Recycle process of white water of papermaking system

A technology of white water and process, applied in papermaking, textiles and papermaking, water/sewage treatment, etc., can solve the problems of unreasonable recycling process settings and high white water treatment costs, achieve major social and environmental benefits, reduce treatment costs, The effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

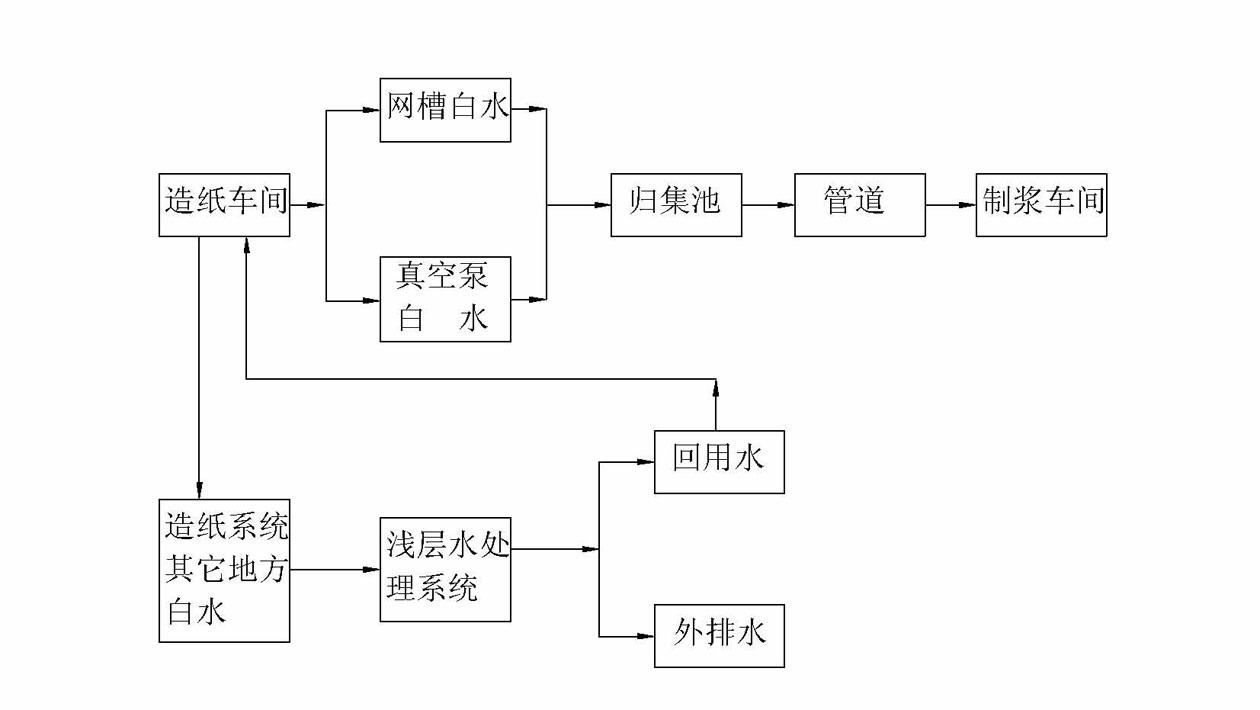

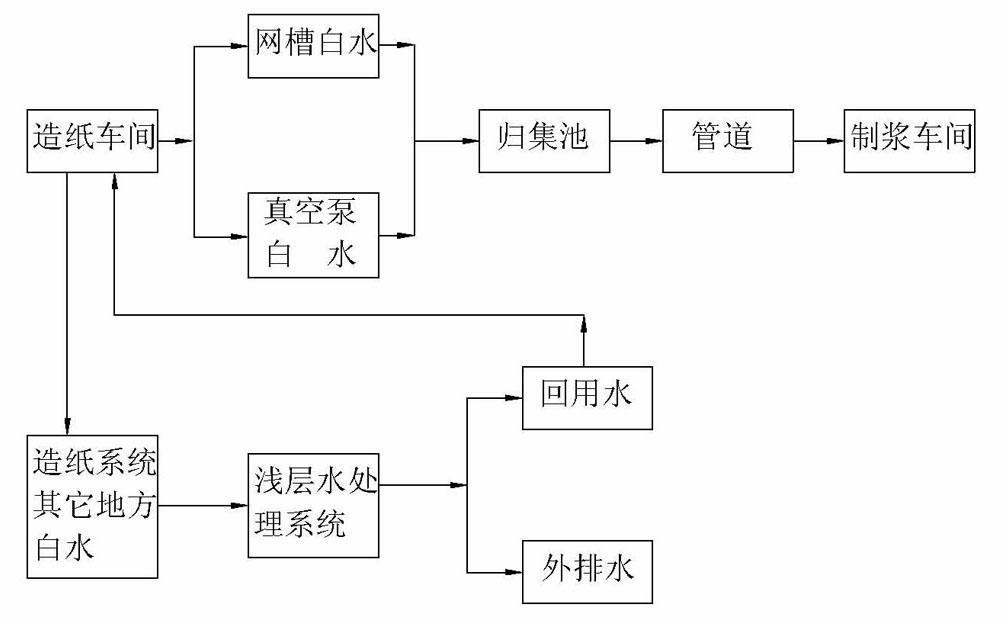

[0010] refer to figure 1 , a papermaking system white water reuse process disclosed in the present invention, which includes the following steps in turn: (1), the white water produced by the papermaking mesh tank and the vacuum pump in the papermaking workshop is transported to the collection pool; (2), the collection pool (3) The sewage generated in other parts of the papermaking system is transported to the shallow water treatment system for treatment, and 80-90% of the treated sewage is sent back The paper workshop is reused, and the remaining sewage is discharged outside after meeting the discharge standards; (4) The short fiber waste pulp generated in the shallow water treatment system is dried by a filter press and then packaged for disposal.

[0011] The above-mentioned shallow water treatment system may use an air flotation machine or other commonly used air flotation equipment.

[0012] In the present invention, the white water discharged from the paper machine net t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com