Method for dewatering desorption gas for flue gas desulfurization and recycling condensate

A condensate and desorption technology, applied in chemical instruments and methods, steam condensation, separation methods, etc., can solve problems such as large increase in water volume, solution dilution, and reduction of rich liquid desorption degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

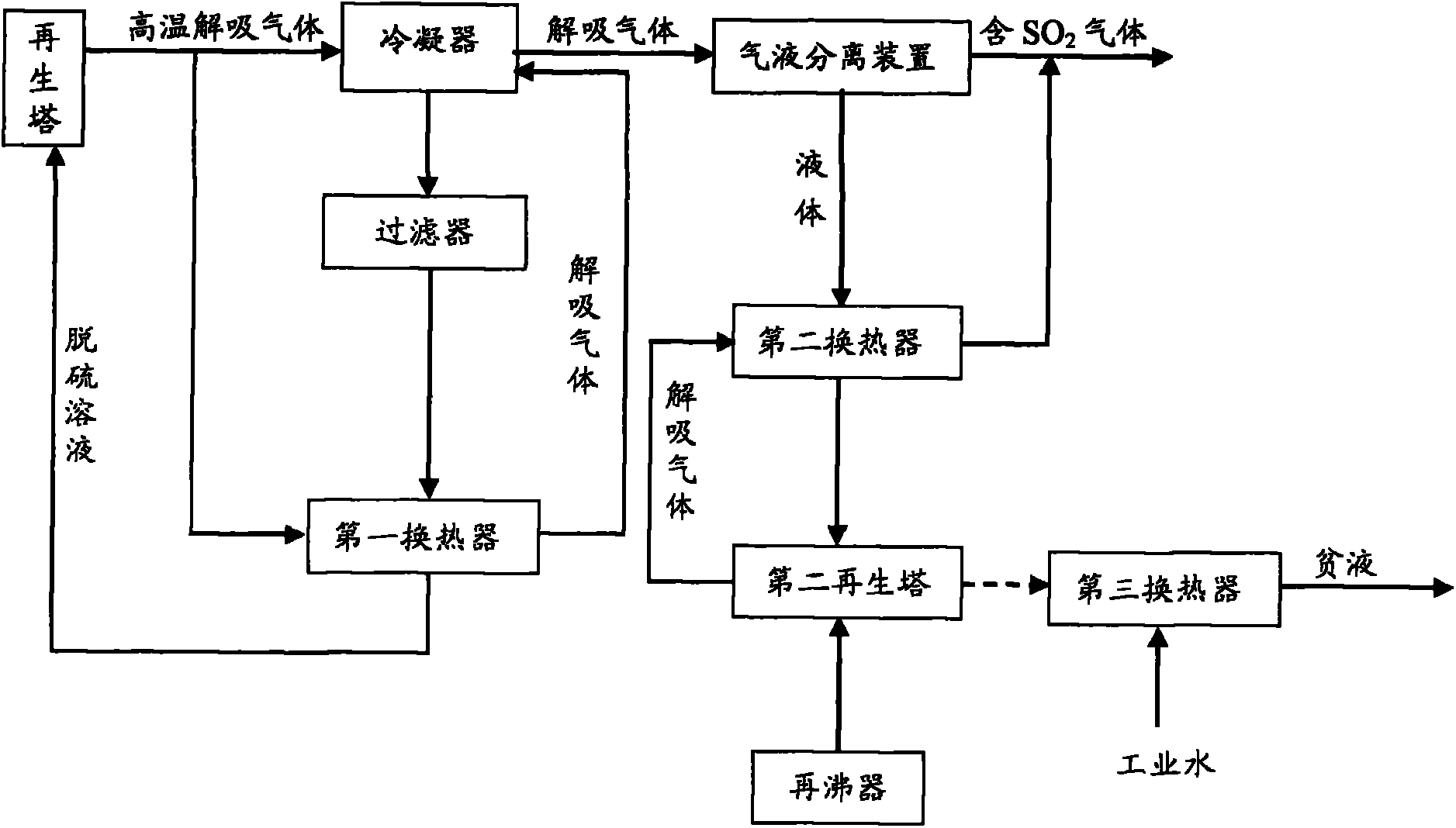

Embodiment 1

[0035] refer to figure 1 , in this embodiment, the high-temperature desorption gas desorbed from the regeneration tower is divided into two paths, and one path of desorption gas is supplied to the condenser for multi-stage condensation to produce condensate and containing water vapor, sulfur dioxide gas and a small amount of desulfurization The desorbed gas of the agent. The condensate mainly contains desulfurizer, some water and impurities, while a large amount of water still exists in the desorbed gas in the form of water vapor. Then, the condensate is supplied to a filter to be filtered to remove impurities, thereby obtaining a condensate mainly including a desulfurizing agent and a part of water (ie, as a desulfurization solution). At the same time, another desorbed gas is supplied to the first heat exchanger to exchange heat with the condensate supplied to the first heat exchanger, so that the temperature of the condensate rises to about 50°C-65°C, so that the filtered c...

