Cotton linter production line

A production line, cotton linters technology, used in textiles and papermaking, fiber raw material processing and other directions, can solve problems affecting product performance, hindering the development of refined cotton, failing to meet high standards, etc., to enhance the effect of impurity removal, sewage The effect of low processing difficulty and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

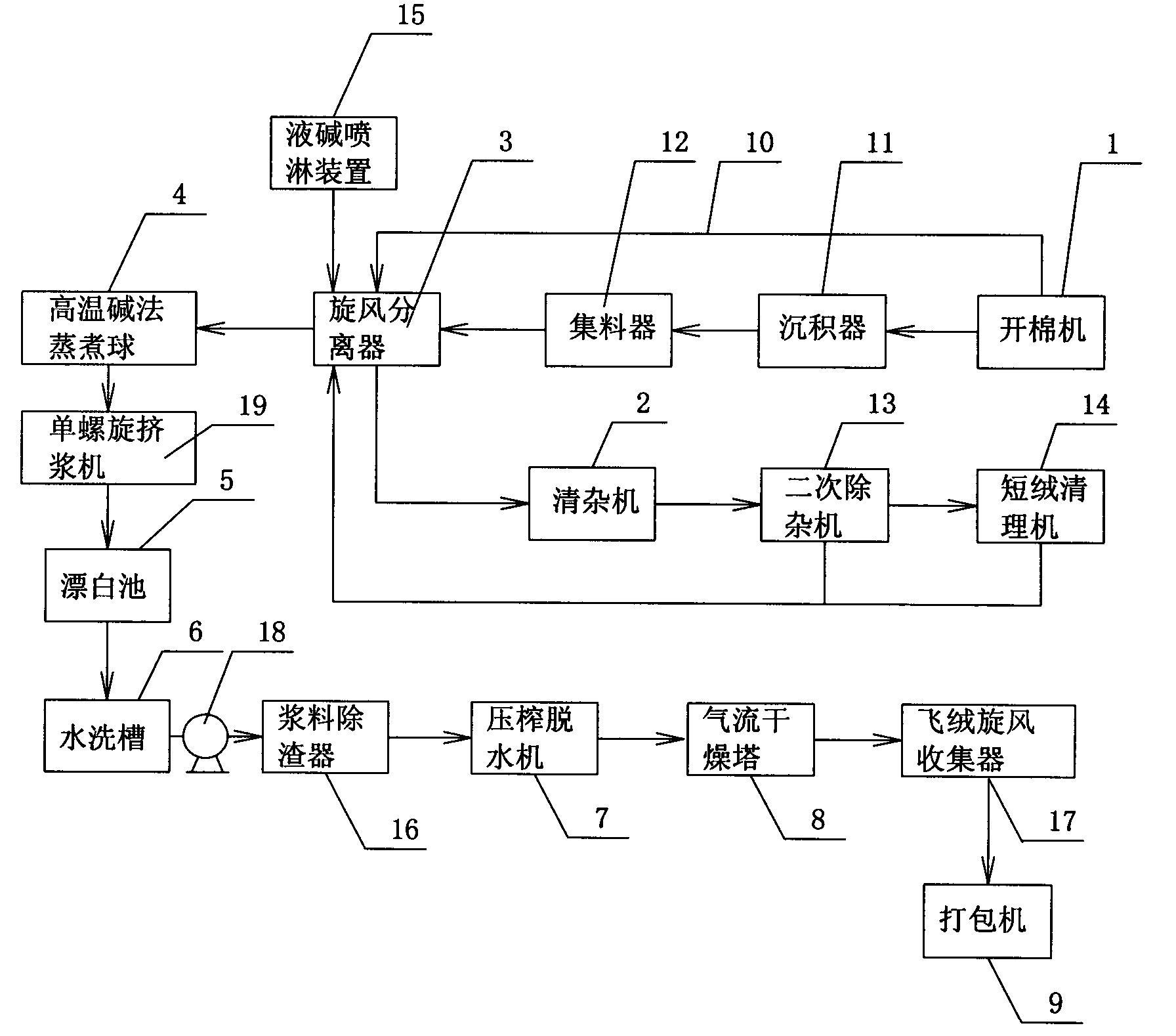

[0013] like figure 1 As shown in the cotton linter production line, its processing equipment includes a cotton opener 1, a cleaning machine 2, a cyclone separator 3 with a lye spray device 15, a high-temperature alkaline cooking ball, a single-screw extruder Pulp machine 19, 4, bleaching tank 5, washing tank 6, press dehydrator 7, airflow drying tower 8 and baler 9, cotton opener 1 passes through the air duct 10 and the cyclone separator with the lye spraying device 15 3 connection, between the cotton opener 1 and the cleaning machine 2, a depositor 11 and a collector 12 are also arranged in sequence, and the collector 12 is connected with the cyclone separator 3 and the cleaning machine 2 respectively through the air duct 10. The trash remover 2 is connected with a secondary impurity remover 13 and a linter cleaning machine 14 successively through the air-introduction pipeline, and the secondary impurity remover 13 and the linter cleaning machine 14 are respectively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com