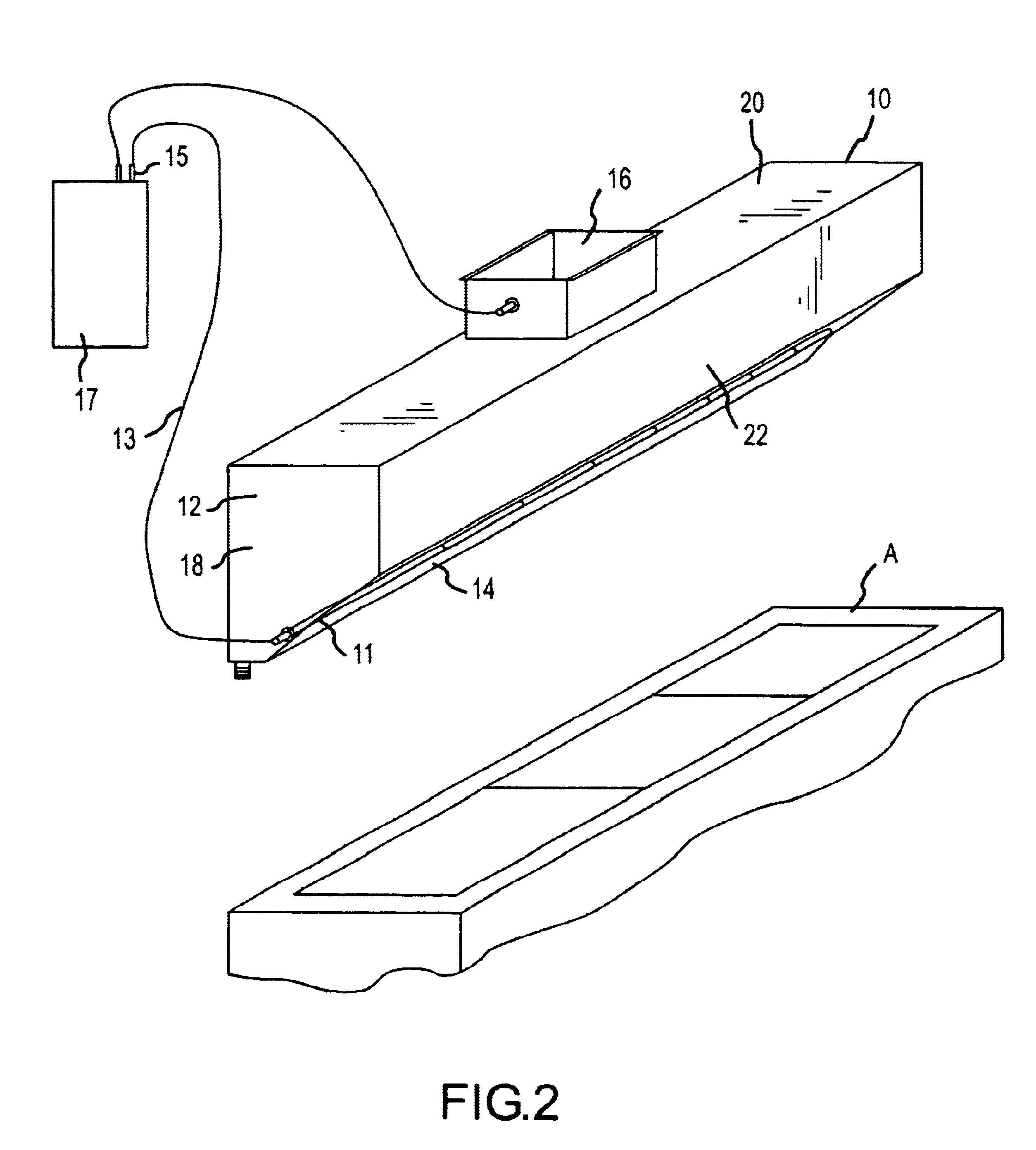

Method and apparatus for removal of grease, smoke and odor from exhaust systems

InactiveUS6817356B2Efficiently and continuously removingAvoid repeated cleaningDomestic stoves or rangesLighting and heating apparatusOzone generatorWater treatment system

Owner:GALLAGHER ARLEN W

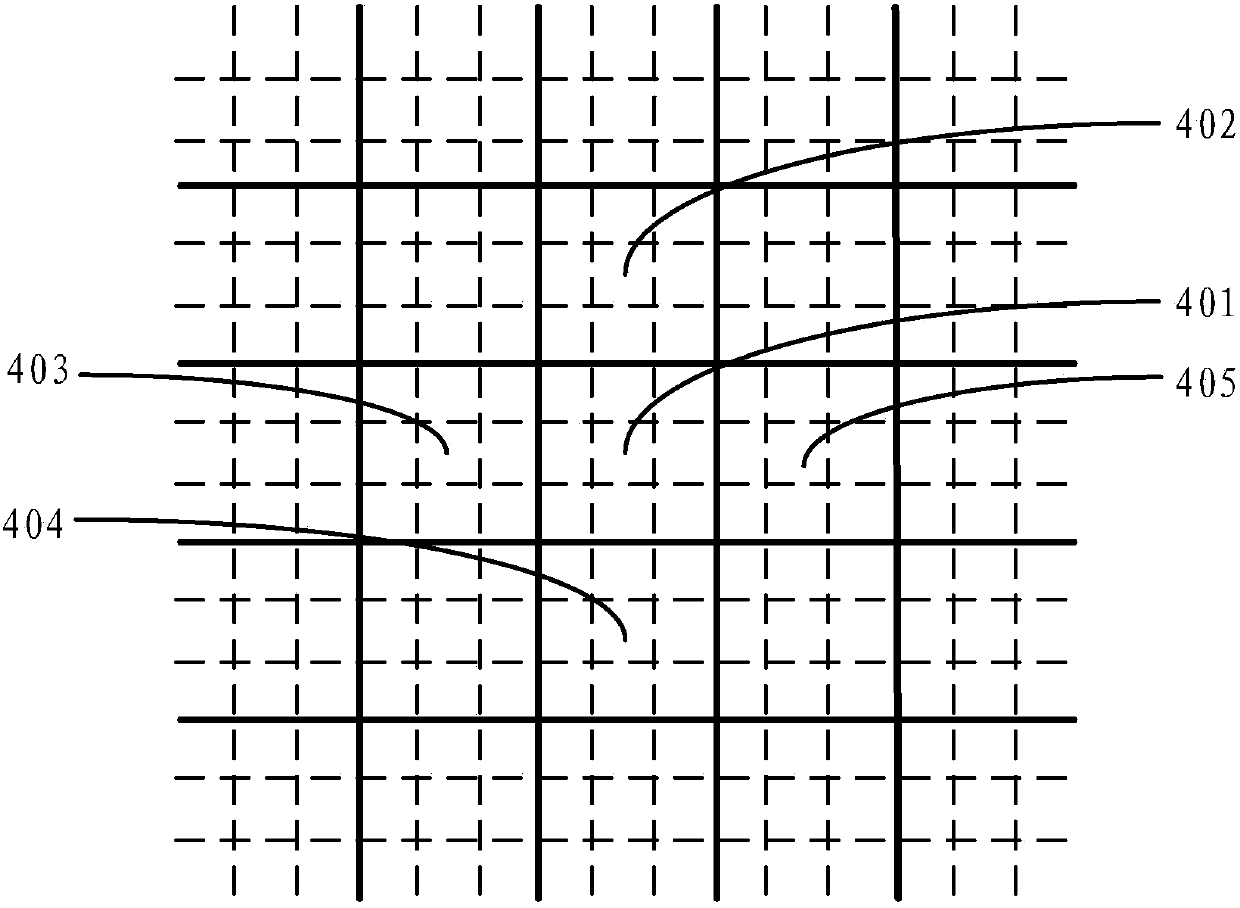

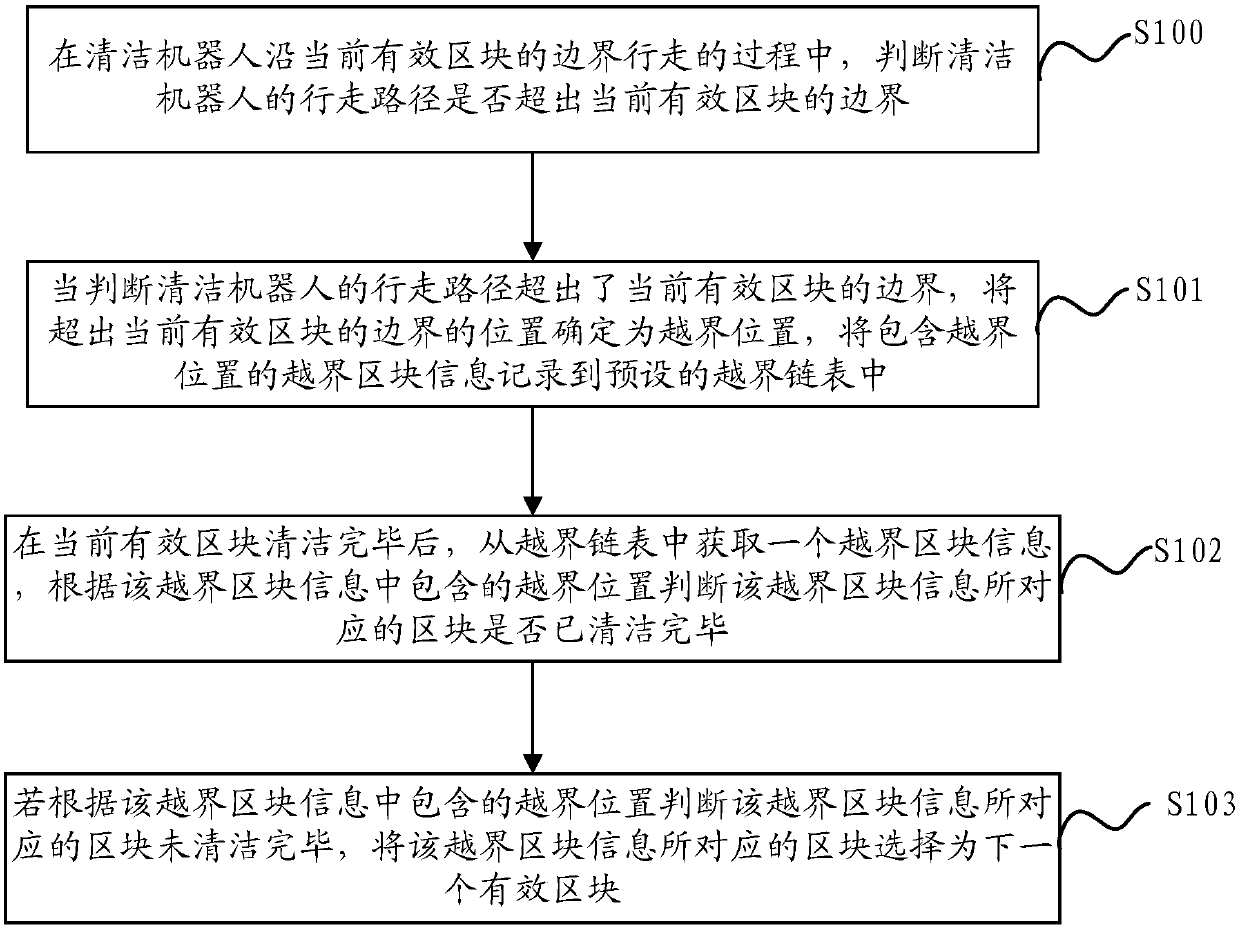

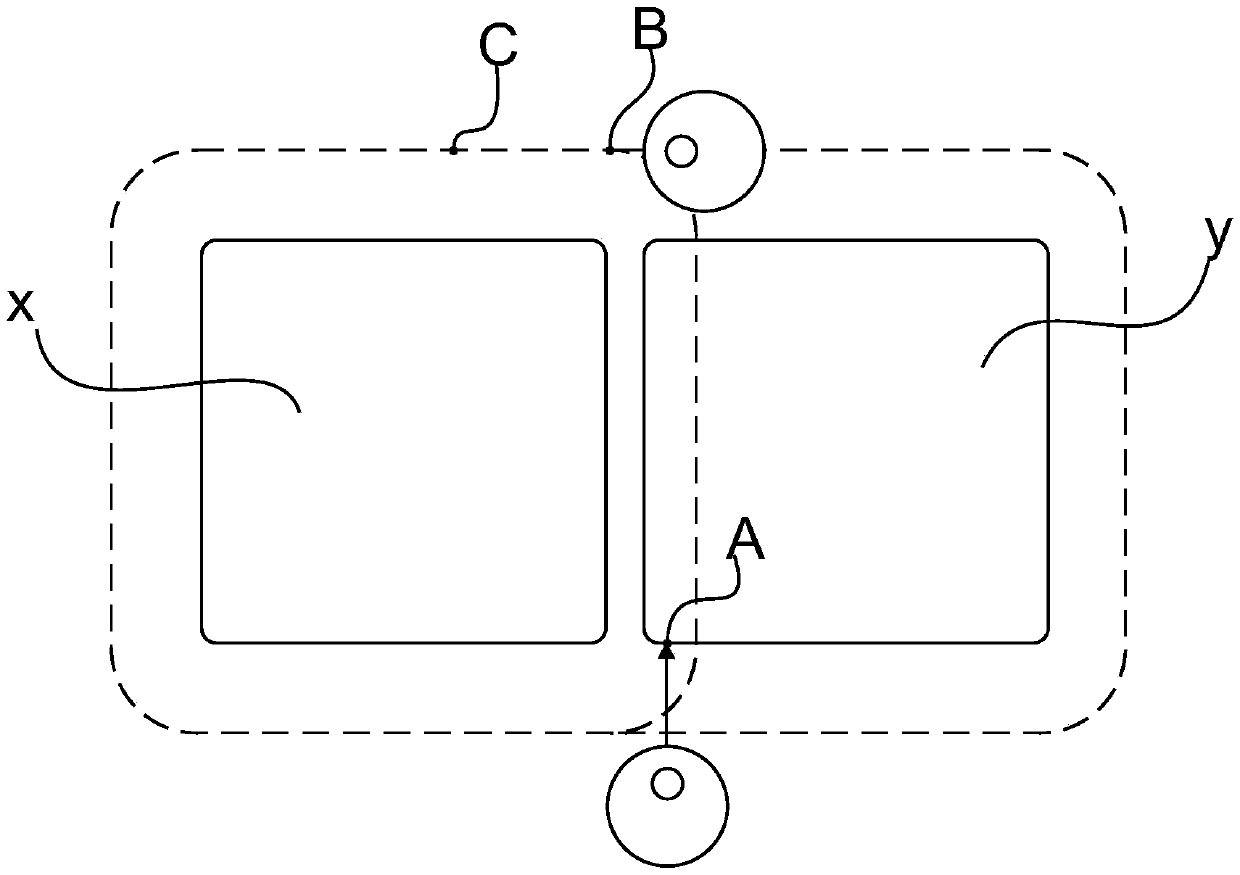

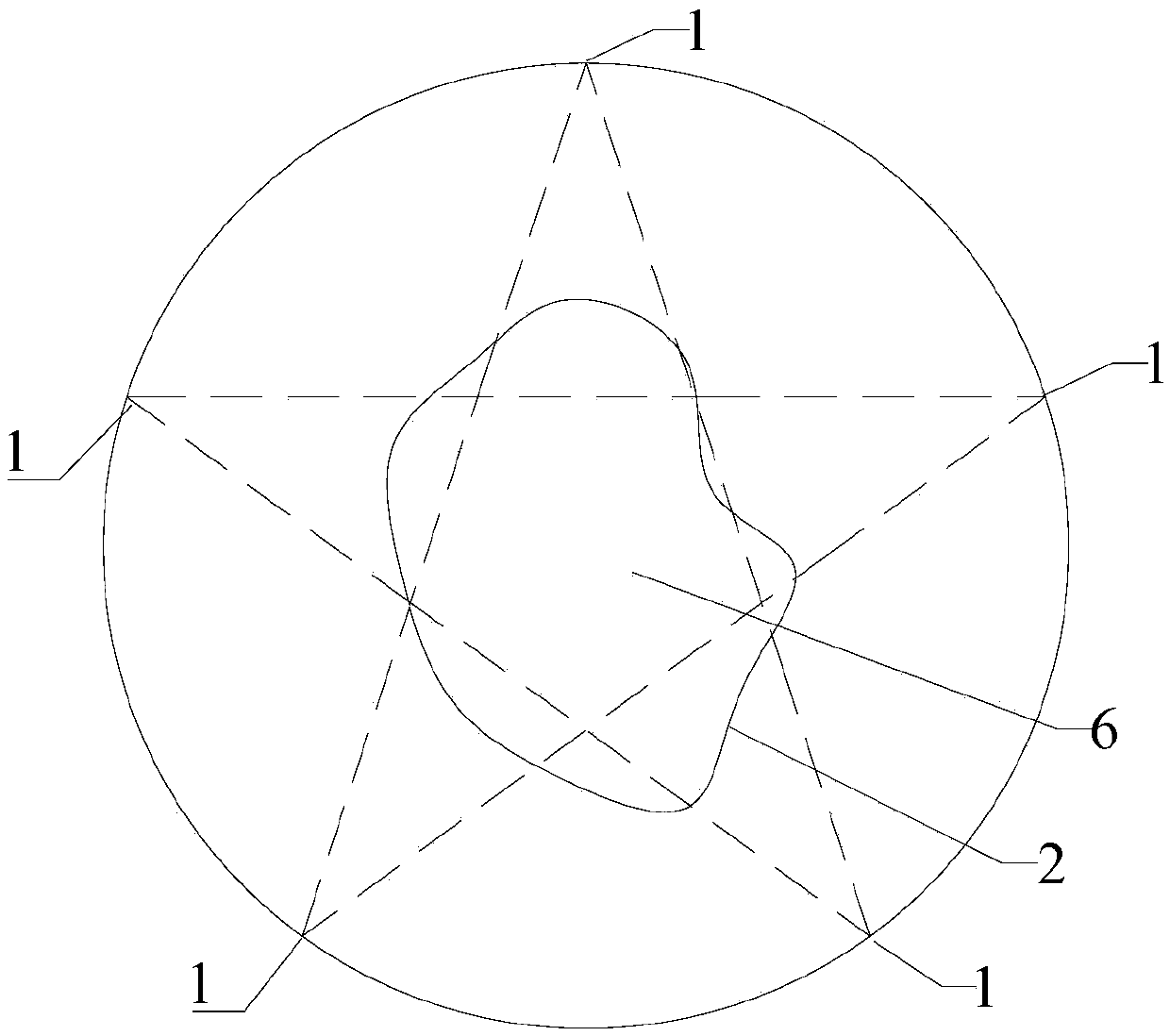

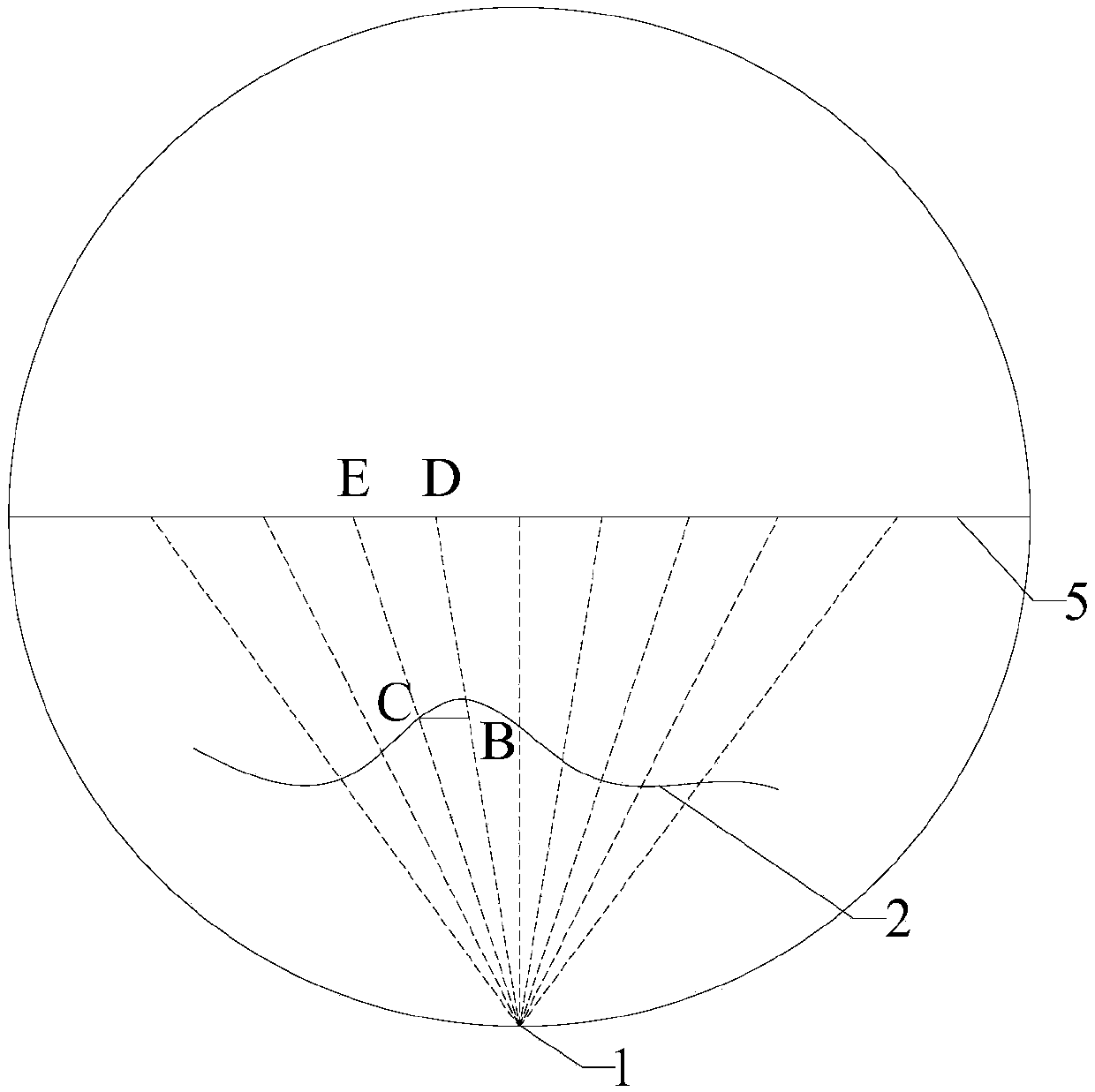

Cleaning robot and block selection method and device for same

ActiveCN107913039AAvoid repeated cleaningAvoid Uncleaned SituationsCarpet cleanersFloor cleanersCross-linkEngineering

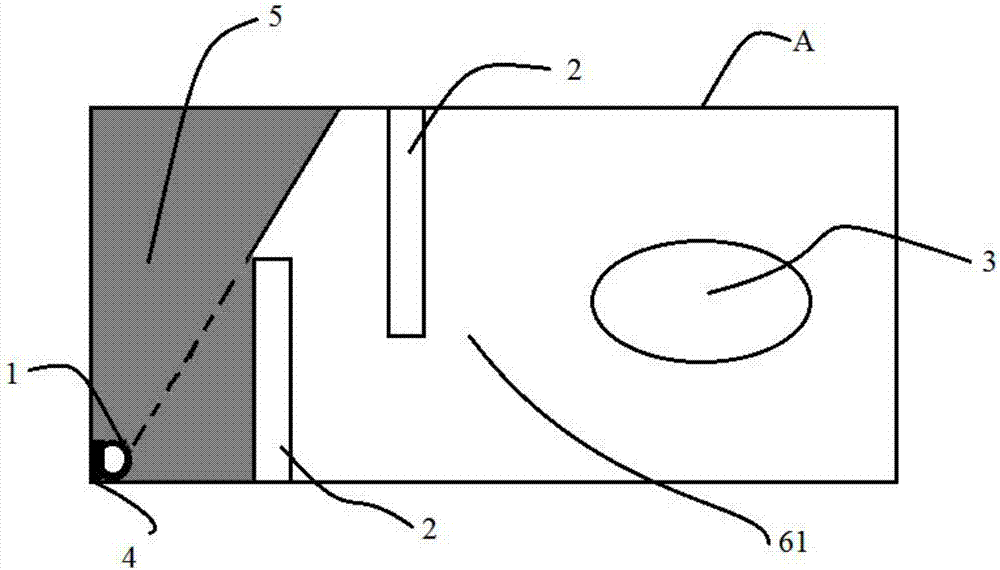

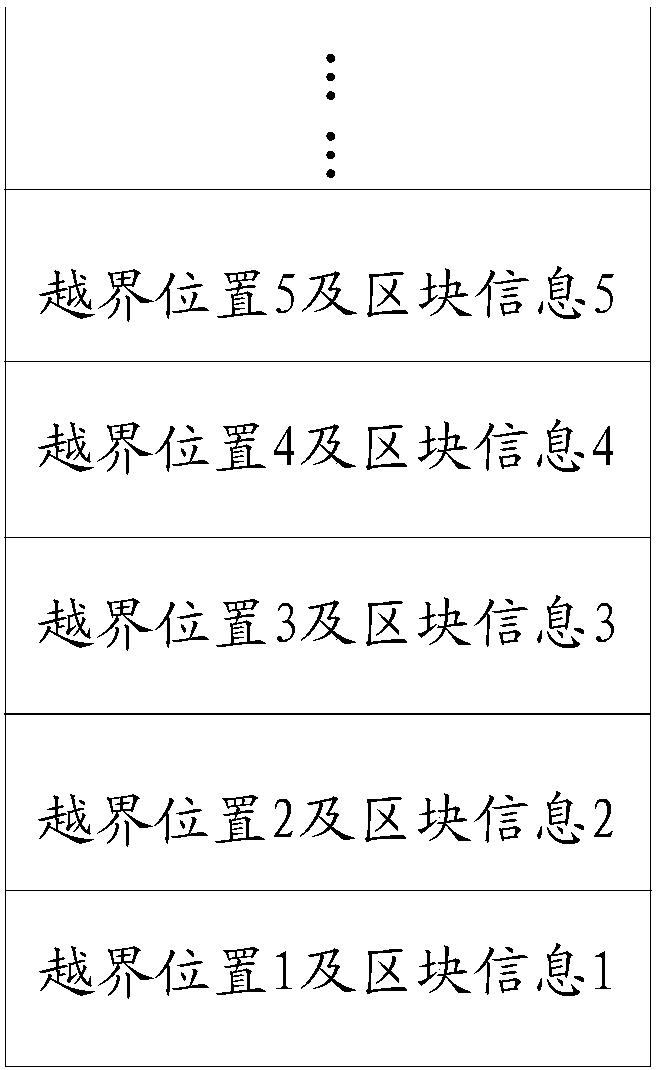

The invention discloses a cleaning robot and a block selection method and a block selection device for the cleaning robot. The block selection method includes judging whether the walking path of the cleaning robot exceeds the boundary of the current effective block or not when the cleaning robot walks along the boundary of the current effective block; if so, then determining the position out of the boundary of the current effective block as a boundary-crossing position according to the judgement result, and recording boundary-crossing block information containing the boundary-crossing positionto a preset boundary-crossing linked list; after finishing cleaning of the current effective block, acquiring one boundary-crossing information from the boundary-crossing linked list, and judging whether the block corresponding to the boundary-crossing block information is cleaned or not according to the boundary-crossing position contained in the boundary-crossing block information; if no, thendetermining the block corresponding to the boundary-crossing block information as the next effective block. By the method, repeated cleaning of the block can be avoided, cleaning efficiency can be improved, omission of cleaning of the block can be avoided, and cleaning quality can be guaranteed.

