Medium-density fiberboard production waste drainage closed cycle loop back technique

A waste water production and recycling technology, applied in fiber raw material treatment, application, household components, etc., can solve the problems of high sewage treatment costs, large investment, and increased production costs of enterprises, achieving simple structure, low investment, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

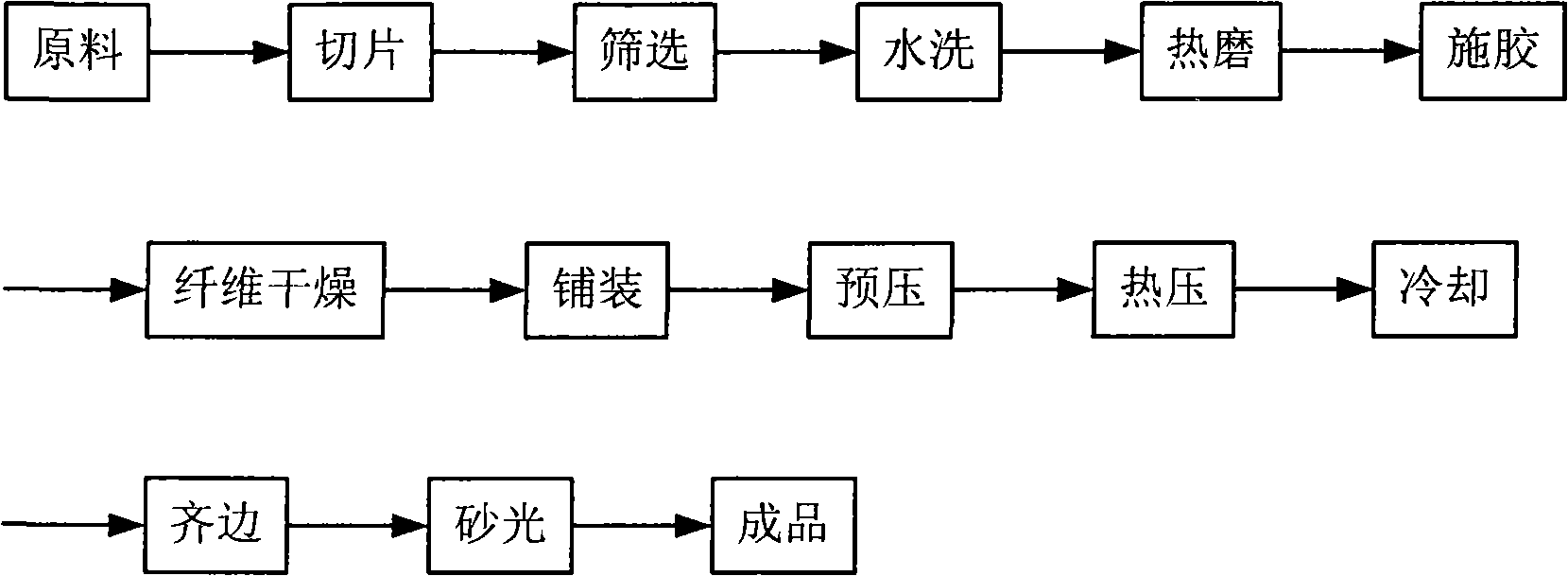

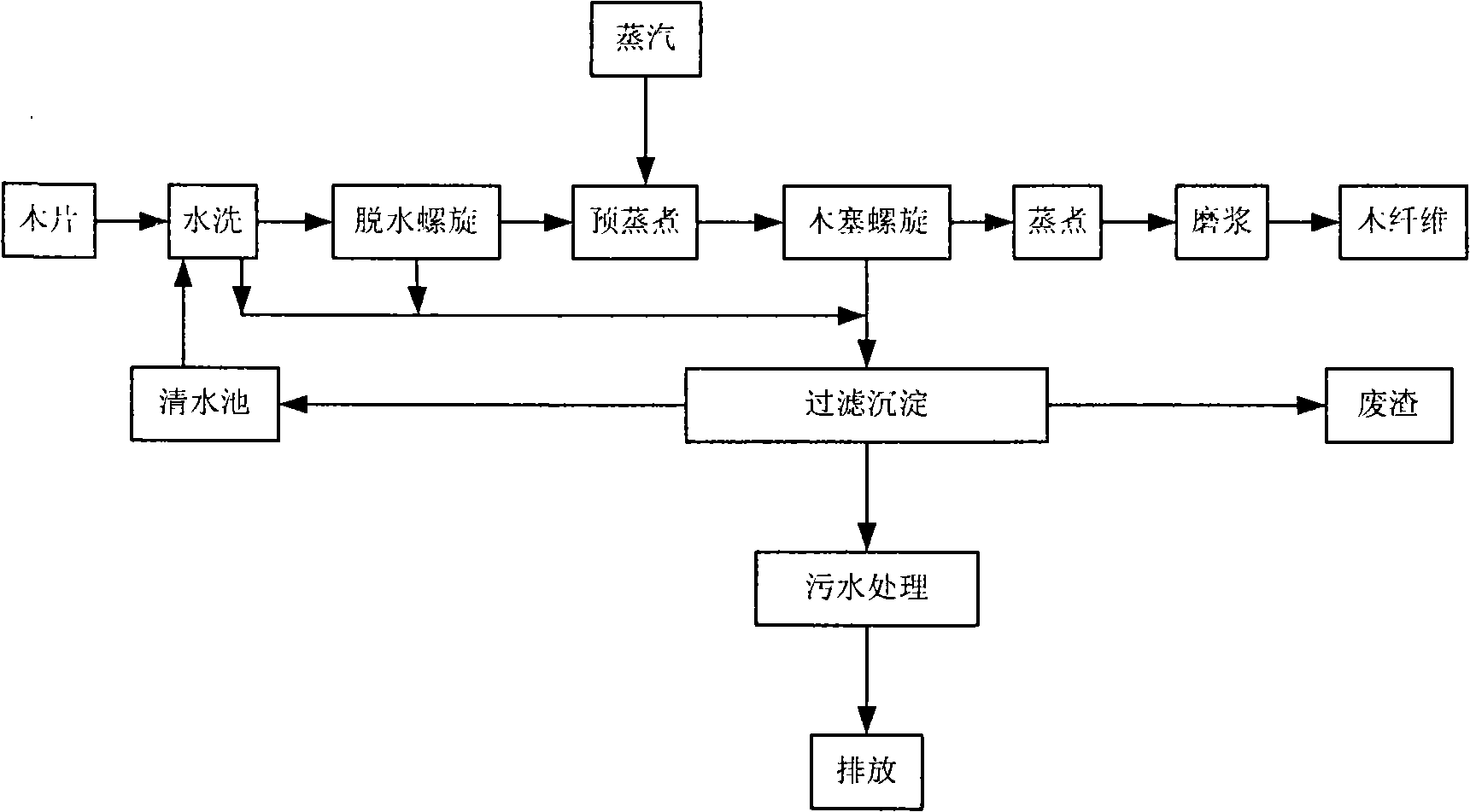

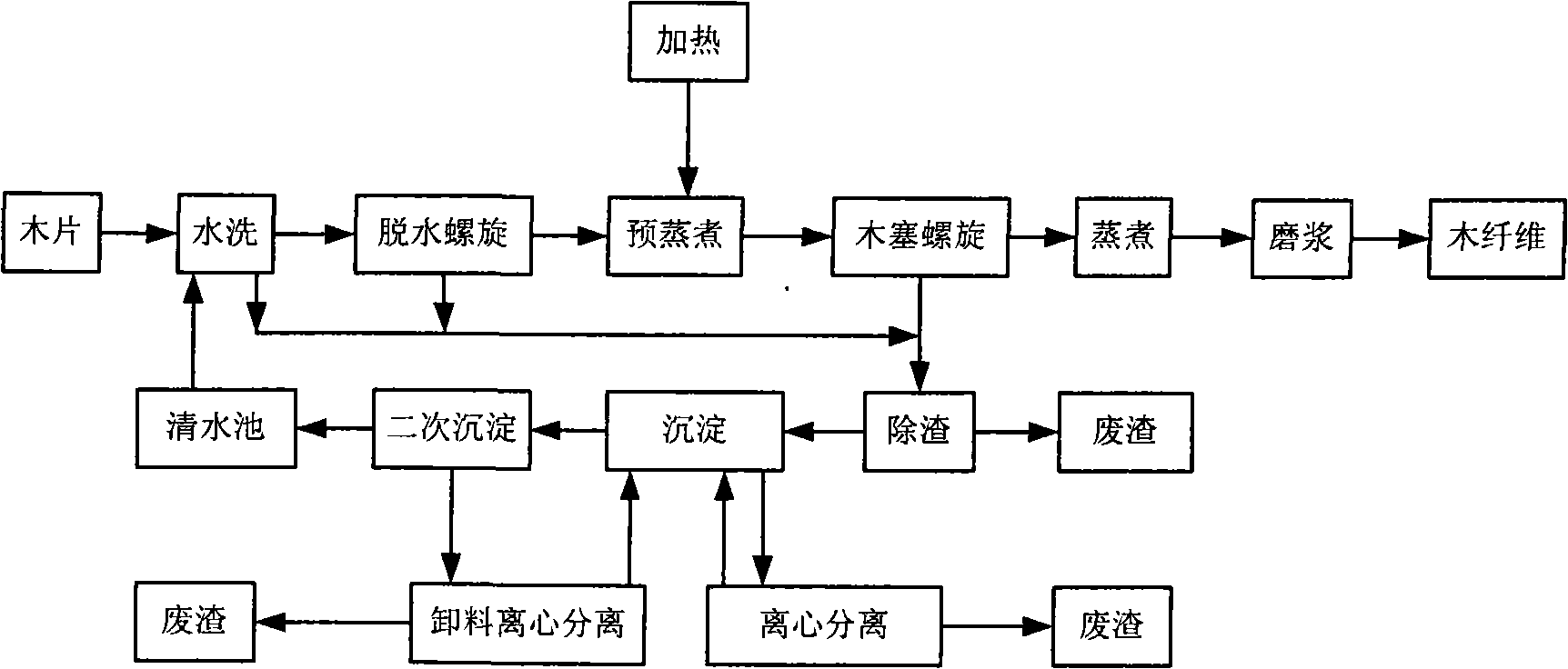

[0016] An embodiment of the present invention, such as image 3 , Figure 4 As shown, a fully closed cycle recycling technology for medium density fiberboard production wastewater, in which the production process of density fiberboard is: raw material → slicing → screening → washing → hot grinding → sizing → fiber drying → paving → pre-pressing → hot pressing →cooling→edge trimming→sanding→finished product; among them: the washing section includes the washing process and the dehydration screw process; the heat grinding process includes pre-cooking, cork screwing, cooking, and refining processes; After the waste water is collected, it will be deslagged by the belt-type slag remover, and the solid waste will be discharged into the slag yard. The waste water after deslagging will flow into the sedimentation tank for sedimentation and then be introduced into the secondary sedimentation tank for further precipitation; the water and waste residue in the lower layer of the sedimentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com