Double-airflow cleaning device of peanut picker

A peanut picking machine and cleaning device technology, which is applied to harvesters, digging harvesters, agricultural machinery and implements, etc., can solve the problems of increasing energy consumption and production costs, reducing the cleanliness of peanuts, and reducing work efficiency, etc. , to achieve reasonable structure, reduce fruit loss rate, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

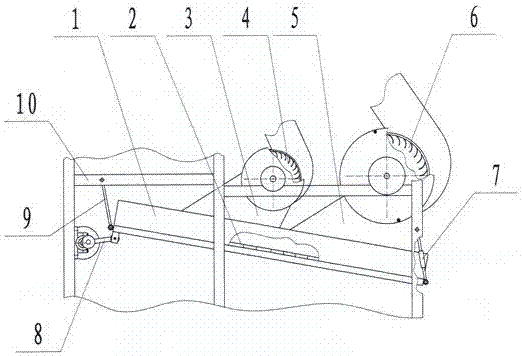

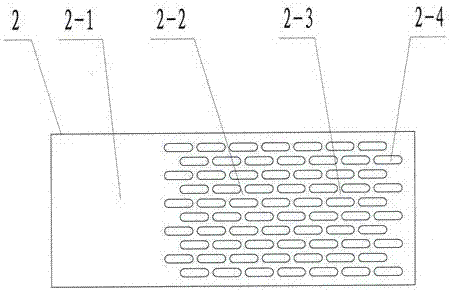

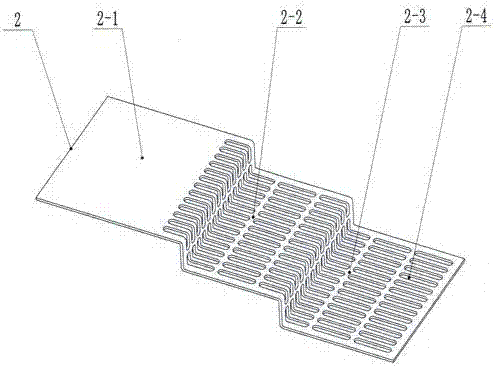

[0007] The embodiment is described in detail in conjunction with the accompanying drawings. It is a framed vibrating screen 1 with a high front and a low rear installed in the frame 10. A crank connecting rod 8 and a boom 9 are connected at the front end between the frame and the vibrating screen. The end is connected with a swing connecting rod 7, the main improvement point is: a section of front suction area 2-2 and rear suction area 2-3 are arranged in sequence behind the upper material receiving area 2-1 of the sieve plate 2 of the vibrating screen. A front cross-flow fan 4 is installed on the frame above the front suction area, and a front cross-flow fan 4 is provided on the front cross-flow fan to stretch out the front suction hood 3 above the front suction area, and the frame above the rear suction area A rear cross-flow fan 6 is installed on the rear cross-flow fan, and a suction port is provided on the rear cross-flow fan and stretches toward the rear suction hood 5 ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com