Owner:BEIJING QIHOO TECH CO LTD

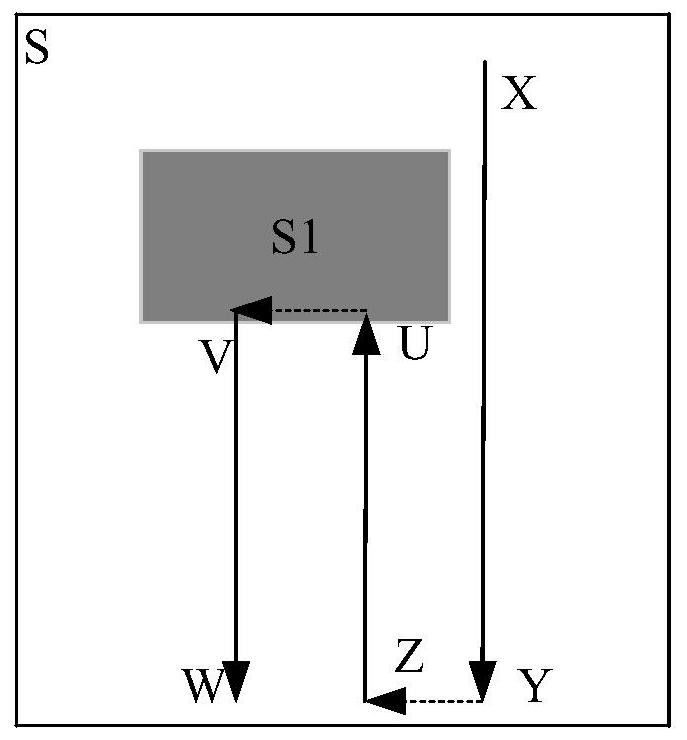

Position detecting system and method of the same

InactiveUS20080154457A1Short timeLow production costVehicle position/course/altitude controlDistance measurementLocation detectionEngineering

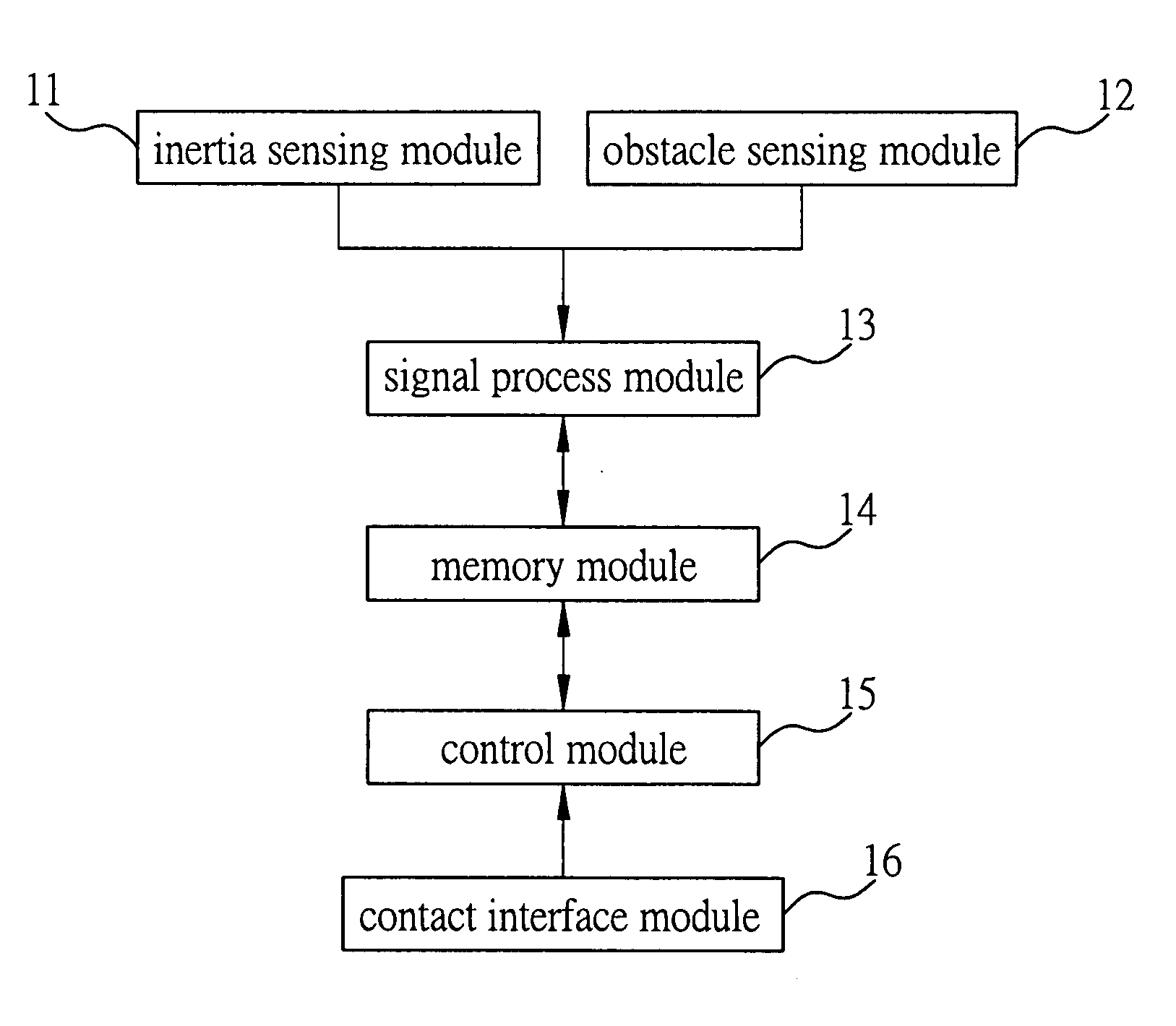

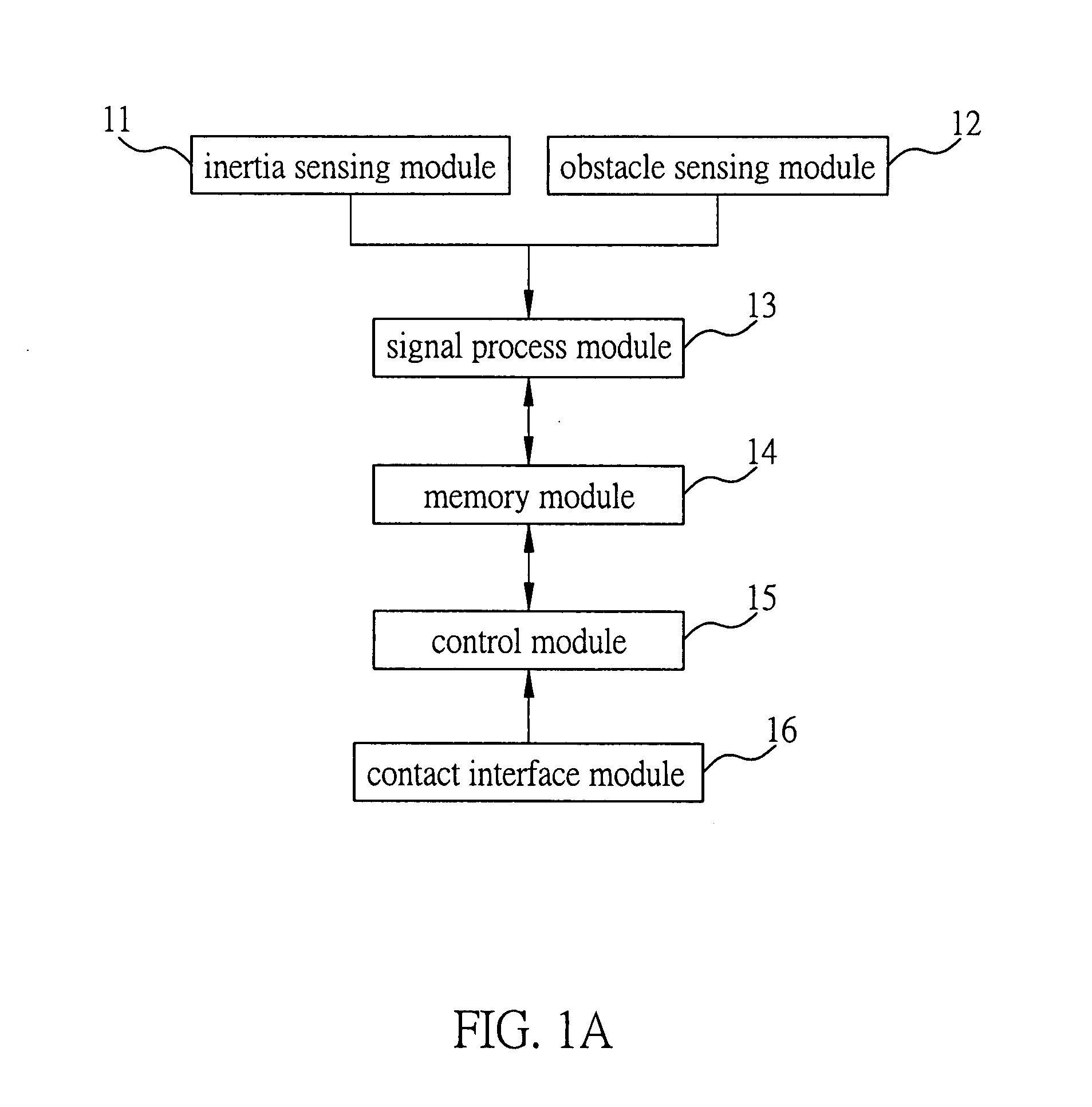

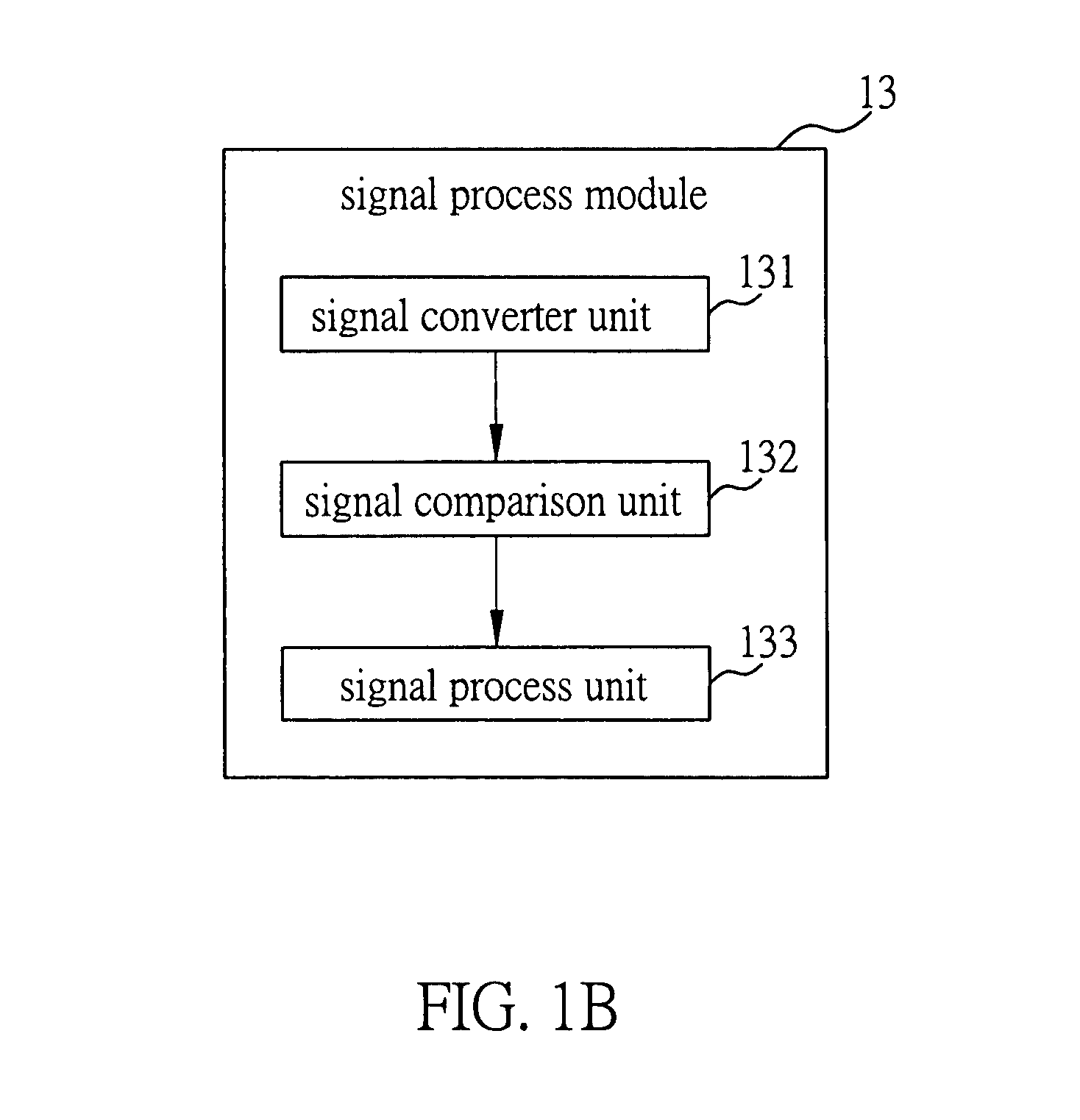

A position detecting system and a method of the same are disclosed according to the present invention as follows: an inertia sensing module and an obstacle sensing module are adapted to detect a displacement signal of a cleansing apparatus and a distance signal of a distance between the cleansing apparatus and an obstacle respectively; and then a signal processing module is adapted to convert the displacement signal and the distance signal into an actual displacement path and an obstacle distance respectively, and then compare the actual displacement path and the obstacle distance with a preset path respectively to determine if the cleansing apparatus is traveling at the same place over again, or if the cleansing apparatus is going to hit the obstacle, and then the signal processing module will adjust a traveling path based on comparison results; and a control module is adapted to control traveling of the cleansing apparatus based on the adjusted traveling path. Hence, the cleansing apparatus is capable of repeating the foregoing steps for detecting and positioning purposes at any time during a cleansing process, thereby avoiding repetitive cleaning at the same place.

