Dust blowing type die cleaning device

A technology for cleaning devices and molds, which is applied in the direction of cleaning methods using gas flow, smoke and dust removal, cleaning methods and utensils, which can solve the problems of scattering and even falling, and achieve the effect of simple structure and avoiding repeated cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

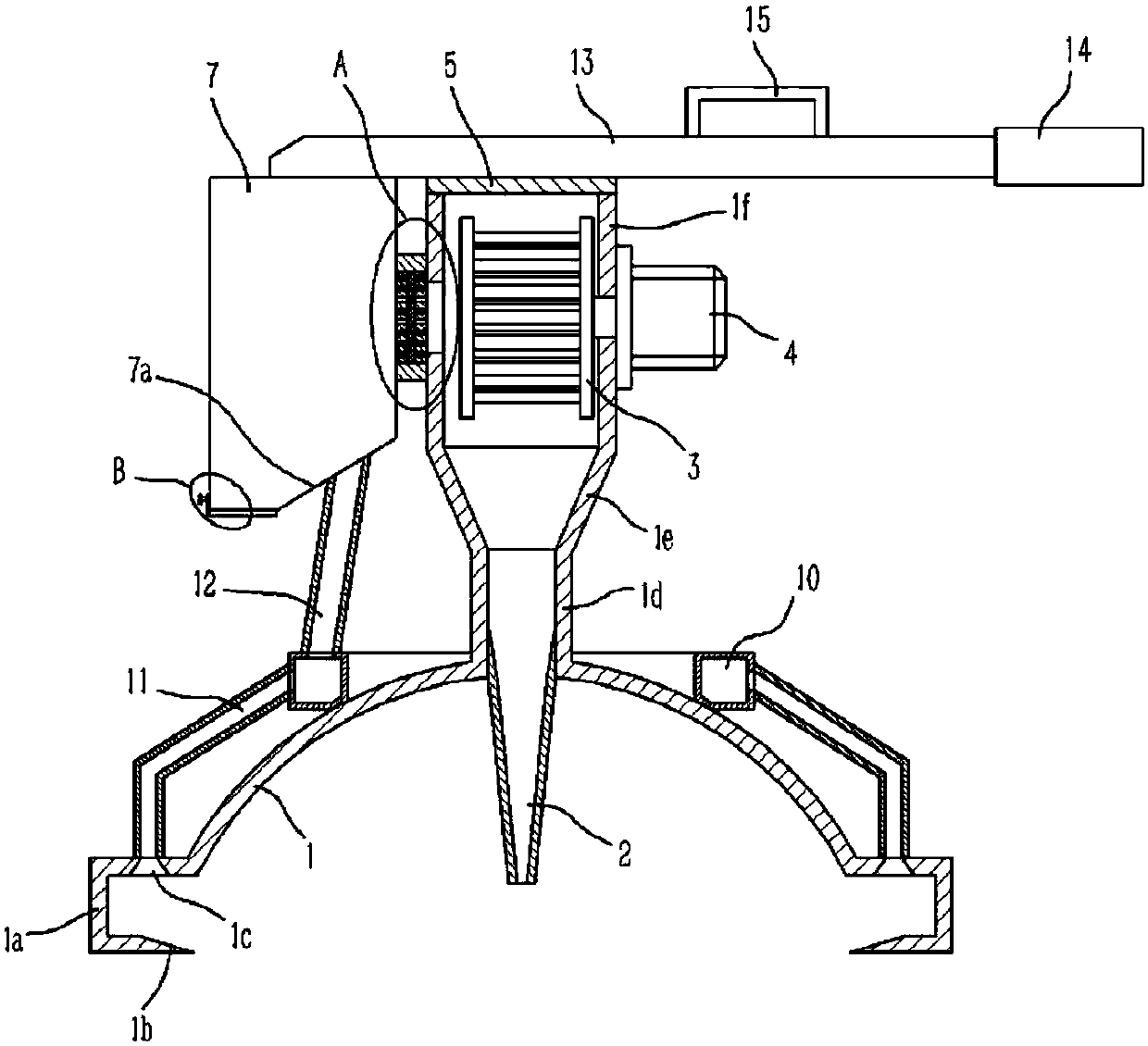

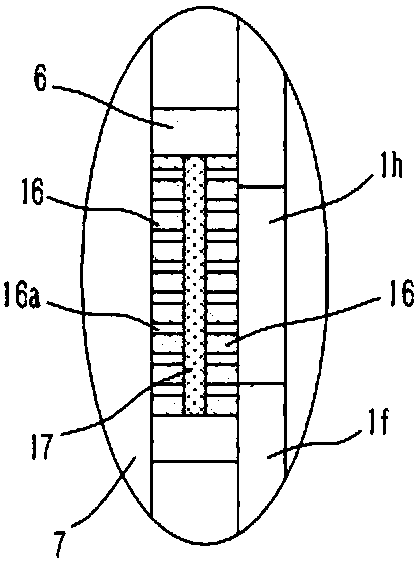

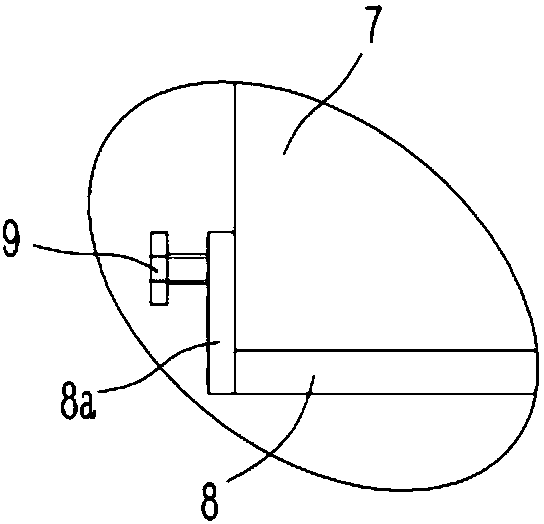

[0016] Example: see figure 1 , 2 As shown in , 3, a dust-blowing type mold cleaning device includes a spherical dust collection cover 1, the top of the dust collection cover 1 is formed with a vertical air outlet pipe 1d, and the upper end of the air outlet pipe 1d is formed with a volute The air chamber 1f, the volute type air chamber 1f is inserted with the impeller 3, the impeller 3 is fixed on the rotating shaft of the motor 4, the motor 4 is fixed on the outer wall of the volute type air chamber 1f, and the top of the volute type air chamber 1f is fixed There is a cover plate 5, and an air inlet hole 1h is formed on the side wall of the volute type air chamber 1f, and an air inlet pipe 6 connected with the air inlet hole 1h is fixed on the outer wall of the volute type air chamber 1f, and the air inlet pipe 6 is fixed Connected to the dust storage chamber 7, the bottom of the dust storage chamber 7 is formed with an inclined slant plate 7a, the filter screen 17 is insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com