Mixing station waste slurry recycling process and device

A mixing station and slurry water technology, which is applied in cement mixing equipment, clay preparation equipment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of unhelpful reduction of waste slurry in mixing stations, difficulty in accurately controlling the amount of mixing, and volume reduction To solve the problems such as limited waste pulp, to achieve the effect of significantly reducing the amount of waste pulp, reducing working hours and reducing work burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

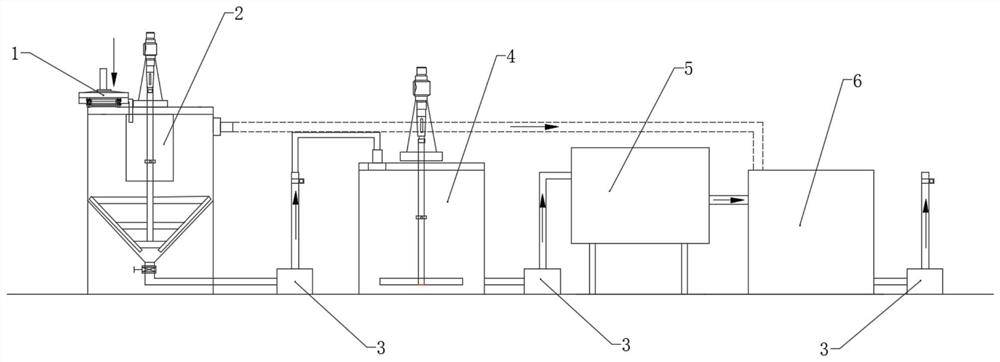

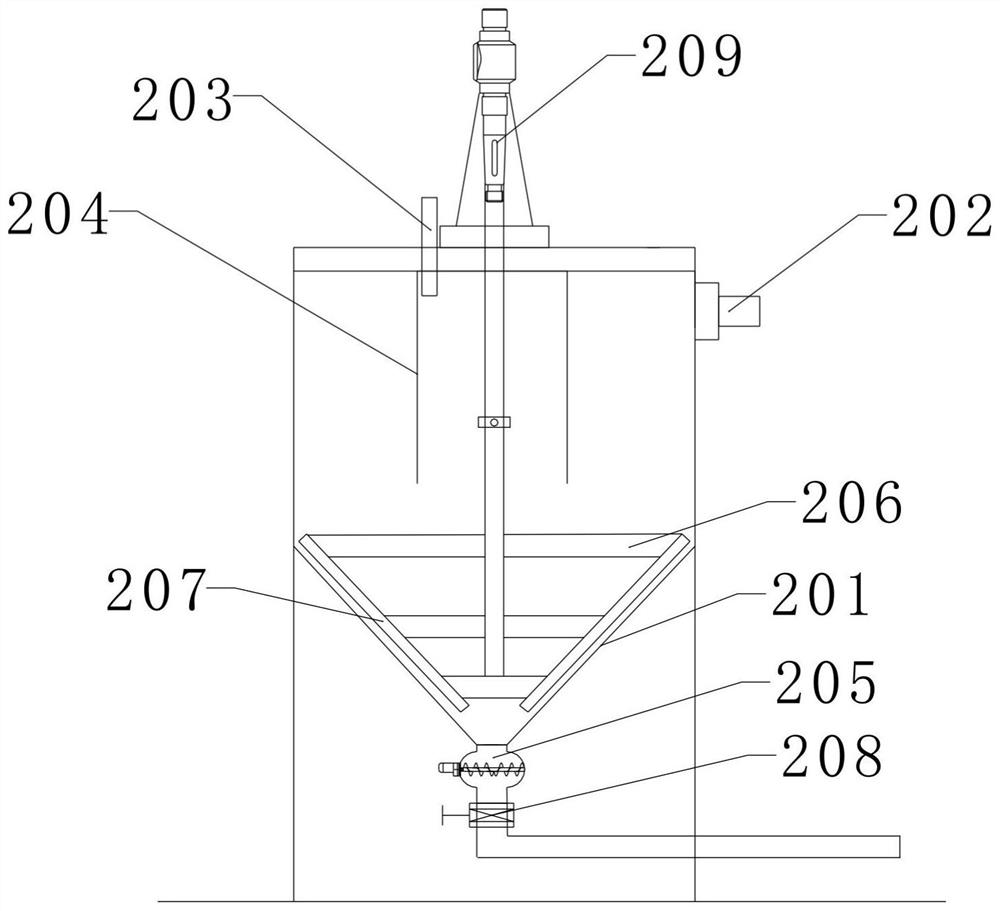

[0053] A process for reuse of waste slurry water in a mixing station, comprising the following steps:

[0054] S1. Separation

[0055] Use screening equipment to separate the particles with a particle size greater than 2mm in the waste slurry water produced by the mixing station to obtain the remaining waste slurry;

[0056] S2. Concentration

[0057] Add 0.01% of its volume to the waste slurry water obtained in step S1, and the concentration residence time in the concentrator is 60 minutes; respectively obtain clear water with a solid content of less than 0.1% and underflow waste slurry with a solid content of more than 20%;