Owner:IND TECH RES INST

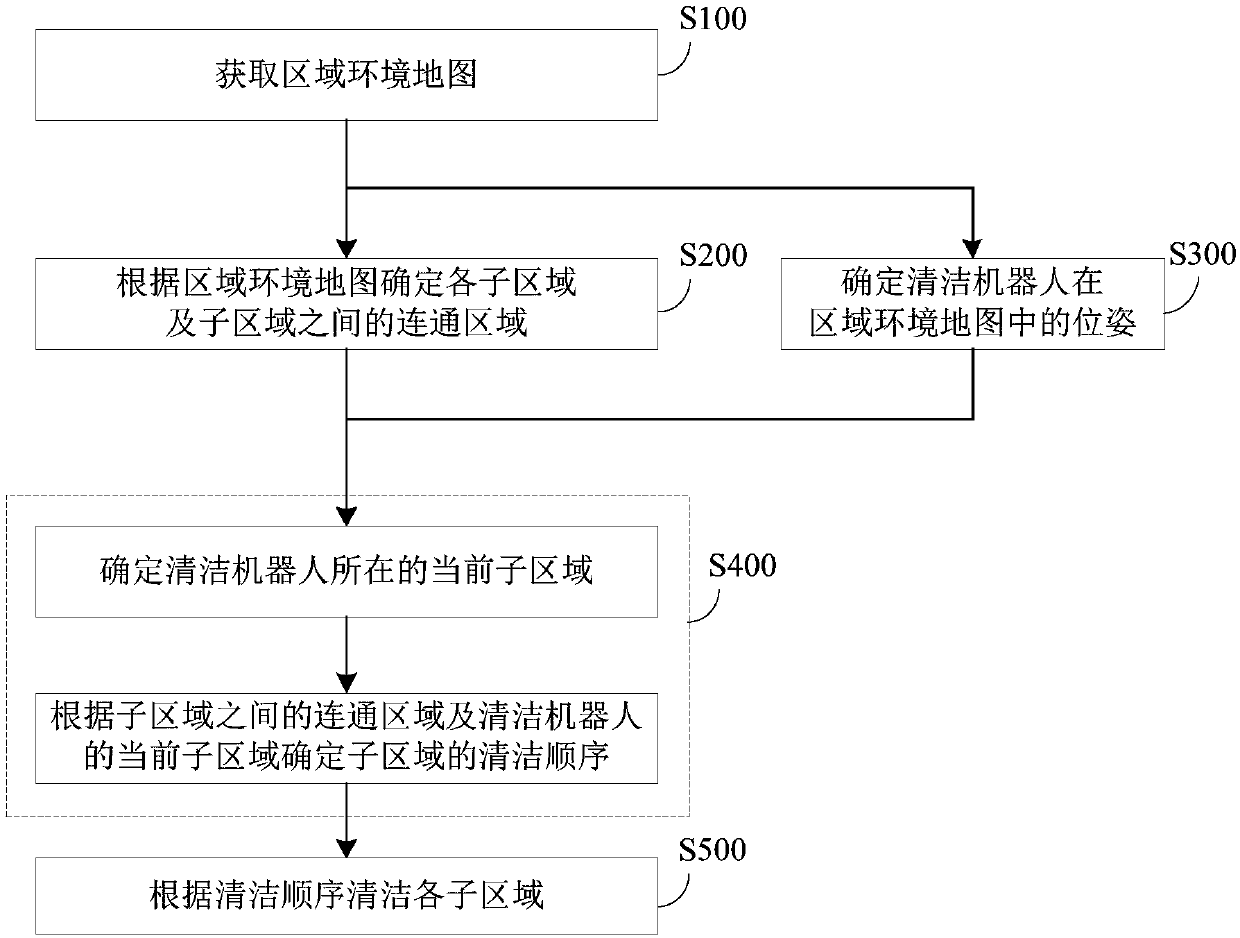

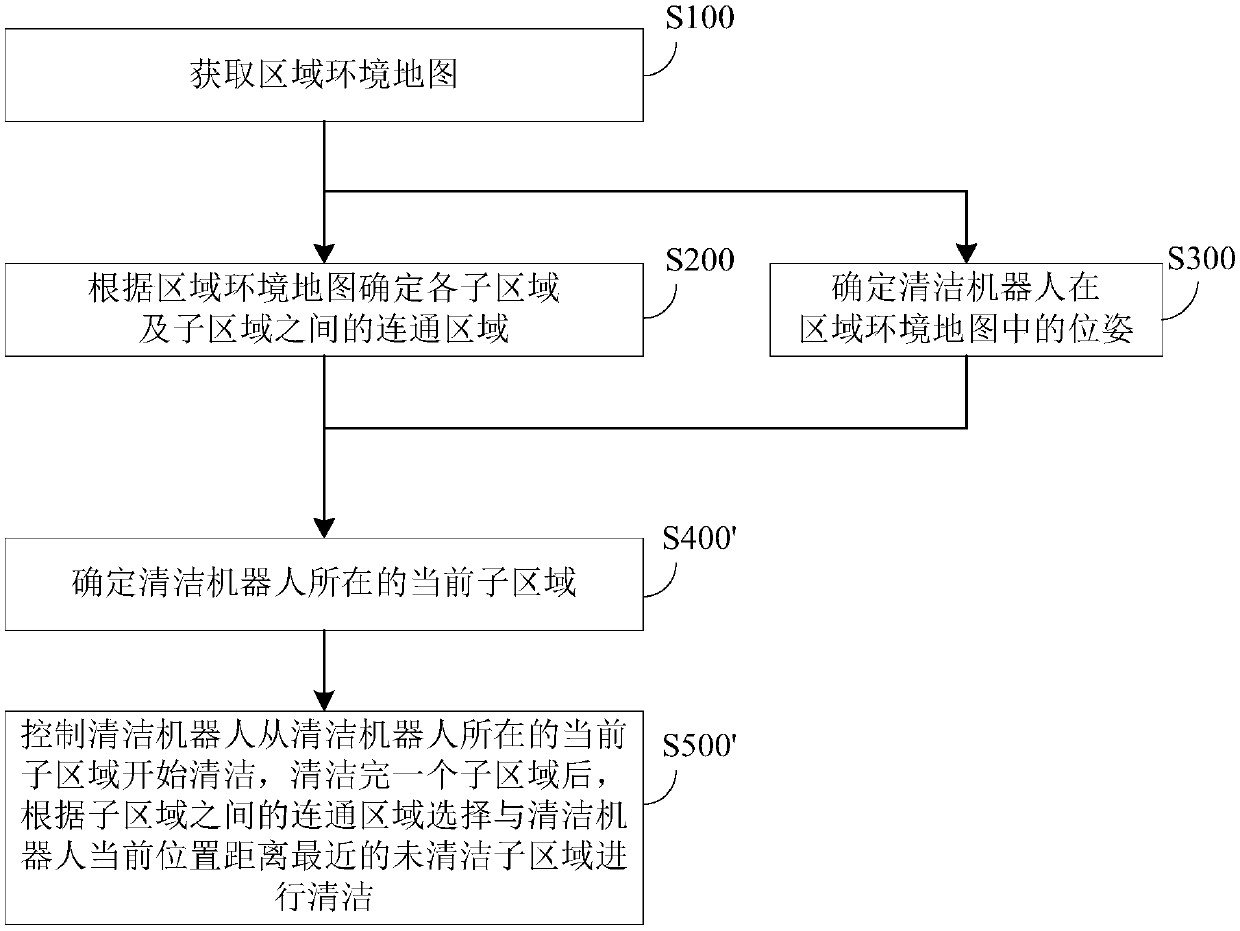

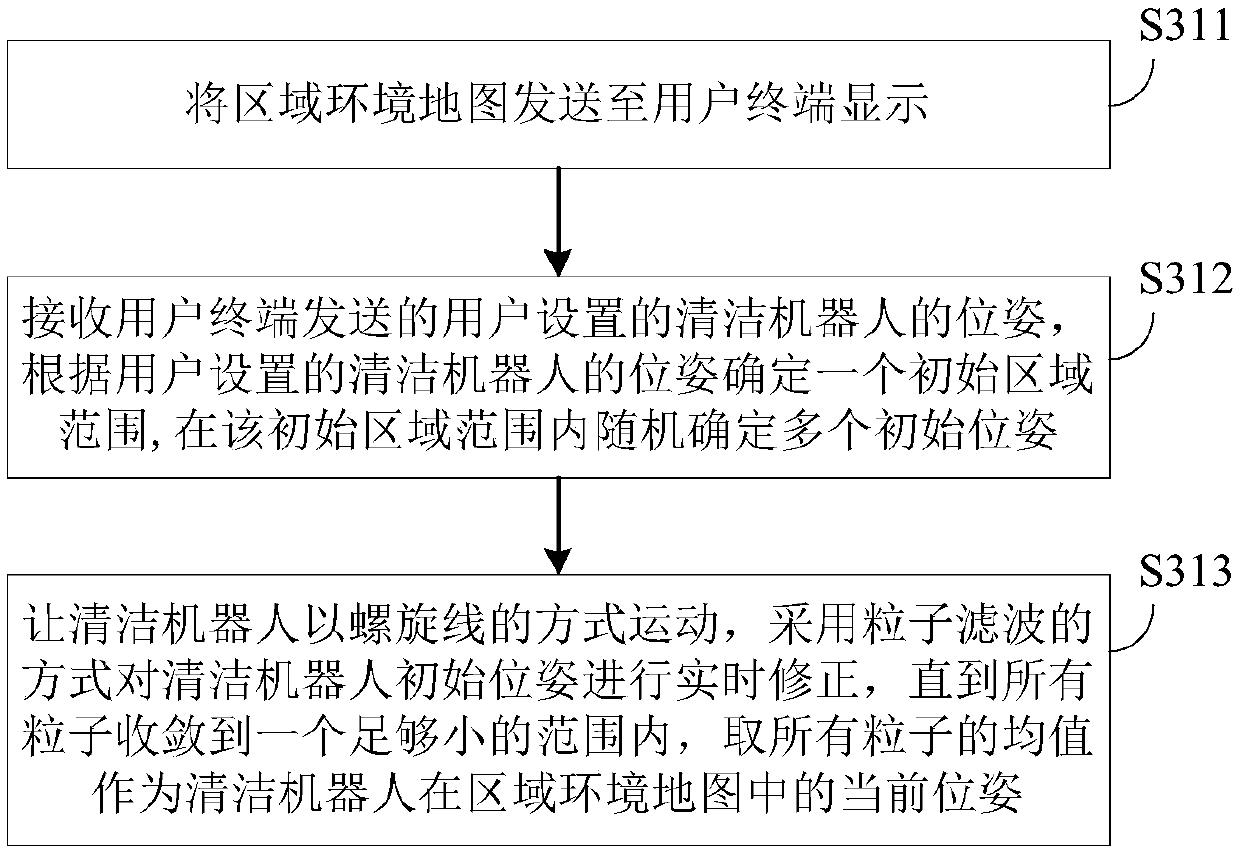

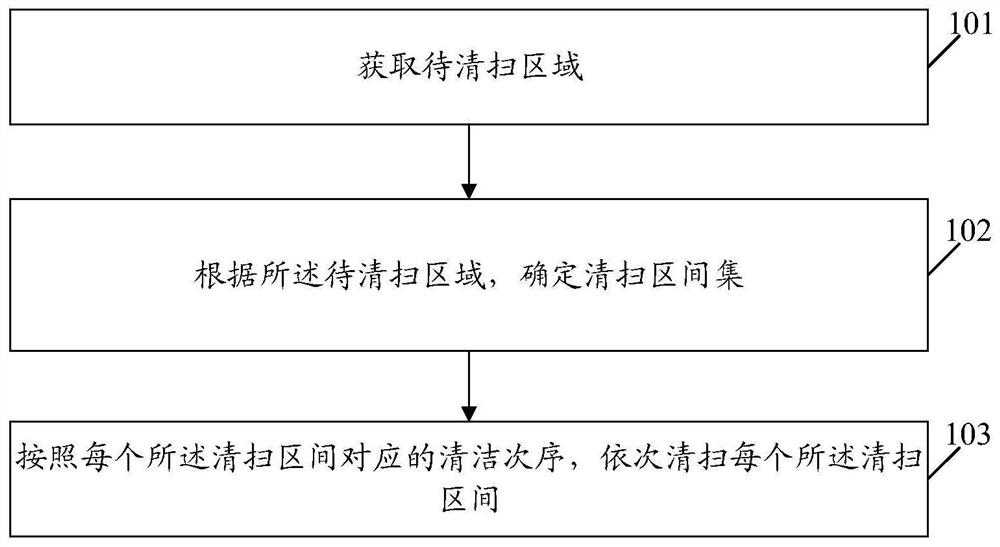

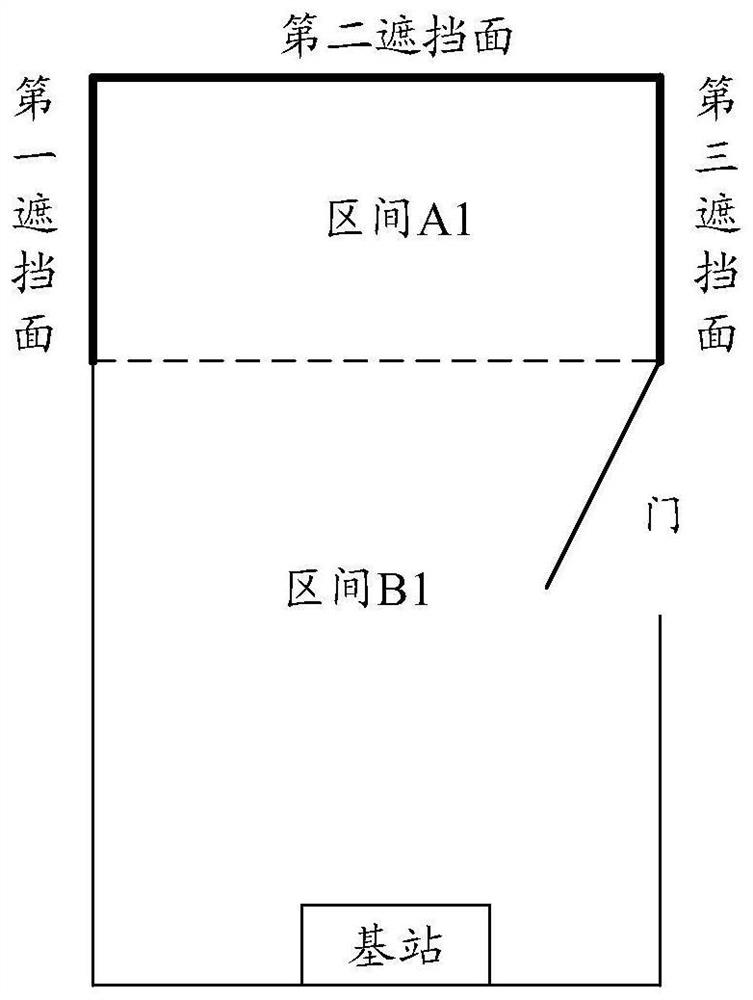

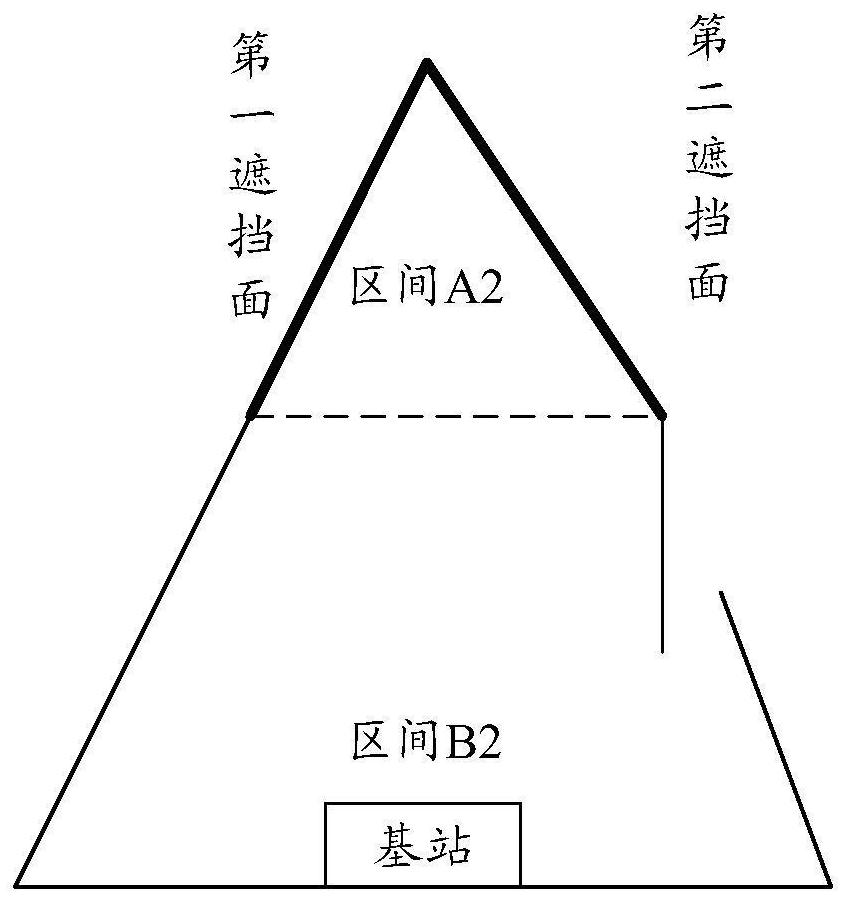

Cleaning robot and multi-region cleaning method thereof

PendingCN110833361AImprove experienceAvoid repeated cleaningCarpet cleanersFloor cleanersWorkspaceProcess engineering

The invention provides a cleaning robot and a multi-region cleaning method thereof. The method comprises the following steps of acquiring a region environment map; determining sub-regions and communication regions between the sub-regions according to the region environment map; determining a pose of the cleaning robot in the region environment map; determining a cleaning sequence of the sub-regions according to the pose of the cleaning robot in the region environment map and the communication regions between the sub-regions, wherein the cleaning sequence ensures that the amount of the sub-regions repeatedly passed by the cleaning robot is minimum or the total moving distance of the cleaning robot after cleaning is shortest; and controlling the cleaning robot to clean the sub-regions according to the cleaning sequence. The cleaning robot can avoid repeated cleaning, can clean the larger working region under the same battery power, and has the characteristics of being high in cleaning efficiency, high in endurance capability and good in user experience.

Owner:SUGAN TECH BEIJING

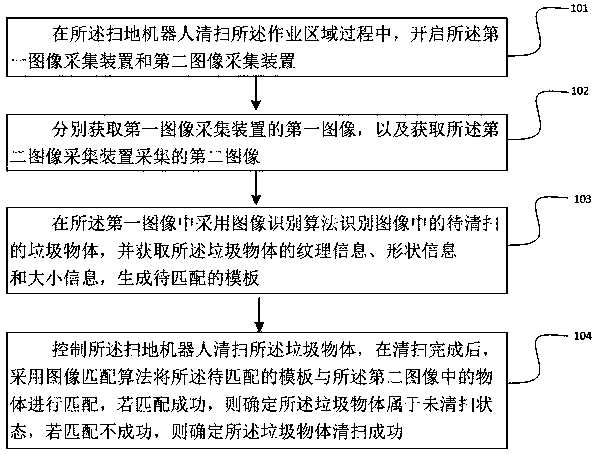

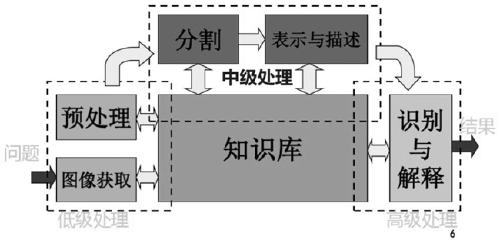

Cleaning control method and device of visual robot, chip and sweeping robot

ActiveCN111358362AAvoid repeated cleaningGuaranteed work effectCarpet cleanersFloor cleanersRecognition algorithmEngineering

The invention relates to a sweeping control method and device of a visual robot, a chip and a sweeping robot, and belongs to the field of intelligent robots. The robot control method comprises the steps: starting a first image acquisition device and a second image acquisition device in the process that the robot sweeps an operation area; respectively acquiring a first image of the first image acquisition device and a second image acquired by the second image acquisition device; adopting an image recognition algorithm in the first image to recognize a to-be-swept garbage object in the image, acquiring texture information, shape information and size information of the garbage object, and generating a to-be-matched template; and controlling the robot to sweep the garbage object, after sweeping is completed, adopting an image matching algorithm to match the to-be-matched template with the object in the second image, and if matching succeeds, determining that the garbage object is in an unswept state. According to the scheme, the unswept garbage object can be swept multiple times, and the operation effect is guaranteed.

