Liquid container

A liquid container and cover technology, which is applied in the field of liquid containers, can solve problems such as mutual pollution, high cost of replacing essential oils, and unsatisfactory fragrance effects, so as to avoid mutual pollution and interference, and ensure the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

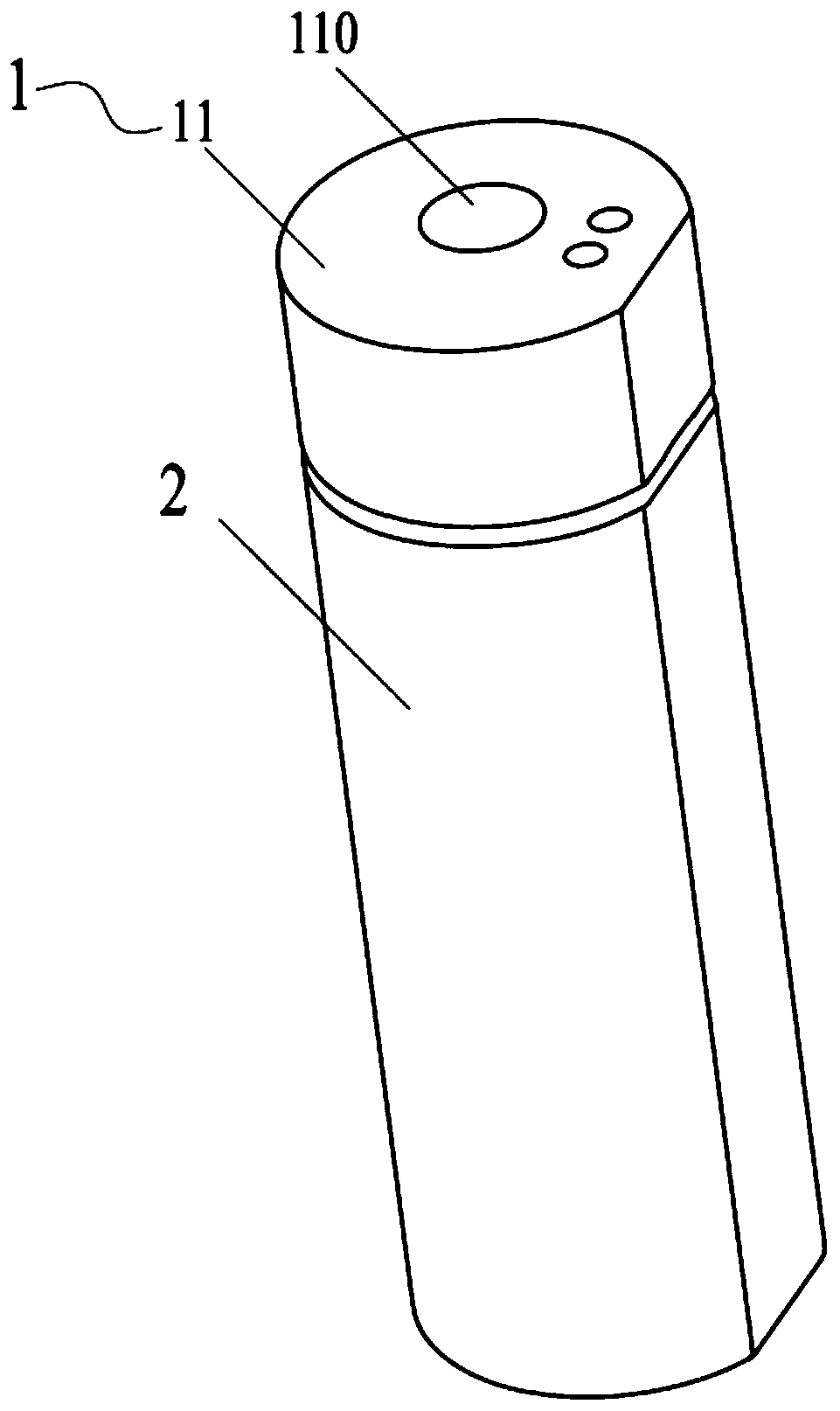

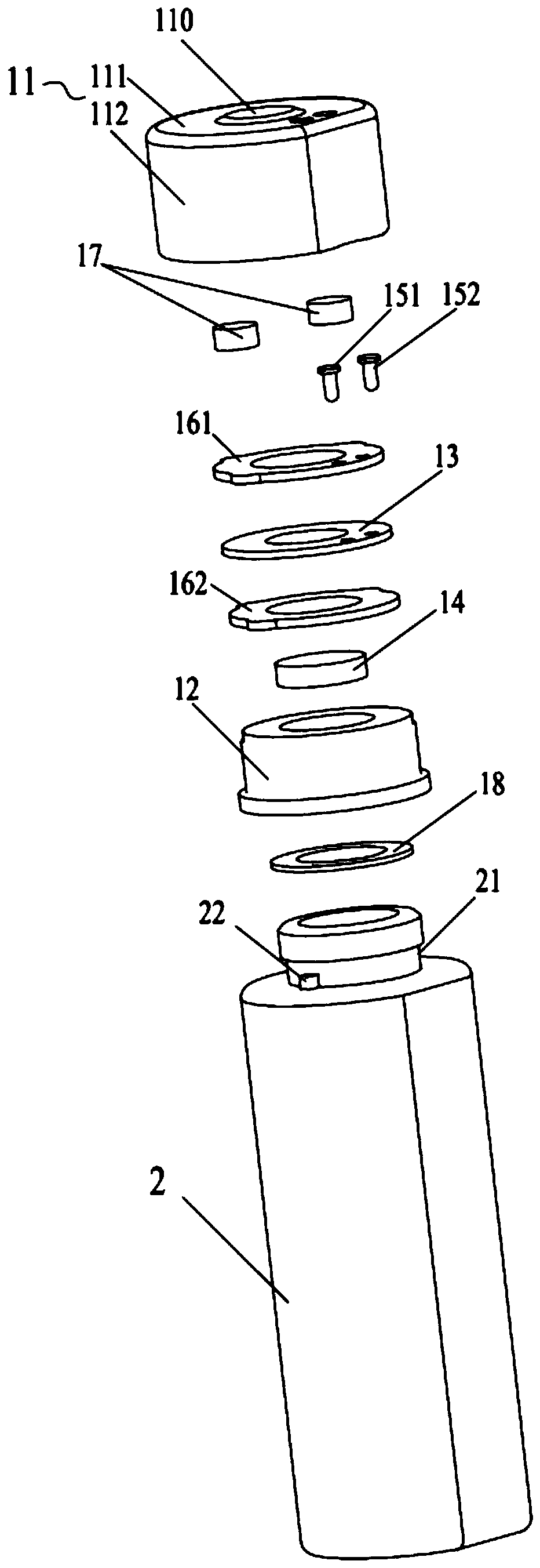

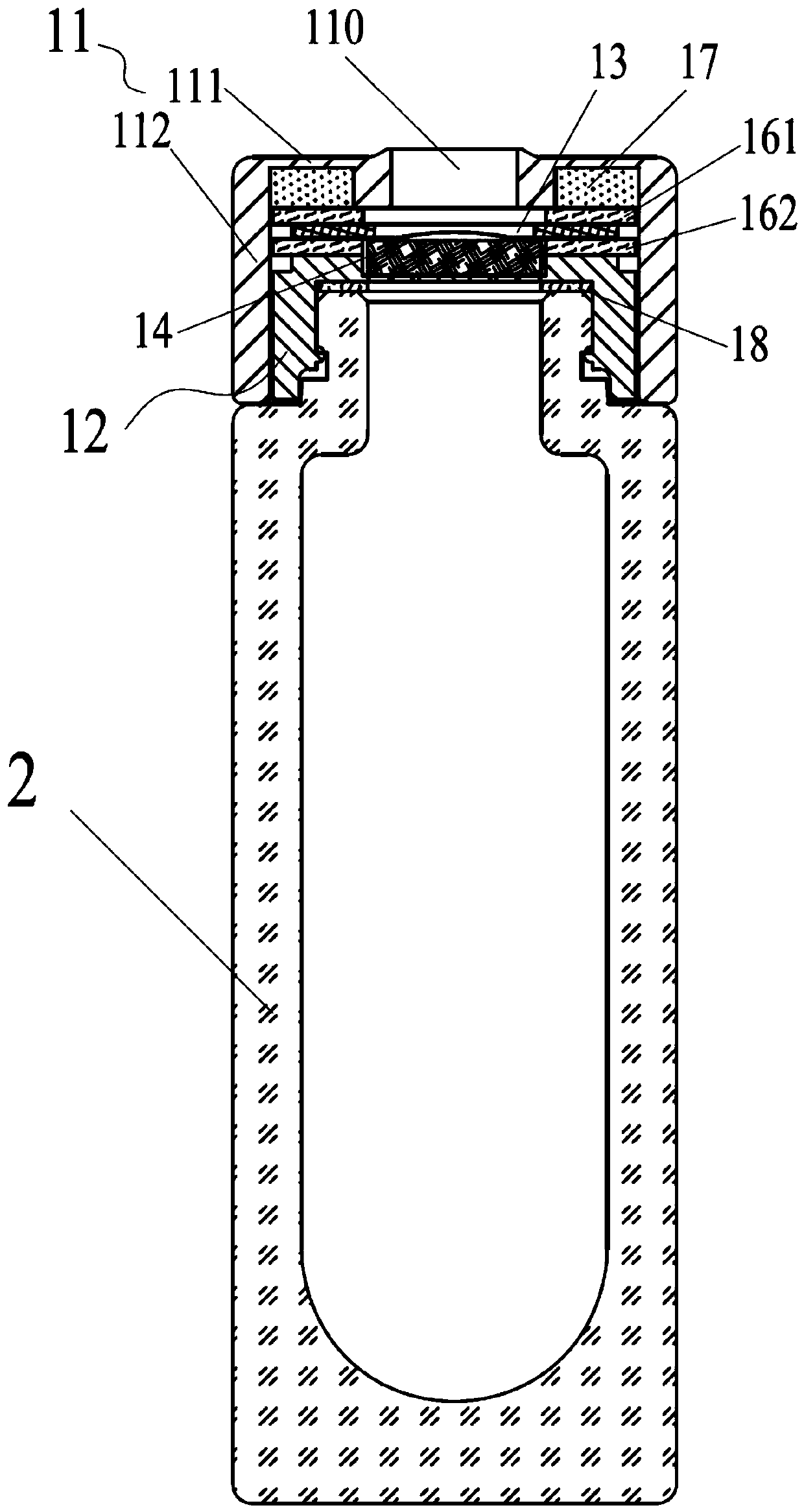

[0060] combine Figure 1 to Figure 5 As shown, a liquid container includes a cover assembly 1 and a bottle body 2, the cover assembly 1 is hermetically connected to the bottle body 2, the cover assembly 1 has a spray port 110, and the spray port 110 directly contact with the external environment, and is used to diffuse the droplets to the external environment; the