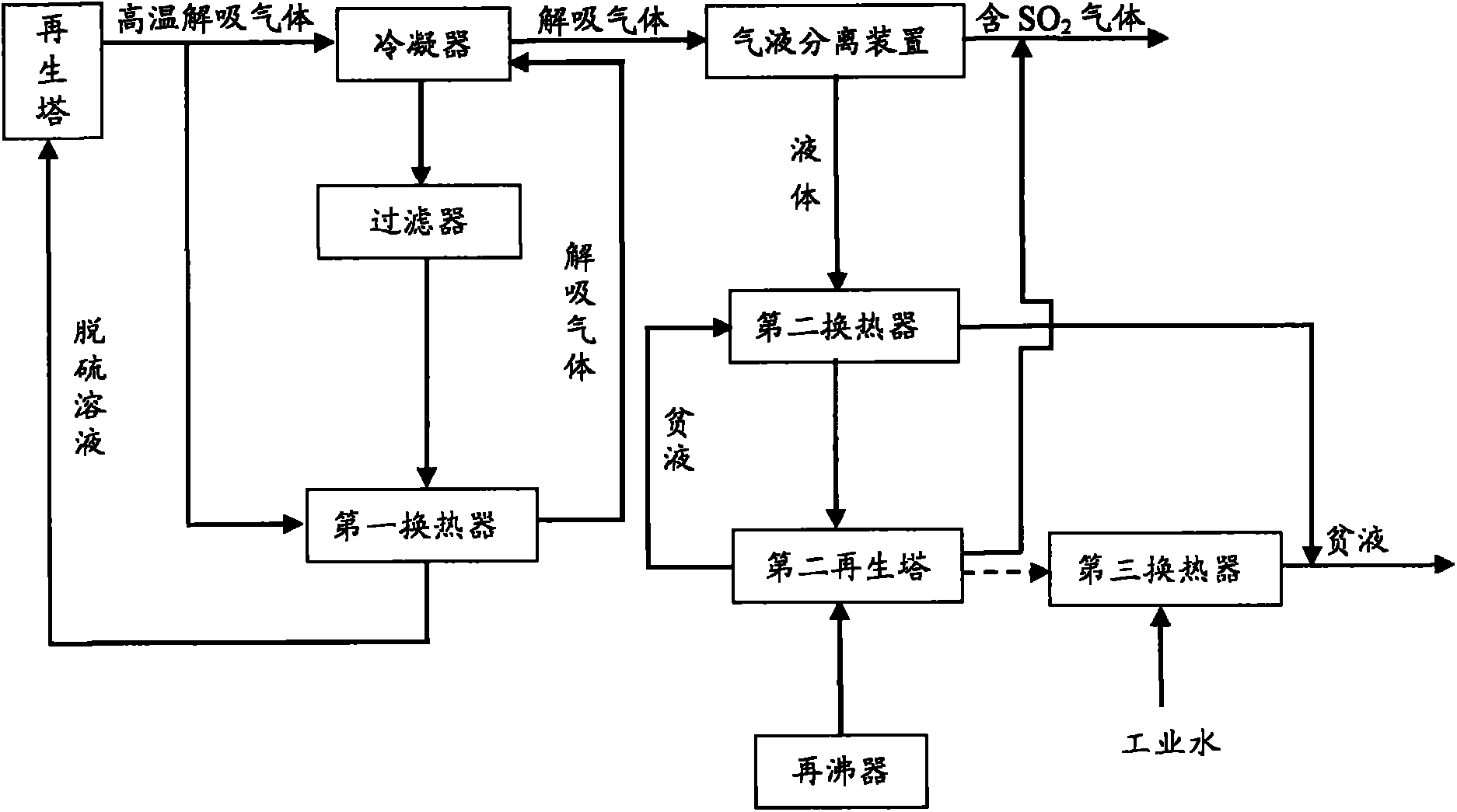

Embodiment 2

[0039] refer to figure 2 , in this embodiment, a part of the lean liquid produced in the second regeneration tower can be supplied to the second heat exchanger to exchange heat with the liquid produced after gas-liquid separation, and then the heat-exchanged liquid Part of the cooling lean liquid is discharged; at the same time, the desorption gas mainly containing sulfur dioxide produced in the second regeneration tower and containing high-purity SO 2 The gas is supplied to the acid system or stored together, except that the process steps of this embodiment are the same as those of Example 1. In addition, optionally, the remaining part of the lean liquid produced in the second regeneration tower is supplied to the third heat exchanger for heat exchange with industrial water, and then the part of the cooled lean liquid that undergoes heat exchange is supplied to the washing water system.