Owner:AMICRO SEMICON CORP

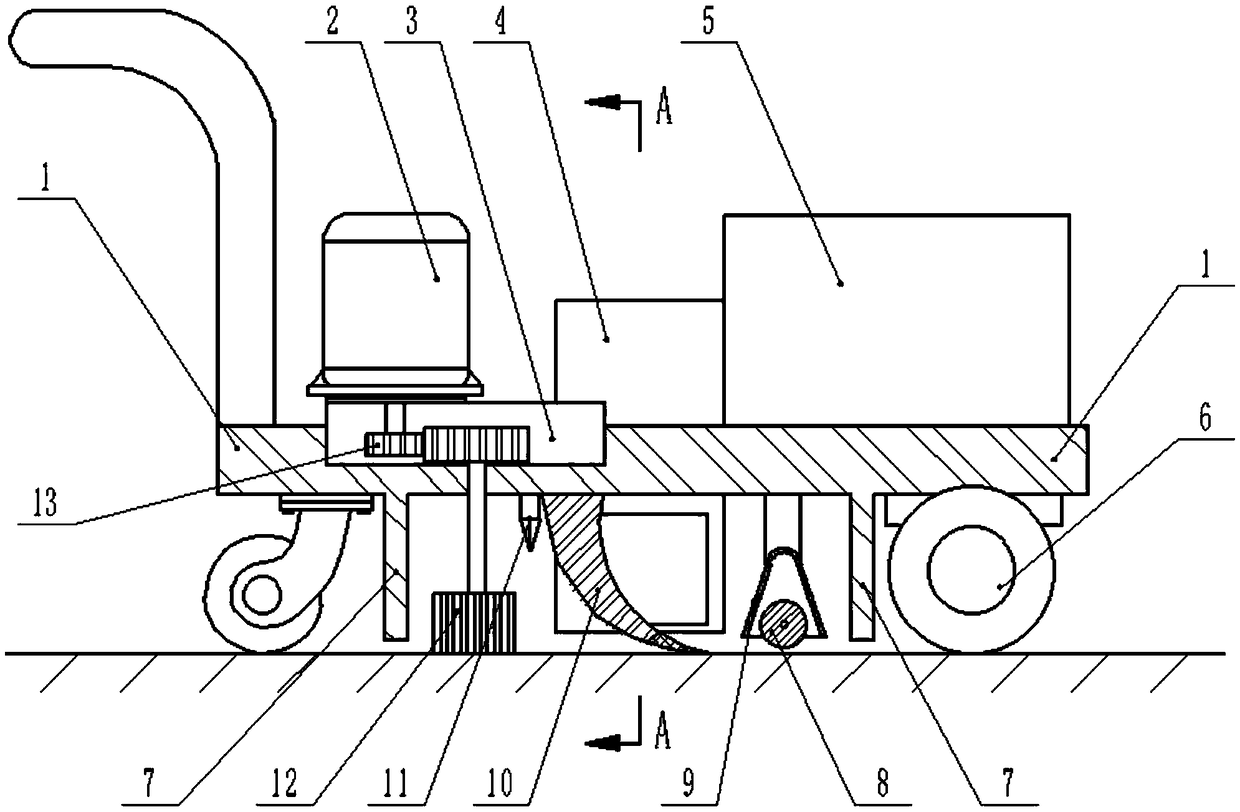

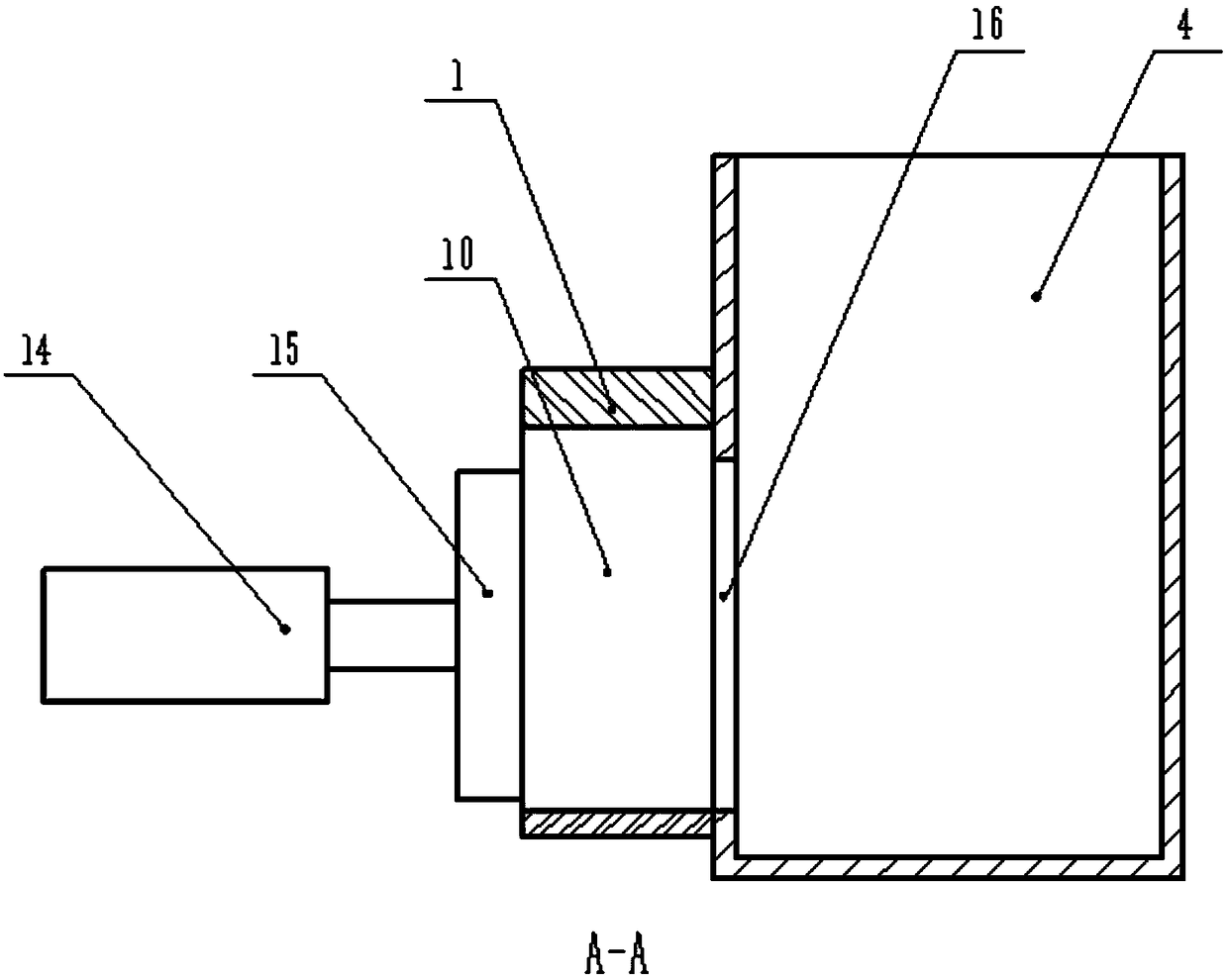

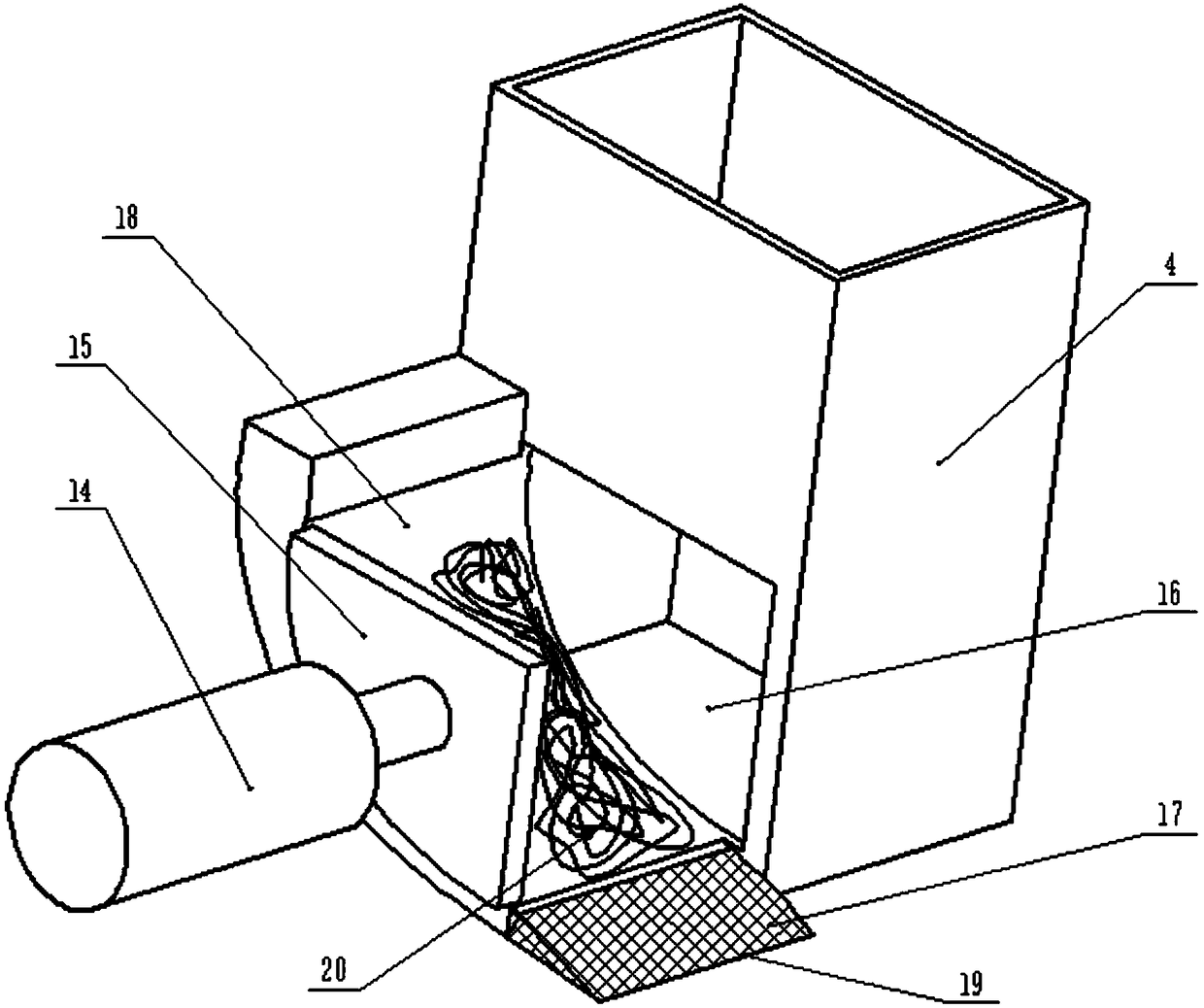

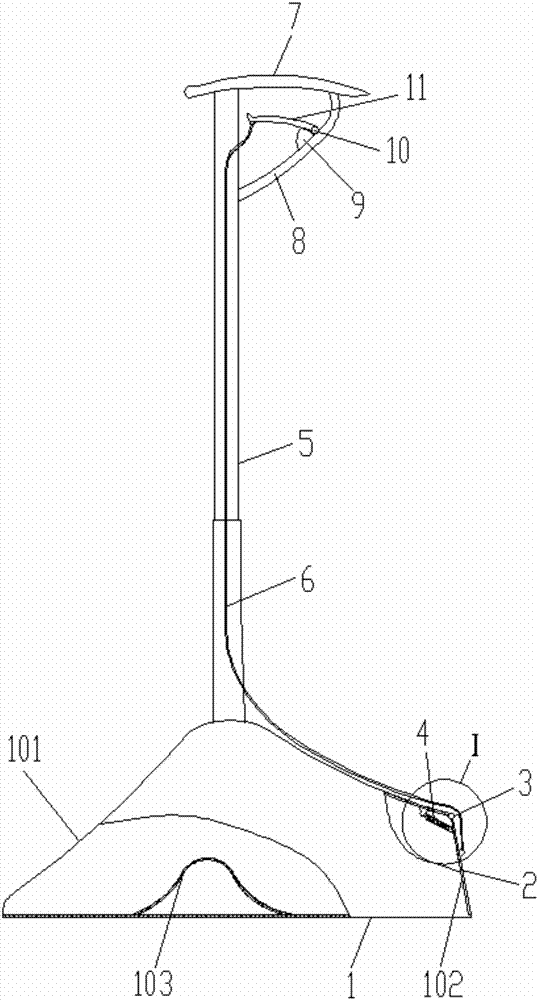

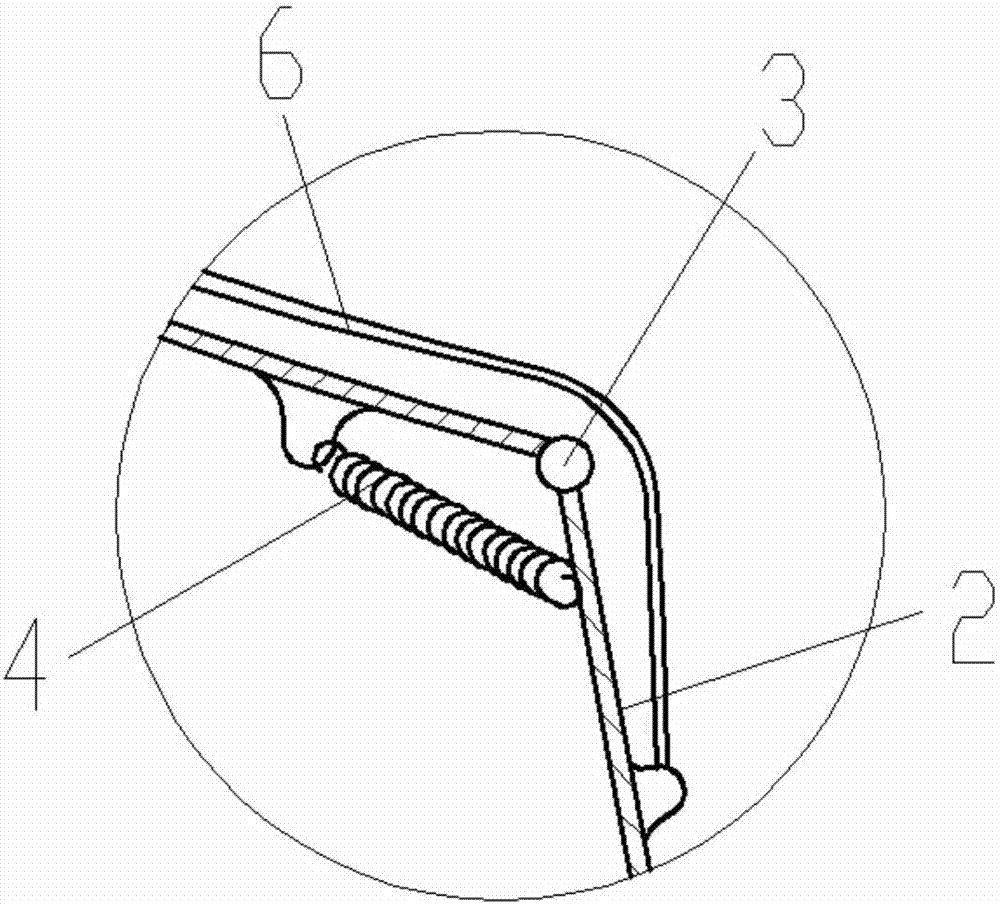

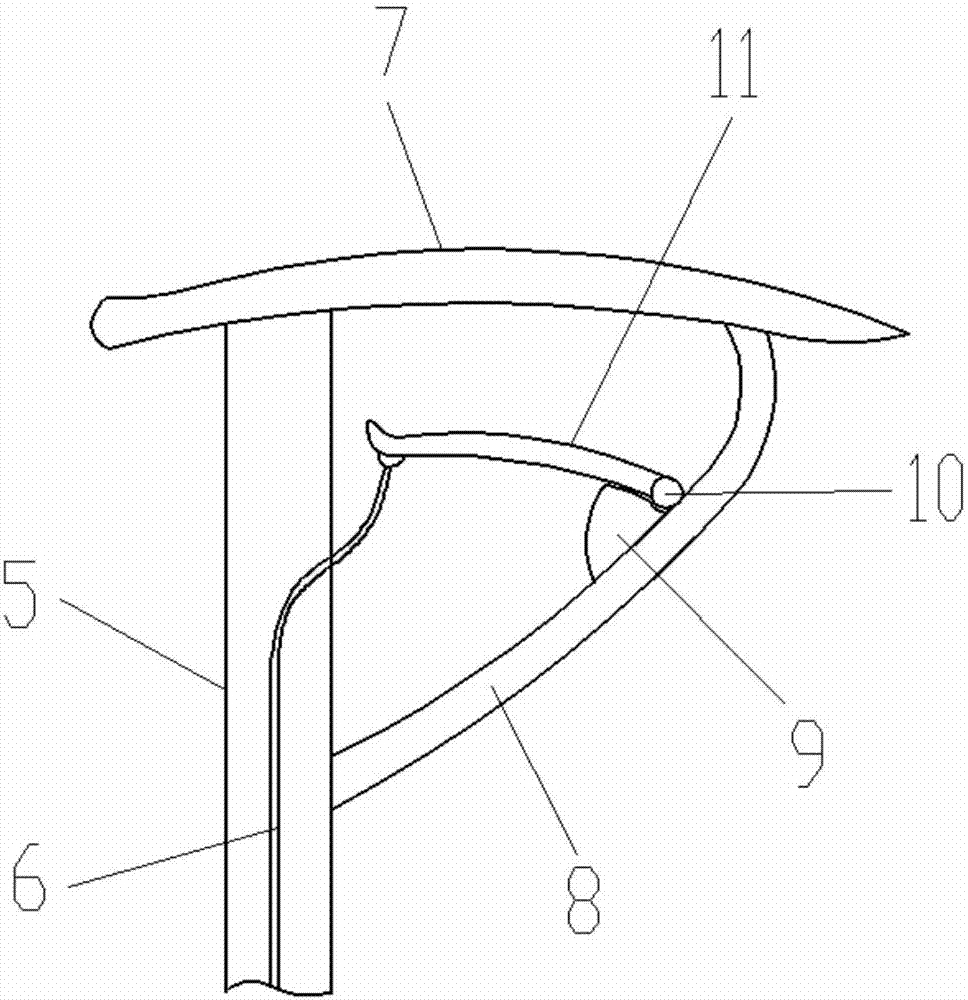

Road marking line remover

The technical scheme of the invention relates to a road marking line remover, and belongs to the technical field of road construction. The remover includes the body, a baking device, a blade, a battery, a waste line collection device and a backup cleaning device, A battery is mounted on the upper part of the vehicle body, the above-mentioned bake device, blades, scrap line collectors and spare cleaning devices are installed under the body. the device overcomes the noise and dust generated in the working process of the traditional road marking removing device, The damage to the pavement is alsoreduced to a very low degree, and the vibration generated by the device is very small when the operator uses the device to clear the road marking, thereby reducing the nuisance to the operator due tothe vibration and reducing the labor intensity.

Owner:刘一帆

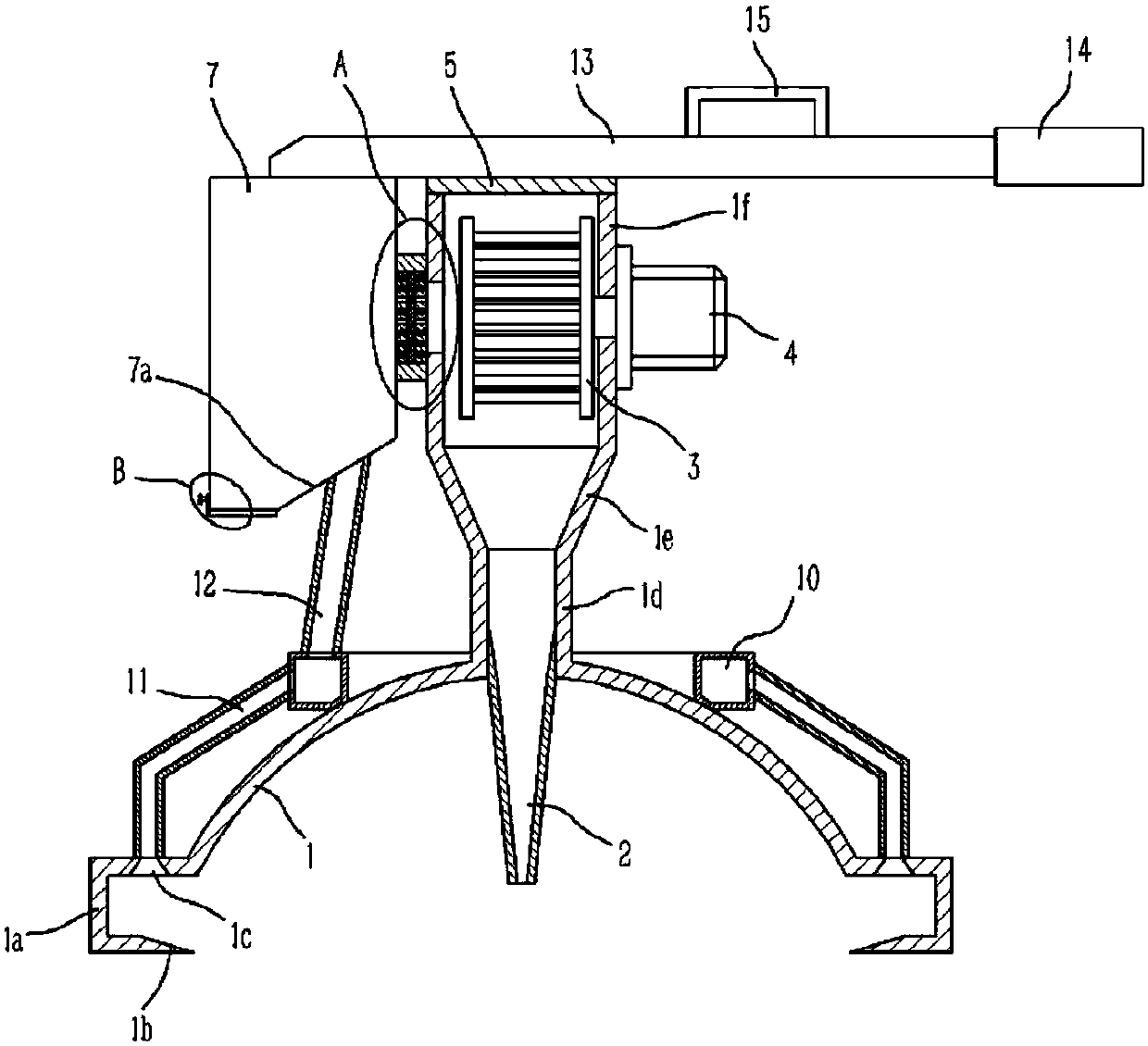

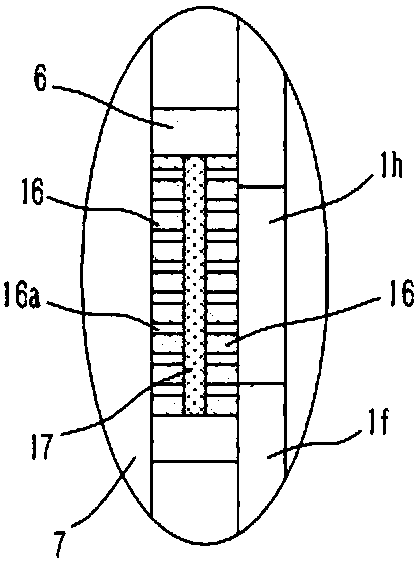

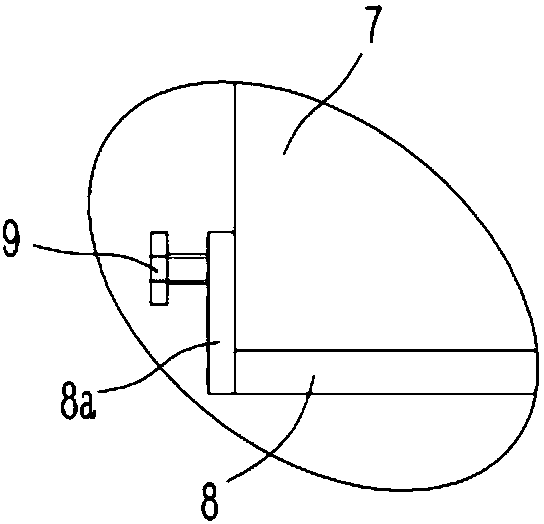

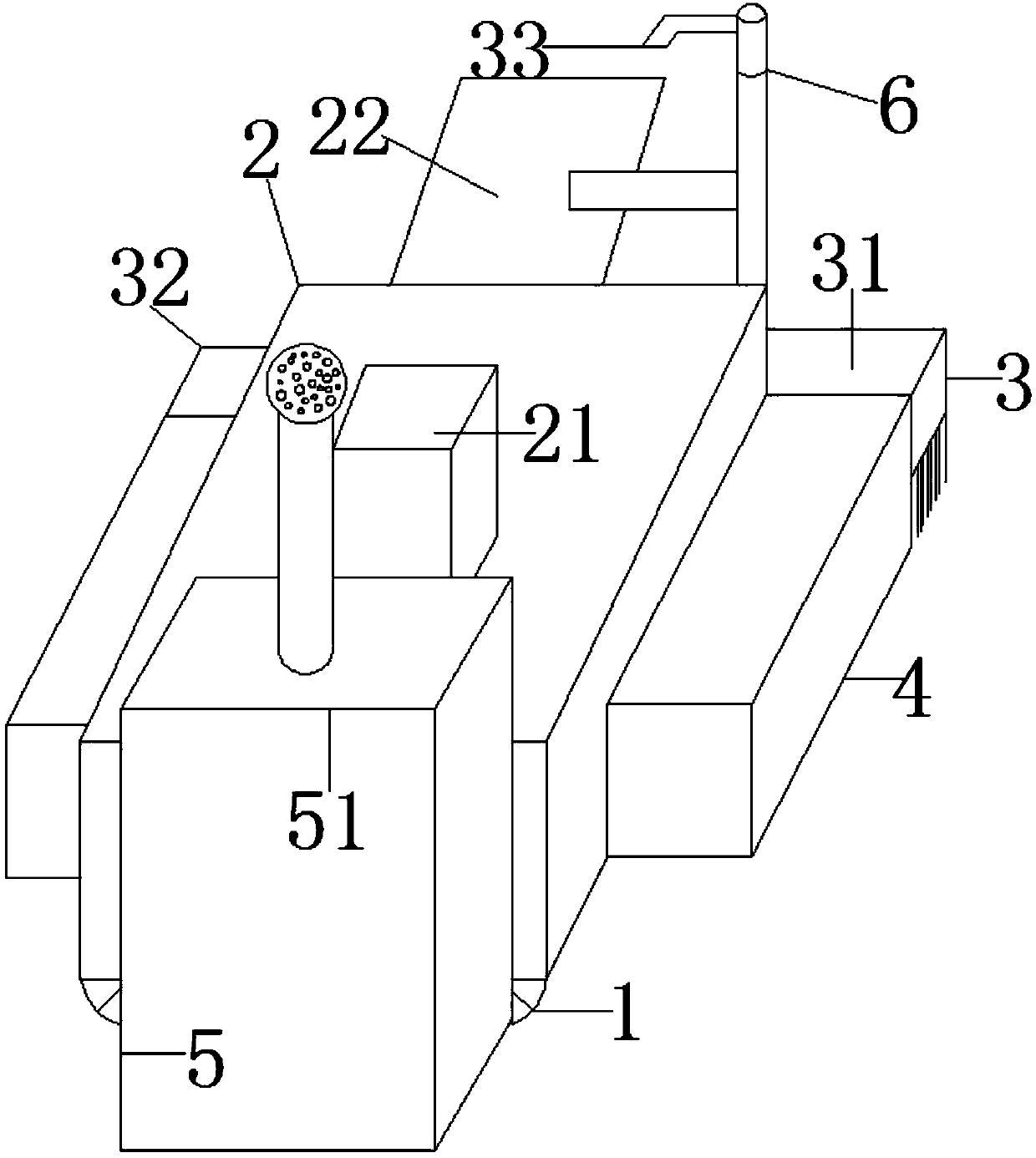

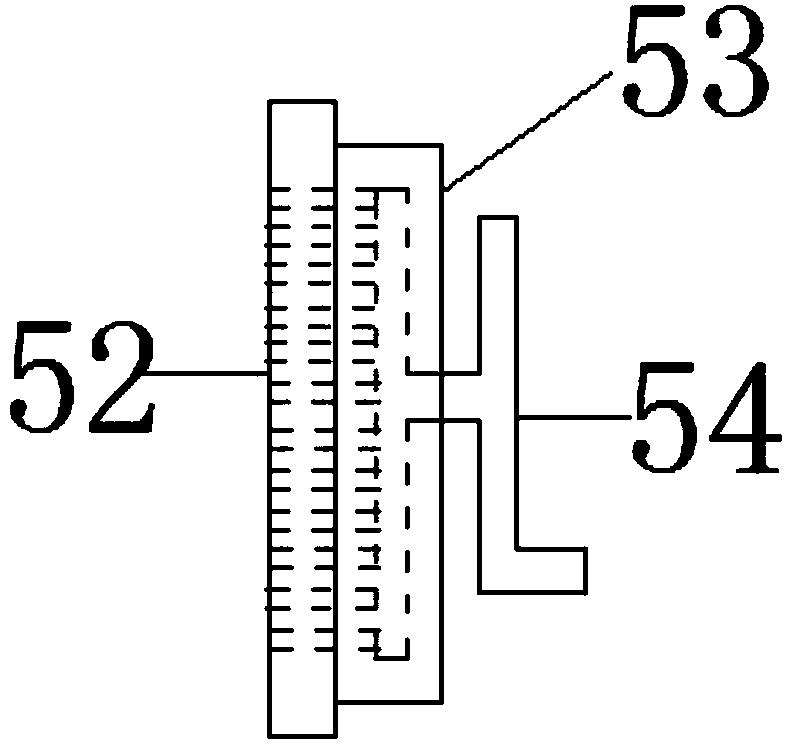

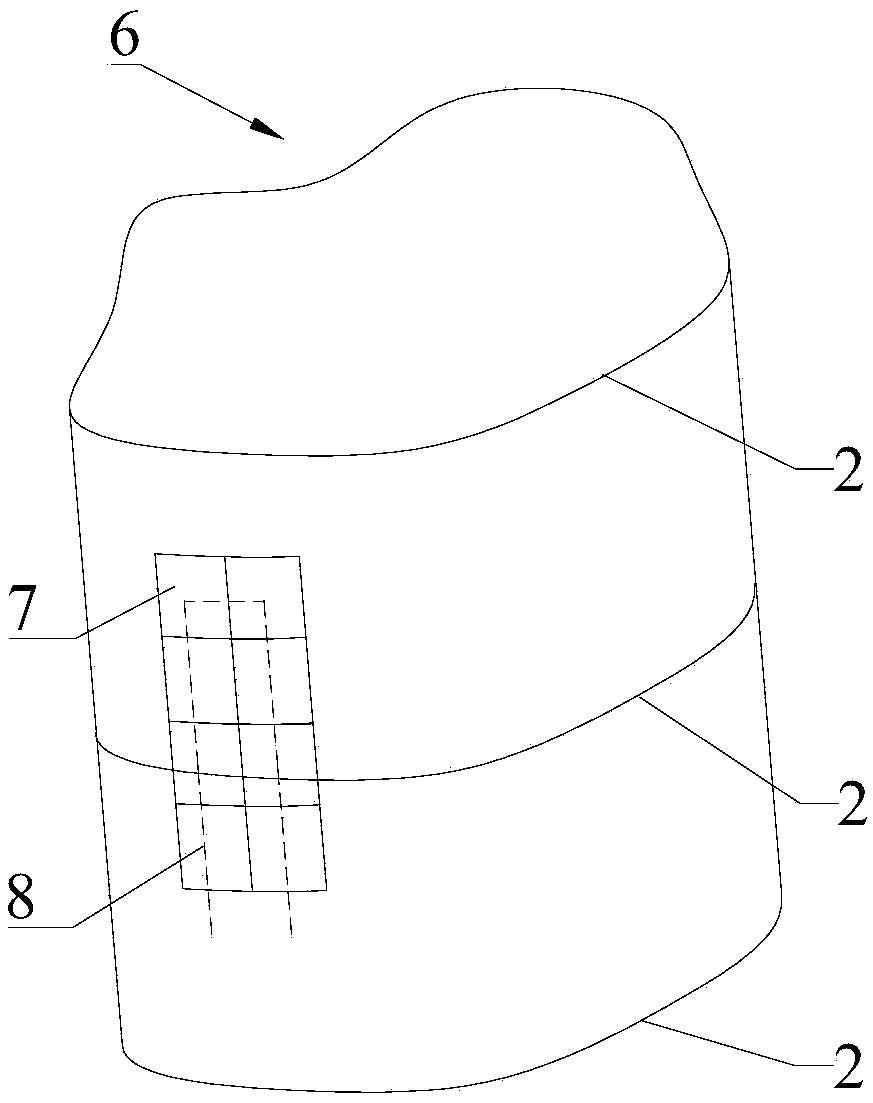

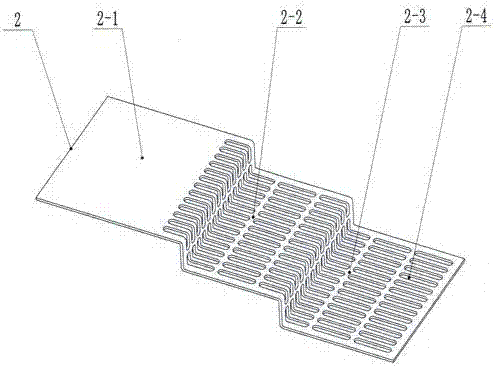

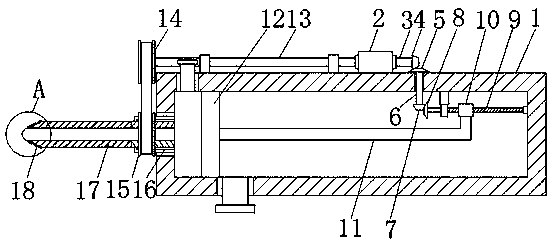

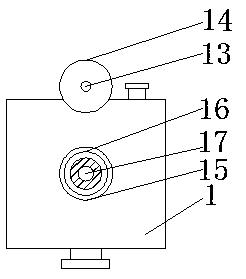

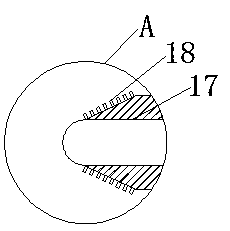

Dust blowing type die cleaning device

InactiveCN107597725AImplement a cleanupSimple structureDirt cleaningCleaning using gasesEngineeringVibration transmission

The invention discloses a dust blowing type die cleaning device. The device comprises a spherical dust hood, wherein a vertical dust suction tube is formed at top end of the dust hood; the upper end of the dust suction tube is inserted into a vent seat and is bent to form a flange; the flange is pressed against the bottom surface of the vent seat; a damping spring is arranged on the dust suction tube in a sleeving mode; the two ends of the damping spring are pressed against the vent seat and the dust hood respectively; a vent hole is formed in the side wall of the vent seat; a vent tube communicating with the vent hole in the vent seat is fixed on the outer wall of the vent seat; the vent tube is fixed on a dust storage box; a dust suction fan is fixedly connected to the dust storage box;a concave table is formed on the inner wall of the upper end of the dust storage box; a installing plate is inserted and fixed in the concave table of the dust storage box; a micro-vibration motor isfixedly connected to the installing plate; a vibration transmission rod is fixedly connected with the micro-vibration motor; and the vibration transmission rod is inserted into the dust suction tube of the dust hood. According to the dust blowing type die cleaning device, an integrated dust blowing and dust sucking function is used to replace a simple dust blowing function, thus one-time cleaningof chippings in a die installing hole is achieved, and the phenomenon of repeated cleaning is avoided.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

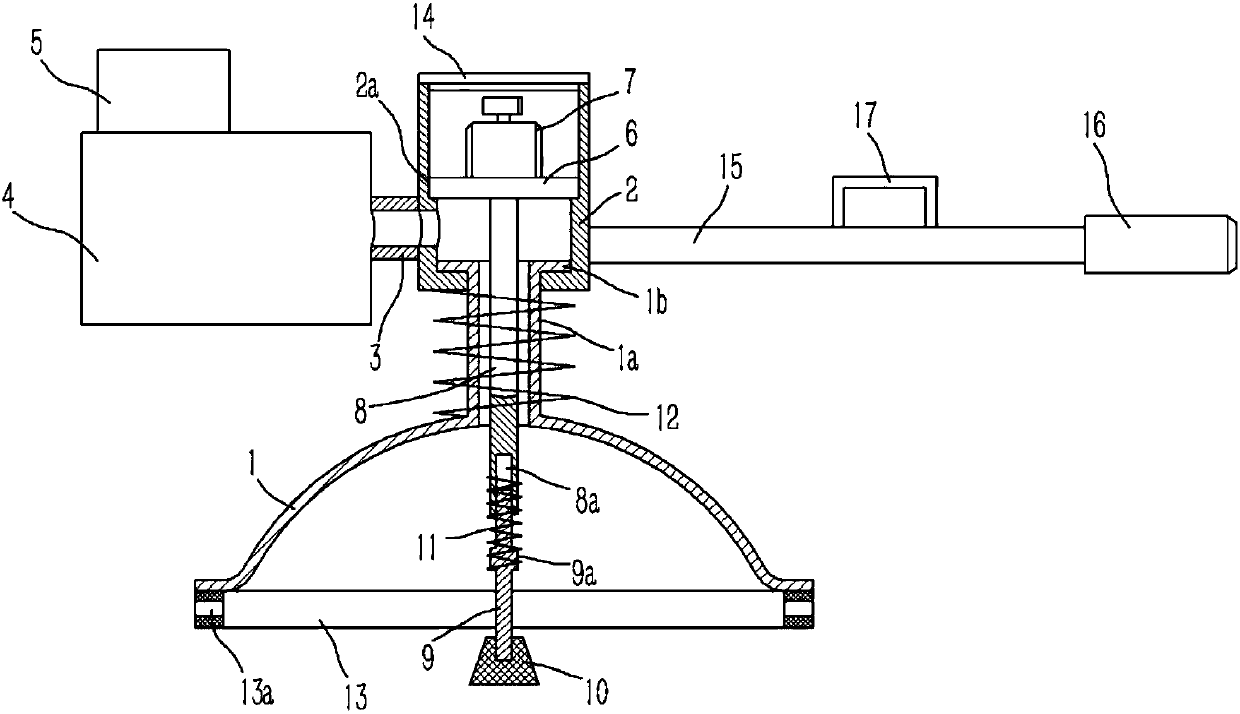

Vibration type die cleaning device

InactiveCN107597739AImplement a cleanupSimple structureDirt cleaningEngineeringVibration transmission

The invention discloses a vibration type die cleaning device. The device comprises a spherical dust hood, wherein a vertical dust suction tube is formed at top end of the dust hood; the upper end ofthe dust suction tube is inserted into a vent seat and is bent to form a flange; the flange is pressed against the bottom surface of the vent seat; a damping spring is arranged on the dust suction tube in a sleeving mode; the two ends of the damping spring are pressed against the vent seat and the dust hood respectively; a vent hole is formed in the side wall of the vent seat; a vent tube communicating with the vent hole in the vent seat is fixed on the outer wall of the vent seat; the vent tube is fixed on a dust storage box; a dust suction fan is fixedly connected to the dust storage box; aconcave table is formed on the inner wall of the upper end of the dust storage box; a installing plate is inserted and fixed in the concave table of the dust storage box; a micro-vibration motor is fixedly connected to the installing plate; a vibration transmission rod is fixedly connected with the micro-vibration motor; and the vibration transmission rod is inserted into the dust suction tube ofthe dust hood. According to the vibration type die cleaning device, a vibration and dust sucking structure is used to replace a simple dust blowing function, thus one-time cleaning of chippings in a die installing hole is achieved, and the phenomenon of repeated cleaning is avoided.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Dustpan capable of preventing garbage from sliding out

Provided is a dustpan capable of preventing garbage from slipping out, comprising a dustpan body and a hand-held rod. The upper part of the dustpan body is in the shape of a case. There is a front opening, the front part of the bottom plate inside the dustpan body is horizontally provided with a garbage blocking structure, the rear end of the dustpan body is provided with a rear opening, the rear opening of the dustpan body is covered by a rear cover that rotates up and down, and the inner side of the rear cover The elastic tensioning device is connected with the upper wall of the rear part of the inner cavity of the dustpan body, and the rear cover is connected with the handle through the pulling device. The invention can prevent the dustpan from being tilted when loading garbage, and the original garbage inside the dustpan can be prevented from being blown away by the wind. convenient.

