Liquid blending device with spiral cleaning structure

A cleaning structure and spiral technology, applied in mixers with rotating stirring devices, cleaning hollow objects, cleaning methods and utensils, etc., can solve problems such as difficult cleaning, and achieve the effect of easy movement, avoidance of repeated cleaning, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

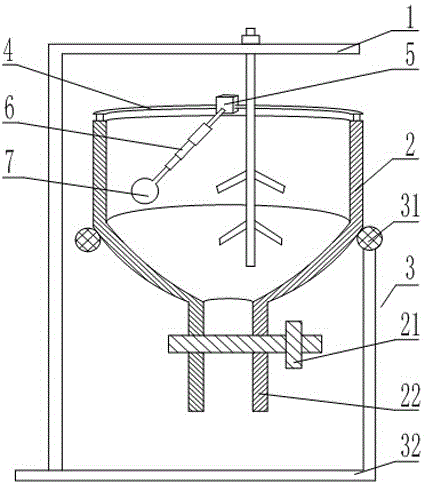

[0018] Such as figure 1 As shown, the liquid mixing device with a spiral cleaning structure includes a stirring device 1, a liquid distribution device 2, and a fixing device 3. The distribution liquid 2 is made of hard aluminum alloy. The stirring device 1 is a blade type stirring structure, and the distribution liquid 2 There is a liquid inlet at the top, and a liquid outlet 22 is provided at the bottom of the distribution liquid 2, and a valve 21 is arranged on the liquid outlet 22. The top of 2 is provided with slide rail 4, is provided with slide block 5 on slide rail 4, is provided with control switch on slide block 5, and one end of connecting rod 6 is connected with slide block 5, and the other end is connected with cleaning ball 7, and connecting rod 6 is bamboo Sectional telescopic rod, the length of every joint of connecting rod 6 is consistent with the diameter of cleaning ball 7.

[0019] The sliding block 5 makes a circular motion on the slide rail 4, so that the...

Embodiment 2

[0021] In this embodiment, on the basis of Embodiment 1, the fixing device 3 includes a support 32 and a fixed ring 31 arranged on the upper end of the support 32. The inner diameter of the fixed ring 31 is consistent with the maximum outer diameter of the concave surface at the bottom of the distribution liquid 2. .

[0022] The fixing device 3 of this structure is not completely fixed with the distribution liquid 2, so that the distribution liquid 2 can be taken out of the fixing device at any time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com