Treatment and reuse system and treatment and reuse method for wastewater produced during cleaning of finished products and/or raw materials of automobile parts

A technology for auto parts and wastewater cleaning, applied in water/sewage treatment, metallurgical wastewater treatment, biological water/sewage treatment, etc., can solve problems affecting the normal use of equipment, affecting the effect of desalination treatment, high oil content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

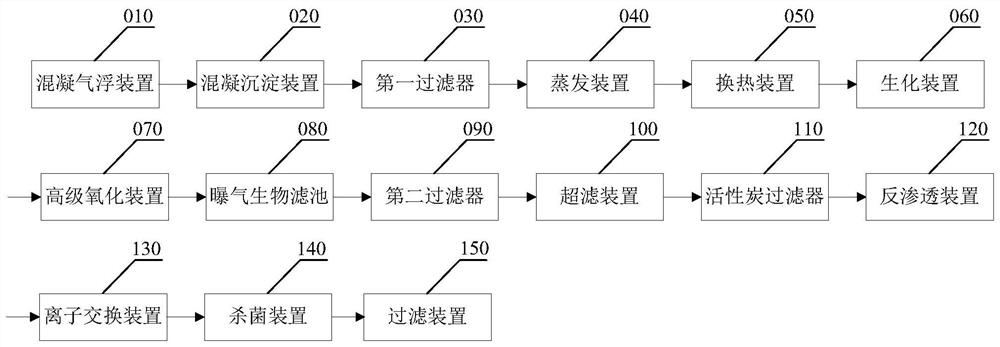

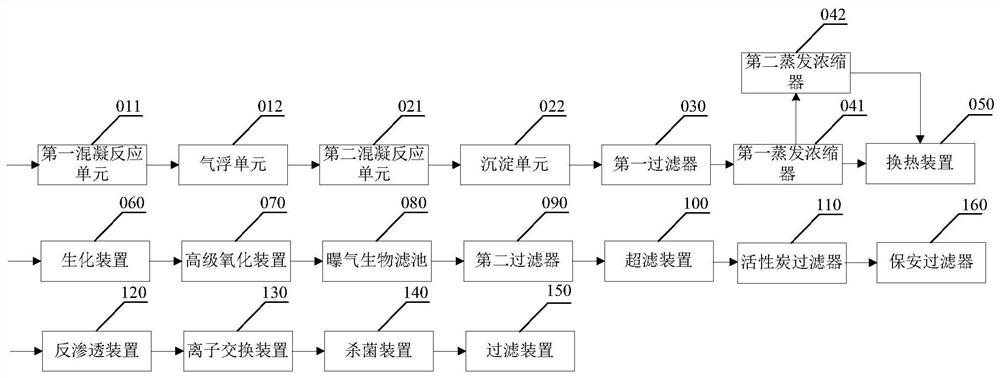

Method used

Image

Examples

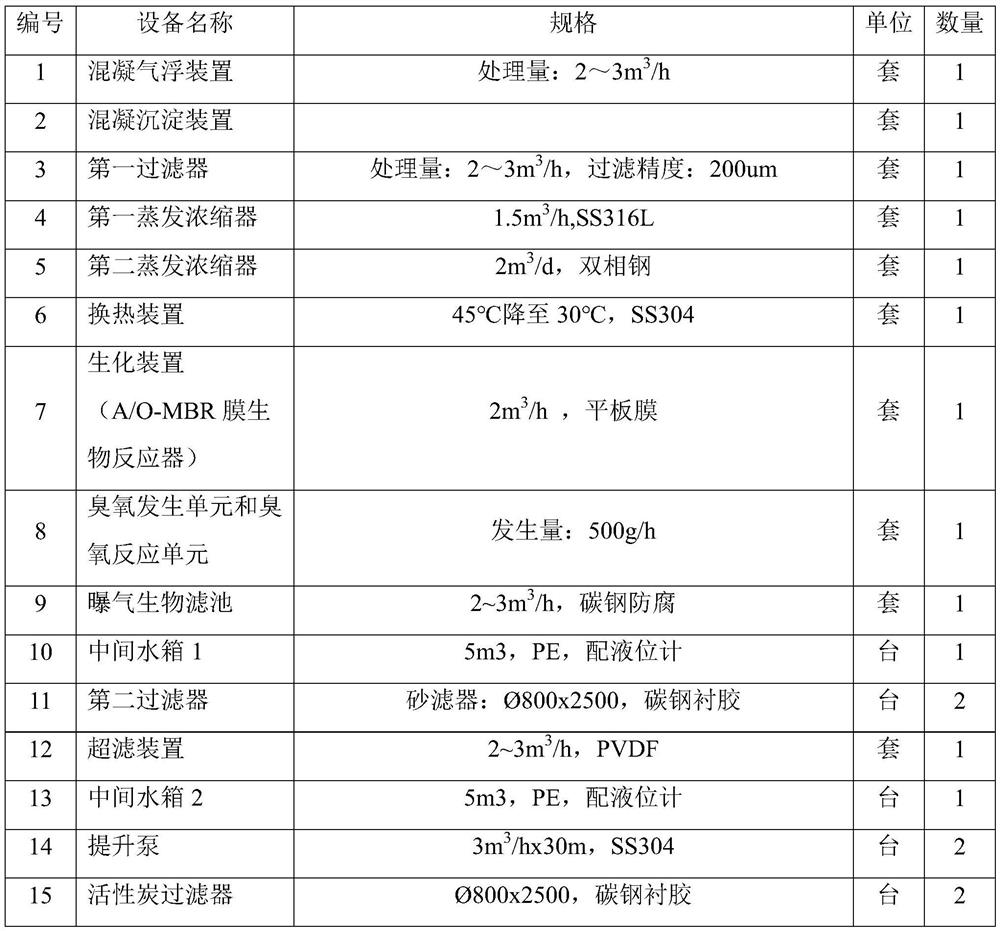

Embodiment 1

[0138] A large-scale domestic joint venture automobile bearing manufacturing plant originally built a wastewater treatment station, which mainly treats the cleaning wastewater and wet dust removal wastewater discharged from the bearing raw material and finished product cleaning production line. The raw water of the cleaning production line adopts the existing pure water system in the factory. Water is used as the replenishment water source, and the water quality of the reclaimed water after the cleaning wastewater treatment is difficult to meet the water requirements of the bearing bush raw materials and finished product cleaning production line. The industrial park has strict restrictions on the total amount of industrial wastewater discharged by the enterprise. The discharge will directly affect the production and operation of the company, so it is urgent to build a deep waste water reuse system. The water quality after treatment can meet the water quality requirements for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com