Extension method for circulating water system of power plant

A technology of circulating water system and circulating cooling system, applied in water supply pipeline systems, buildings, water supply installations, etc., can solve the problems of large loss of self-power generation, long construction period, economic loss of the company, etc., so as to reduce economic losses and shorten downtime time, the effect of meeting the requirements of process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

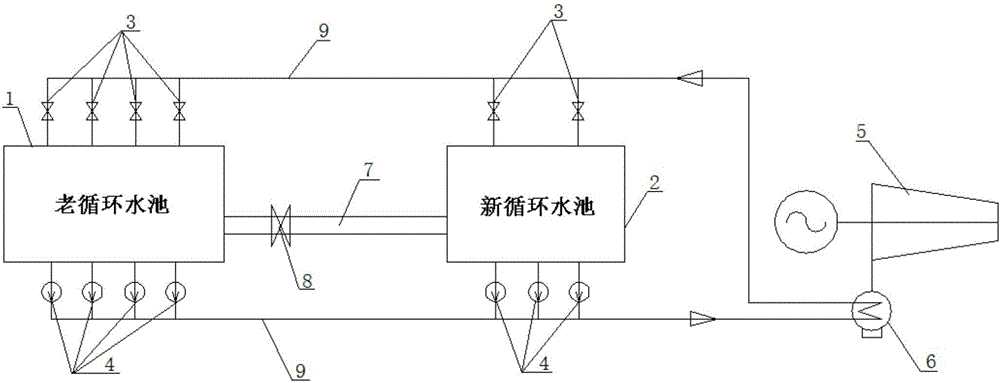

[0023] refer to figure 1 As shown, the expansion method of the power plant circulating water system in an embodiment provided by the present invention, the old circulating cooling system includes the old circulating water pool 1, and the water inlet and the water outlet of the old circulating water pool 1 are respectively provided with a plurality of cooling tower water supply valves 3 and a plurality of circulating pumps, one end of a plurality of cooling tower water valves 3 is collected and then connected to the water outlet end of the condenser 6 in the turbogenerator unit 5 through a main pipe 9, and one end of a plurality of circulating pumps is collected and passed through a main pipe 9 The pipe 9 is connected to the water inlet end of the condenser 6 in the turbogenerator set 5, and is characterized in that, on the basis of the old circulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com