bottle body 2 and / or the cover assembly 1 is also provided with a positioning structure, and the positioning structure is used to fix and install the liquid container when in use on the driving device of the liquid container.

[0061] The cover assembly 1 includes an outer cover 11, an inner cover 12 and an atomizing sheet 13, the inner cover 12 is nested in the outer cover 11, and a gap is formed between the outer cover 11 and the inner cover 12 Cavity, the atomizing sheet 13 is located in the cavity, the atomizing sheet 13 is provided with at least one microhole, and the microhole is used to pass through the micro...

Embodiment 2

[0097] The main difference between this embodiment and embodiment 1 is that the outer edge of the atomizing sheet 13 is in sealing connection with the outer cover 11 .

[0098] The atomizing sheet 13 is embedded in the inner side of the first top wall 111 , or, the atomizing sheet 13 is embedded in the accommodation formed by the first top wall 111 and the first side wall 112 inside the space.

[0099] In a possible implementation manner, the atomizing sheet 13 and the outer cover 11 may be installed separately, and the interference fit ensures that the contact portion between the outer edge of the atomizing sheet 13 and the outer cover 11 is sealed.

[0100] In a possible implementation manner, the atomizing sheet 13 can also be integrally formed with the outer cover 11 to achieve a sealing effect, such as through an injection molding process or a similar thermal fusion process.

[0101] The cover assembly 1 also includes an insulating seal, and the insulating seal exposes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com