Owner:王晗哲

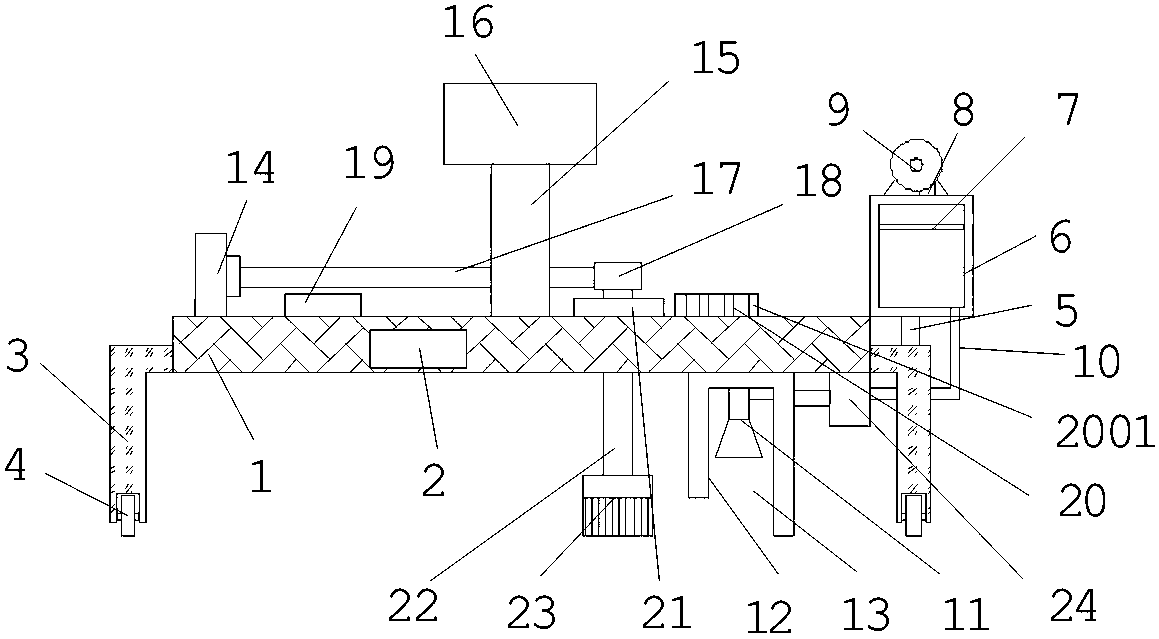

Scavenging machine for classroom

InactiveCN108784546ASimple structureInnovative designAutomatic obstacle detectionTravelling automatic controlTorsion springEnvironmental quality

The invention discloses a scavenging machine for a classroom. The scavenging machine comprises a placement board, a sliding chute, a storage battery, support legs, rolling wheels, a fixed column, a dust storage shell, a filtering net, an air suction pipe, a draught fan, a telescopic pipe, a dust suction head, a dust feeding cylinder, a dust feeding cavity, a linear motor, a fixed rod, a handle, anoutput rod, a fixed block, a first connecting plate, a first pawl, a first torsion spring, a second connecting plate, a second pawl, a second torsion spring, a ratchet wheel, a connecting rod, a scavenging hairbrush and an electric pushing rod. The scavenging machine is simple in structure and novel in design, dust on the ground inside the classroom is scavenged into the dust feeding cylinder through the scavenging hairbrush, so that the scavenged ground does not need to be repeatedly scavenged by virtue of the scavenging hairbrush, the ground in the classroom can be cleaned once, the fluctuation of the dust is avoided, the indoor environmental quality is guaranteed, the scavenging machine is convenient to use, and the scavenged dust can be collected and stored by virtue of the dust storage shell through the cooperation of the draught fan, an air suction pipe and the dust suction head.

Owner:洛阳高昌机电科技有限公司

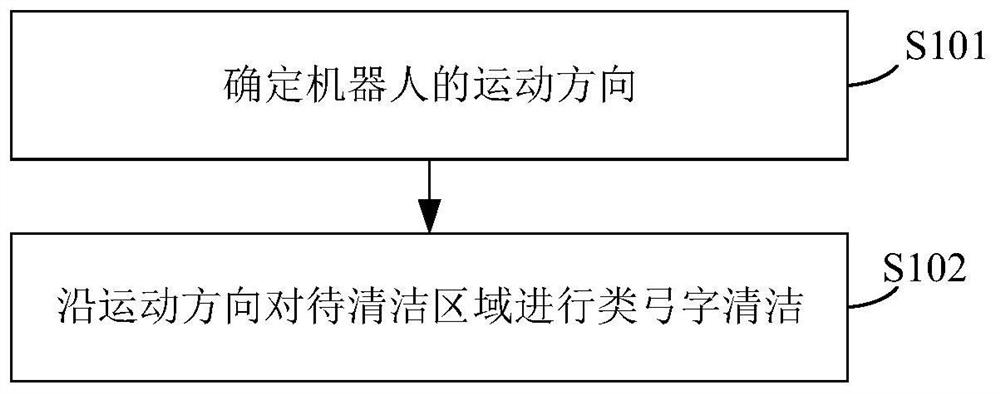

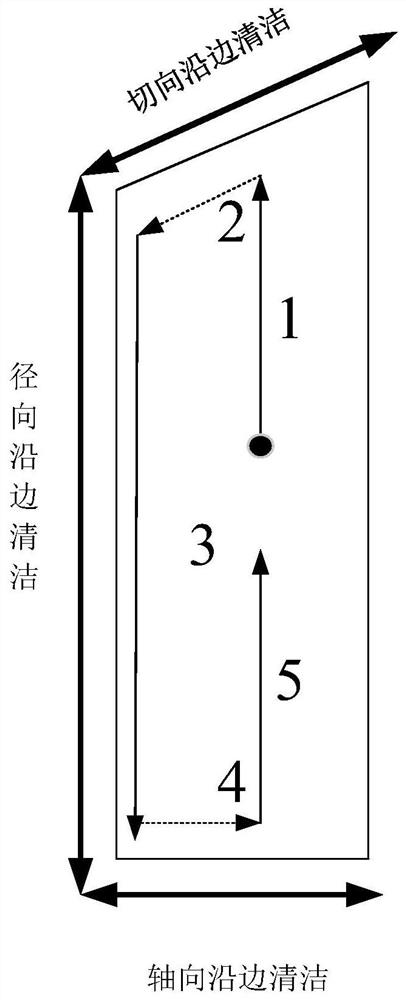

Robot cleaning method and device, robot and storage medium

InactiveCN111802962AGood job cleaningShorten the durationDigital data information retrievalCarpet cleanersEngineeringMechanical engineering

The invention is suitable for the technical field of robots. The invention provides a robot cleaning method and device, a robot and a storage medium. The robot cleaning method comprises the steps thatthe movement direction of a robot is determined, bow-like cleaning is performed on the to-be-cleaned area in the movement direction, wherein the bow-like cleaning comprises radial cleaning and edge cleaning, radial cleaning refers to cleaning in a region along the longitudinal direction of the bow-like shape, the edge cleaning comprises axial edge cleaning, radial edge cleaning and tangential edge cleaning, the axial edge cleaning is edge cleaning in the transverse direction of the bow-like shape, the radial edge cleaning is edge cleaning in the longitudinal direction of the bow-like character, the tangential edge cleaning is edge cleaning in the tangential direction of the inner edge of the area to be cleaned, and the projection length of the edge cleaning path in the transverse direction of the bow-like character does not exceed a first preset value. According to the invention, the total cleaning time can be saved, the cleaning efficiency is improved, and long-distance edge cleaningcan be avoided, so that the cost is saved.

Owner:SHENZHEN LDROBOT CO LTD

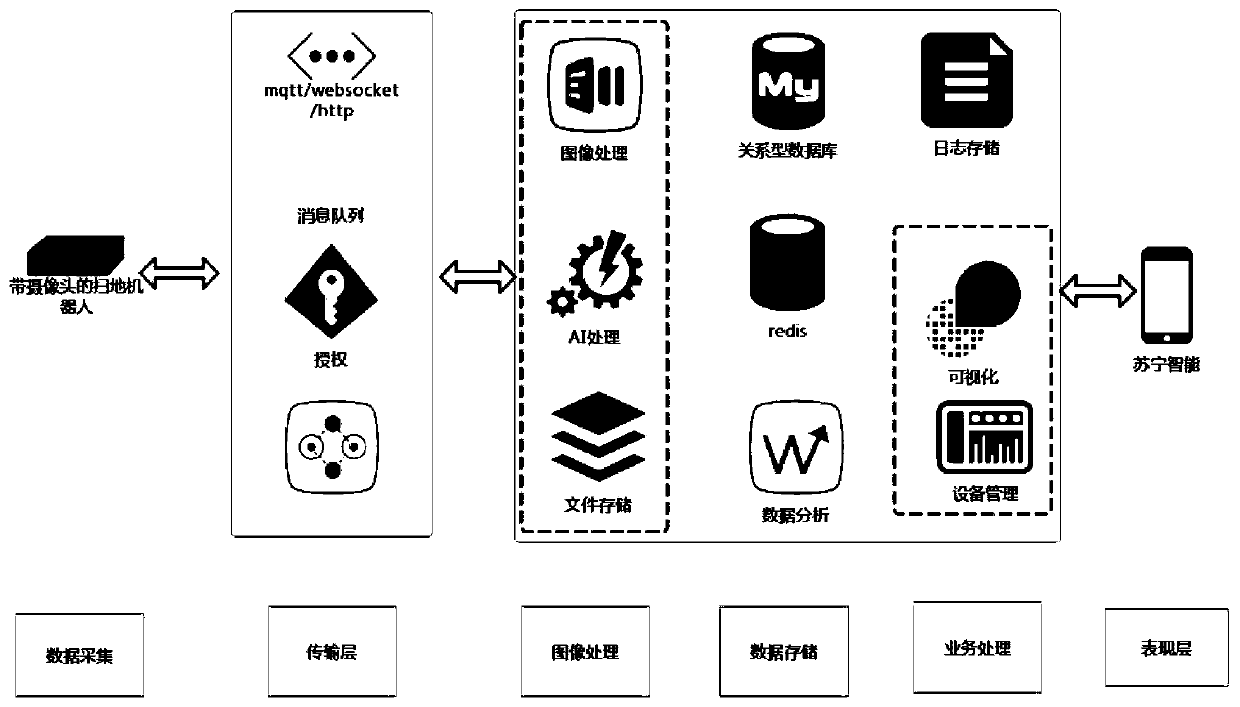

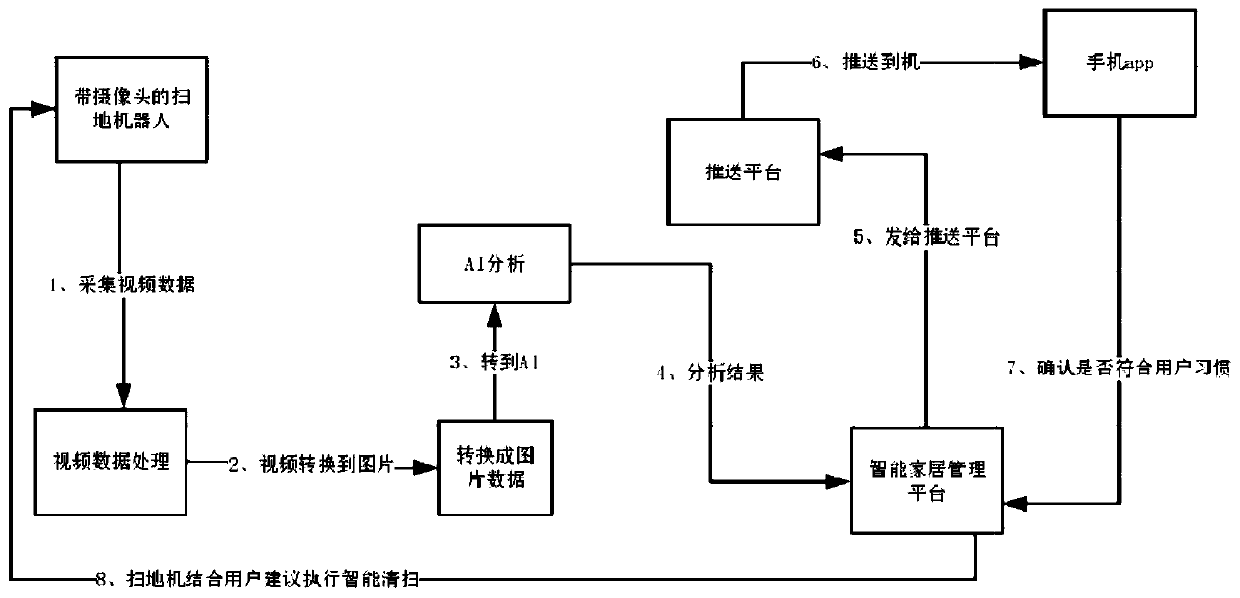

Visual sweeping method and system

InactiveCN111281274AExtended service lifeSave electricityCarpet cleanersCleaning action controlArtificial intelligenceUser management

The invention discloses a visual sweeping method and system. According to the method, the ground and garbage scanned by an AI camera are automatically identified and reported to a server; a place anda map where the garbage exists are recorded, an AI platform analyzes factors influencing a cleaning effect, such as a rule that the home easily dirties, a garbage type and a family member activity rule, the factors influencing the cleaning effect are avoided in an optimal mode, and the autonomous cleaning time, area and cleaning modes of different areas of the sweeping robot are formulated; and finally, indoor cleaning can be carried out autonomously basically without manual operation. The time for a user to manage the sweeping robot can be saved, the intelligent level of the sweeping robot isimproved, the cleaning effect and accuracy of the sweeping robot are improved, repeated sweeping is reduced, the service life of the sweeper is prolonged, and precise sweeping is achieved.

Owner:SUNING INTELLIGENT TERMINAL CO LTD

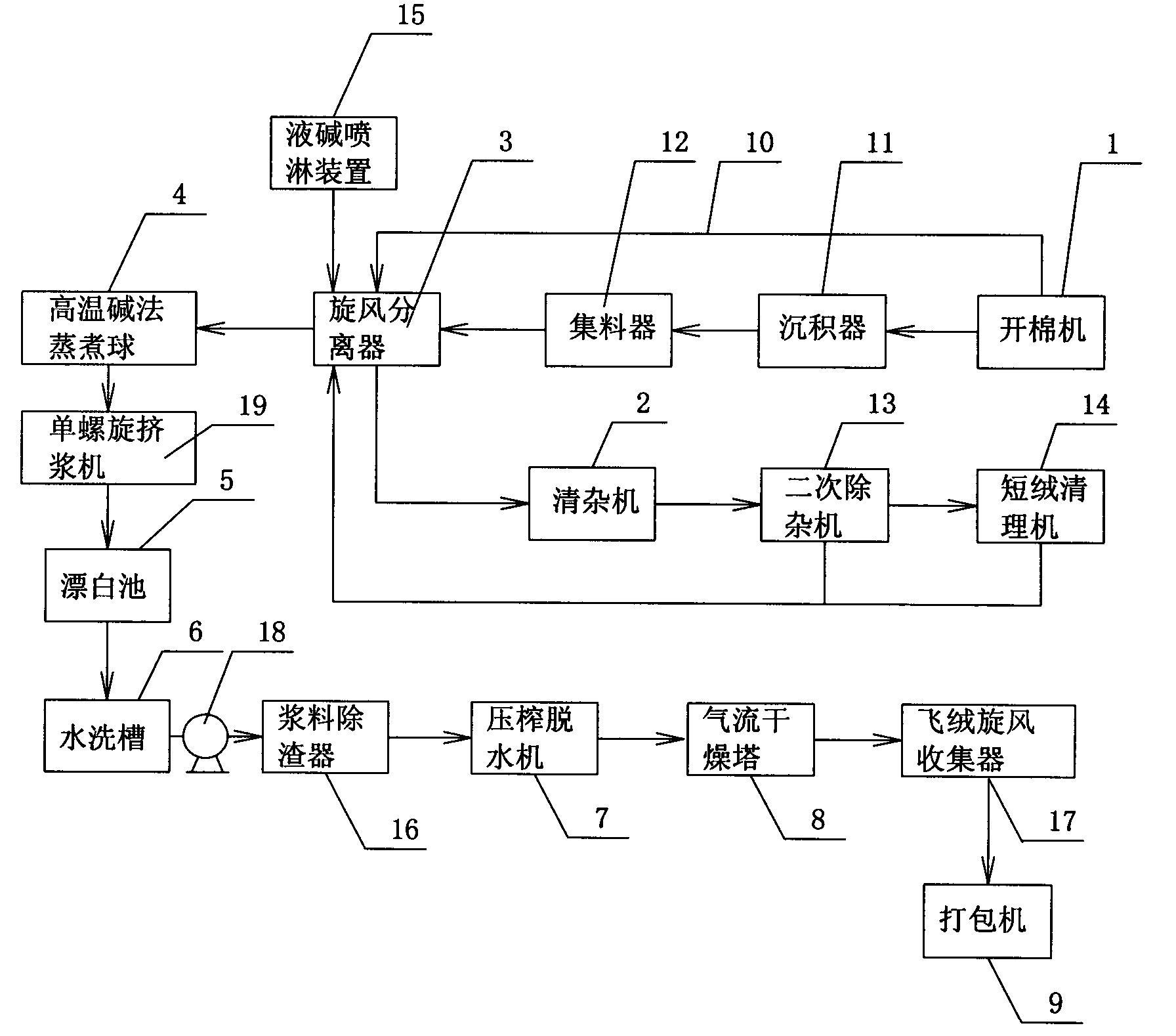

Cotton linter production line

InactiveCN103352386ARelieve pressureAvoid repeated cleaningPaper material treatmentAirflowSewage treatment

The invention discloses a cotton linter production line, which successively comprises the following processing equipment according to process requirements: a cotton opening machine, an impurity clearing machine, a separator, a high temperature alkaline cooking ball, a single-screw pulp squeezer, a bleaching pool, a washing tank, a squeezing dewatering machine, an air flow drying tower and a packaging machine. The cotton linter production line is characterized in that: the cotton opening machine is connected to the separator by an air inducing pipeline, a deposition device and a collector are orderly disposed between the cotton opening machine and the impurity clearing machine. The collector is in connection with the separator and the impurity clearing machine respectively through air inducing pipelines. A secondary impurity clearing machine and a linter cleaning machine are connected to the impurity clearing machine in order through an air inducing pipeline, and are in connection with the separator respectively through air inducing pipelines. The cotton linter production line provided in the invention has the advantages of: reasonable structural design, good impurity clearing effect, high quality production product, low energy consumption, small sewage treatment difficulty, and low production cost.

