Flat mop cleaning barrel and flat mop cleaning method

A flat mop and cleaning bucket technology, applied in the field of mop buckets, can solve the problems that clean water can only be poured out, cannot meet the user's clean and hygienic requirements, dirty hands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

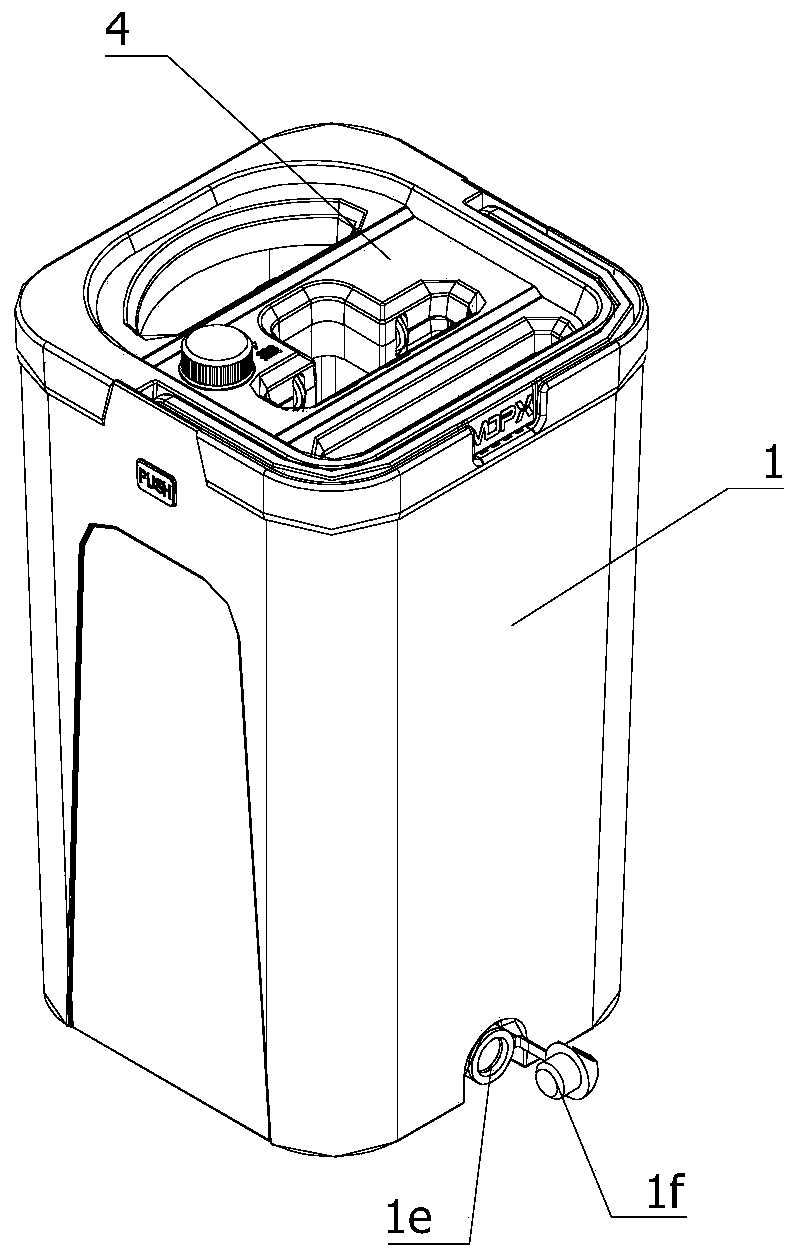

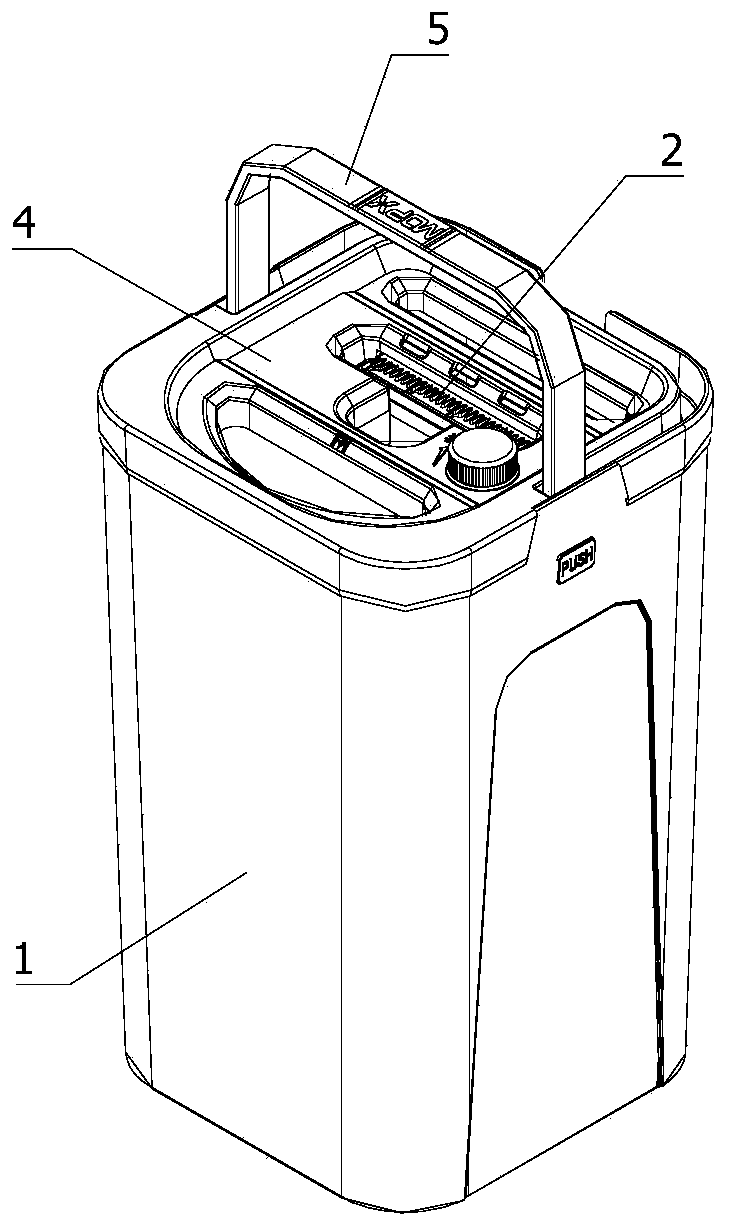

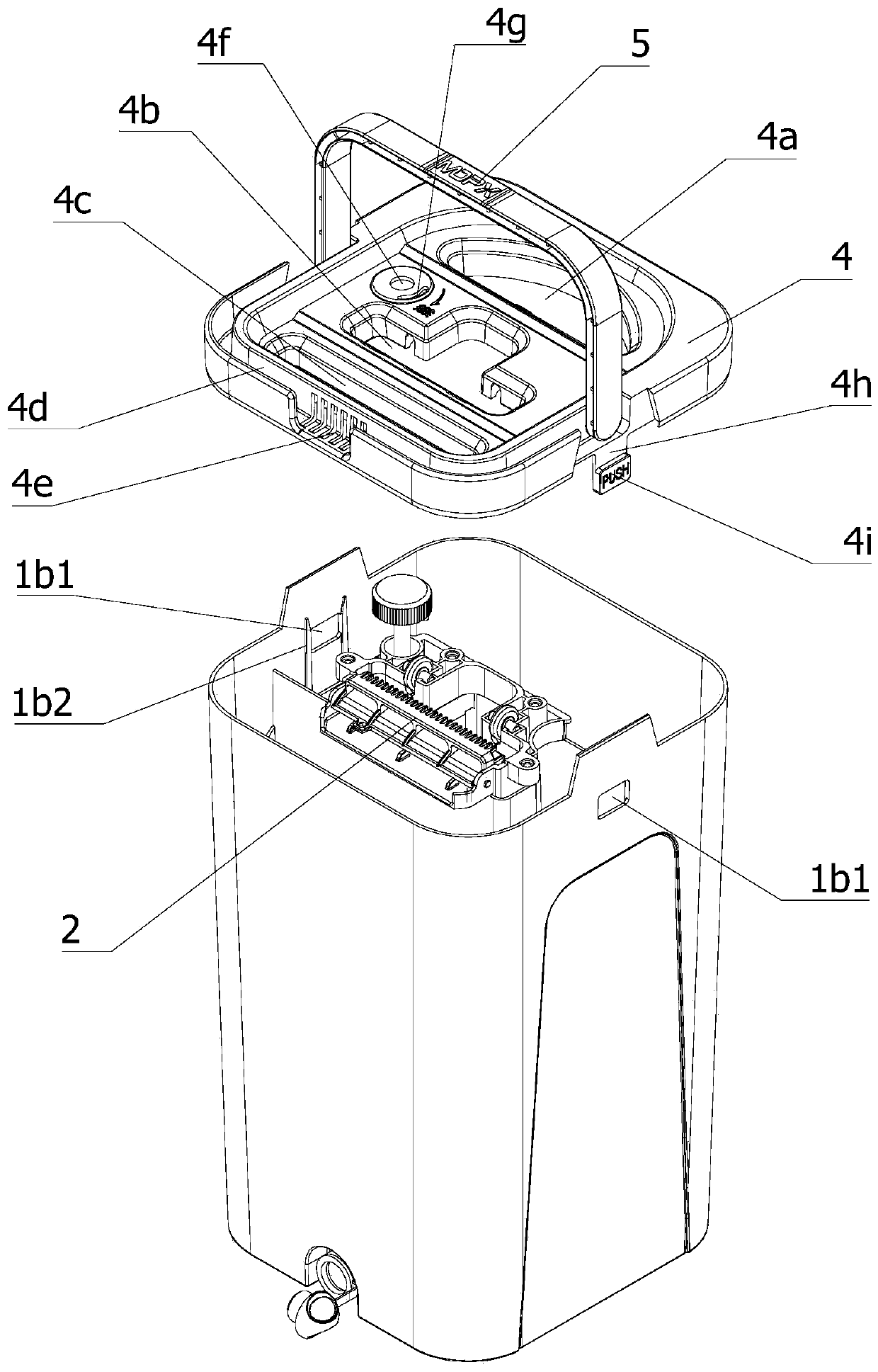

[0076] A kind of flat mop cleaning bucket, refer to Figure 1-14As shown, a barrel body 1 is included, and the interior of the barrel body 1 is provided with a clear water area, a cleaning and dehydration area, a sewage area and a raised area which are independent of each other, and the clean water area, the cleaning and dehydration area and the sewage area are arranged adjacent to