Micro-hydro generator

A hydroelectric power generation device and miniature technology, applied in the directions of injection devices, injection devices, engine components, etc., can solve the problems of large fan blade resistance and affect power generation efficiency, and achieve the effect of improving power generation efficiency, ensuring service life and high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

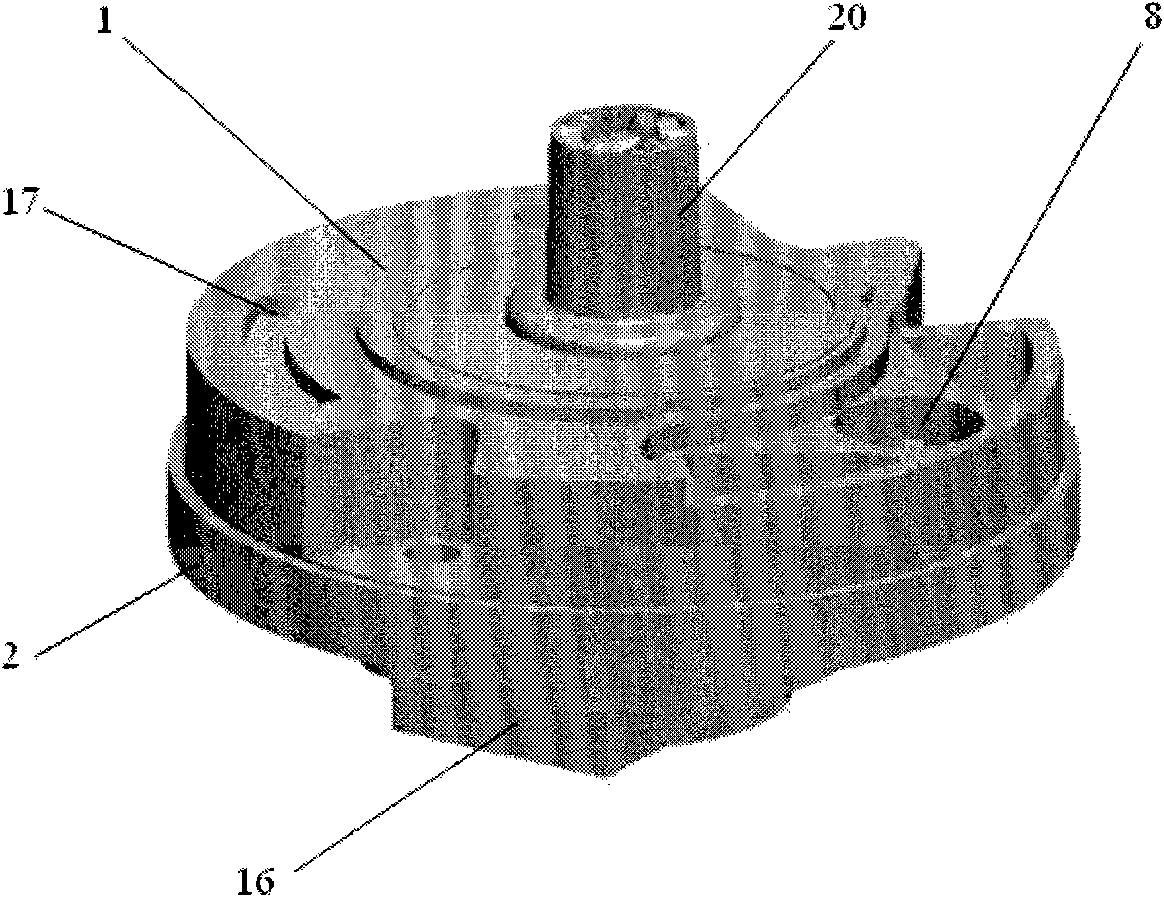

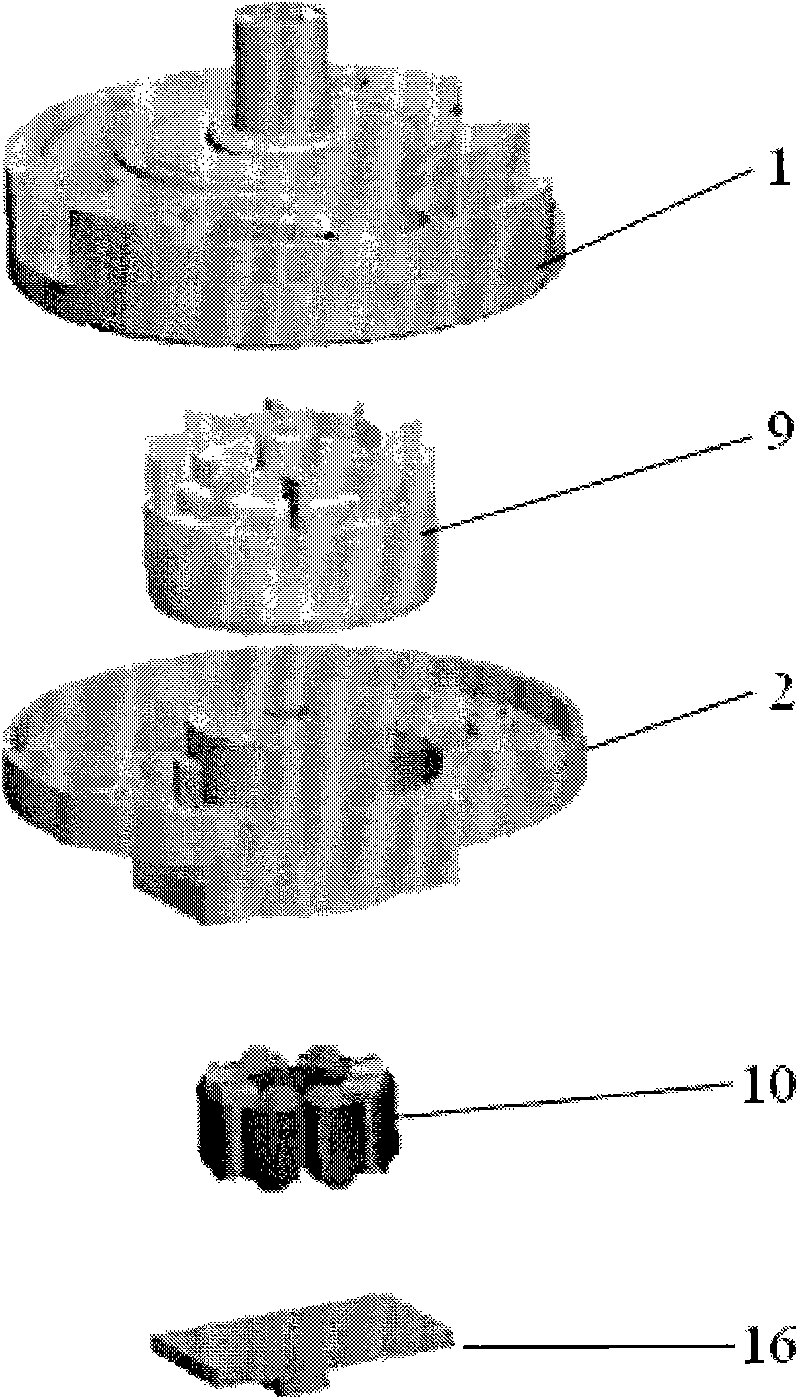

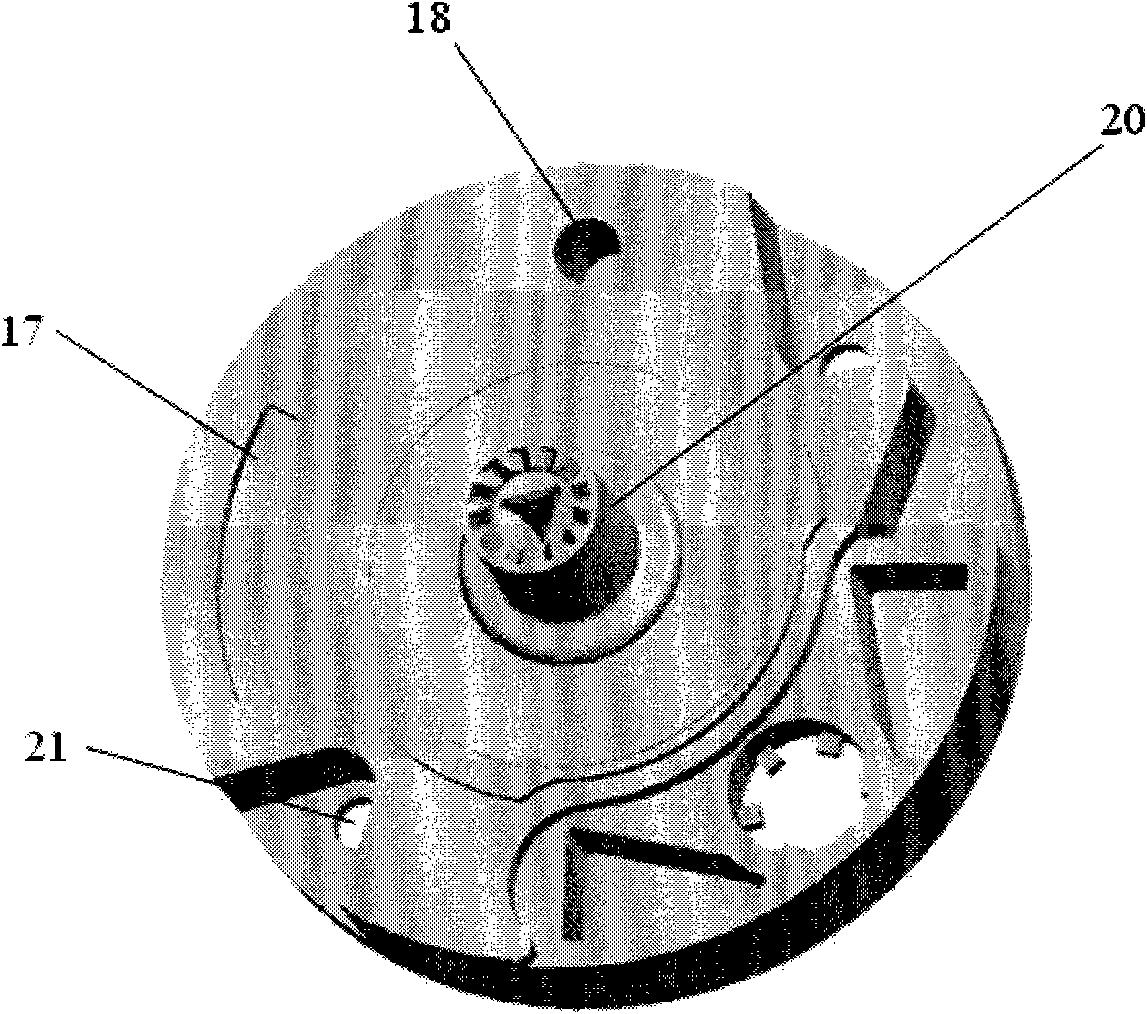

[0044] figure 1 , figure 2 A specific implementation of the micro-hydroelectric power generation device according to the present invention is given. A micro-hydropower generation device includes an upper cover 1 and a lower cover 2, wherein the upper cover 1 is formed with a water storage cavity 3 and a rotor cavity 4. A common wall 5 is provided between the rotor cavity 4 and the water storage cavity 3, and the wall 5 is provided with a flushing port connecting the water storage cavity 3 and the rotor cavity 4, where , Three flushing ports 6, 61, 62 are set, evenly arranged on both sides and the middle of the wall 5 shared by the water storage cavity 3 and the rotor cavity 4, such as Figure 4 Shown. The flushing openings 6, 61, 62 are incisions that deviate from the radial direction of the rotor 9, so as to ensure that the impulse of the water entering the rotor cavity 4 through the three flushing openings performs better on the rotor 9 Speed up and reduce the loss of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com