Water purifying system and automatic working pressure adjusting method thereof

A water purification system and working pressure technology, applied in control/manipulation systems, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as damage to the whole machine, impact on service life, and dry pumping of booster pumps, etc., to achieve Improve reliability, prolong service life, and balance water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

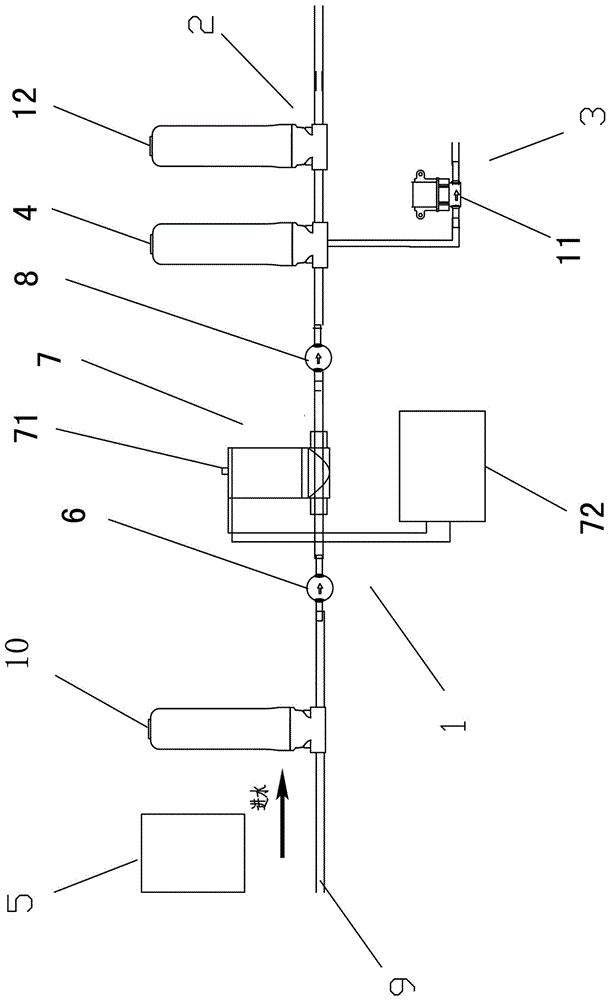

[0032] See figure 2 As shown, a water purification system includes a filter part 1, a pure water part 2, a concentrated water part 3, a reverse osmosis filter element 4 and an electric control device 5, and the filter part 1 is output in two ways through the reverse osmosis filter element 4, one The output is to the pure water part 2, and the other is output to the concentrated water part 3. It is characterized in that the filter part 1 is provided with an inlet water pressure sensor 6, a pressure regulating device 7 and a membrane front water pressure sensor 8, and an electric control device 5 They are respectively electrically connected to the water inlet pressure sensor 6, the pressure regulating device 7 and the water pressure sensor 8 in front of the membrane. The device 7 adjusts the water pressure about to enter the reverse osmosis filter element 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com