Owner:如东县海宇纤维制品有限公司

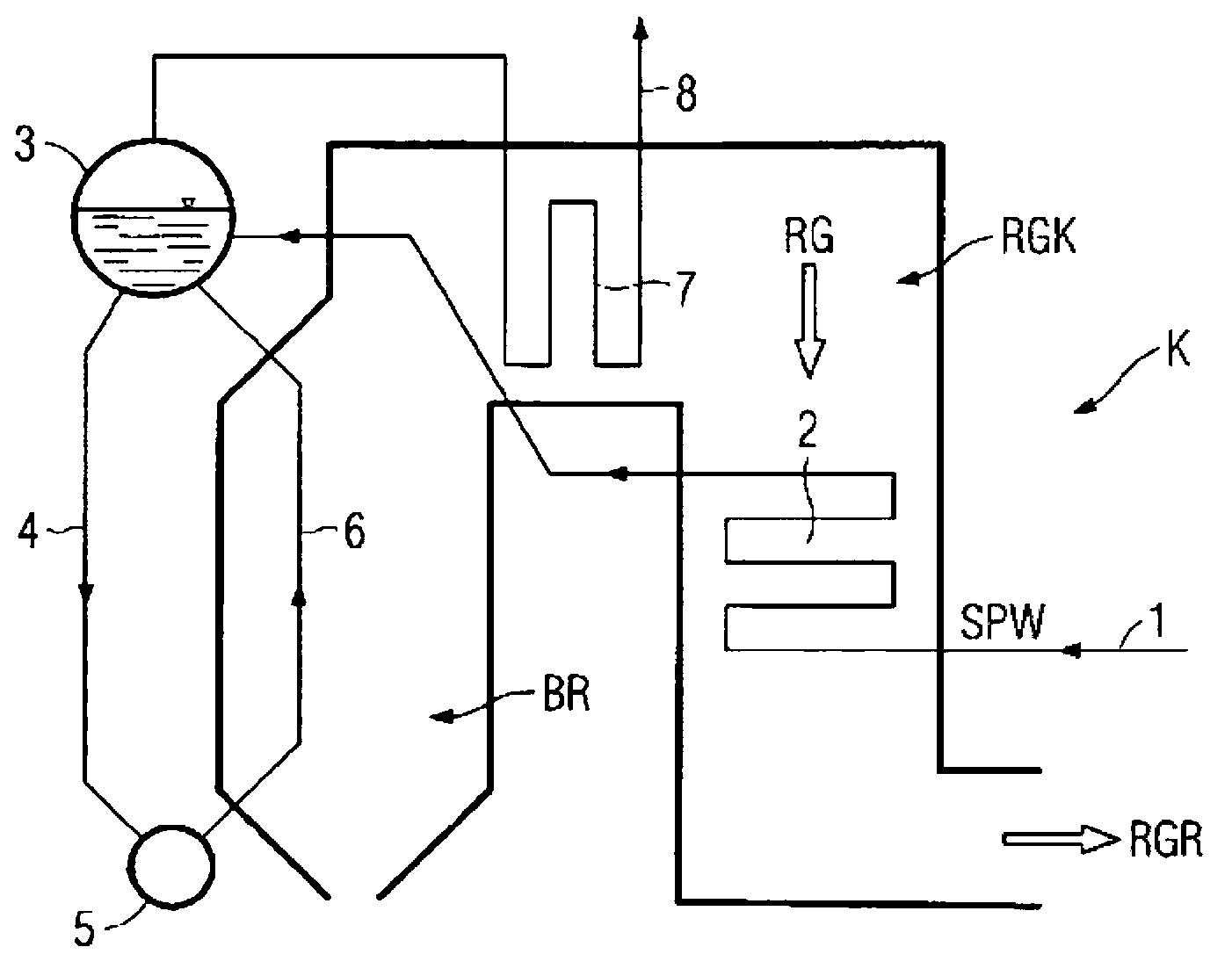

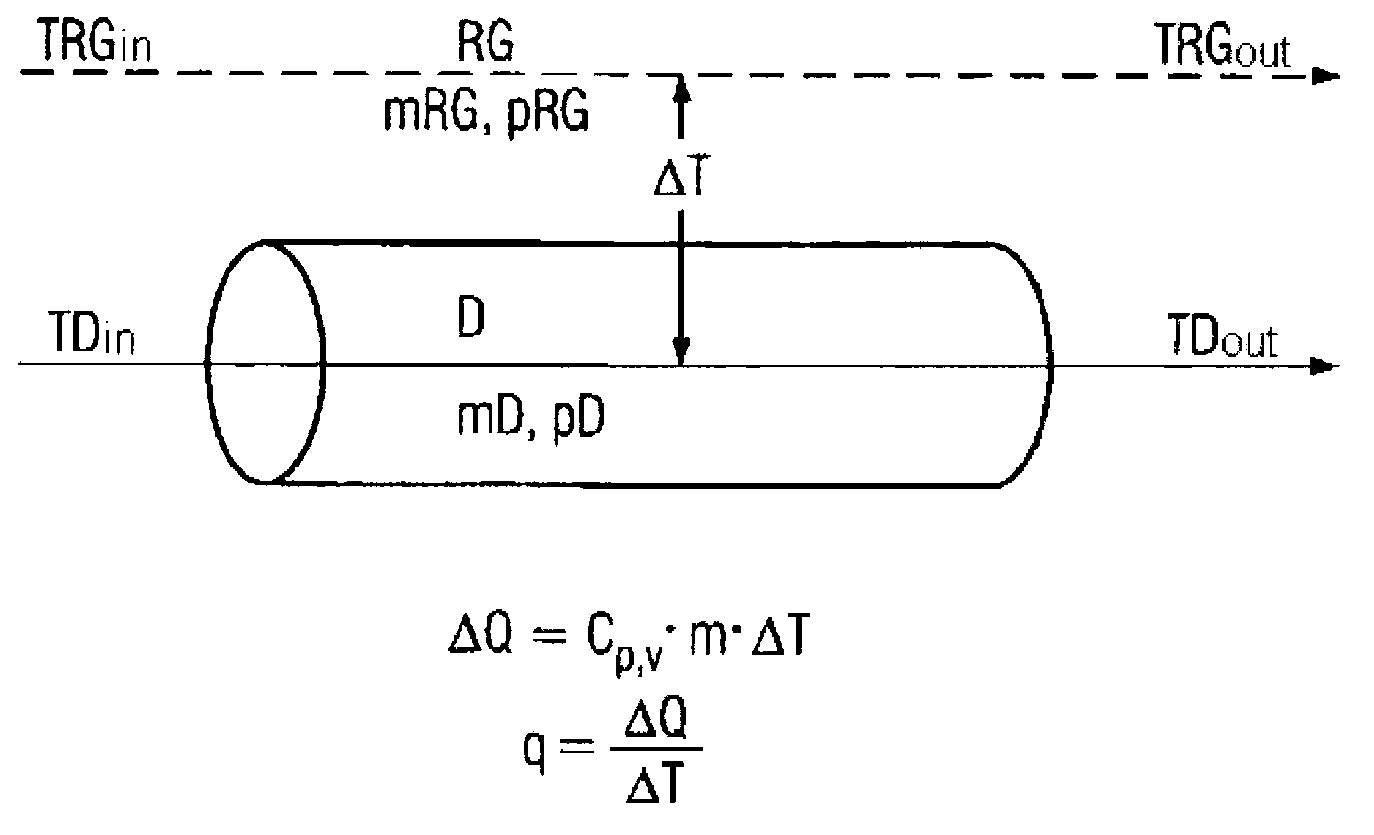

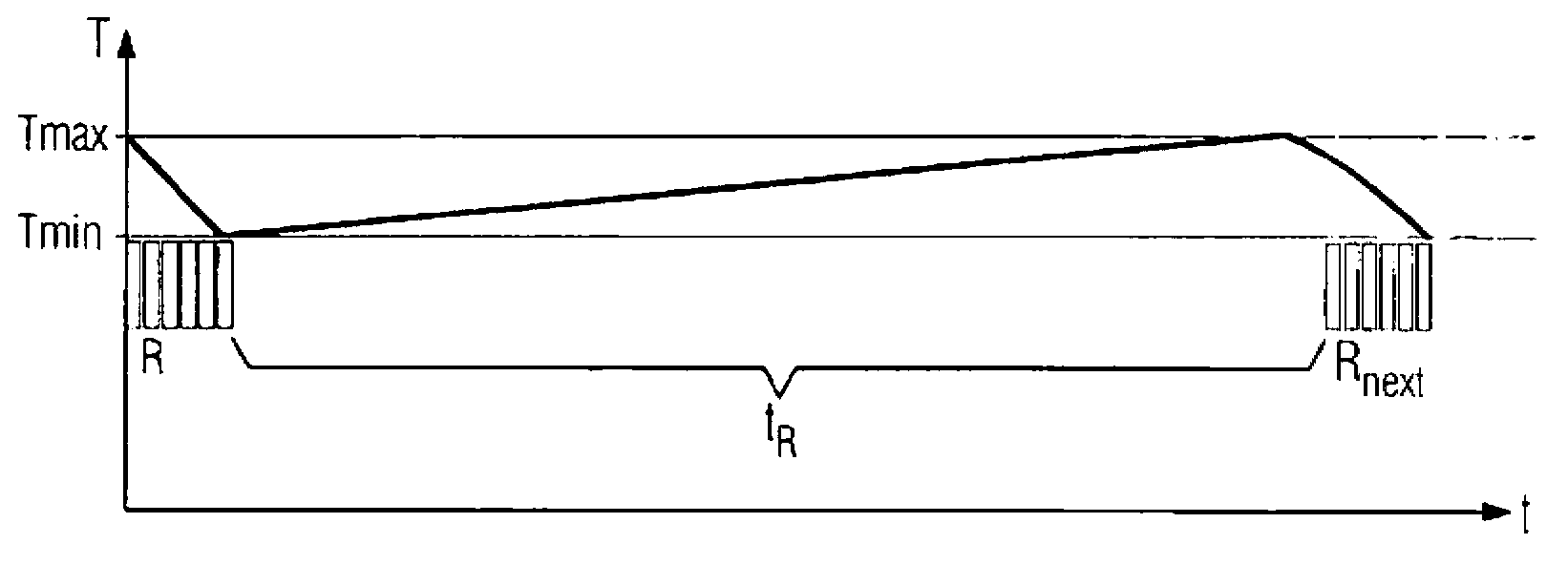

Method and device for controlling the temperature of steam in a boiler

ActiveCN103328887AReduce lossesWide coverageBoiler controlBoiler cleaning control devicesEngineeringSteam temperature

Owner:SIEMENS ENERGY GLOBAL GMBH CO & KG

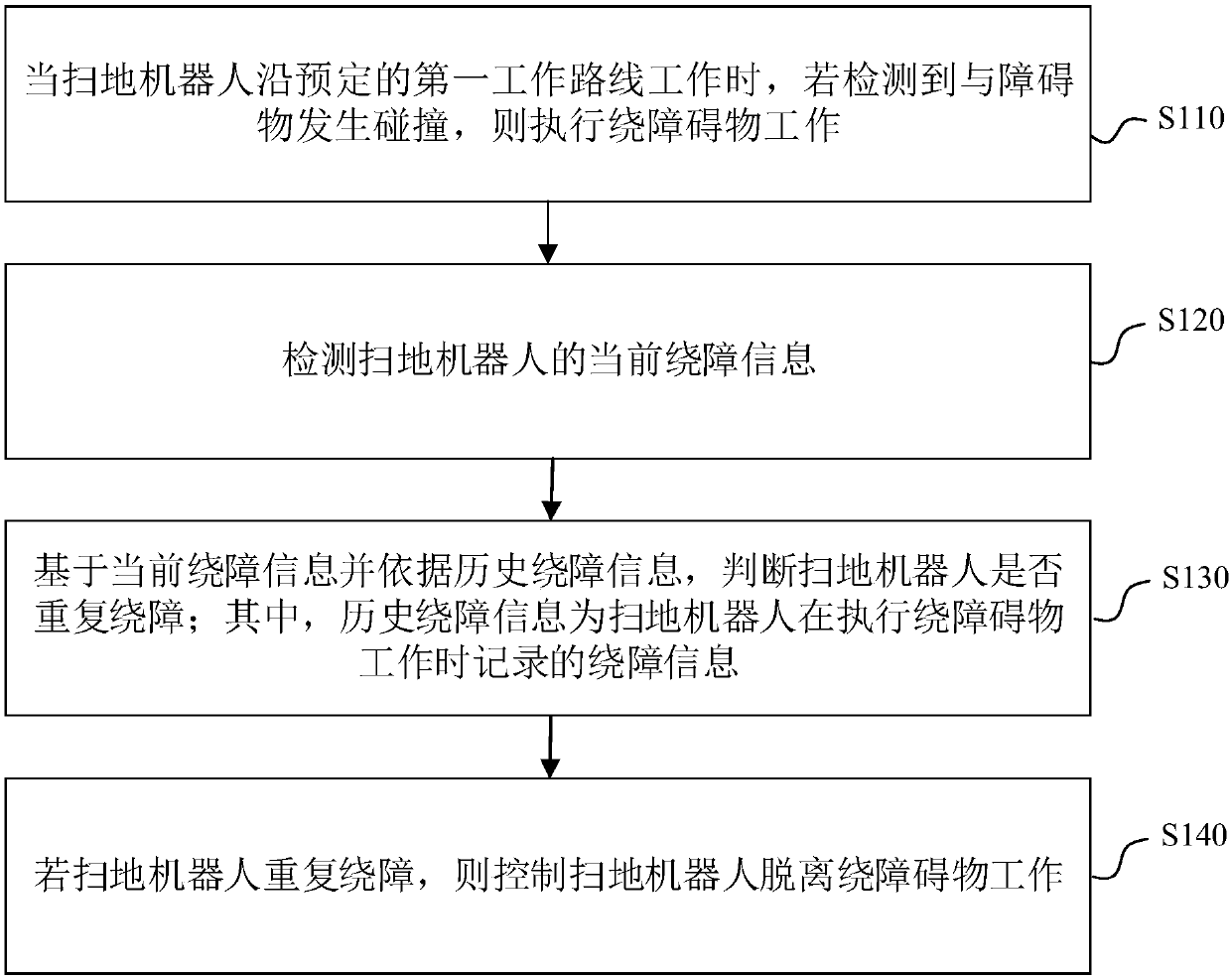

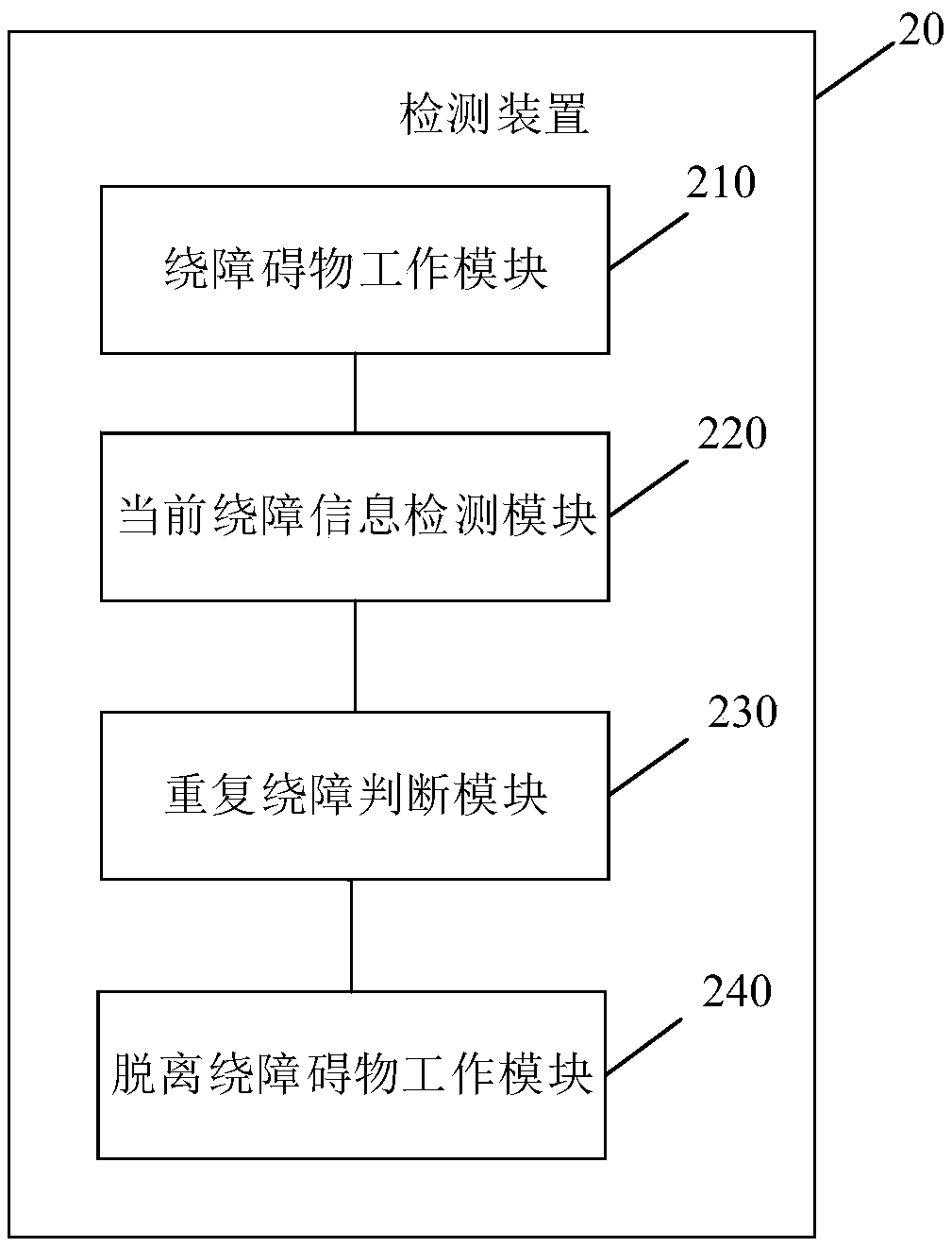

Repeated obstacle avoidance detection method and device, electronic equipment and readable storage medium

PendingCN111240308AAvoid repeated cleaningImprove work efficiencyPosition/course control in two dimensionsVehiclesObstacle avoidanceEnergy consumption

The embodiment of the invention provides a repeated obstacle avoidance detection method and device, electronic equipment and a readable storage medium. The method comprises the steps of: carrying outthe obstacle avoidance work if a sweeping robot is detected to collide with an obstacle when the sweeping robot works along a preset first working route, detecting current obstacle avoidance information of the sweeping robot, based on the current obstacle avoidance information and according to historical obstacle avoidance information, whether the sweeping robot avoids obstacles repeatedly or notis judged, the historical obstacle avoidance information being obstacle avoidance information recorded when the sweeping robot executes obstacle avoidance work, and if the sweeping robot repeatedly avoids the obstacle, controlling the sweeping robot to break away from the obstacle to work. According to the technical scheme provided by the invention, whether the sweeping robot is in a repeated obstacle avoidance state or not is judged according to the current obstacle avoidance information and the historical obstacle avoidance information, the sweeping robot repeatedly avoiding the obstacle iscontrolled to stop avoiding the obstacle in time, repeated sweeping of a swept area is avoided, the working efficiency of the sweeping robot is improved, and energy consumption is reduced.

Owner:BEIJING QIHOO TECH CO LTD

Cleaning device for quilt sewing machine workshop

InactiveCN108043756AAvoid cloggingImprove cleaning efficiencyUsing liquid separation agentCleaning using toolsAssistive device/technologyEngineering

The invention relates to the technical field of quilt sewing machine auxiliary equipment, in particular to a cleaning device for a quilt sewing machine workshop. The cleaning device comprises a powermechanism and a cleaning mechanism. The cleaning mechanism comprises a first cleaning mechanism body, a second cleaning mechanism body and a water spraying mechanism. The first cleaning mechanism bodycomprises a main cleaner, an auxiliary cleaner and a handle. The second cleaning mechanism body comprises a wind inlet, a wind outlet and an inner cavity. The inner cavity comprises a transmission mechanism, an impurity removing plate and a collecting groove. The water spraying mechanism comprises a water tank and a water spraying disc. The water spraying disc comprises a first outer disc, a second outer disc and a stoppage head. According to the cleaning device, by rotating hairbrush plates of the main cleaner and the auxiliary cleaner, large garbage is removed at first, plugging of the windinlet of the second cleaning mechanism body is avoided, an air flow channel between the wind inlet and the wind outlet and an opening of the collecting groove are partitioned through the impurity removing plate, the water spraying mechanism sprays water to cleaned areas, the problem that the quilt sewing machine workshop cleaning efficiency is low is solved, and the body health of personnel is maintained.

Owner:安徽省萧县徽星机械制造有限公司

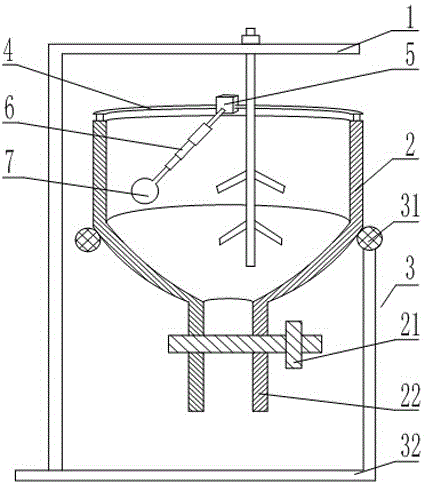

Liquid blending device with spiral cleaning structure

InactiveCN105080396AOvercome the problem of not being easy to cleanAvoid repeated cleaningRotary stirring mixersHollow article cleaningEngineeringJoints types

The invention relates to a liquid blending device with a spiral cleaning structure, comprising a stirring device, a liquid distribution body and a fixing device, wherein the top of the liquid distribution body is provided with a liquid inlet, the bottom of the liquid distribution body is provided with a liquid outlet, the liquid outlet is provided with a valve, the bottom of the liquid distribution body is sunken downwards to form a concave surface, the concave surface is gathered at the liquid outlet, the top of the liquid distribution body is provided with a slide rail, the slide rail is provided with a slide block, the slide block is provided with a control switch, one end of a connecting rod is connected to the slide block, the other end of the connecting rod is connected with a cleaning ball, and the connecting rod is a bamboo joint type telescopic rod. By means of the circling motion of the slide bock, the cleaning ball at one end of the connecting rod is enabled to relatively move along the inner wall of the liquid distribution body and generate friction force, thus thoroughly cleaning particle purities on the inner wall of the liquid distribution body; once the slide block slides for one circle, the connecting rod extends for one section, and the cleaning position of the cleaning ball descends for one section distance, in this way the cleaning ball can thoroughly clean the particle purities on the inner wall of the liquid distribution body, thus solving the problem that an existing liquid distribution device is not easy to clean.

Owner:CHENGDU OLYMVAX BIOPHARM

Method for cleaning surface of irregular columnar object

ActiveCN107891017AAvoid repeated cleaningImprove cleaning efficiencyCleaning using toolsUsing optical meansThree dimensional modelEngineering

Owner:深圳市汯沐科技有限公司

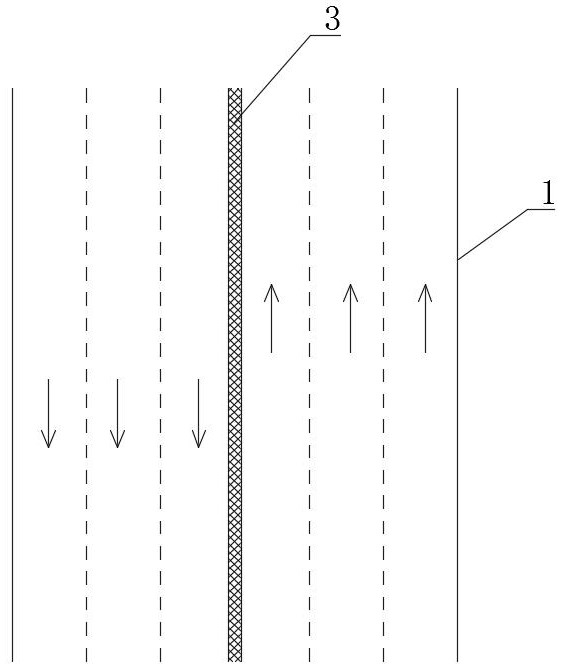

Road full-traversal sweeping path planning method of unmanned sweeper

ActiveCN112241175ANot affected by normal trafficImprove cleaning efficiencyRoad cleaningPosition/course control in two dimensionsDriving riskSingle vehicle

The invention discloses a road full-traversal sweeping path planning method of an unmanned sweeper. The method comprises the following steps that the unmanned sweeper judges the type of a to-be-sweptroad; if the lane is a single lane, autonomously identifying the road edge, the road edge is marked as a welt cleaning area, the welt cleaning area is preferentially cleaned according to related traffic rules, and a spiral inward cleaning path is planned; if the vehicle is in a double-lane or multi-lane mode, the road edge and the middle lane line or the middle isolation belt are autonomously recognized, and a sweeping path is planned according to the principle that the welt sweeping area is swept preferentially, the middle lane line area or the middle isolation belt area is swept secondly andthe area in the lane is swept finally. Planning of various paths complies with traffic rules, no retrograde driving risk exists, the vehicle cannot press or cross a middle lane line or a middle isolation belt to drive, and driving safety is guaranteed; the spiral inward path and the sweeping sequence can guarantee driving safety, sweeping missing and repeated sweeping are avoided, and the sweeping efficiency is improved.

Owner:GUANGZHOU SAITE INTELLIGENCE TECH CO LTD

Remote control type indoor cleaning robot

InactiveCN106725130AQuick installationFor quick replacementAutomatic obstacle detectionTravelling automatic controlAgricultural engineeringTransfer mechanism

The invention discloses a remote control type indoor cleaning robot which comprises an anti-collision mechanism, a body, a driving mechanism, a humidifying mechanism, a lifting mechanism, a mop loading and transferring mechanism, an ultrasonic spraying device and a hardware control system, wherein the ultrasonic spraying device comprises a water tank; the water tank is arranged on the mopping robot; at least one ultrasonic module and a fan are arranged in the water tank; the water tank is externally connected with a water outlet pipe and a nozzle remote control type indoor cleaning robot; water in the water tank is atomized through electronic high-frequency oscillation by the ultrasonic modules; and the water spray is blown to the water pipe joint by the fan and sprayed to the ground by the nozzle. According to the remote control type indoor cleaning robot disclosed by the invention, a manner of removing dust by a dust collector is abandoned, the indoor cleaning robot is low in noise, low in energy consumption and capable of conveniently and rapidly mounting and replacing the mop, repeated cleaning is avoided due to a novel route planning manner, and the working efficiency is improved. Moreover, the problems that water spray is non-uniform and lots of water stains are remained are solved, and water resources are saved.

Owner:HECHI UNIV

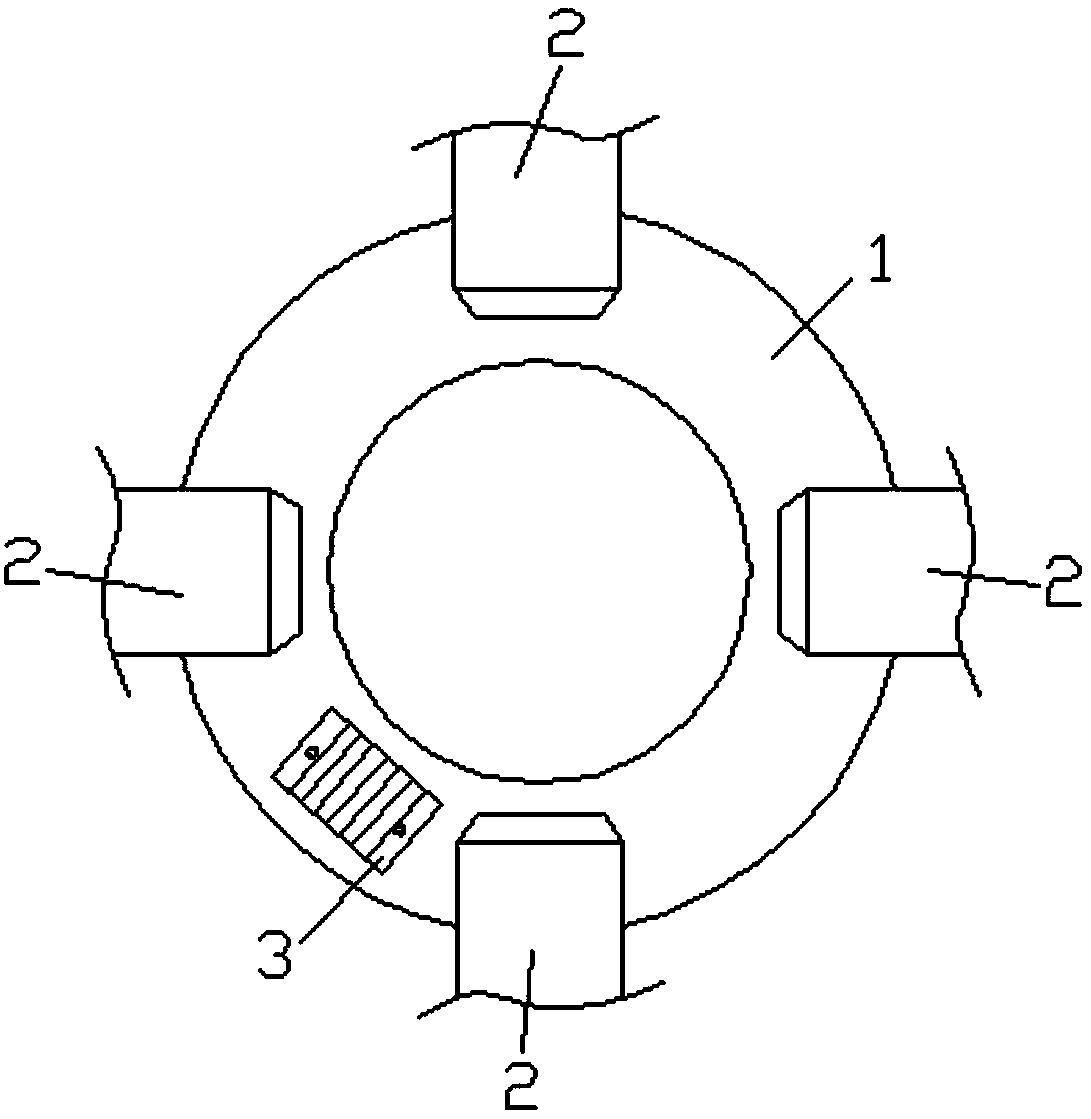

Yaw brake used for wind turbine generator set and provided with automatic cleaning function

PendingCN109372912ASimple and efficient operationEasy to cleanCleaning using toolsBraking elementsMaterial resourcesCalipers

The invention relates to a yaw brake used for a wind turbine generator set and provided with an automatic cleaning function. The yaw brake comprises a yaw brake disc, a drive mechanism, a plurality ofbrake calipers and at least one scraper plate, wherein the yaw brake disc is arranged horizontally; the multiple brake calipers are distributed in the circumferential direction of the yaw brake discat intervals and clamp the yaw brake disc; a pair of friction plates is symmetrically arranged on the part, of each brake caliper, clamping the yaw brake disc, and the yaw brake disc is positioned between the two friction plates; the scraper plate is horizontally and detachably mounted on the yaw brake disc; and the drive mechanism is arranged above the yaw brake disc and drives the yaw brake discto rotate through a gear reducer. The yaw brake has the following beneficial effects: the structure is simple; and powder and oil attached to the surfaces of the friction plates can be effectively cleaned away, and convenient and fast cleaning is achieved, so that the cleaning efficiency is greatly improved, and manpower and material resources are saved.

