Yaw brake used for wind turbine generator set and provided with automatic cleaning function

A technology for wind turbines and yaw brakes, which is applied to the types of brakes, parts of the brakes, cleaning methods using tools, etc. It can solve the problems of yaw brakes such as unstable operation, large vibration amplitude, and large noise, and achieve easy cleaning Fast, easy to operate, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments. The examples given are only used to explain the present invention and are not intended to limit the scope of the present invention.

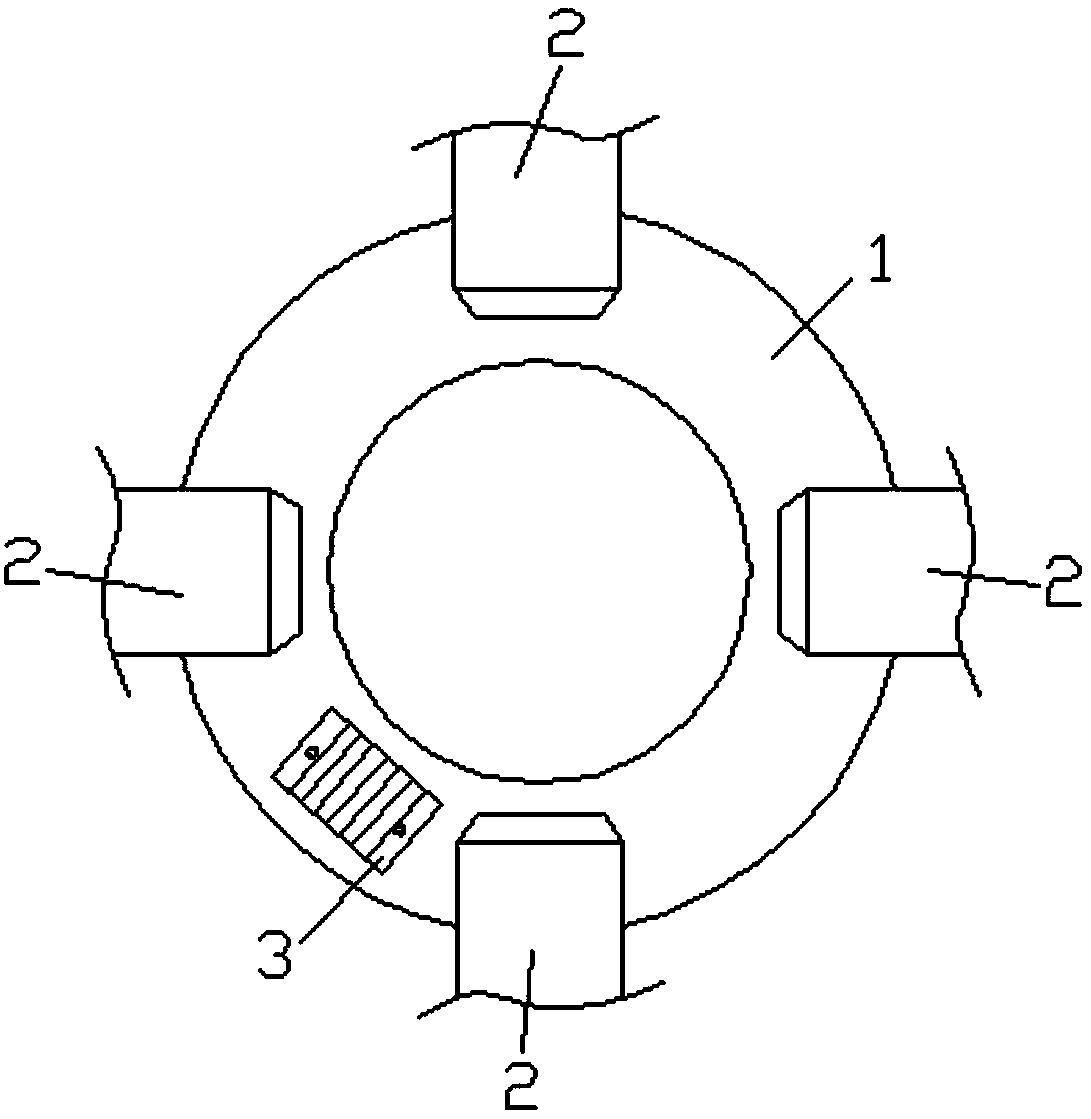

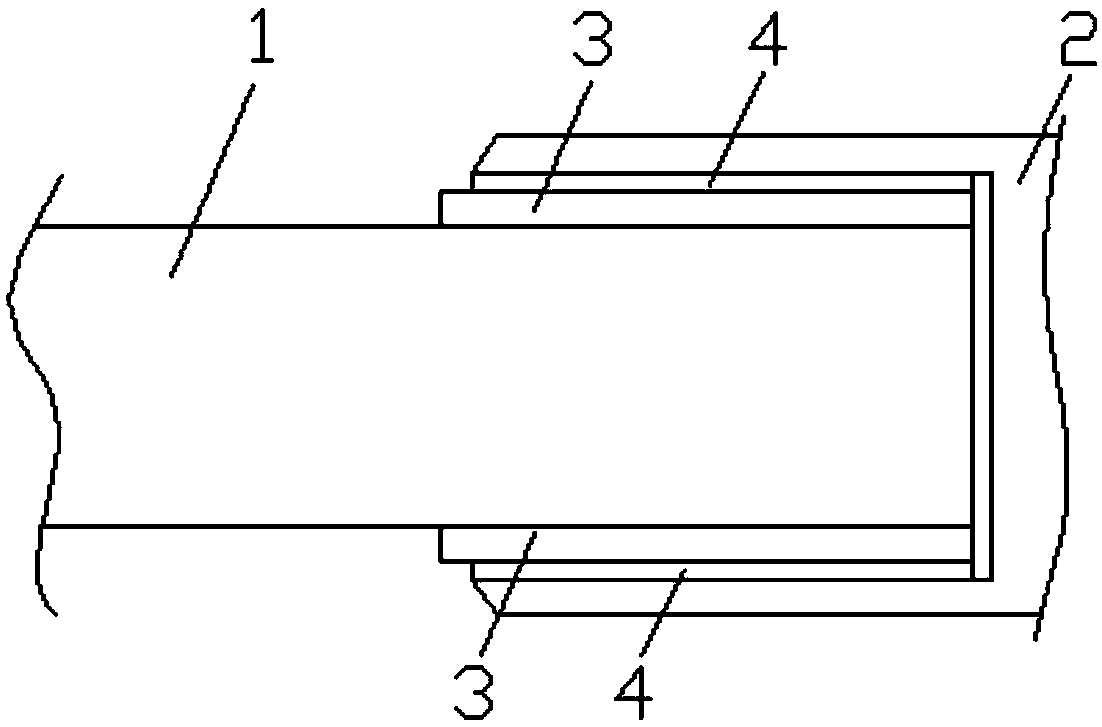

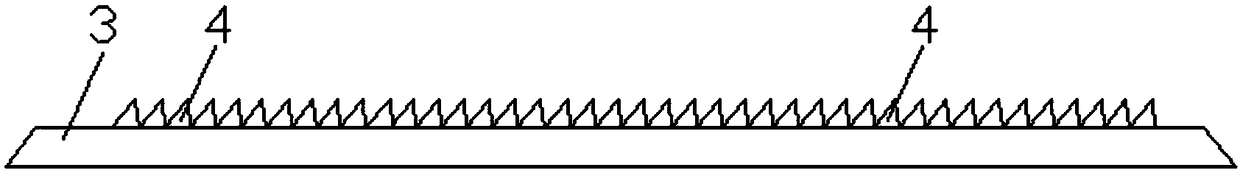

[0030] Such as figure 1 system Figure 4 As shown, the present invention provides a wind turbine yaw brake with automatic cleaning function, which is characterized in that it includes a yaw brake disc 1, a drive mechanism, a plurality of brake calipers 2 and at least one scraper 3, and The brake disc 1 is arranged horizontally, and a plurality of brake calipers 2 are distributed along the circumferential direction of the yaw brake disc 1 to clamp the yaw brake disc 1, and the plurality of brake calipers 2 are installed on the frame; each brake A pair of friction plates 4 are arranged symmetrically on the part where the moving caliper 2 clamps the yaw brake disc 1 . It is integrally formed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com