each other in the horizontal direction , the clear water area and the raised area are adjacently arranged in the vertical direction, the raised area is located below the clear water area, the bottom height of the cleaning and dewatering area is equal to the bottom height of the raised area; the top of the cleaning and dewatering area is installed with a water outlet The direction is towards the sewage cleaning device 2 installed in the sewage area. The barrel body 1 is provided with a water hole connecting the clean water area and the cleaning and dehydration area. The water hole is arranged near the...

no. 2 example

[0105] Such as Figures 16-22 As shown, the difference with the first embodiment is:

[0106] The cleaning and squeezing device 2 also includes a lifting mechanism 2e. The lifting mechanism 2e includes a slider 2e1, a slide rail 2e2, an electric push rod 2e3 and a clamp 2e4. The slider 2e1 is arranged on both sides of the base 2a, and the slide rail 2e2 is arranged on the On both sides of the barrel body 1, the slider 2e1 and the slide rail 2e2 are vertically arranged and slidably connected, the electric push rod 2e3 is fixedly installed on the barrel body 1, the working end of the electric push rod 2e3 is set vertically upward, and the clamp 2e4 is set on the On the side of the base 2a, the fixture 2e4 is fixedly connected to the output end of the electric push rod 2e3, and the slider 2e1, the fixture 2e4 and the base 2a are integrated.

[0107] There is a button on the body of the barrel to control the opening and closing of the electric push rod 2e3. The user can turn on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com