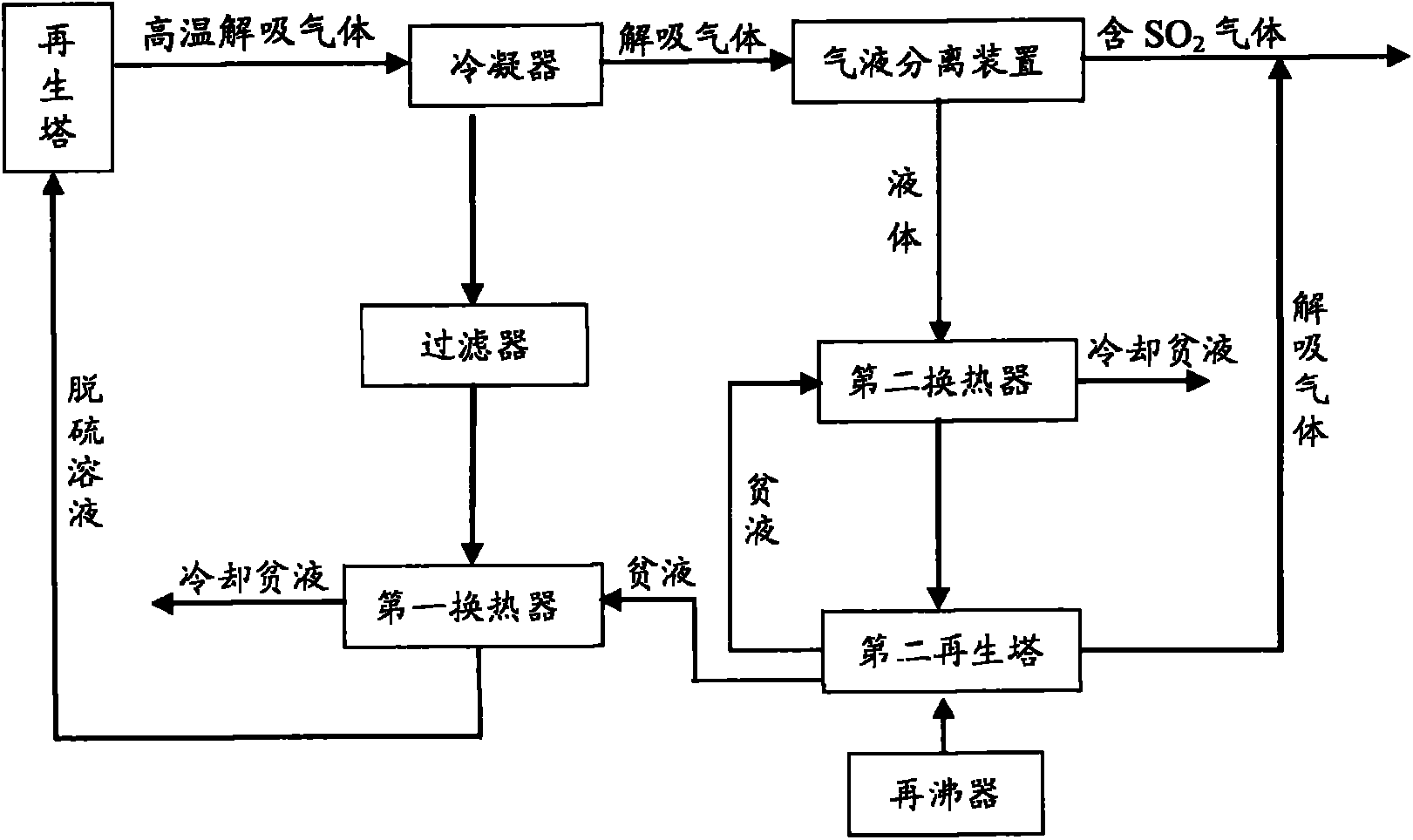

Embodiment 3

[0041] refer to image 3 , In this embodiment, the high-temperature desorption gas desorbed from the regeneration tower is supplied to the condenser for multi-stage condensation to produce condensate and desorption gas mainly containing water vapor, sulfur dioxide gas and a small amount of desulfurization agent. The condensate mainly contains desulfurizer, some water and impurities, while a large amount of water still exists in the desorbed gas in the form of water vapor. Then, the condensate is supplied to a filter to be filtered to remove impurities, thereby obtaining a condensate mainly including a desulfurizing agent and a part of water (ie, as a desulfurization solution). Then, the condensate is exchanged in the first heat exchanger, so that the temperature of the condensate is raised to 50° C. to 65° C., and then the heated condensate is returned to the regeneration tower.

[0042] In addition, the generated desorbed gas is supplied to a gas-liquid separator for gas-liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com