Owner:CHONGQING HAIZHUANG WINDPOWER ENG CO LTD

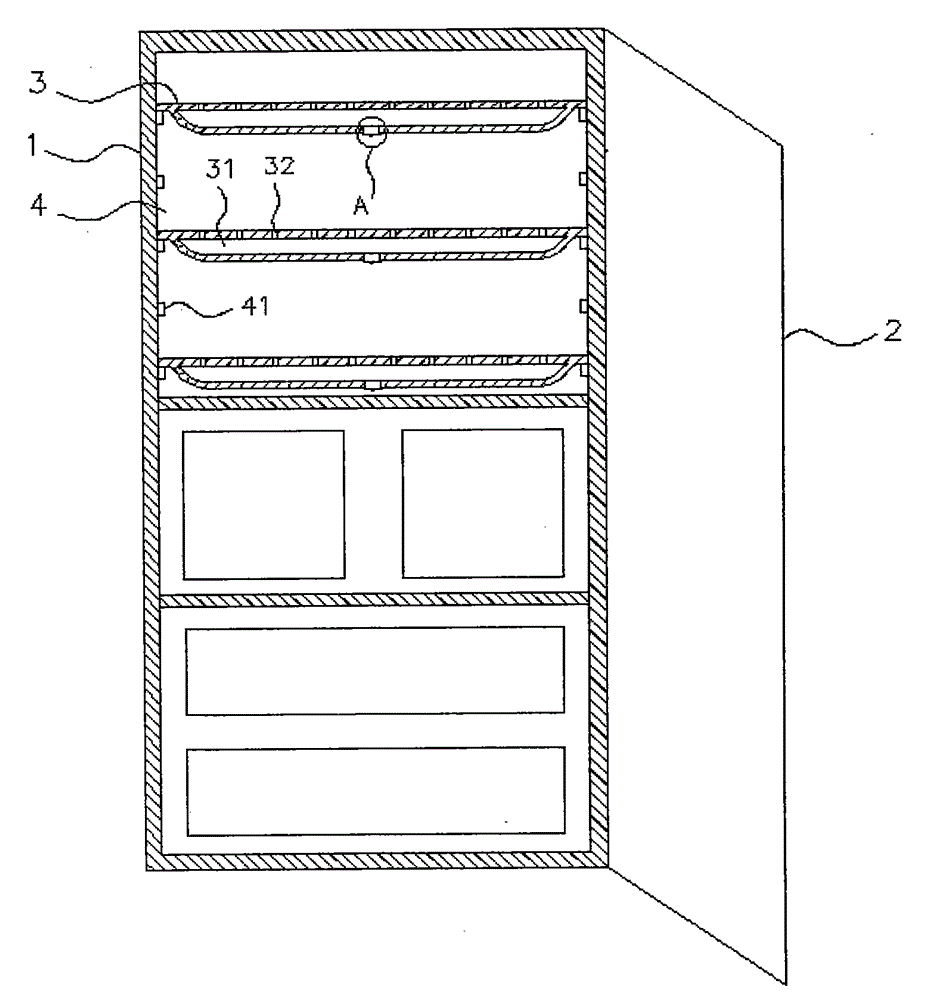

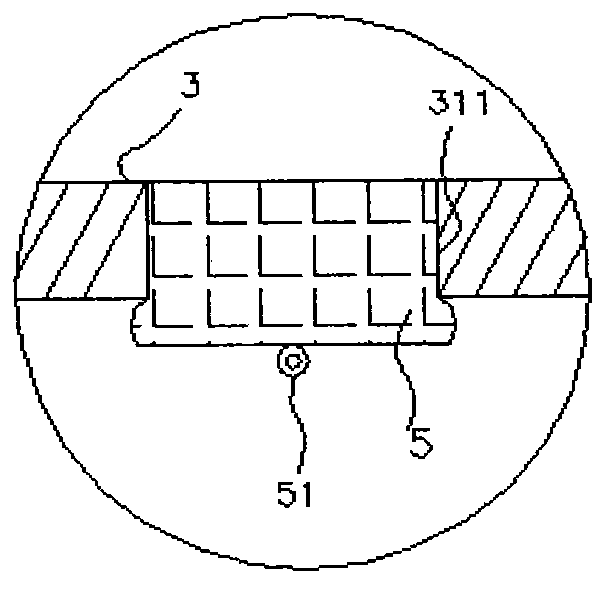

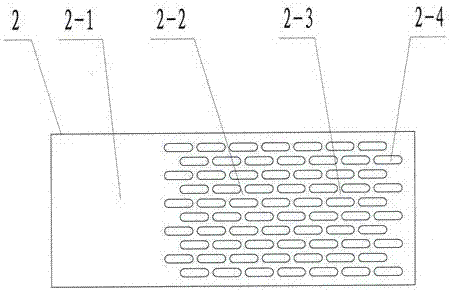

Novel refrigerator

InactiveCN104359272AAvoid repeated cleaningReduce labor intensityLighting and heating apparatusDomestic refrigeratorsEngineeringMechanical engineering

The invention relates to a novel refrigerator which comprises a refrigerator body, a door body and a spacing plate, wherein a containing space is defined in the refrigerator body; the door body is arranged on the refrigerator body and is used for opening or closing the containing space; the spacing plate is connected with the side wall of the containing space and is used for loading articles; a water storage chamber is downward extended from the lower surface of the spacing plate; a plurality of water seepage holes are uniformly arranged in the spacing plate; the water seepage holes are communicated with the water storage chamber. The novel refrigerator has the convenience in collecting superfluous water on the spacing plate.

Owner:胡立宇

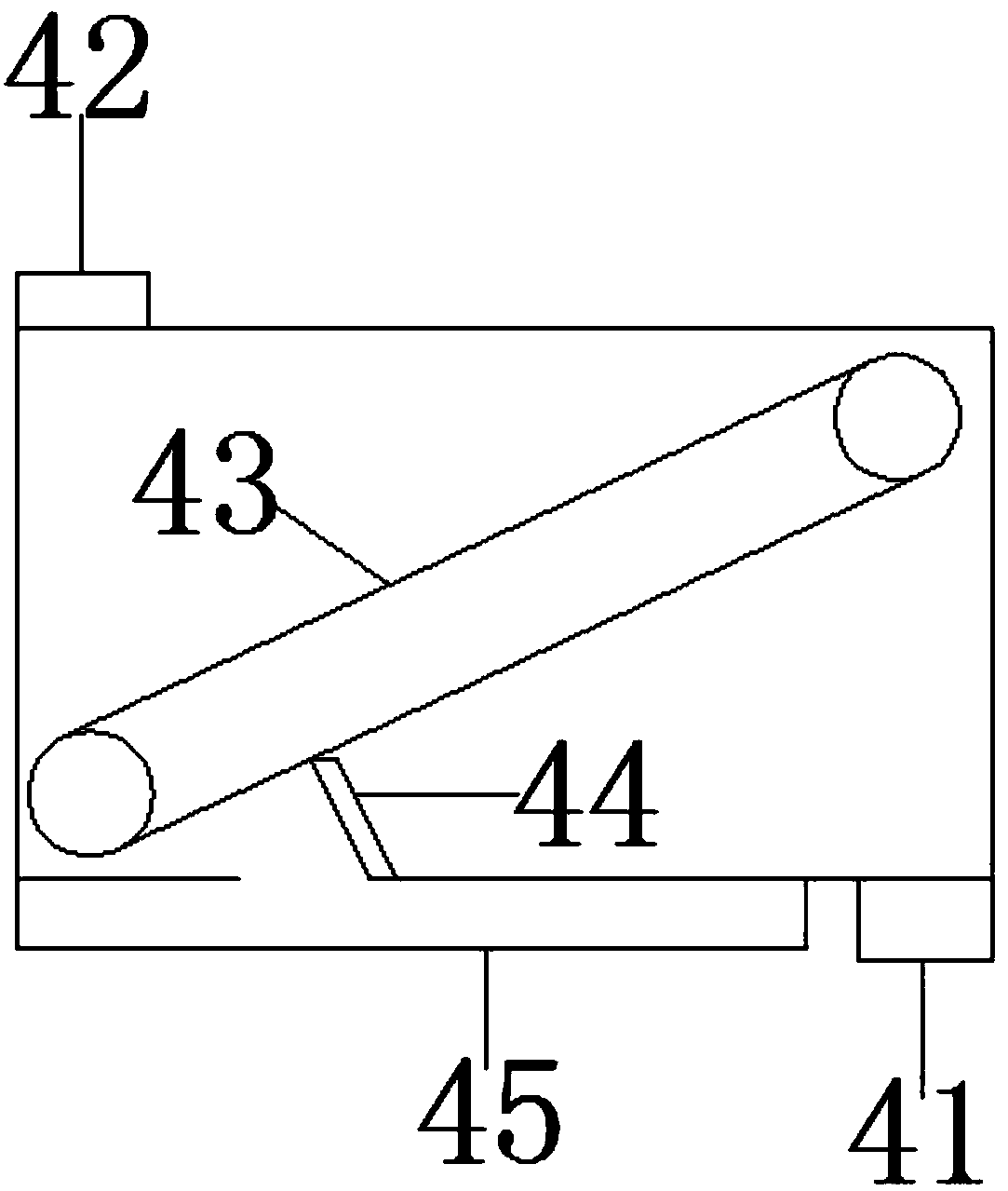

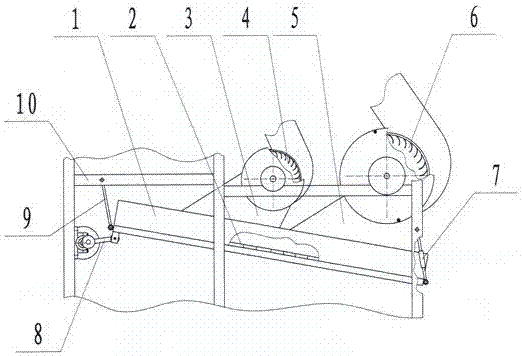

Double-airflow cleaning device of peanut picker

PendingCN107251703AReduce loss rateReasonable structureDigger harvestersEngineeringStructural engineering

The invention discloses a double-airflow cleaning device of a peanut picker. A framed vibrating screen with the high front part and the low rear part is installed inside a rack, a crank connecting rod and a suspender are connected to the front end between the rack and the vibrating screen, a swinging connecting rod is connected to the rear end, a front air suction region and a rear air suction region are sequentially arranged behind a receiving region on a screen plate of the vibrating screen, a front cross flow fan is installed at the portion, above the front air suction region, of the rack, a front air suction hood with an air suction inlet stretching into the front air suction region is arranged on the front cross flow fan, a rear cross flow fan is installed at the portion, above the rear air suction region, of the rack, a rear air suction hood with an air suction inlet stretching to the rear air suction region is arranged on the rear cross flow fan, an air through channel is reserved between the front and rear air suction hoods of the two cross flow fans, and sieve holes are uniformly distributed in the screen plate of the front and rear air suction regions. The double-airflow cleaning device has the advantages of being reasonable in structure and good in disposable cleaning and separation effect, avoiding repeated cleaning, lowering energy consumption, lowering fruit loss rate and saving the production cost.

Owner:河南瑞锋机械有限公司

Nasal cavity cleaning device used for pediatric department clinic treatment

The invention discloses a nasal cavity cleaning device used for pediatric department clinic treatment, and relates to the technical field of the pediatric department clinic treatment. By aiming at theproblem of foreign matter cleaning in a children nasal cavity cleaning process, the invention puts forward the following scheme that the nasal cavity cleaning device comprises a shell, wherein the outer wall of the top of the shell is fixedly connected with a two-axis motor; the right output end of the two-axis motor is provided with a first rotary shaft; the right end of the first rotary shaft is provided with a first driving bevel gear; a first driven bevel gear is arranged below the first driving bevel gear; the first driving bevel gear and the first driven bevel gear are in engaged transmission; and the bottom end of the first driven bevel gear is provided with a second rotary shaft. Through the combination of various structures, foreign matters in the children nasal cavity can be cleaned without injuring the children nasal cavity. In a use process, the device can automatically collect and clean foreign matters and nasal mucus in the nasal cavity, repeated cleaning is avoided, anda cleaning speed is quickened so as to shorten time when a child feels uncomfortable. In addition, the device is convenient in cleaning and can be reused, and therefore, cost is saved.

Owner:张芳芳

Cleaning method and device and computer storage medium

ActiveCN112971645AAvoid repeated cleaningAvoid secondary pollutionAutomatic obstacle detectionTravelling automatic controlProcess engineeringManufacturing engineering

Owner:MIDEA ROBOZONE TECH CO LTD

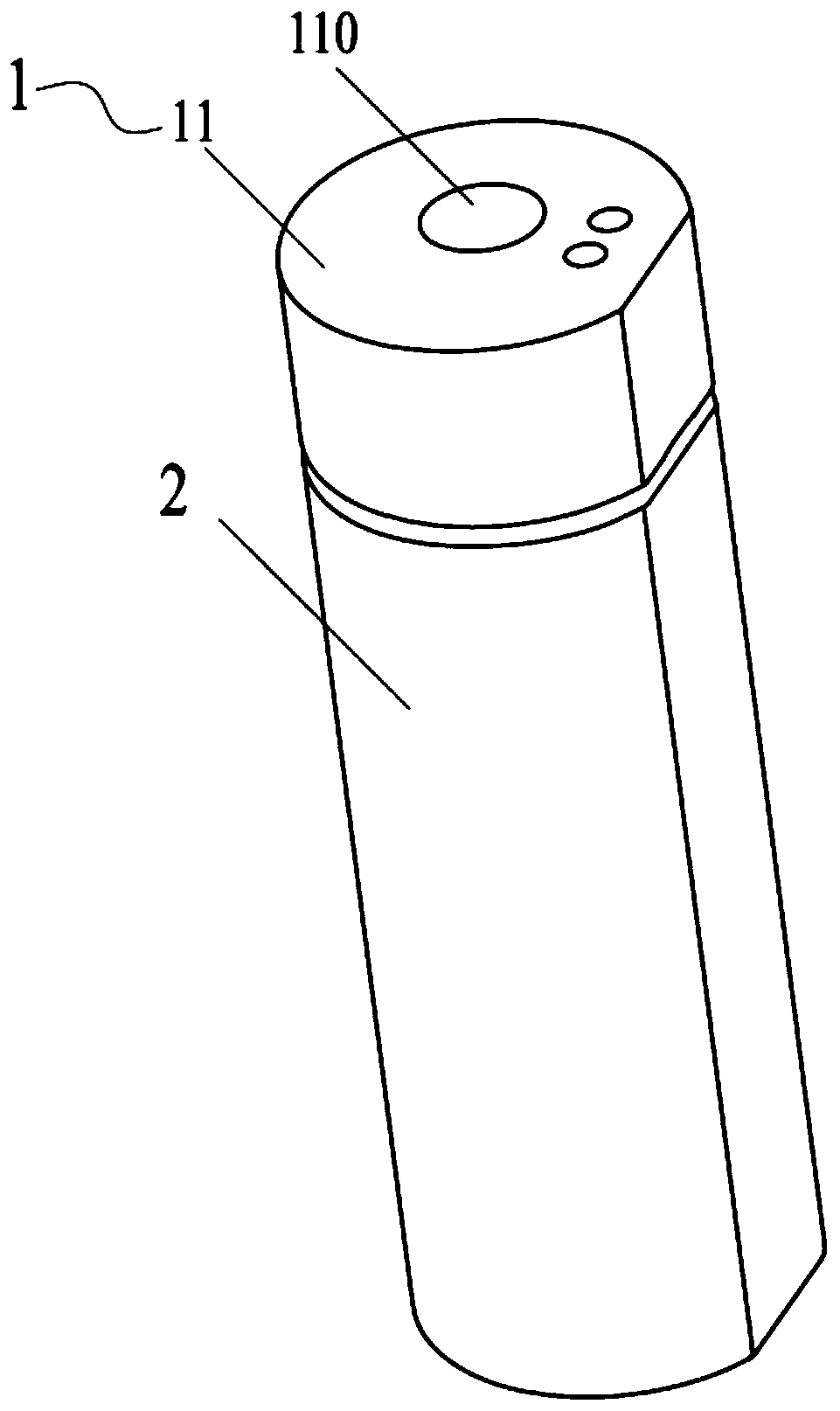

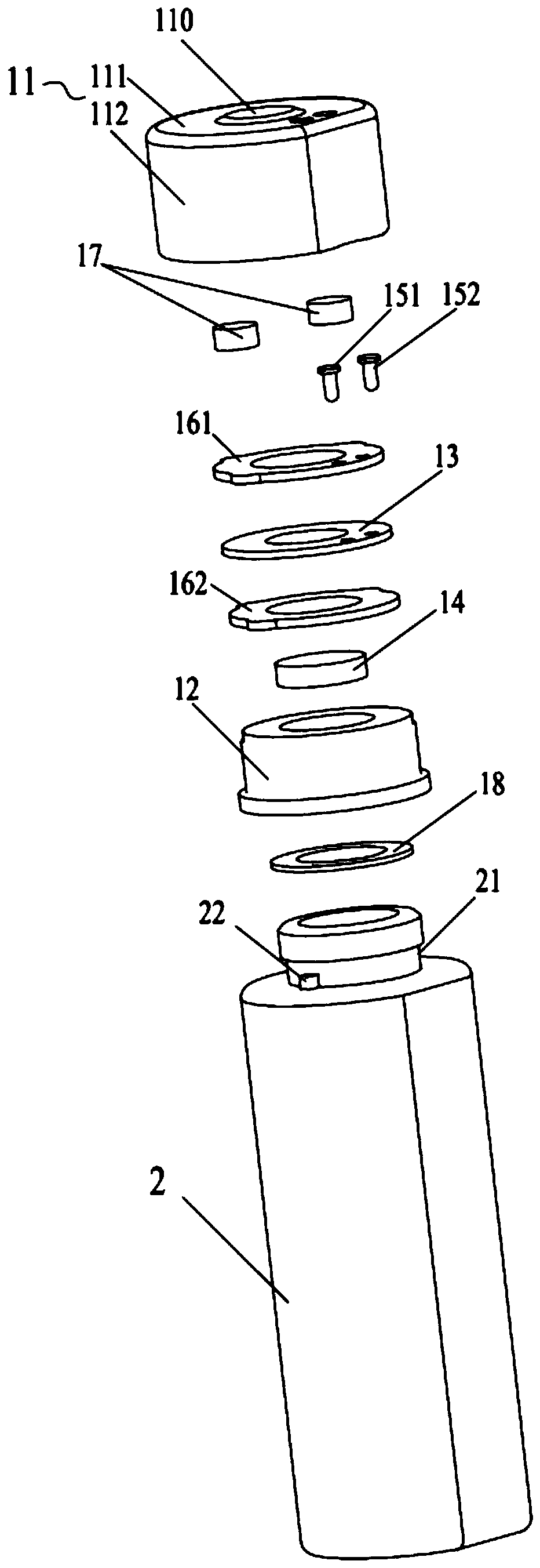

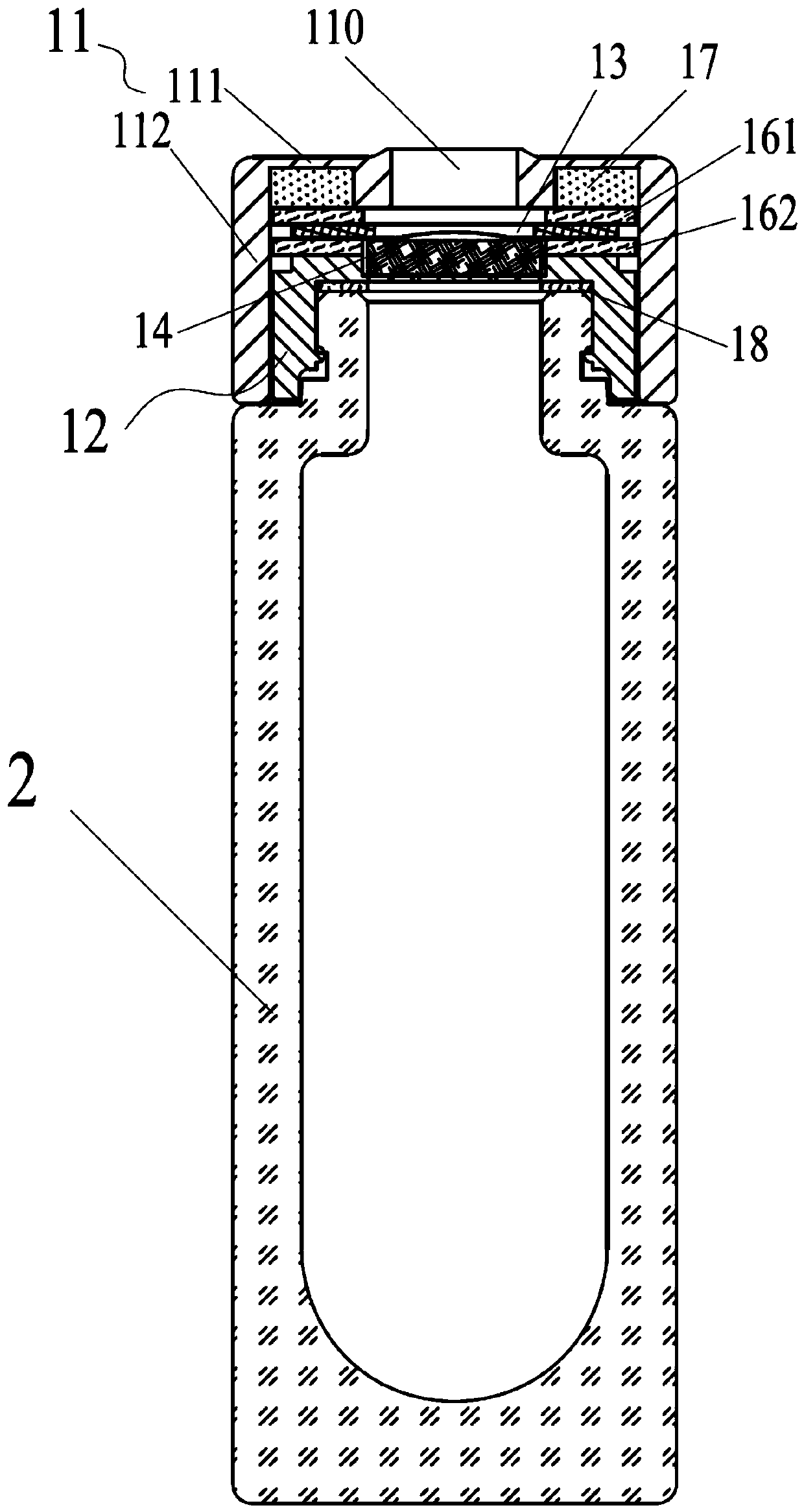

Liquid container

The invention provides a liquid container. The liquid container comprises a cover body assembly and a bottle body, the cover body assembly is in sealing connection with the bottle body, wherein the cover body assembly is provided with a mist spray port, the mist spray port is in direct contact with an external environment, and is used for diffusing mist drops to the external environment, the bottle body and / or the cover body assembly is further provided with a positioning structure, the positioning structure is used for fixedly mounting the liquid container on a driving device of the liquid container during use. According to the liquid container, atomizing sheets are integrated in the cover body assembly to serve as a part of the liquid container, and then the situation of mutual contamination and interference of liquids in different containers due to sharing of the same ultrasonic atomizing portion is avoided.

