Method and device for controlling the temperature of steam in a boiler

A steam temperature and boiler technology, applied in boiler cleaning control devices, control systems, steam generation, etc., can solve problems affecting the adjustment process, troublesome and complicated boiler thermal adjustability, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

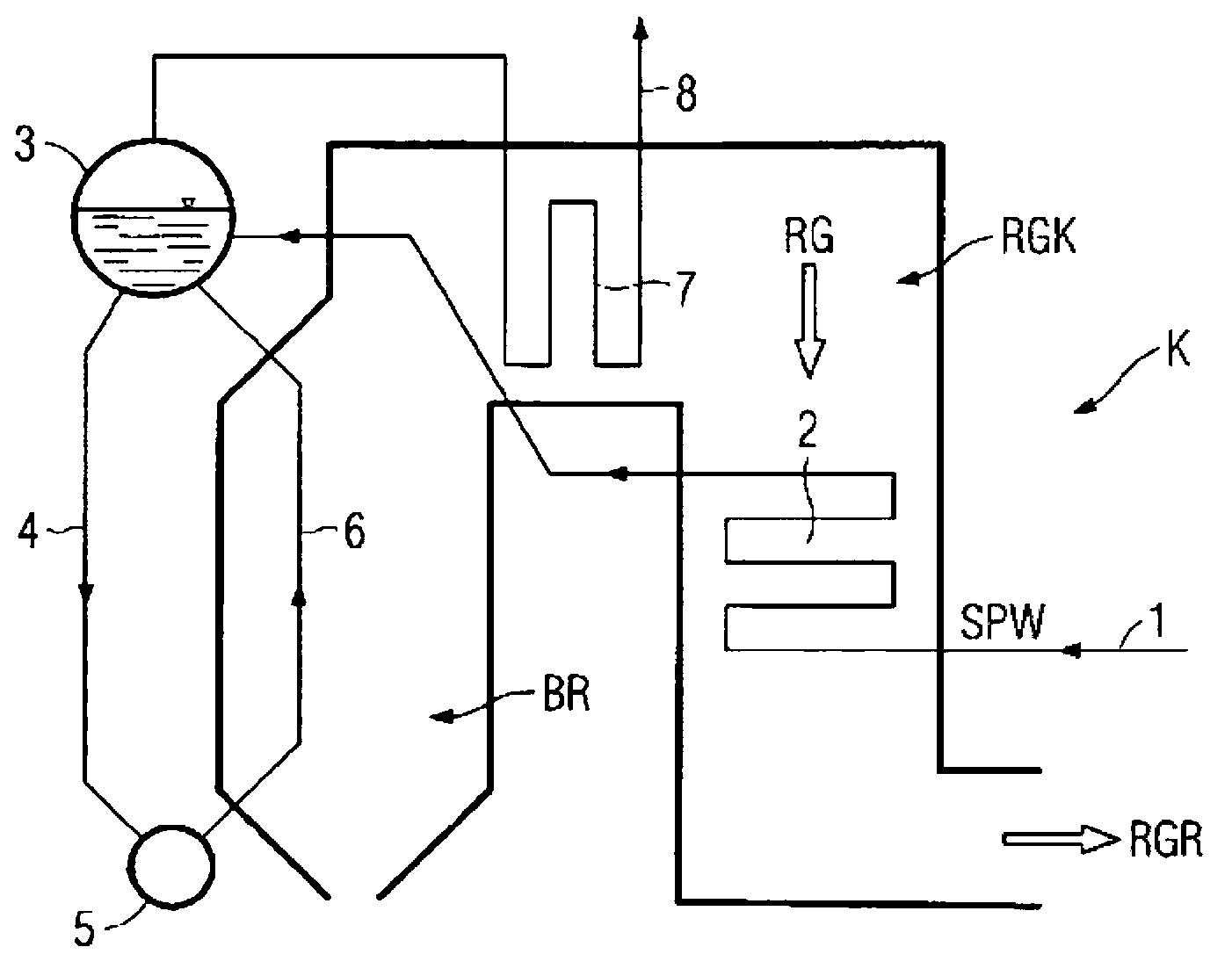

[0042] figure 1 The steam generator is shown in a very simplified form. In the combustion chamber BR of the boiler K, solid fossil fuels such as carbon dust are burned. The flue gas RG produced in this process is conducted via a flue gas line RGK to a flue gas cleaning device RGR. Evaporation of the supply water SPW takes place in the piping of the evaporation chamber and in the piping of the heat exchanger. The system is generally configured such that feedwater is supplied from a feedwater tank 1 to a feedwater preheater 2 (ECO). From the preheater, the water-steam mixture enters the drum 3 and is fed to the superheater (7 or ), which is then supplied to the turbine 8. Additionally, the superheater Can also include reheater

[0043] According to the invention on which this application is based, the steam temperature is controlled and regulated by means of a sootblower device which creates a certain fouling on the heat exchanger surfaces inside the boiler.

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com