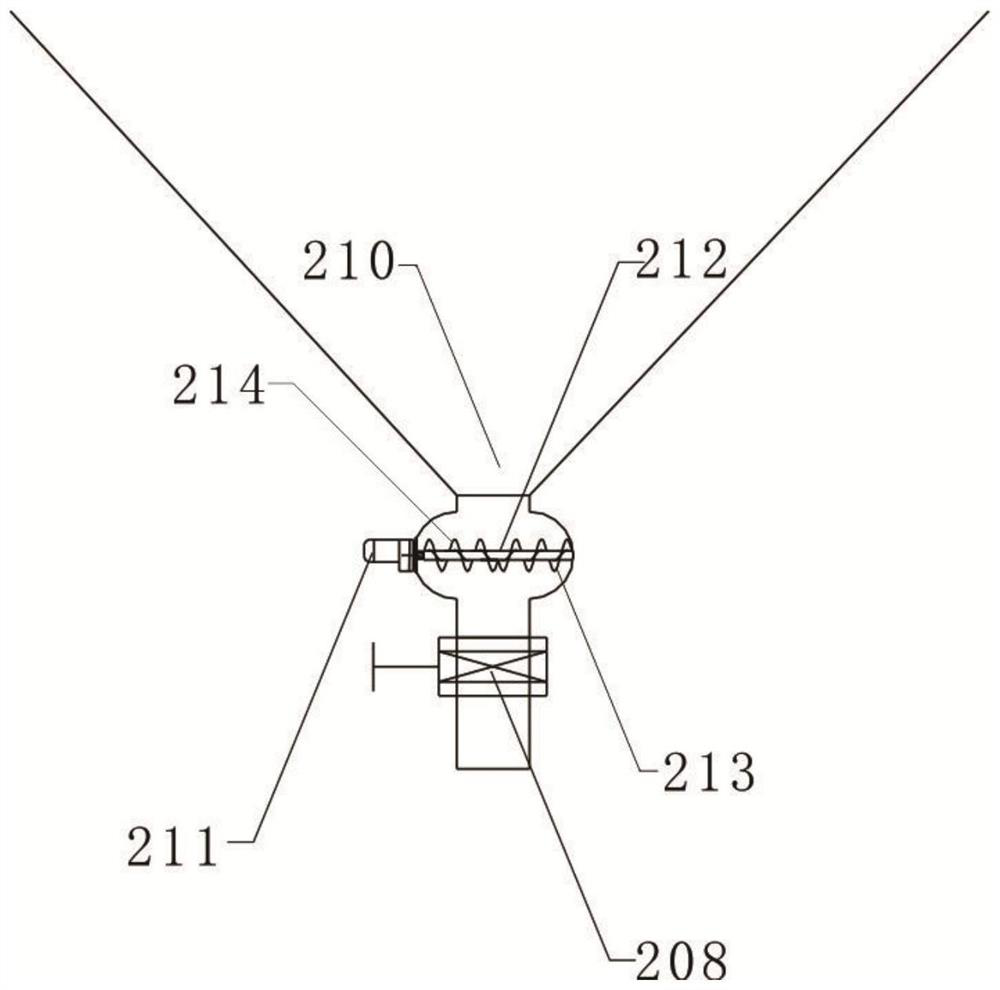

[0058] S3. Vacuum desliming

[0059] The underflow waste slurry obtained in step S2 is pumped into a deslimer, and deslimed in an environment of 0.04 MPa, and the waste residue and deslimed waste slurry are collected, and the deslimed waste slurry is returned to step S2 for further concentration.

Embodiment 2

[0061] A process for reuse of waste slurry water in a mixing station, comprising the following steps:

[0062] S1. Separation

[0063] Use screening equipment to separate the particles with a particle size greater than 2mm in the waste slurry water produced by the mixing station to obtain the remaining waste slurry;

[0064] S2. Concentration

[0065] Add 0.01% of its volume to the waste slurry water obtained in step S1, and the concentration residence time in the concentrator is 60 minutes; respectively obtain clear water with a solid content of less than 0.1% and underflow waste slurry with a solid content of more than 20%;

[0066] S3. Vacuum desliming

[0067] The underflow waste slurry obtained in step S2 is pumped into a deslimer, and deslimed in an environment of 0.05 MPa, and the waste residue and deslimed waste slurry are collected, and the deslimed waste slurry is returned to step S2 for further concentration.

Embodiment 3

[0069] A process for reuse of waste slurry water in a mixing station, comprising the following steps:

[0070] S1. Separation

[0071] Use screening equipment to separate the particles with a particle size greater than 2mm in the waste slurry water produced by the mixing station to obtain the remaining waste slurry;

[0072] S2. Concentration

[0073] Add 0.01% of its volume to the waste slurry water obtained in step S1, and the concentration residence time in the concentrator is 60 minutes; respectively obtain clear water with a solid content of less than 0.1% and underflow waste slurry with a solid content of more than 20%;

[0074] S3. Vacuum desliming

[0075] The underflow waste slurry obtained in step S2 is pumped into a deslimer, and deslimed in an environment of 0.06 MPa, and the waste residue and deslimed waste slurry are collected, and the deslimed waste slurry is returned to step S2 to continue to concentrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com