Owner:北京福兆朗风科技有限公司 +1

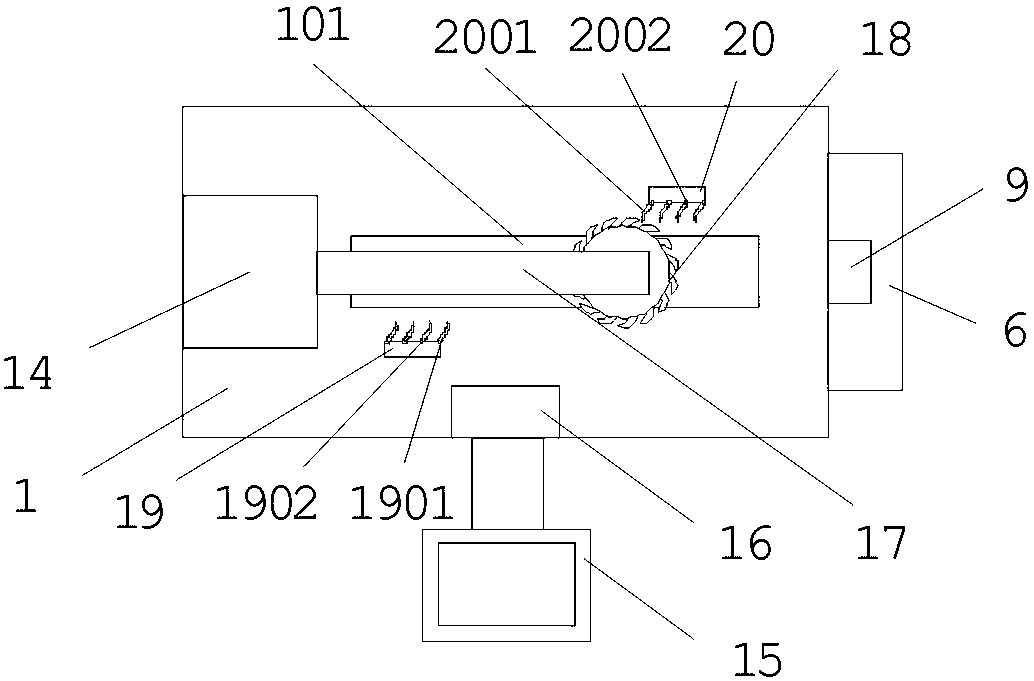

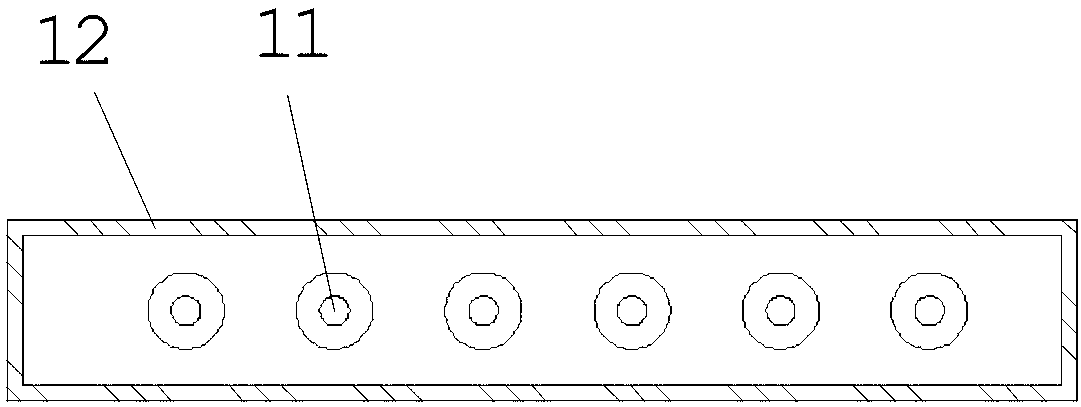

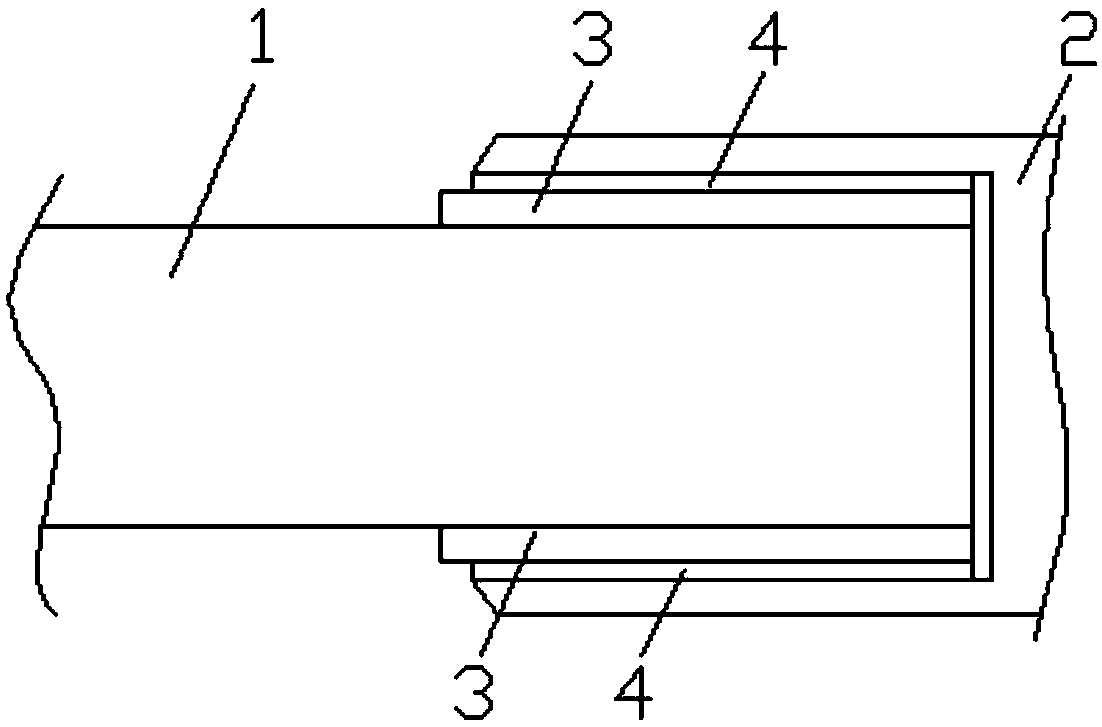

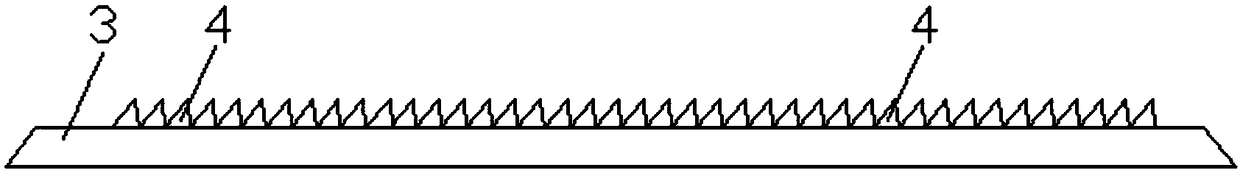

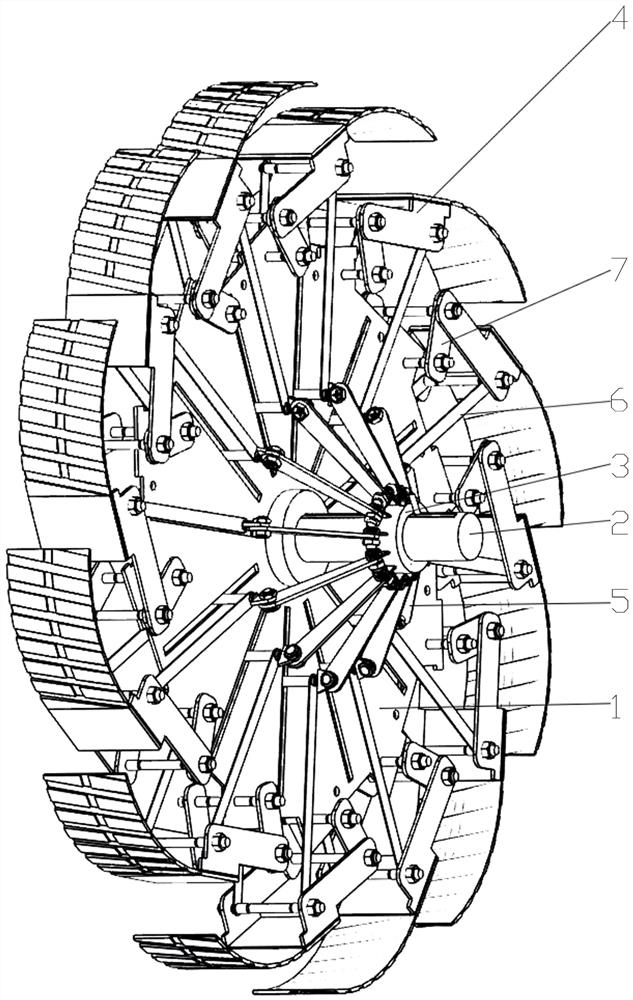

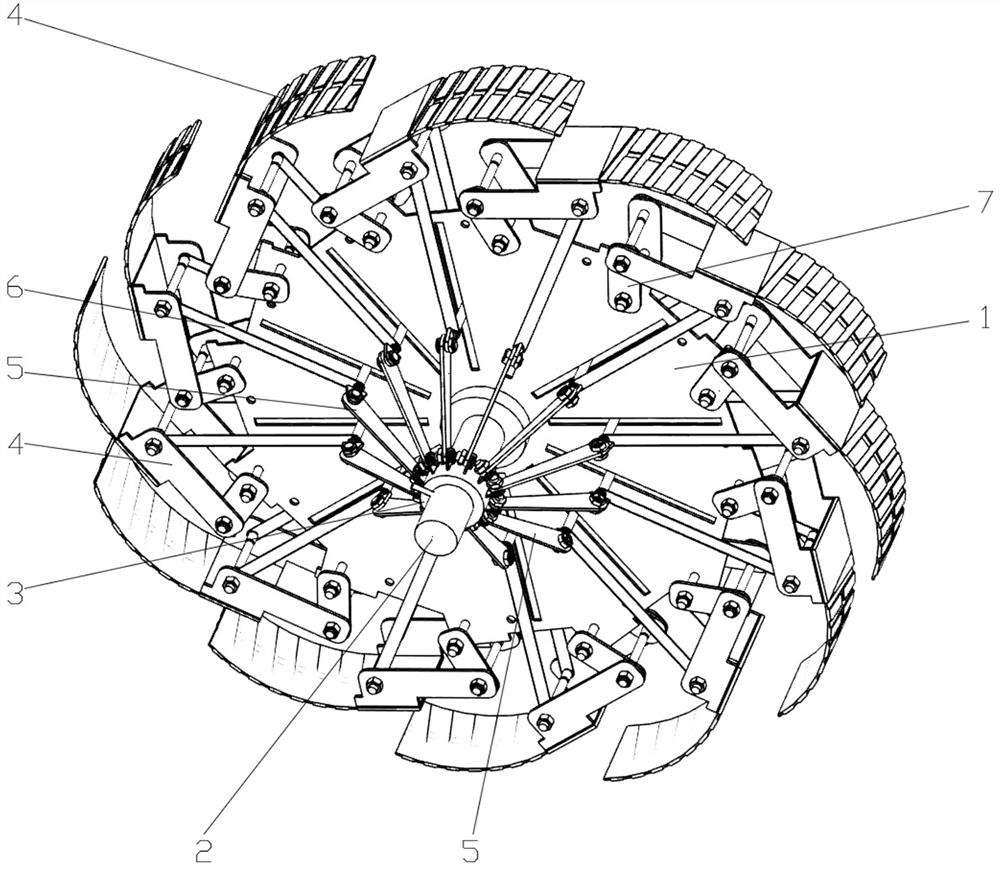

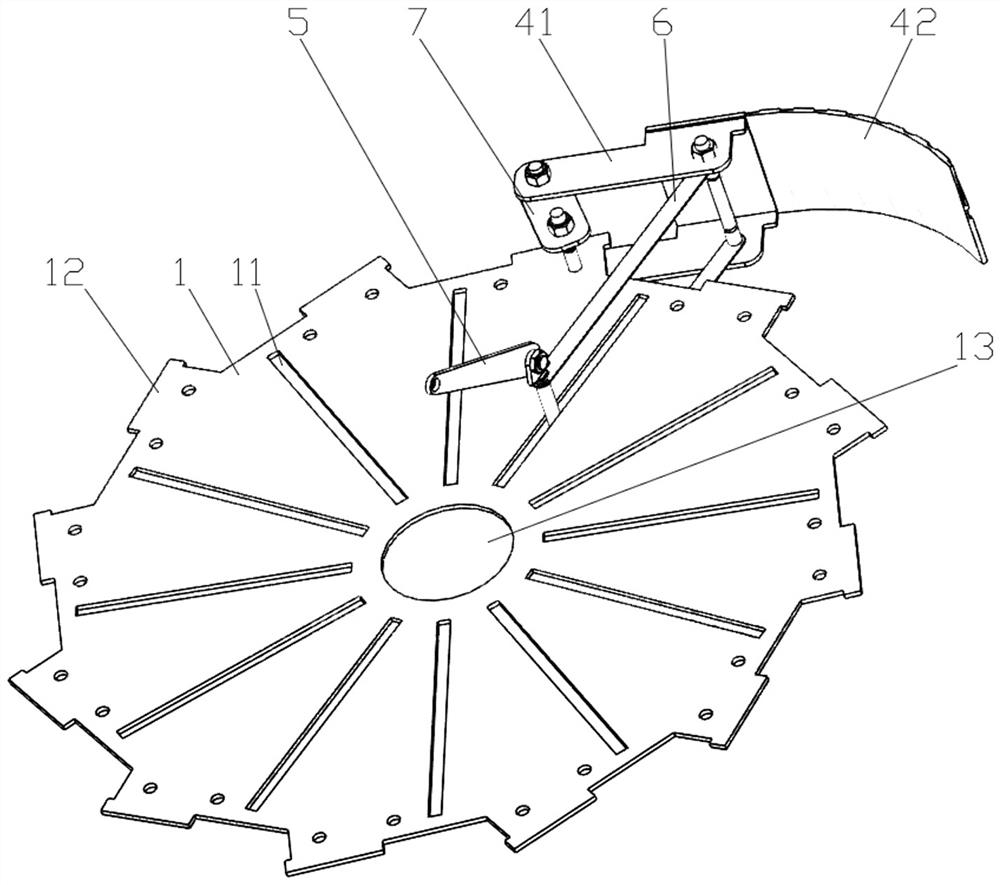

Diameter-adjustable front disc assembly for pipeline cleaning and pipeline cleaning machine

The invention discloses a diameter-adjustable front disc assembly for pipeline cleaning and a pipeline cleaning machine. The diameter-adjustable front disc assembly comprises a front disc, a main shaft, an axial sliding sleeve, cleaning blades and a connecting rod transmission mechanism. The cleaning blades are installed on the circumferential edge of the front disc in a surrounding mode, a main shaft is perpendicularly arranged at the center of the end face of the front disc, the front disc can be driven by the main shaft to rotate, the main shaft is sleeved with the axial sliding sleeve, the position of the axial sliding sleeve can be adjusted in the axial direction of the main shaft, and the axial sliding sleeve is connected with the cleaning blades through a connecting rod transmission mechanism. The position of the axial sliding sleeve on the main shaft is adjusted so that the cleaning blades can be integrally expanded outwards or contracted inwards. The device is reasonable in structural design, convenient to operate and capable of being suitable for cleaning operation of pipelines with different pipe diameters.

Owner:LUOYANG INST OF SCI & TECH

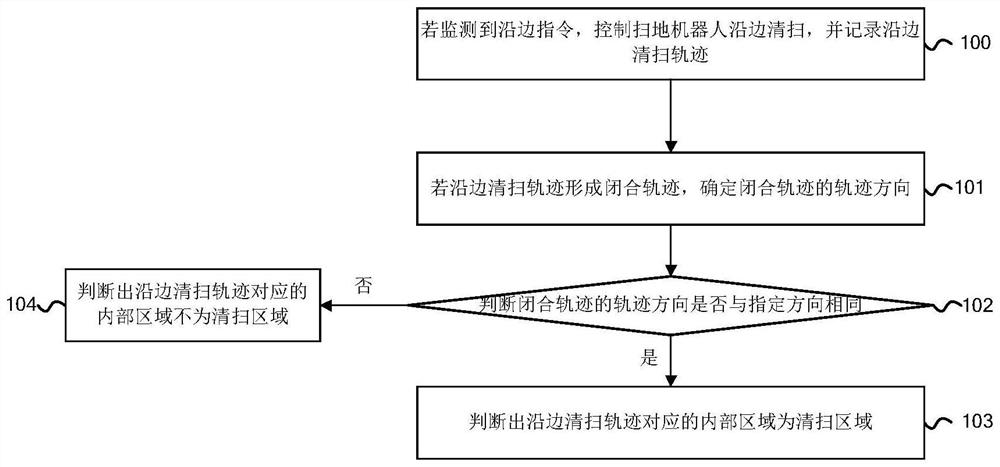

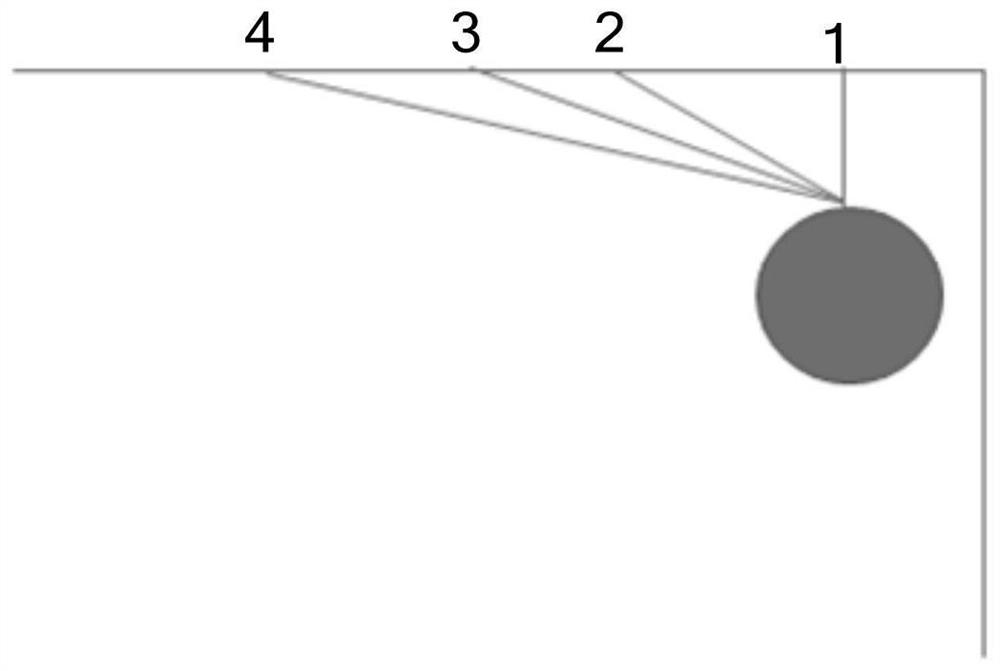

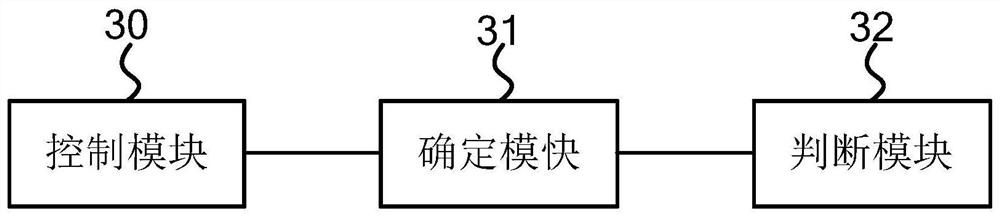

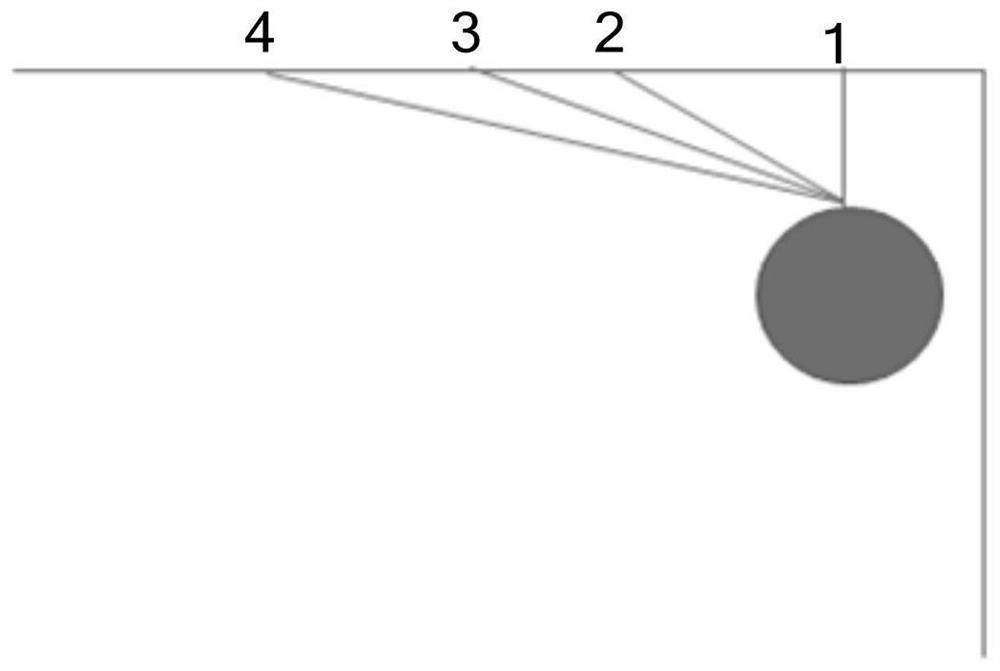

Method for detecting sweeping area of sweeping robot, device, equipment and storage medium

ActiveCN112137512AAvoid repeated cleaningImprove cleaning efficiencyAutomatic obstacle detectionTravelling automatic controlSimulationReal-time computing

The invention discloses a method for detecting sweeping area of a sweeping robot, a device, equipment and a storage medium. The method comprises the following steps: controlling the sweeping robot tosweep along the edge if an edge instruction is monitored, and recording an edge sweeping track; if the edge sweeping track forms a closed track, determining the track direction of the closed track; ifthe track direction is the same as the specified direction, judging that the internal area is the cleaning area; and if the track direction is different from the specified direction, judging that theinternal area is not the sweeping area, so that the detection of the maximum coverage area of the current space is realized, the sweeping missing area is effectively reduced, the repeated sweeping phenomenon is avoided, and the sweeping efficiency is improved.

Owner:PUPPY ELECTRONICS APPLIANCES INTERNET TECH (BEIJING) CO LTD

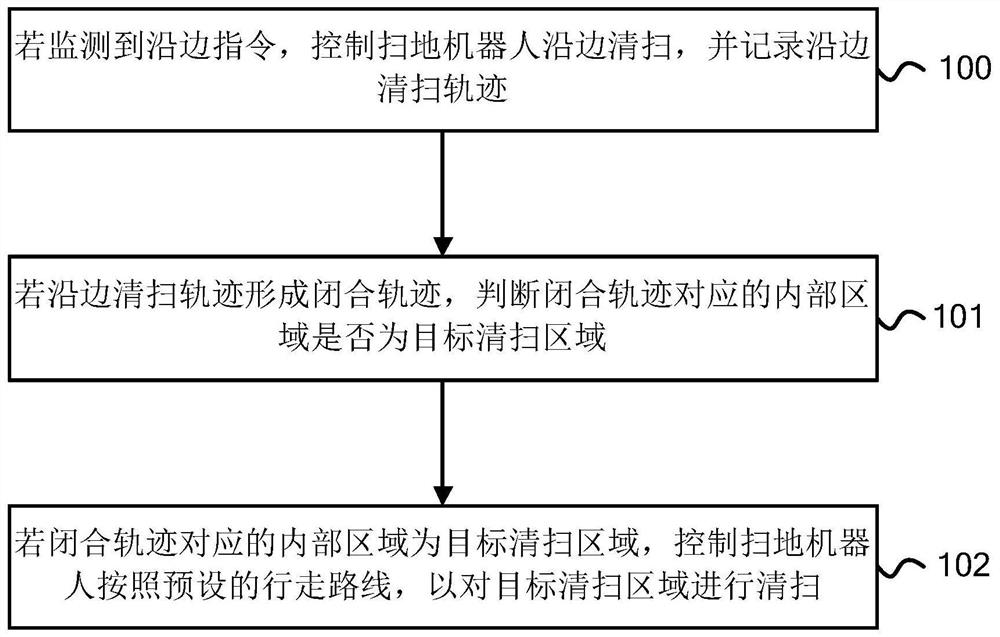

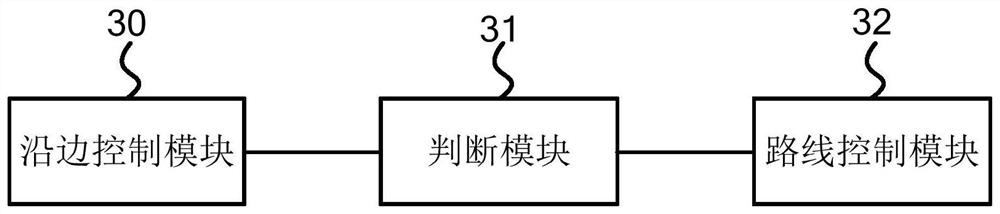

Sweeping robot control method, device and system and storage medium

ActiveCN112022011AAchieve cleaningAvoid repeated cleaningCarpet cleanersFloor cleanersSimulationRobot control

The invention discloses a sweeping robot control method, device and system and a storage medium. The method comprises the steps: controlling a sweeping robot to sweep along an edge if an edge instruction is monitored, and recording an edge sweeping track; if the closed track is formed along the edge cleaning track, judging whether an internal region corresponding to the closed track is a target cleaning region or not; and if the internal region is the target cleaning region, controlling the sweeping robot to sweep the target cleaning region according to a preset walking route, thereby realizing sweeping of the current space under the maximum coverage rate, effectively reducing sweeping missing areas, avoiding repeated sweeping and improving the sweeping efficiency.

Owner:PUPPY ELECTRONICS APPLIANCES INTERNET TECH (BEIJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com