Vibration type die cleaning device

A cleaning device and vibrating technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of scattering or even falling, achieving the effect of simple structure and avoiding repeated cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

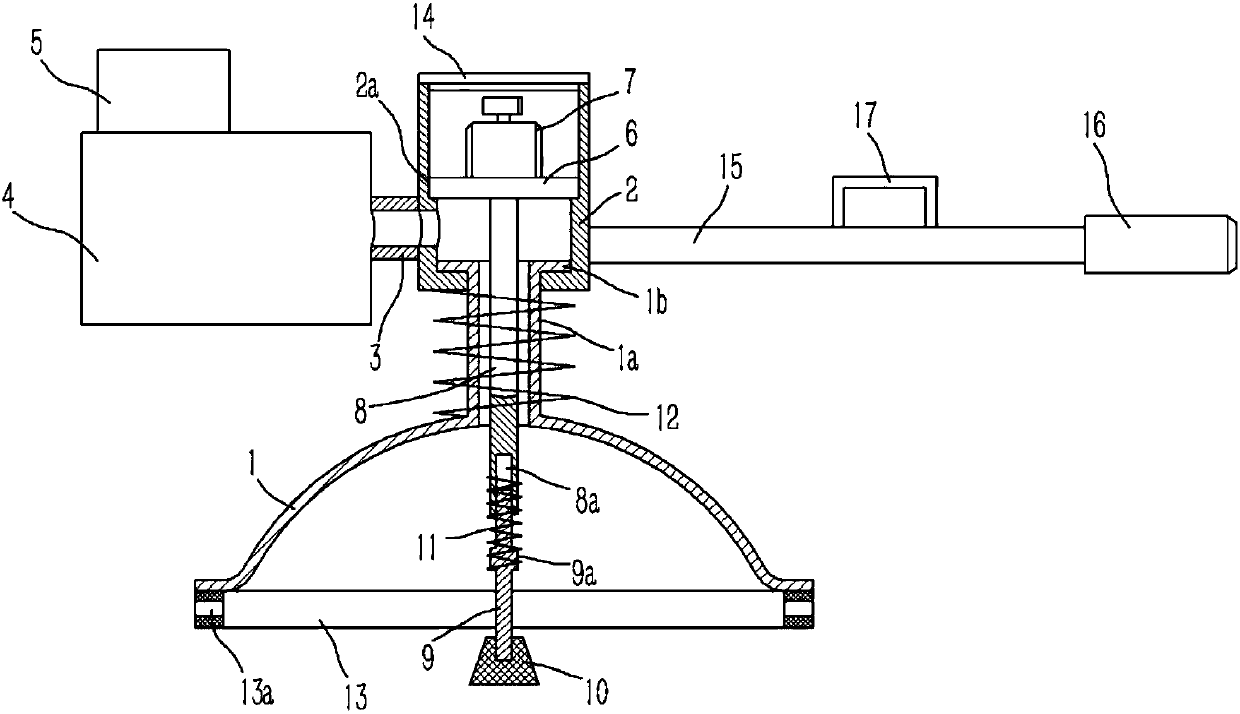

[0014] Example: see figure 1 As shown, a vibrating mold cleaning device includes a spherical dust collection cover 1, the top of the dust collection cover 1 is formed with a vertical suction pipe 1a, and the upper end of the suction pipe 1a is inserted into the ventilation seat 2 And bending forming has rib 1b, and rib 1b presses against the bottom surface of ventilating seat 2, and the shock-absorbing spring 12 is inserted on the suction pipe 1a, and the two ends of shock-absorbing spring 12 press against ventilating seat 2 and ventilating seat 2 respectively. On the dust collection cover 1, a ventilation hole is formed on the side wall of the ventilation seat 2, and a ventilation pipe 3 connected with the ventilation hole on the ventilation seat 2 is fixed on the outer wall of the ventilation seat 2, and the ventilation pipe 3 is fixed on the dust storage box 4, A dust suction fan 5 is fixedly connected to the dust storage box 4; a concave platform 2a is formed on the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com